Thanks guys, for all the wonderful comments and support. I really appreciate y’all. Frankly I was more than surprised to see so many nice things said considering it’s just a silly little roof brace, but I sure appreciate the support nonetheless.

Thank you.

Looks great Donovan. What mm nozzles do you paint with? Also I assume you use an inline filter or water separator? Also what psi do you spray at? You are getting so close, keep up the ridiculously good work.

Christian, I have 3 main guns that I rely heavily on.

I have a dedicated primer gun with a huge 2.0 tip on it, a Finex base/clear gun with a 1.5 or 1.6 tip (can’t remember exactly), and a DeVilbiss touch up gun with a 1.4 tip. With these 3, I haven’t found anything I can’t do with them.

I have a TON of filtration and dryers between the compressor and the point of use, clean dry air is critical to achieving good paint results. I have 3 inline filters out of the compressor, a particulate, a coalescing, and a charcoal that knock out the crap as soon as possible. In this pic, they are in that order from right to left. I also incorporated a bypass so that the system doesn’t have to be bled down to change the filters:

Once the air leaves the filters, it goes through a regulator to dial down system pressure to whatever I want. Out of the regulator, it goes into a refrigerated dryer...

...to cool the air down and condense any water that’s still suspended in the airstream. On the opposite side of the shop, I have yet another dryer, this time a dessicant one as a final fail safe.

I have never had to drain any water out of this dryer.

Note the multiple air line connections I have out of this dryer, in case I want to use more than one air hose at a time or have friends over that need air at the same time I do. What’s not visible here is the air hose that I have on a reel, hidden inside the end of my work bench:

There’s also a timed drain on the drain of the compressor that automatically drains the condensate from inside the compressor tank:

(It helps that this is my profession, and that I have access to all these things in my day to day work). 😁😁

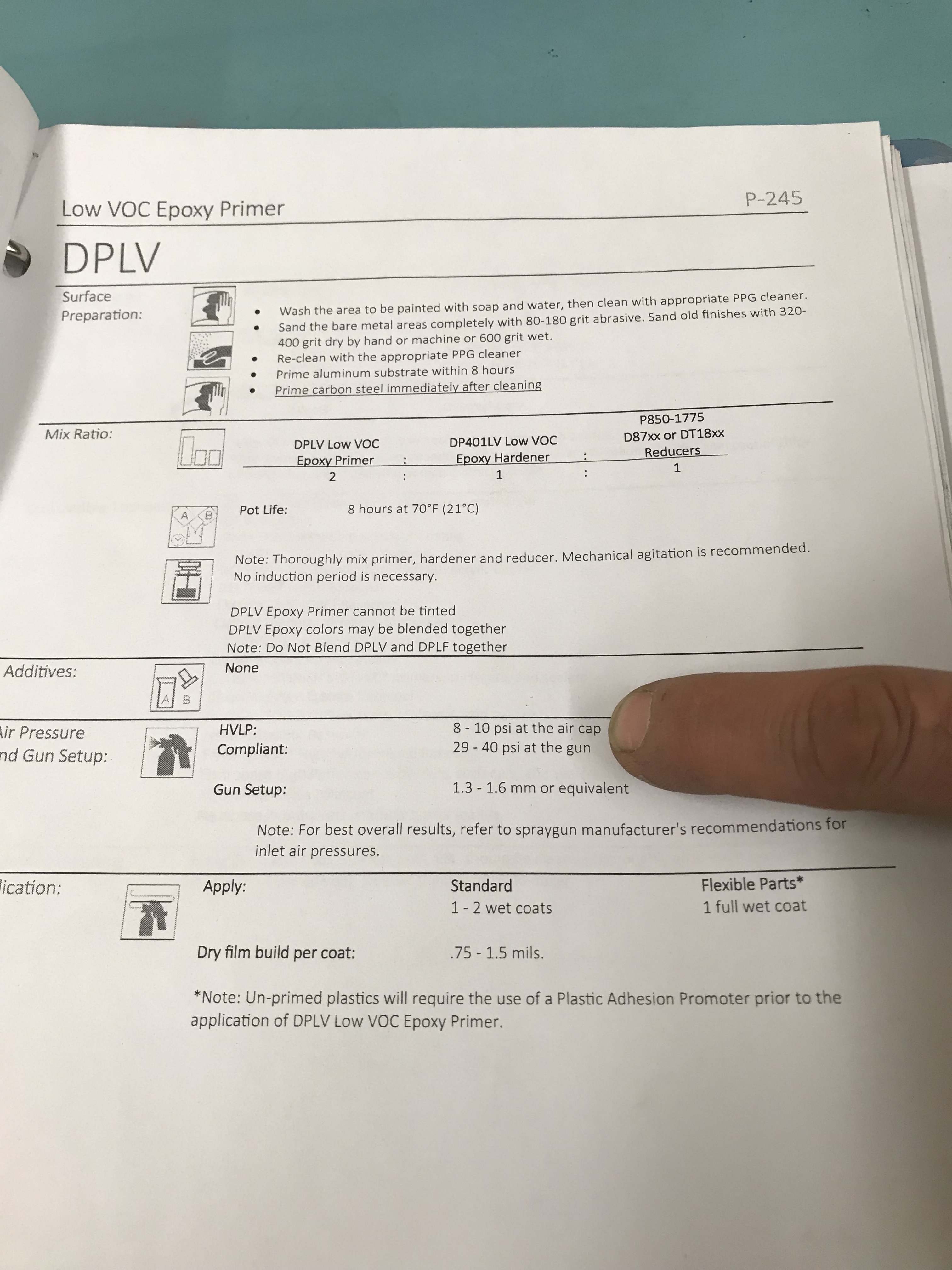

As for the air pressure that I spray at, for a relative newbie I strongly recommend following the paint or primer manufacturers P sheets. It will vary from product to product, but usually it’ll be around 8-10 psi at the air cap for an HVLP gun. I personally have been spraying so long, I can usually set up my gun using their recommendations as a baseline, then fine tune it from there by ear and spraying a couple of test passes to get the pattern and fluid adjustments right on a piece of masking paper.

If you’ve never seen a P sheet, they’re available when you purchase your product, and it gives you all the particulars on what your product requires. Number of coats, flash times, dry and cure times, air pressure, prep, cleanup, everything.

It’ll look like this, and sometimes the information is available online as well. Note the recommended air pressure where my finger is:

Hope this helps you out on your ‘88, good luck!

D.