Come on slacker

CHOP CHOP

Lets see some progress!!!!!!

Yeah, slacker I guess, but certainly not by choice. Life has been doing a wonderful job of keeping me occupied, and unfortunately very little of it has had anything to do with the cars.

Now that being said, I’ve tried to squeeze in whatever time I can on it, but it’s been mostly an hour or two here, 20 minutes there kinda thing. I have some progress and pics for you guys, just nothing terribly interesting or exciting. It’s all continuing to be on the trim pieces.

Further to the conversation Kiko and I had previously, my curiosity got the better of me and I decided the lower rocker panel trim pieces we were discussing bore further investigation. I can’t speak for the GP’s, but unlike the ‘81-‘88 Cutlasses, the ‘78-‘80 Cutlass models have a lower trim piece on each side BELOW the wider upper door and fender pieces.

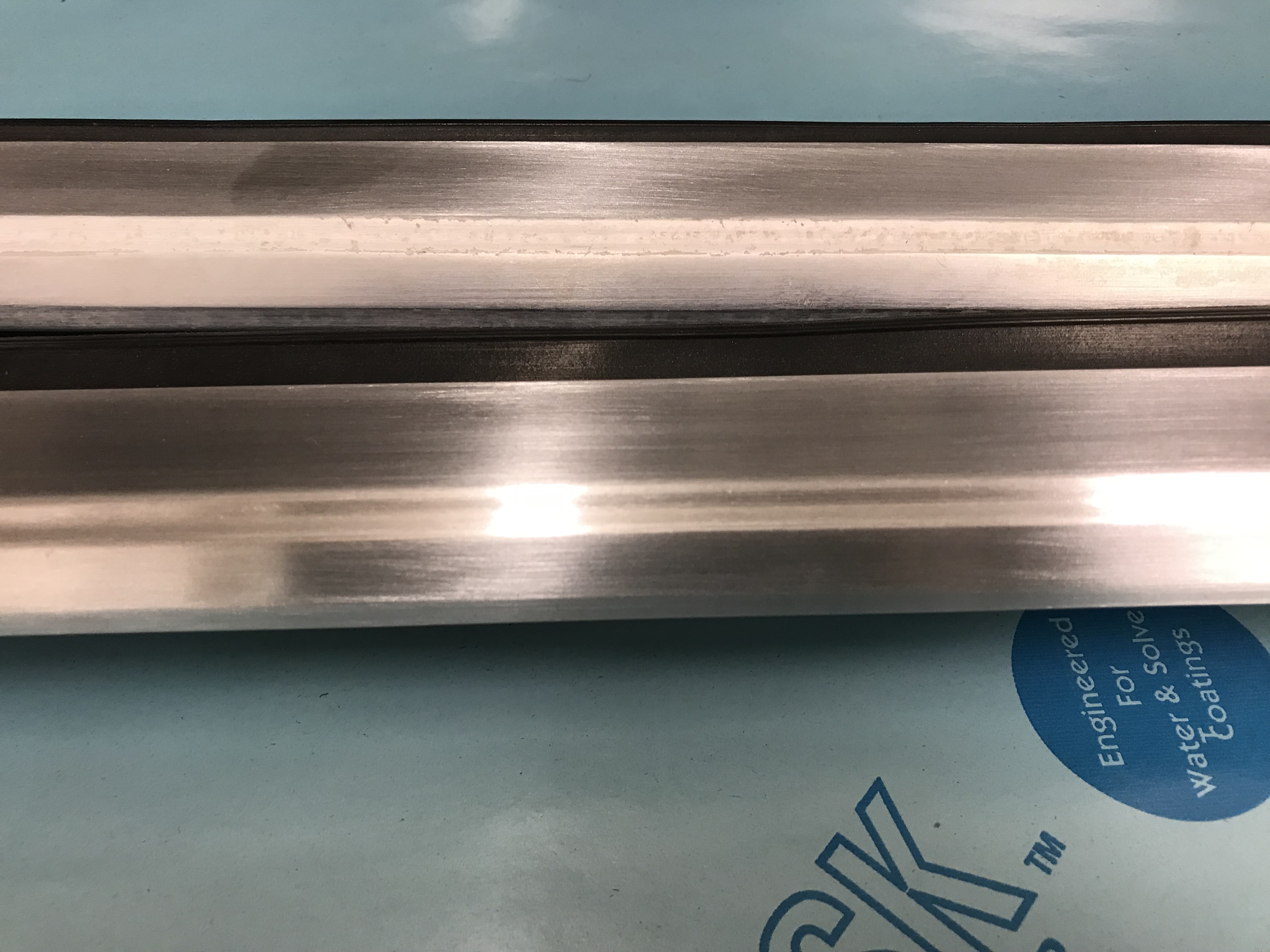

Kiko seemed to think that his were clear anodized aluminum on his GP, so I chucked one of my rocker trims up in the vise and proceeded to investigate:

What I found was actually quite interesting and puzzling. There is definitely no clear anodized layer on them, which leads me immediately to believe they’re stainless as I thought. However, upon testing the iron content with a magnet, I found that they’re also definitely not 100% stainless. The magnet pulls quite strongly on them, yet they don’t rust in their natural “exposed” state.

The only answer to this riddle I can think of, is that they’re a low grade of stainless steel, probably 304 or less. Just enough stainless content not to oxidize without a coating, but not enough to be too costly to mass produce.

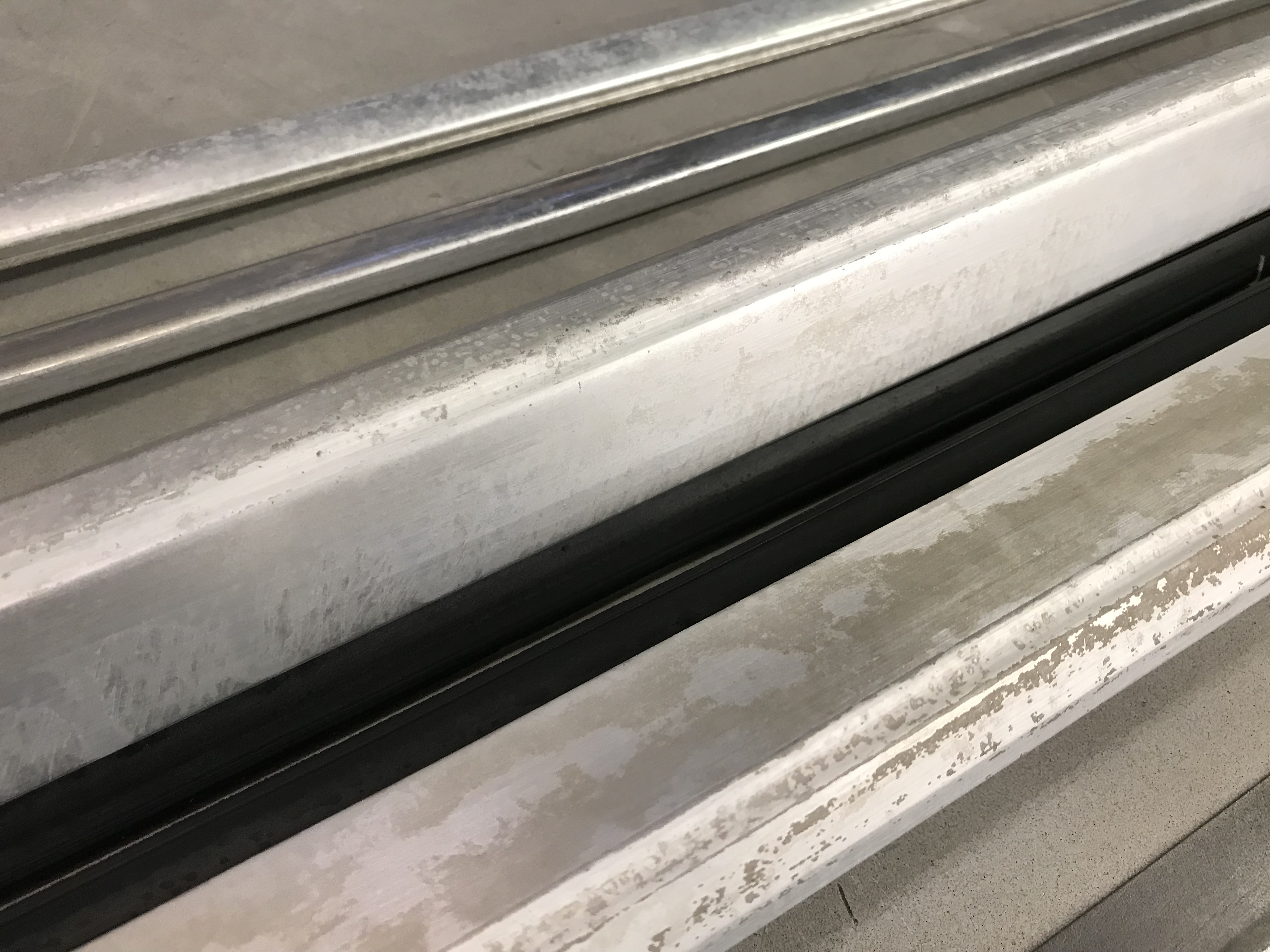

As you can see in the following pictures, mine have seen better days and are pretty dented up, to be expected for unrestored 39 year old pieces.

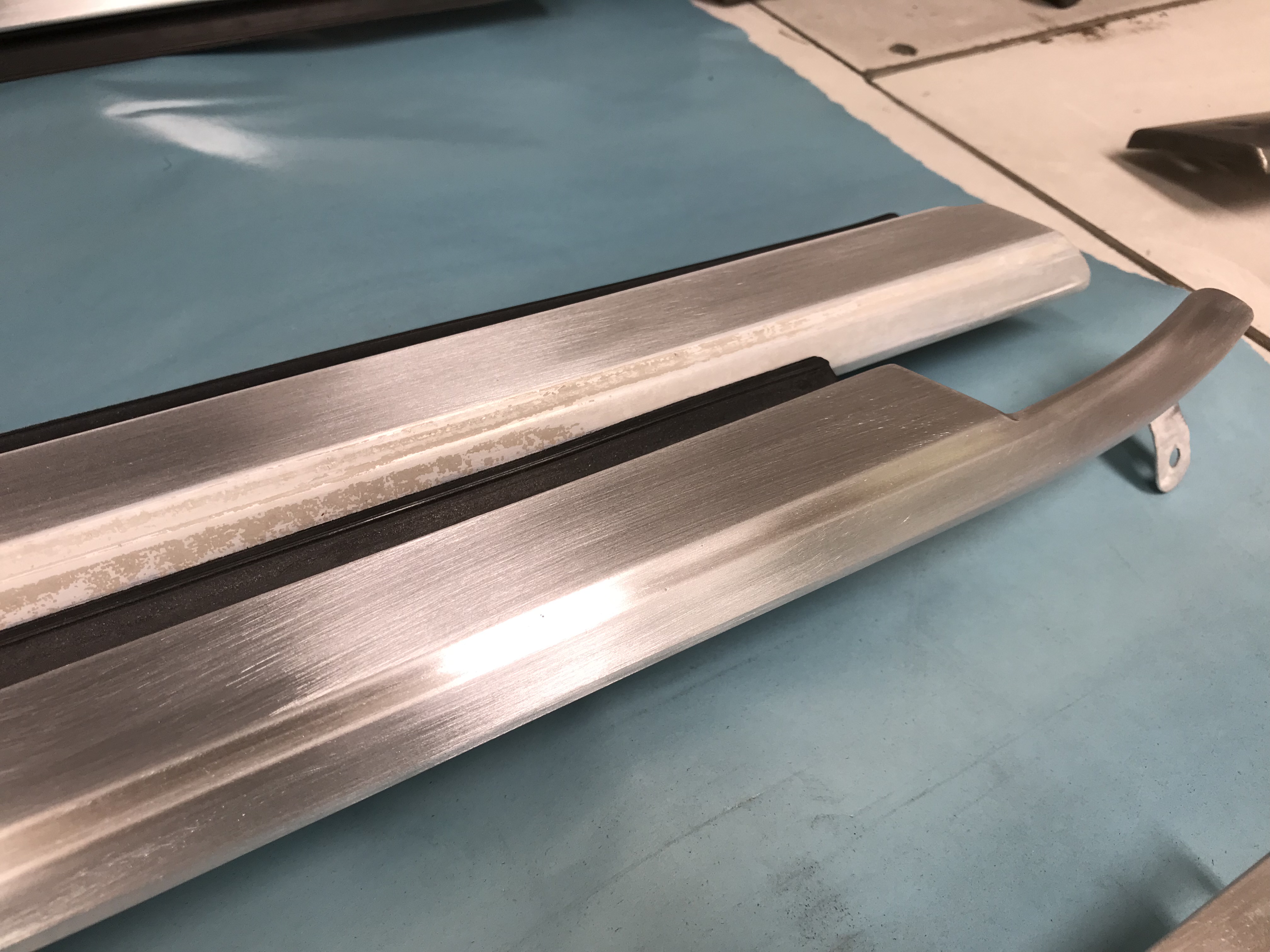

After applying my restoration techniques to this one tho, it looks like they should be able to be restored.

The downside to this however, is that it’s EXTREMELY time consuming and harder to work with than the aluminum pieces, by a factor of about 50%. Repairing the tiny little section shown above took approximately 4 hours to do, and it’s still not 100% in my opinion. I’ll have to revisit these pieces at a later date in the future.

What I’ve been consistently trying to work on lately though, are the two door belt mouldings and the two proper upper drip rail pieces I snagged at the JY last fall. The drip rail trims I have on the car now are cut down Malibu hardtop ones as I couldn’t locate the proper Cutlass ones before then, and they don’t exactly fit the way they’re supposed to.

As part of my restoration process, after I get the dents and damage levelled out on them, I scuff up the pieces with sandpaper and then hit them several times with a heavy duty oven cleaner application and cold water rinse. Scott (Injectedcutty) asked me recently if this process really works, and I can say that it definitely does. It doesn’t remove all the anodizing, but it definitely breaks it down and significantly reduces the amount of effort required to sand the rest of it off.

Here’s what it looks like when it’s applied, make sure to do it outside to reduce the risk of premature death from the wife. (She definitely won’t like the smell, not to mention it’s extremely caustic stuff).

I lay on a thick coat of the stuff, then let sit and work for 20-30 minutes:

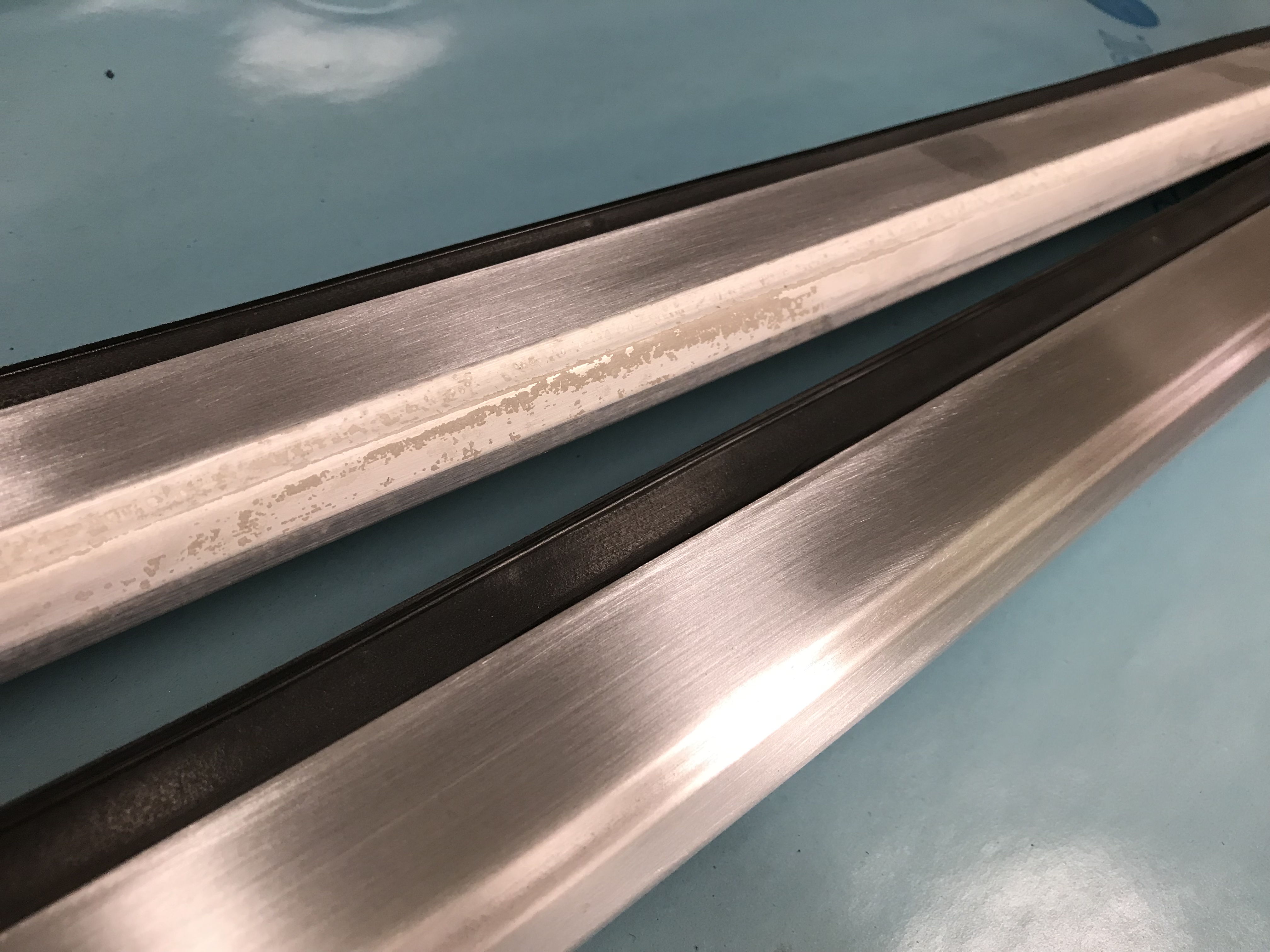

Rinse with cold water afterwards, then reapply and repeat as necessary. When the coating is sufficiently weakened, they’ll look something like this:

At this point they obviously need to be sanded again, but now the anodizing comes off a helluva lot easier. I can vouch for this personally.

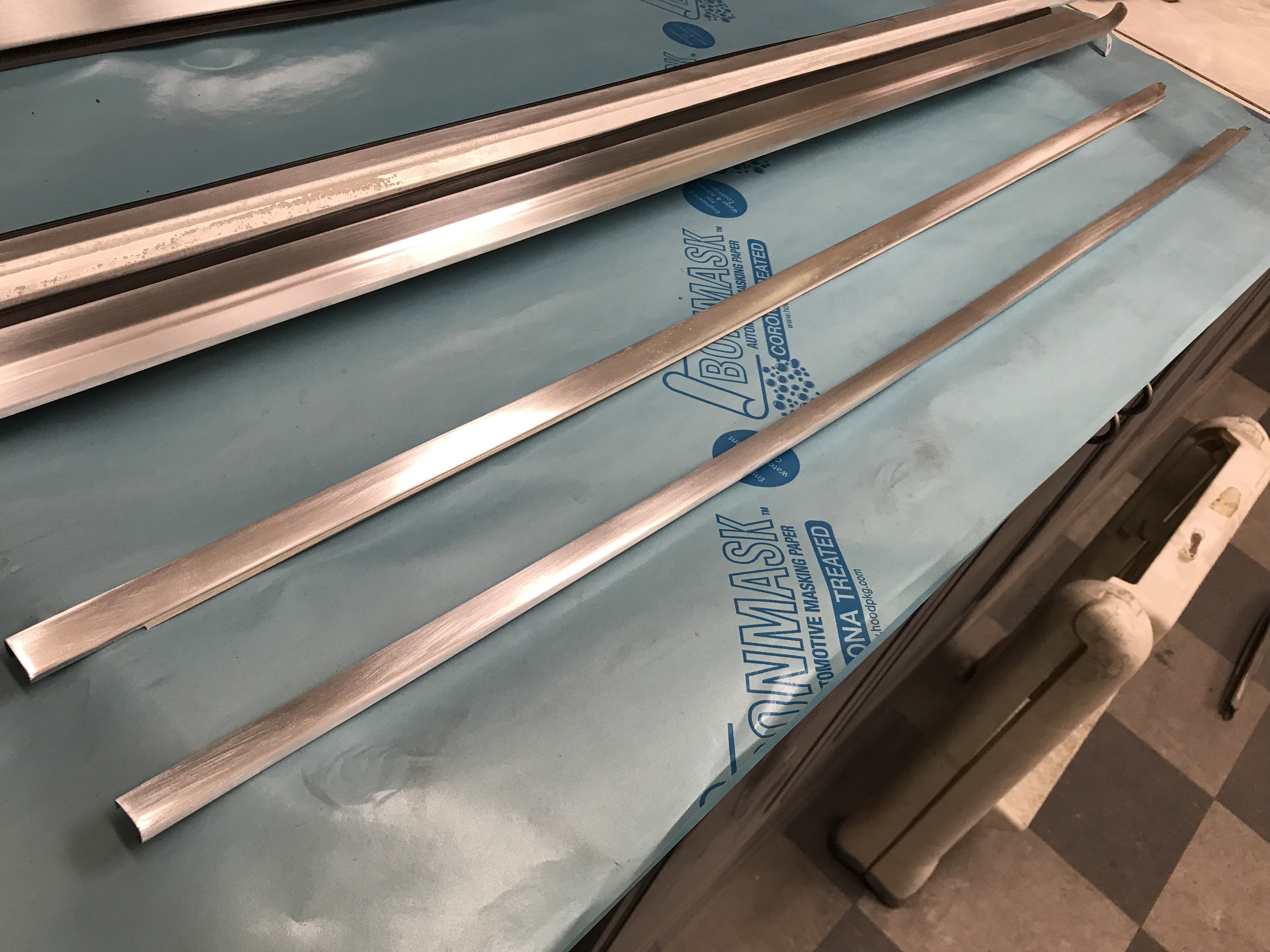

So far, I’ve completed straightening, stripping and sanding both upper drip rail pieces, the entire passenger door belt moulding, and am approximately halfway through the final sanding of the driver’s side one.

Here’s where I stand as of right now:

Although I’m almost done with sanding the last of the weakened anodizing off, all the pieces will need to be mounted up either on the car or in the vise, as the very last step before clear coating them will be to carefully sand them in long linear lines from one end to the other to eliminate all the starting and stopping marks. From then on it’ll be handling them with latex gloves for the final wipe down.

That’s all I’ve got for y’all for now, hopefully this post was somewhat educational and interesting. But I won’t be offended if y’all found it about as interesting as watching flies f*ck.

😅

Thanks everyone for continuing to show interest in the build, until next time friends.

D.