BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Even the wheel caps will be amazing. That is very common with the multiple light dome/map lights. Almost none that I have owned have switched on and off like they should.

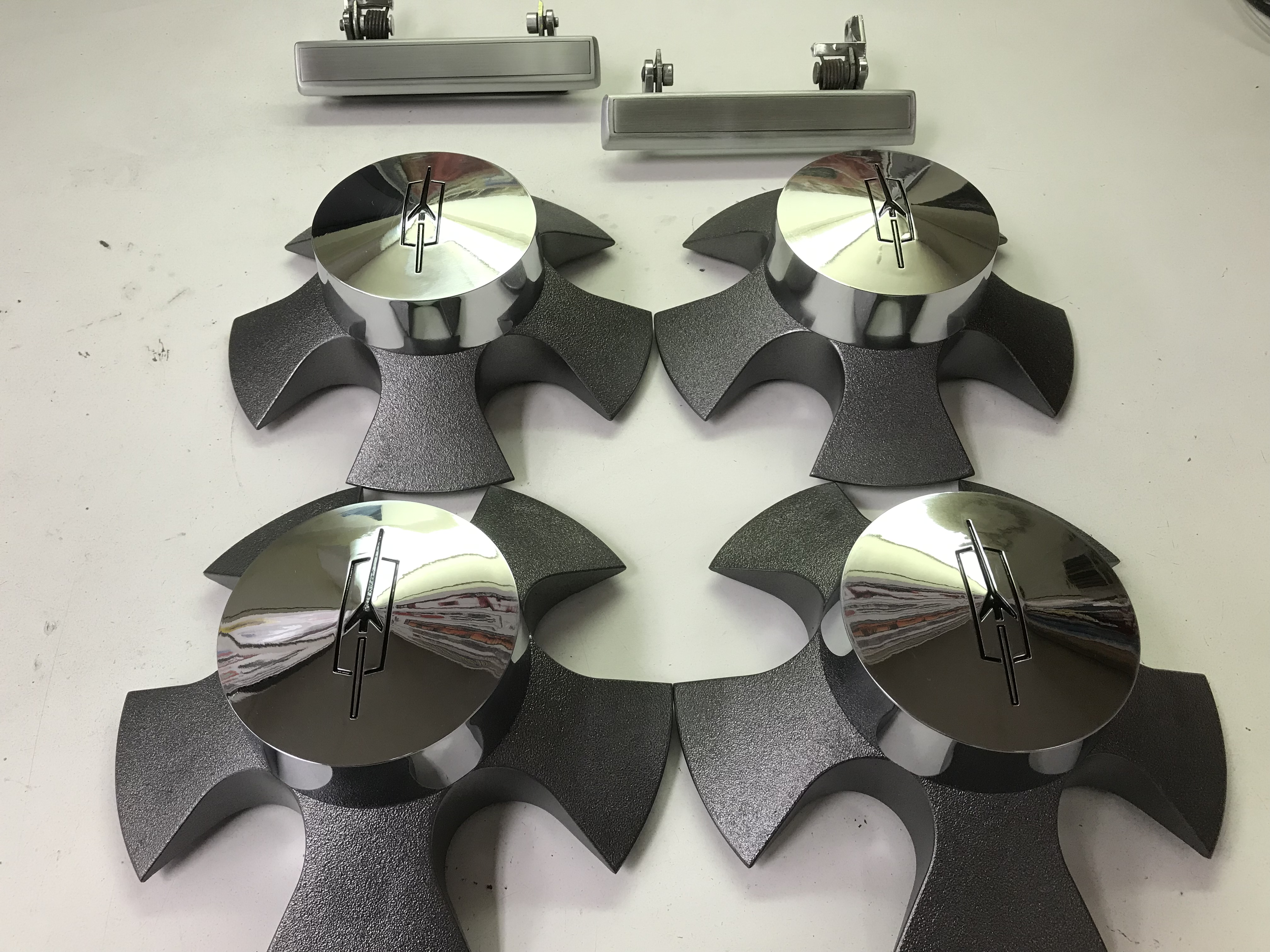

The center caps are now done.

And as far as the dome light is concerned, I have that style in both my cars, and have never had a problem with them up until now. And like I said, the issue turned out to be just a bad switch for the passenger’s side map light.

Truth be told, I’d MUCH rather prefer to have the map light style dome light than the regular round light. More light, and all around nicer looking. IMO of course.

I’m glad I grabbed several dome lights from the JY crawl as the one I ended up replacing it with has much smoother map light switches. The old ones were sticky and sounded like you were snapping a tree branch when you turned them on. On the plus side, I now have 3 spares if anyone needs one. You’d just have to supply your own chrome bezel and lens.

Time for some LED replacement bulbs!

Agreed!

It’s on the list of planned upgrades, I just didn’t have any on hand when I installed the light. Bigger fish to fry at the moment, like GETTING THIS FRIGGING THING PAINTED!!!

Next time I’m at the auto parts store, I’ll have to remember to grab the 3 bulbs it takes but in LED. I’ve already upgraded the bulbs in the instrument cluster, so I’m certainly not opposed to using them.

In other news, and as I mentioned above, the new (to me) minty center caps for the 442 wheels are now finished.

Last night I carefully unmasked them and inspected the paint job, they all turned out great. Then it was time for the Testor’s touch. Some simple Testors gloss black model paint, and painted the rocket logos.

Yeah I know it looks sloppy as all get out, but that was mostly intentional. Had to ensure I got full coverage inside the logo areas including the sides, so it ends up looking like Stevie Wonder got loose with the paint brush. 🙄

Not to worry though, once they were dry, a little lacquer thinner on some Q-Tips gets them looking right as rain again:

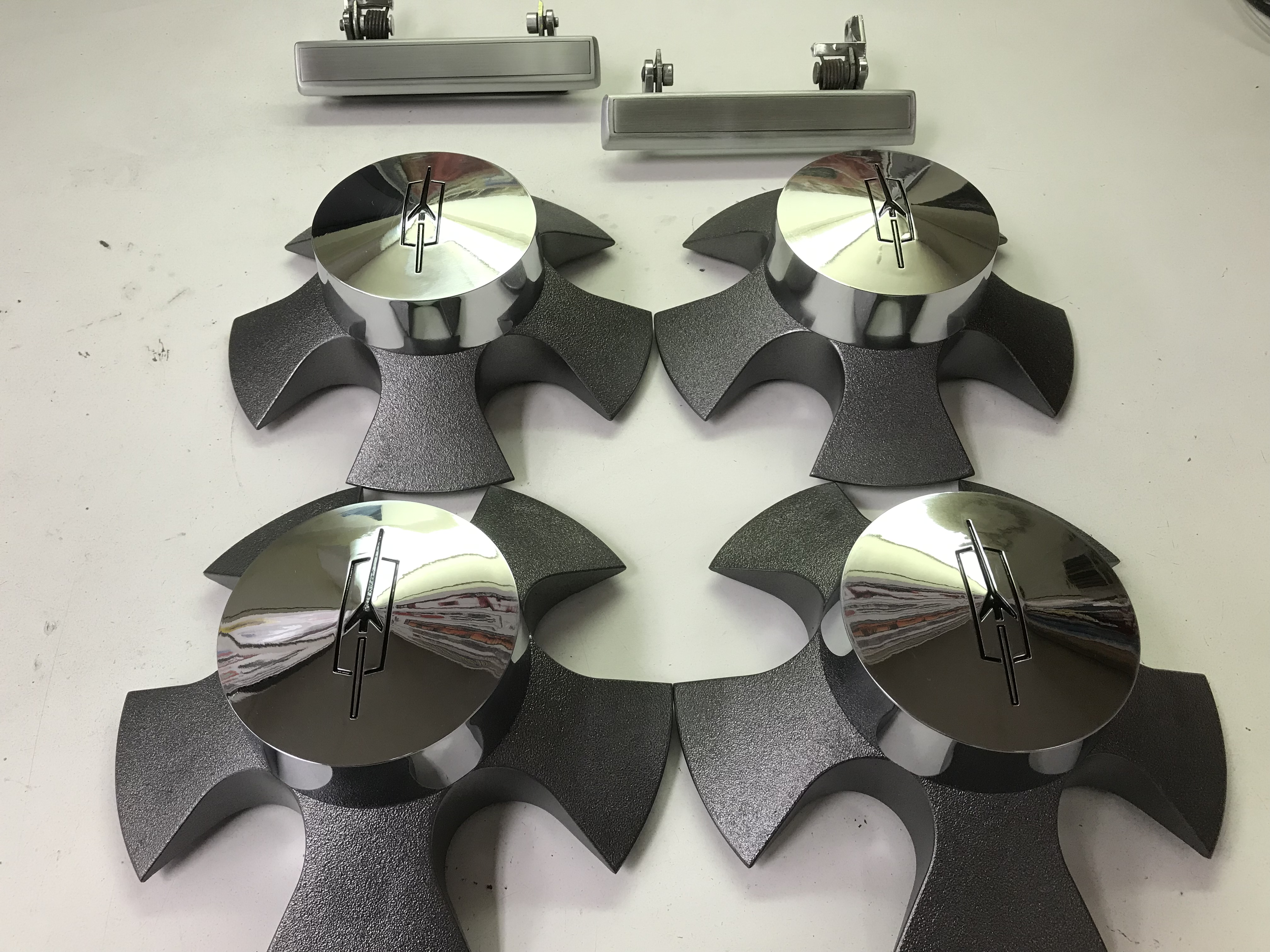

And here we go, all 4 done and ready to be swapped onto the car tonight:

This obviously won’t take me long to install them, so afterwards I’ll be starting on refurbishing the 2 belt mouldings. Lots of little dents in them to work out, and plenty of sanding.

That’s it for now, thanks for everybody’s interest in the thread!

😁

D.

Last night I carefully unmasked them and inspected the paint job, they all turned out great. Then it was time for the Testor’s touch. Some simple Testors gloss black model paint, and painted the rocket logos.

Yeah I know it looks sloppy as all get out, but that was mostly intentional. Had to ensure I got full coverage inside the logo areas including the sides, so it ends up looking like Stevie Wonder got loose with the paint brush. 🙄

Not to worry though, once they were dry, a little lacquer thinner on some Q-Tips gets them looking right as rain again:

And here we go, all 4 done and ready to be swapped onto the car tonight:

This obviously won’t take me long to install them, so afterwards I’ll be starting on refurbishing the 2 belt mouldings. Lots of little dents in them to work out, and plenty of sanding.

That’s it for now, thanks for everybody’s interest in the thread!

😁

D.

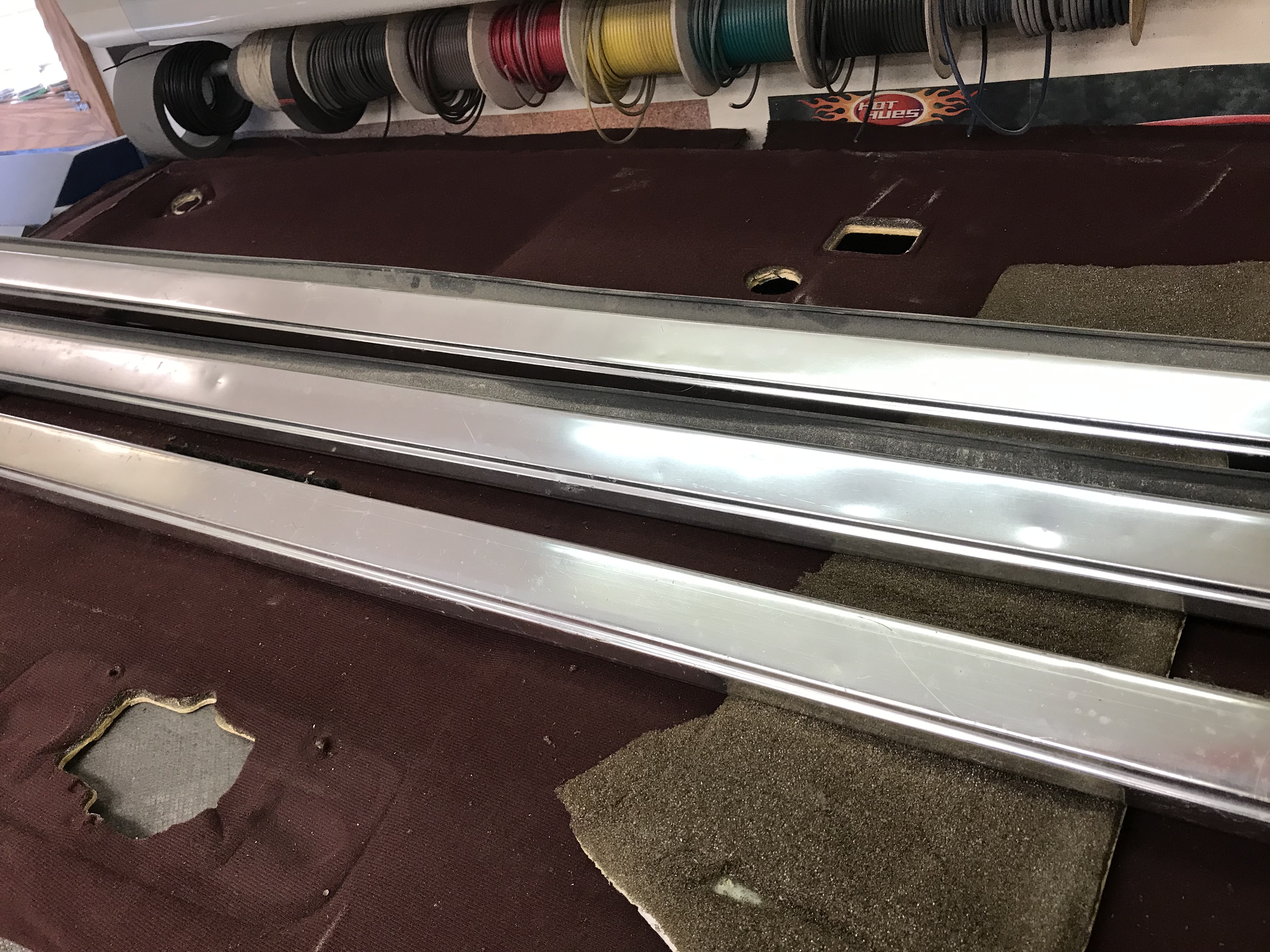

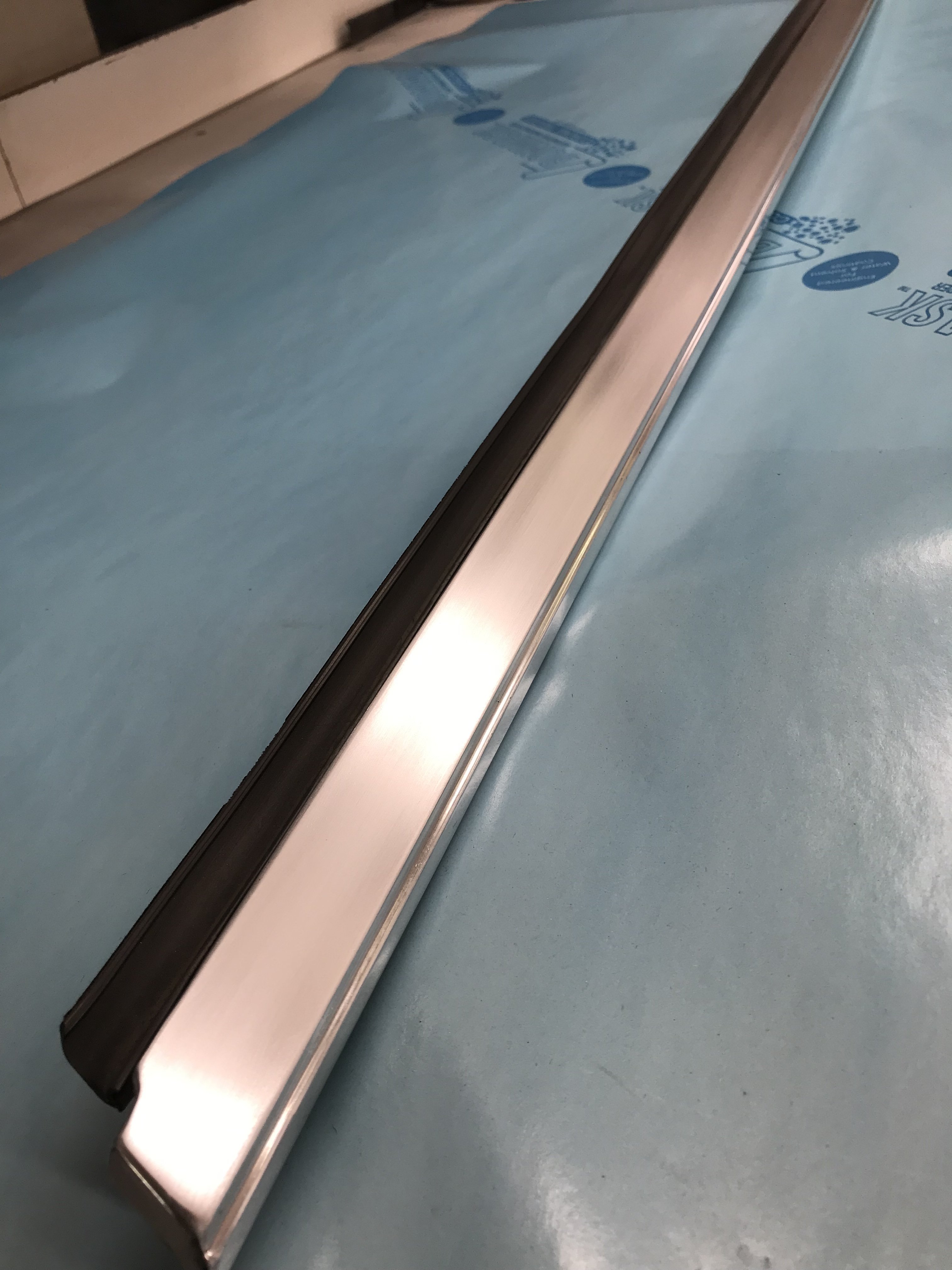

Been a bit since I’ve posted, just been plugging away on belt mouldings V 2.0.

V 2.0 because the on the first go-round I got a little aggressive on some of the deeper dents and over worked the material a bit too much.

Ok, a LOT too much.

I had the top surface so thin in spots I could literally move the material with nothing more than the force of a fingernail! Obviously unacceptable, so he we are on Versions 2.0.

I won’t bore y’all with the details of how I go about straightening and refinishing these unless it’s requested, but that doesn’t mean I can’t share a couple pictures of the progress.

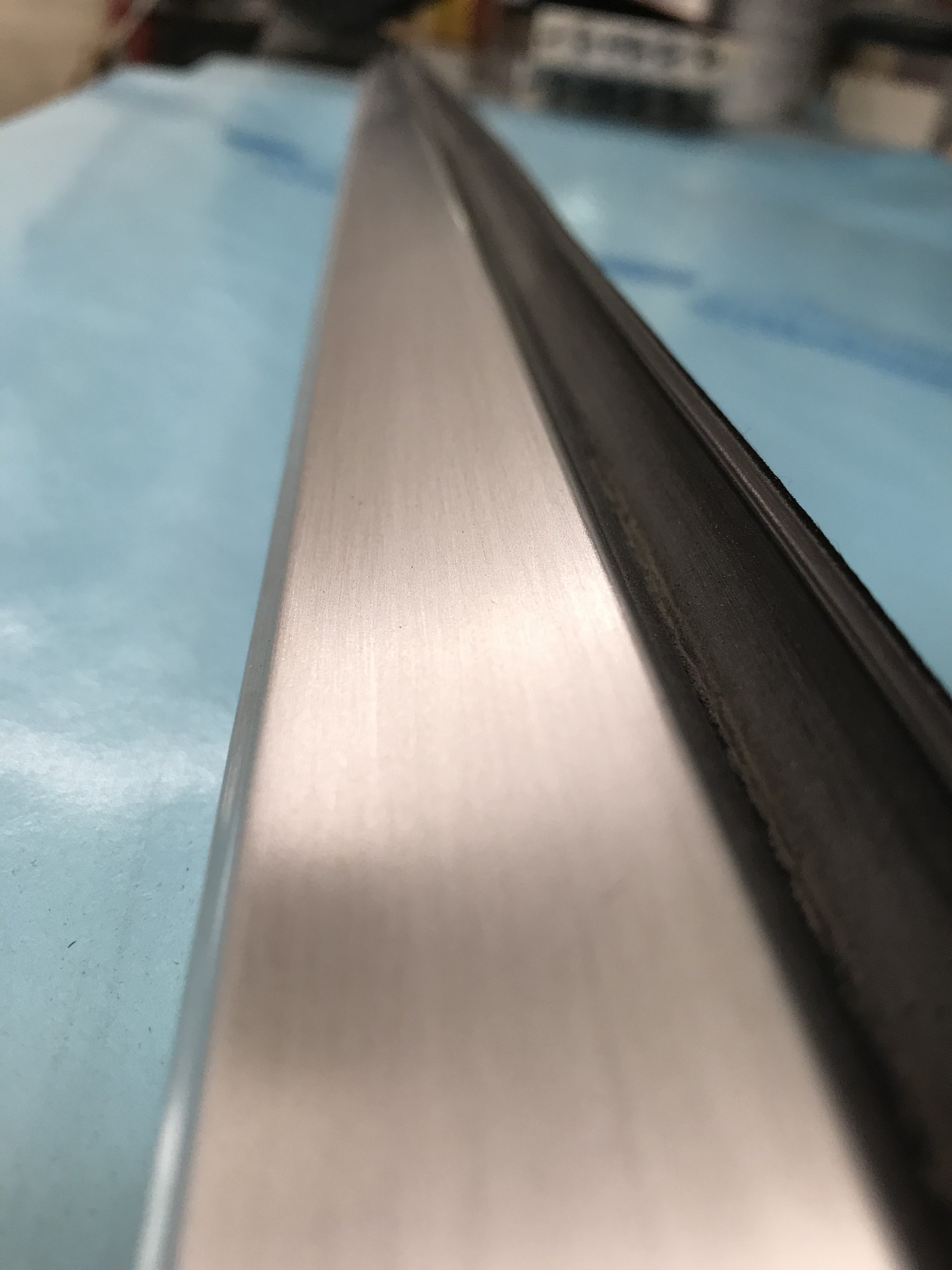

As it stands as of right now, I have the top of the passenger’s side straightened and brushed, this is by far the hardest and most time consuming part. I’ve also started repeating the process now on the driver’s side moulding.

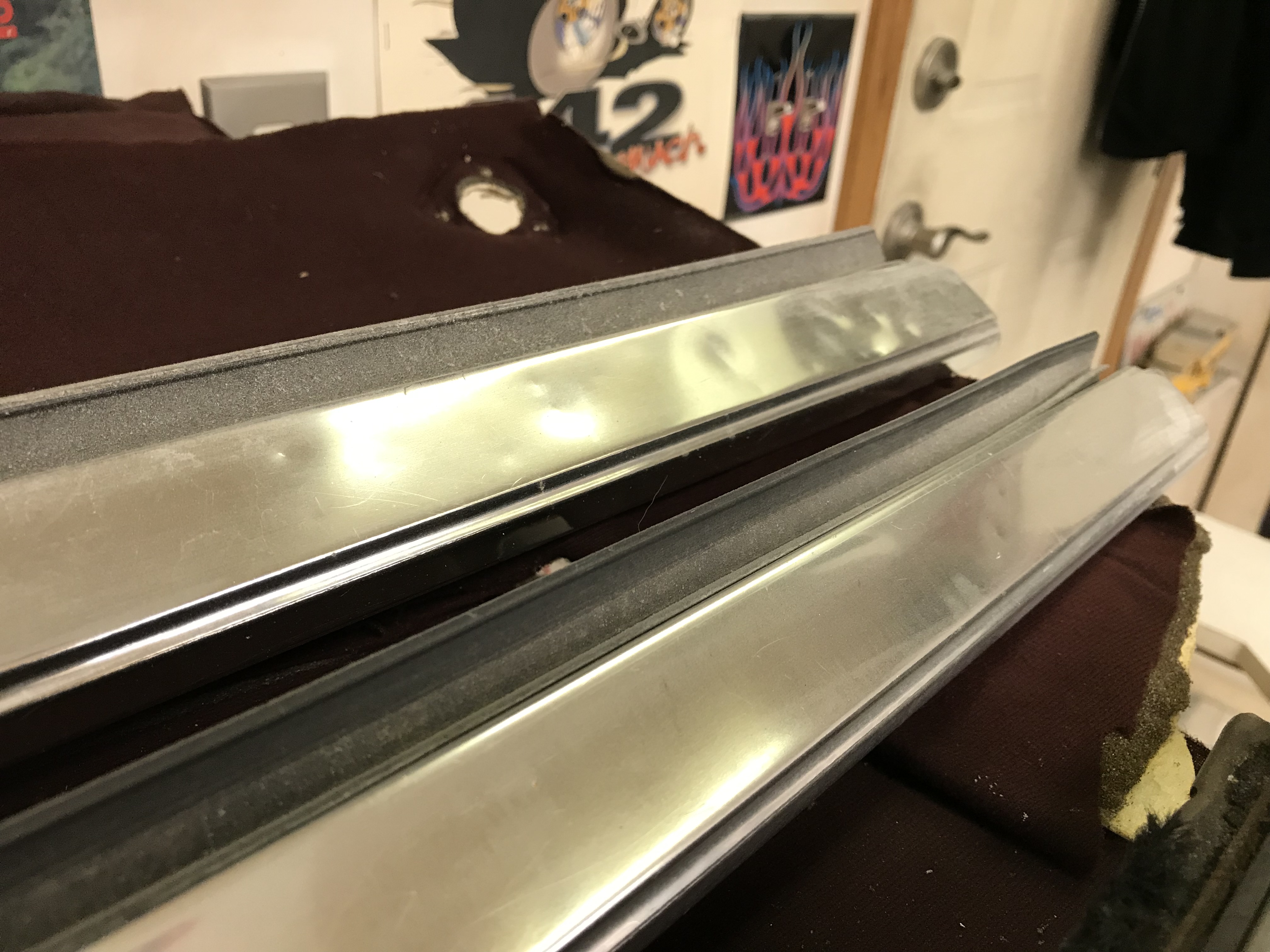

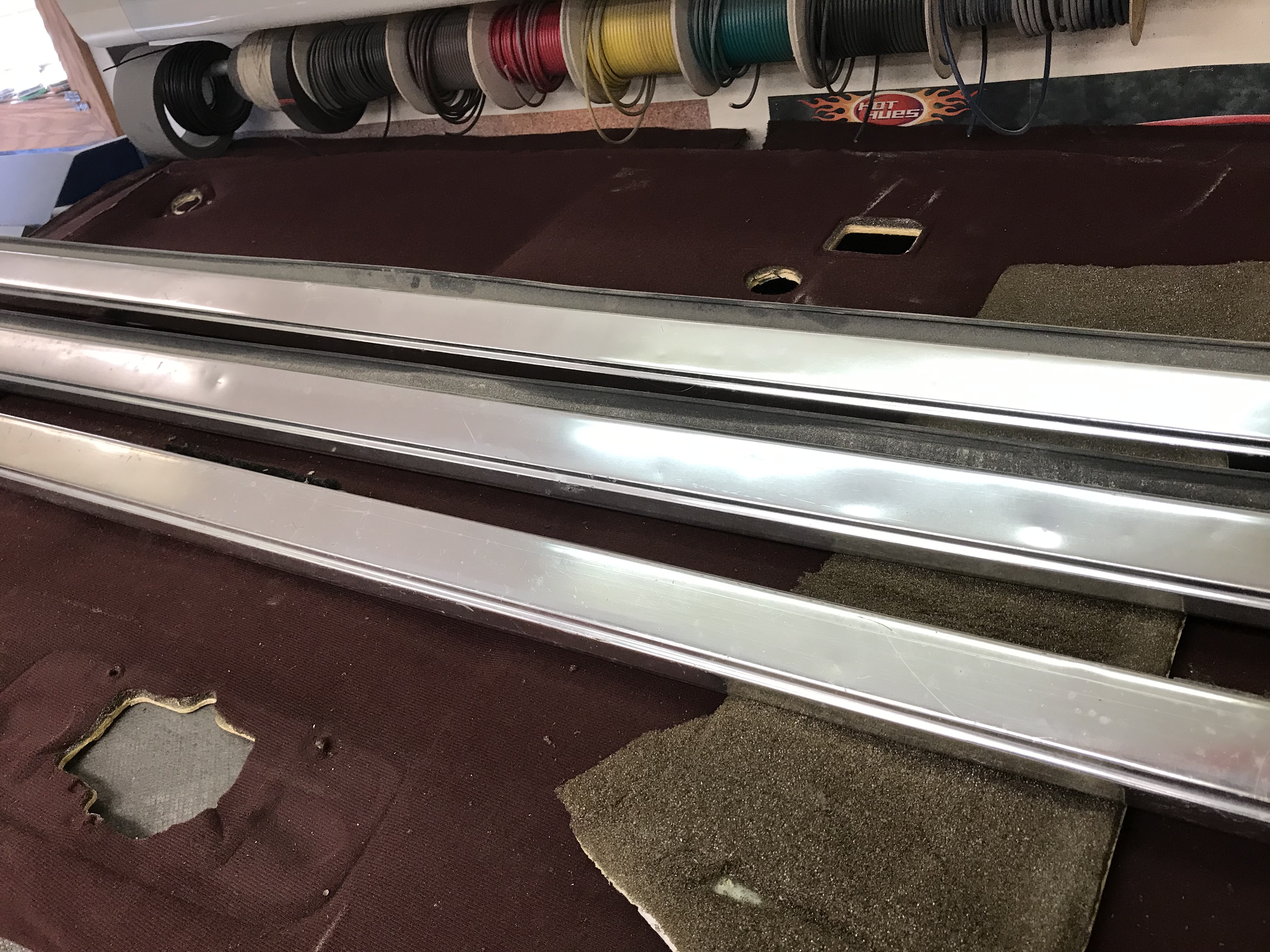

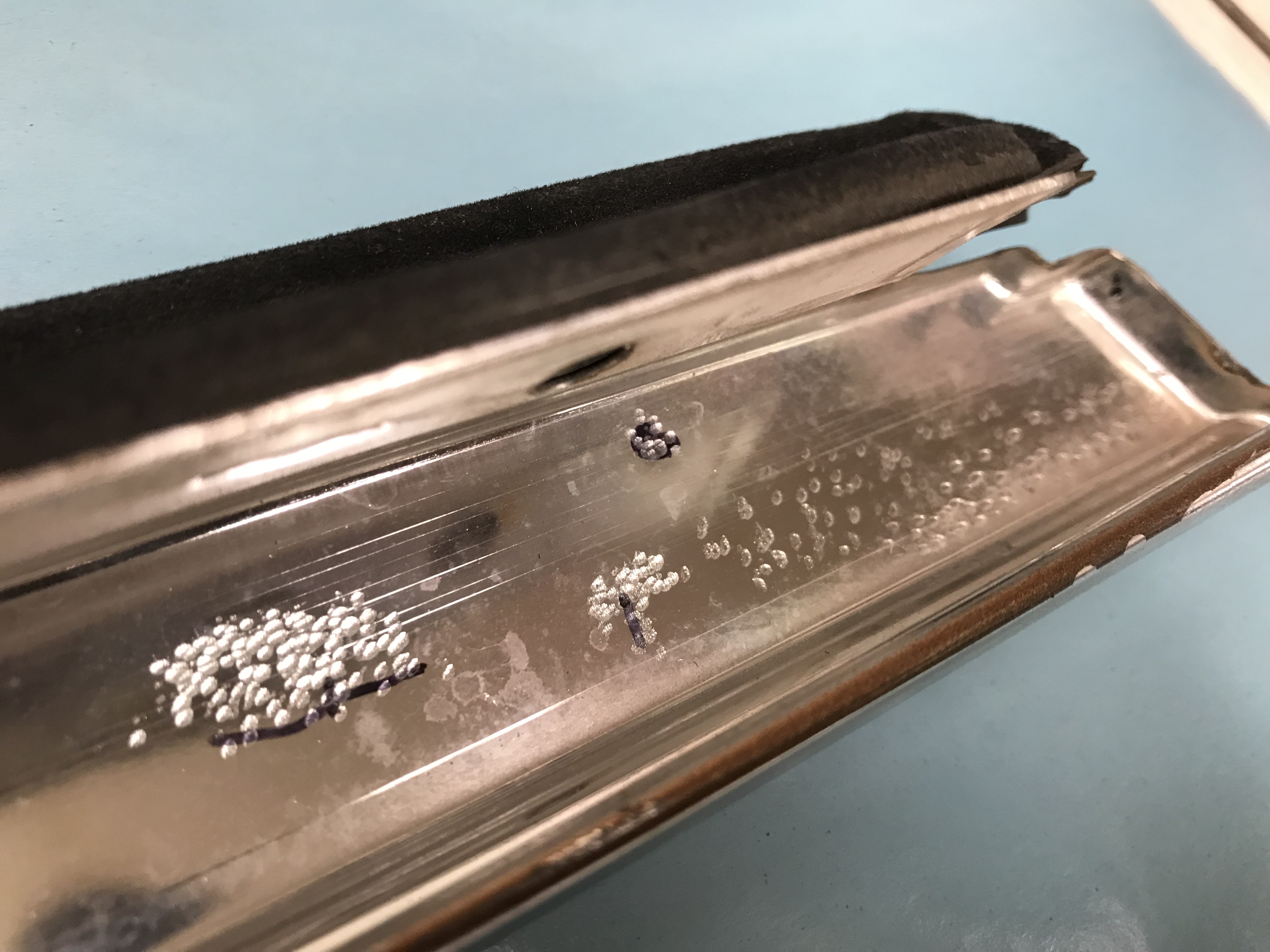

It all starts with choosing a suitable candidate, these are some of the ones that didn’t make the cut for obvious reasons:

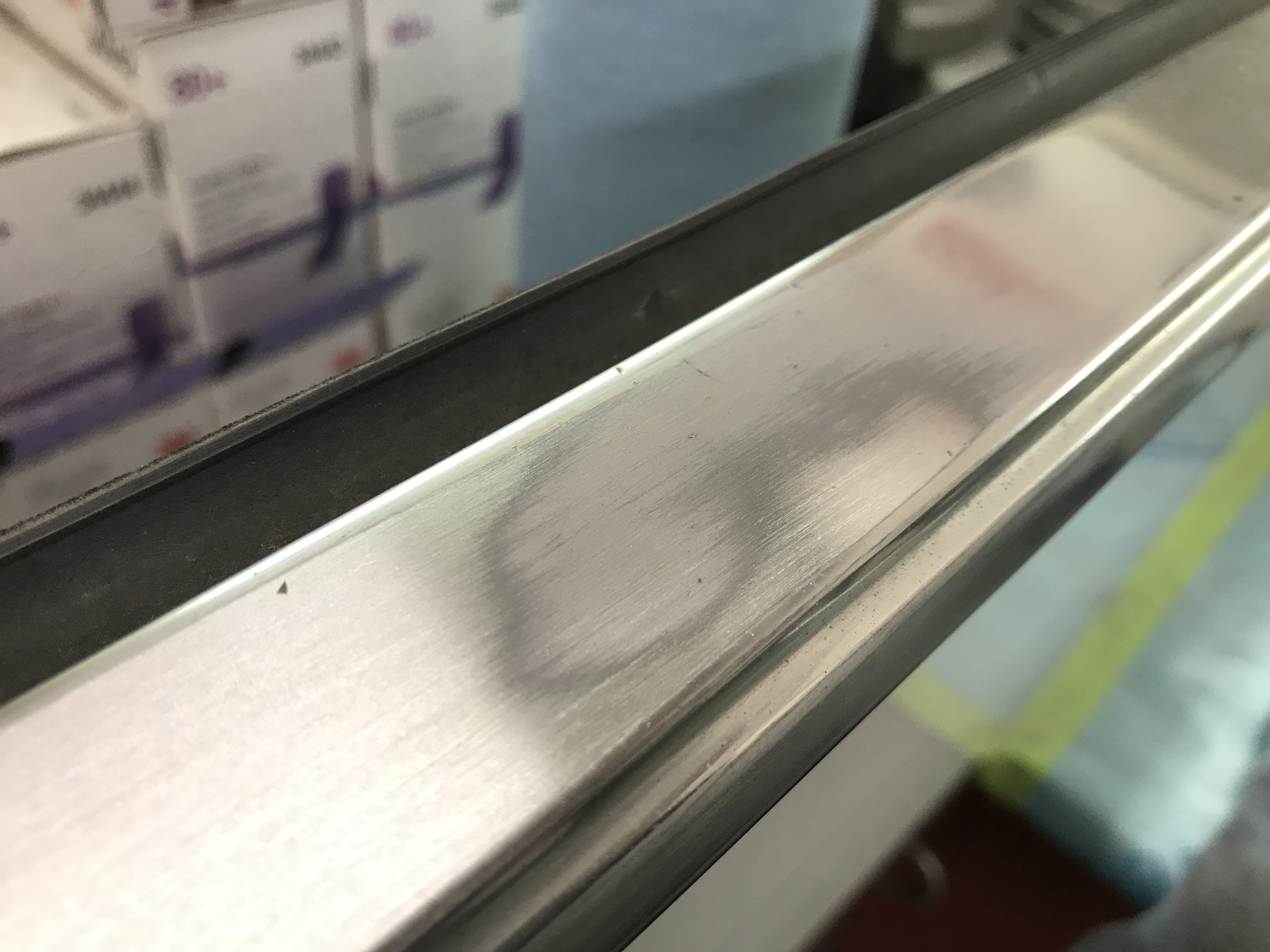

From there and once I’ve chosen a suitable piece, nearly all the work gets done on the vise. Here’s my current work station, the towel is for cleaning out the pores of the sandpaper as the aluminum clogs up the 220 grit paper pretty quickly:

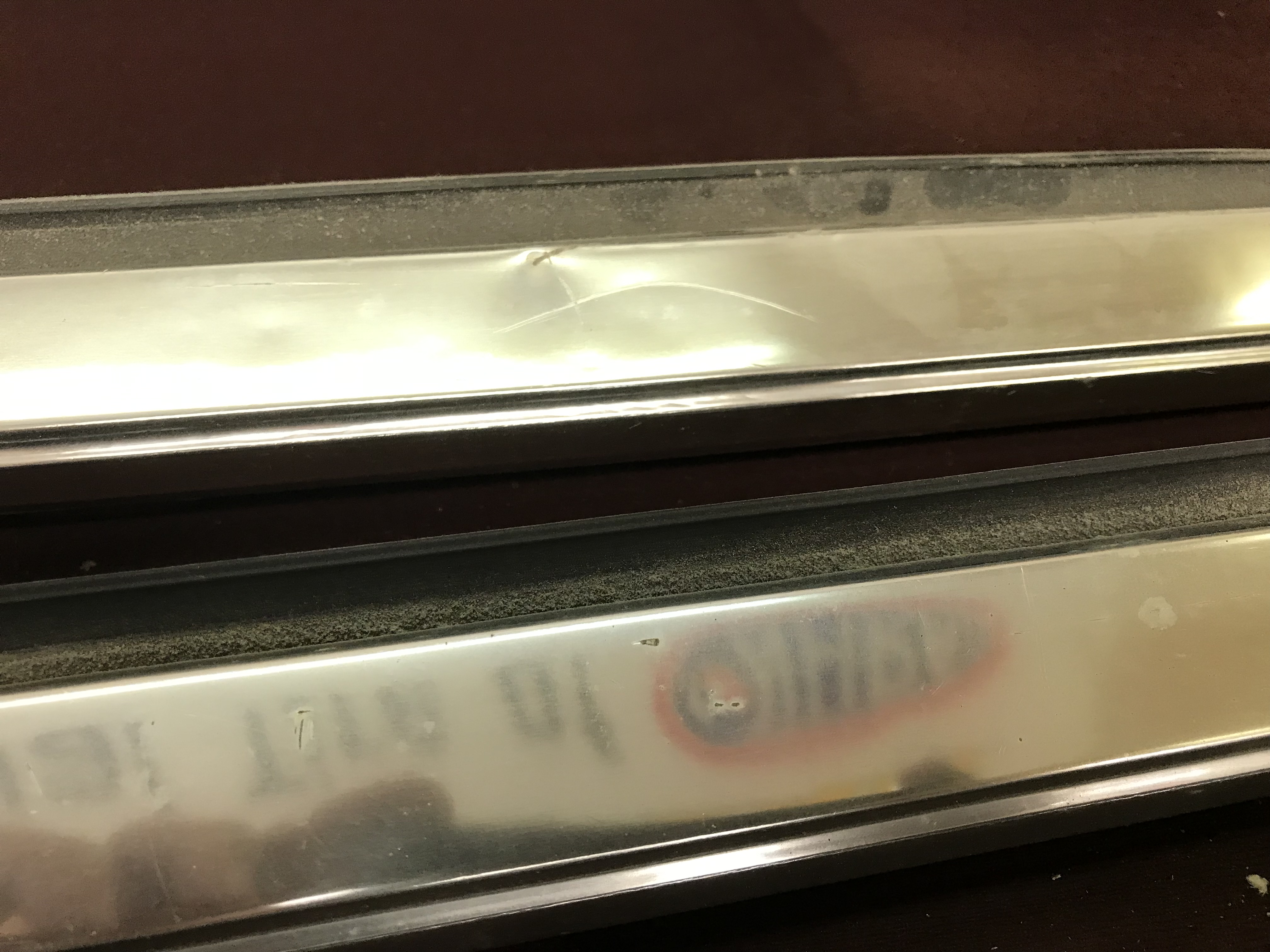

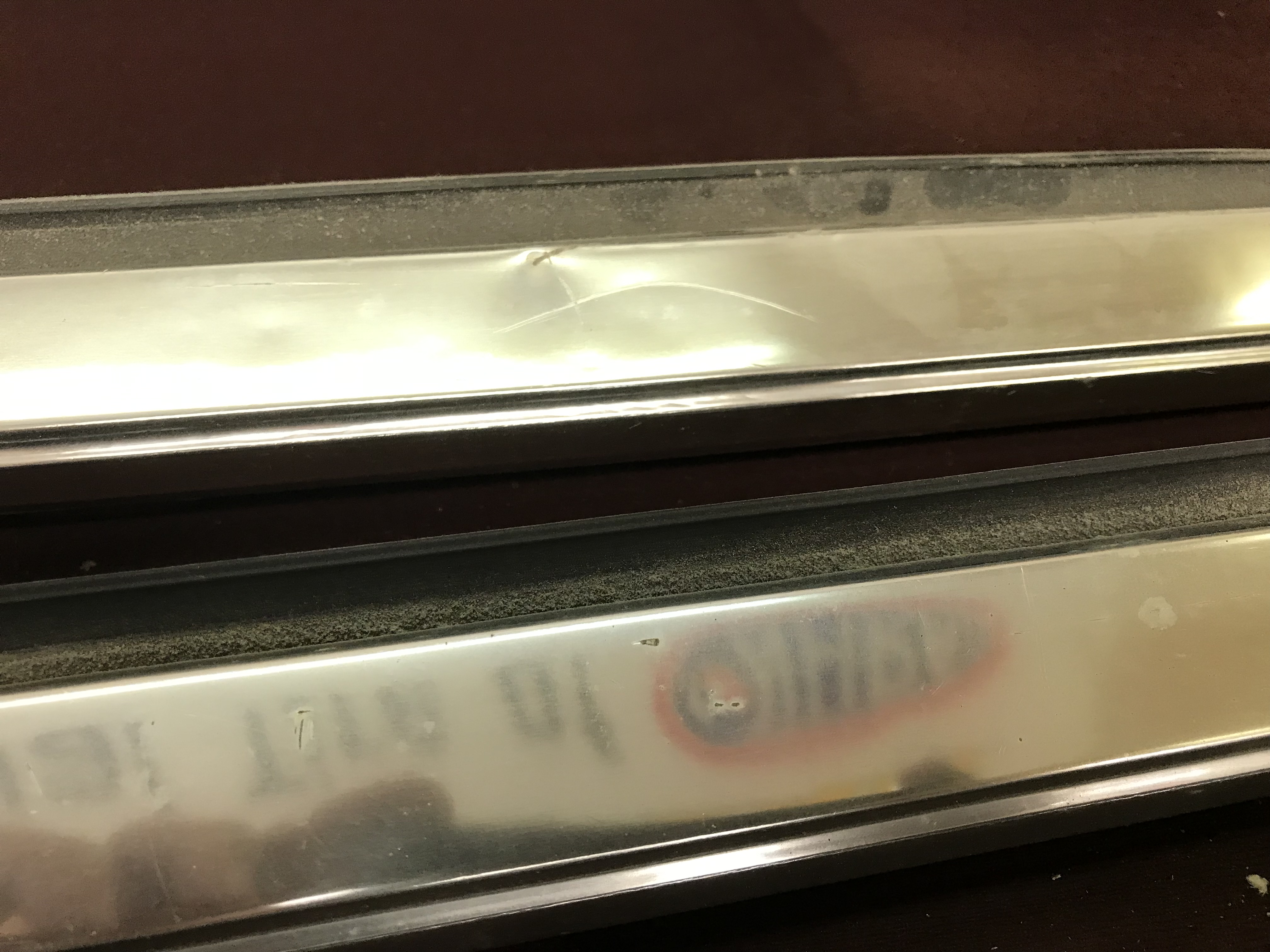

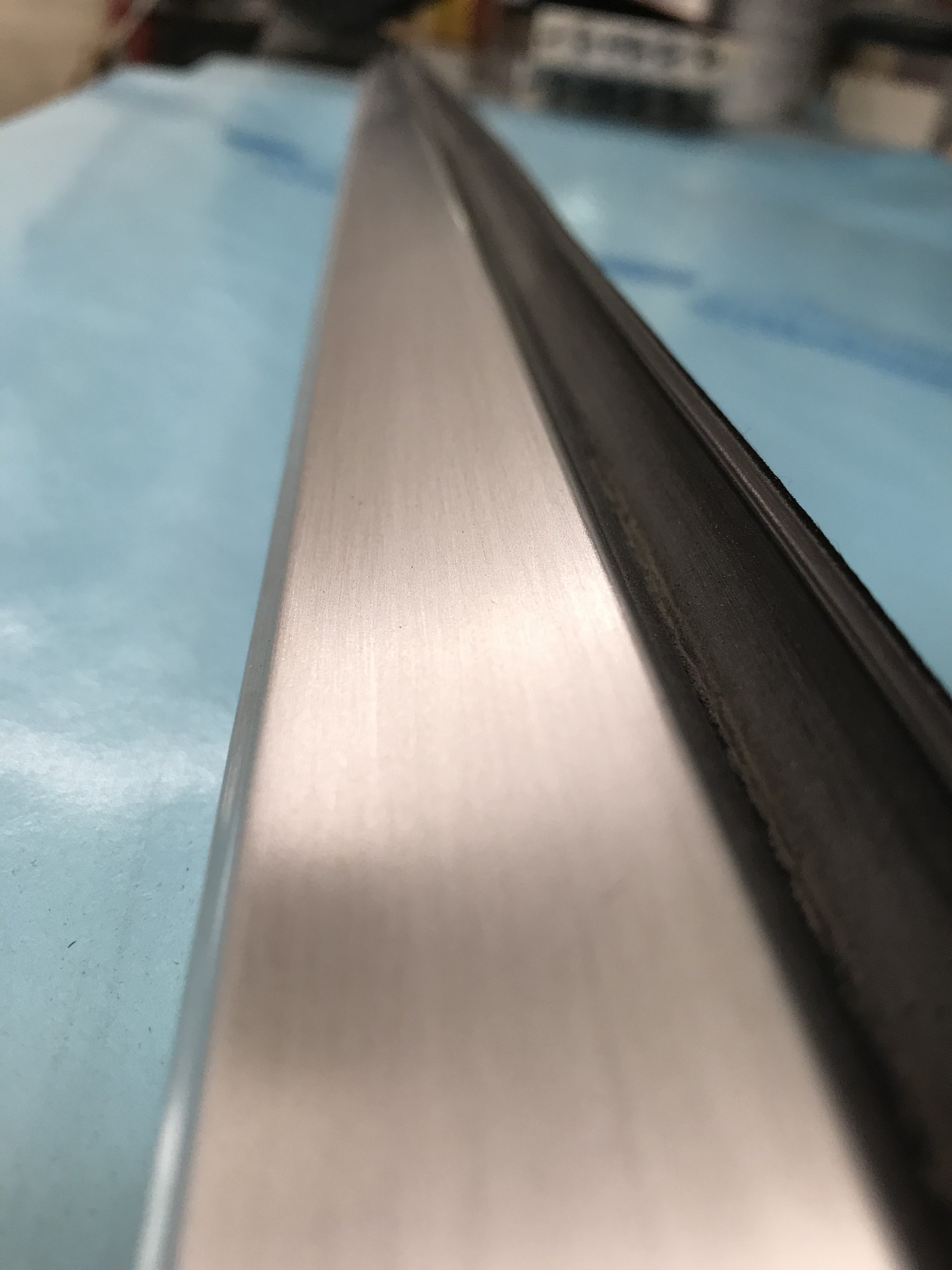

It’s pretty tough to see any of the dents, deep scratches, pits and multitude of imperfections in this pic, but trust me, after nearly 40 years of use and abuse, they’re there. This is actually a really good piece to start with:

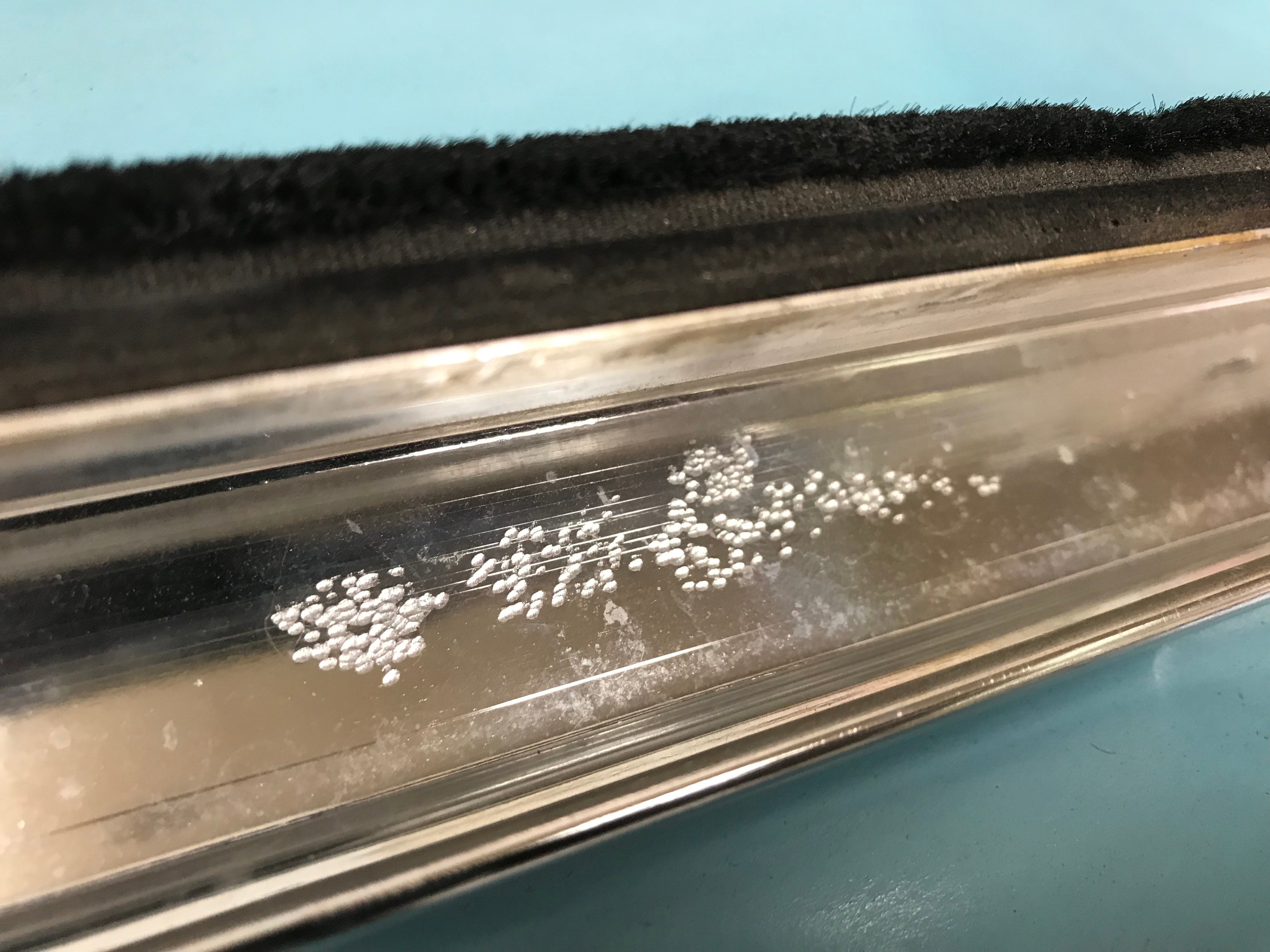

The deepest dents and most extreme damage is always tackled first, if these areas can’t be repaired seamlessly, there’s no point in continuing with the rest of it. The process is less like paintless dent repair, and more like old school pick and filing technique. Sometimes hundreds of little tiny pick marks up from the underside depending on the severity of the damage...

...then carefully block sanded in a crosshatch pattern until it’s either flush and flat, or needs to be worked more.

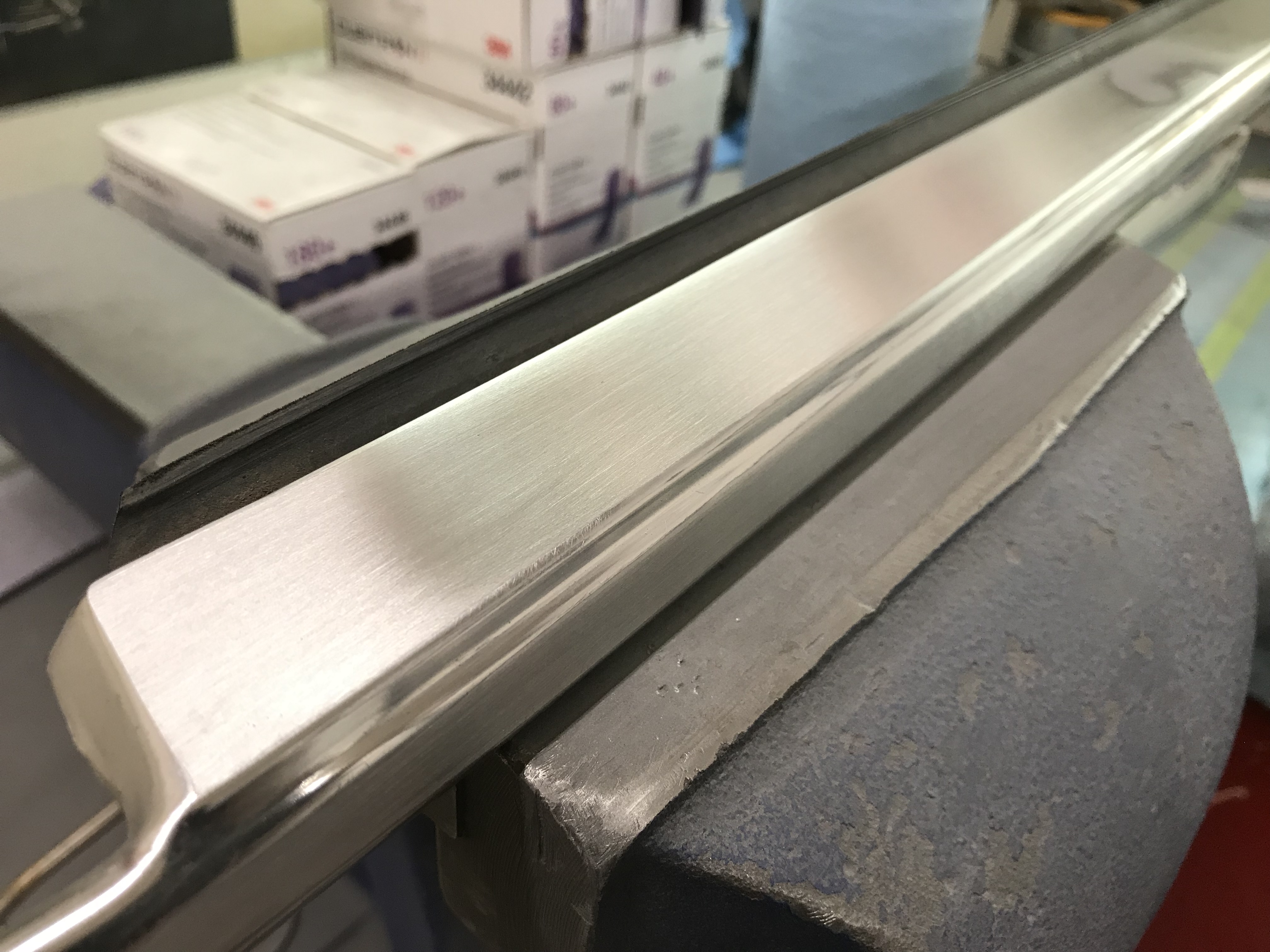

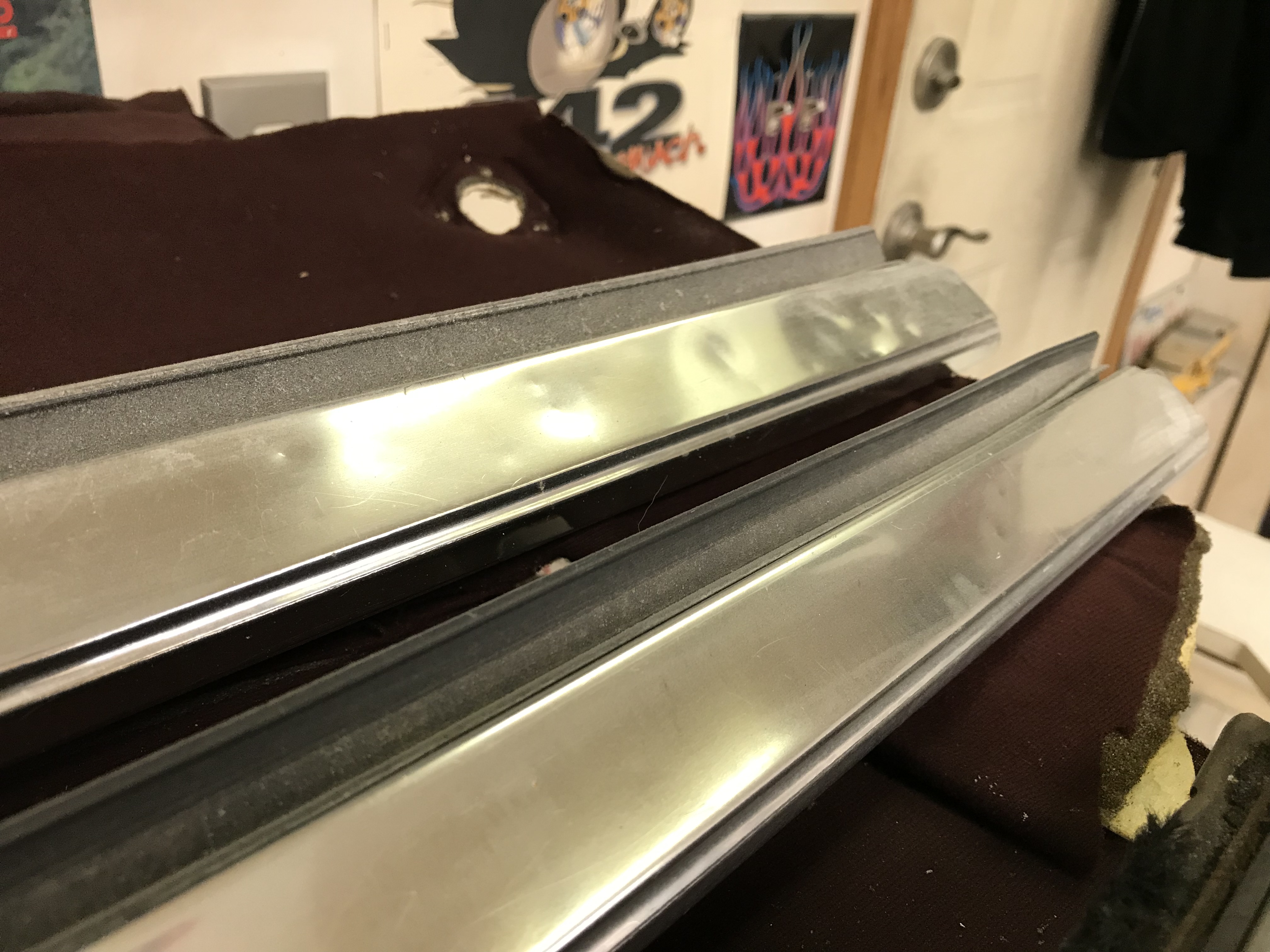

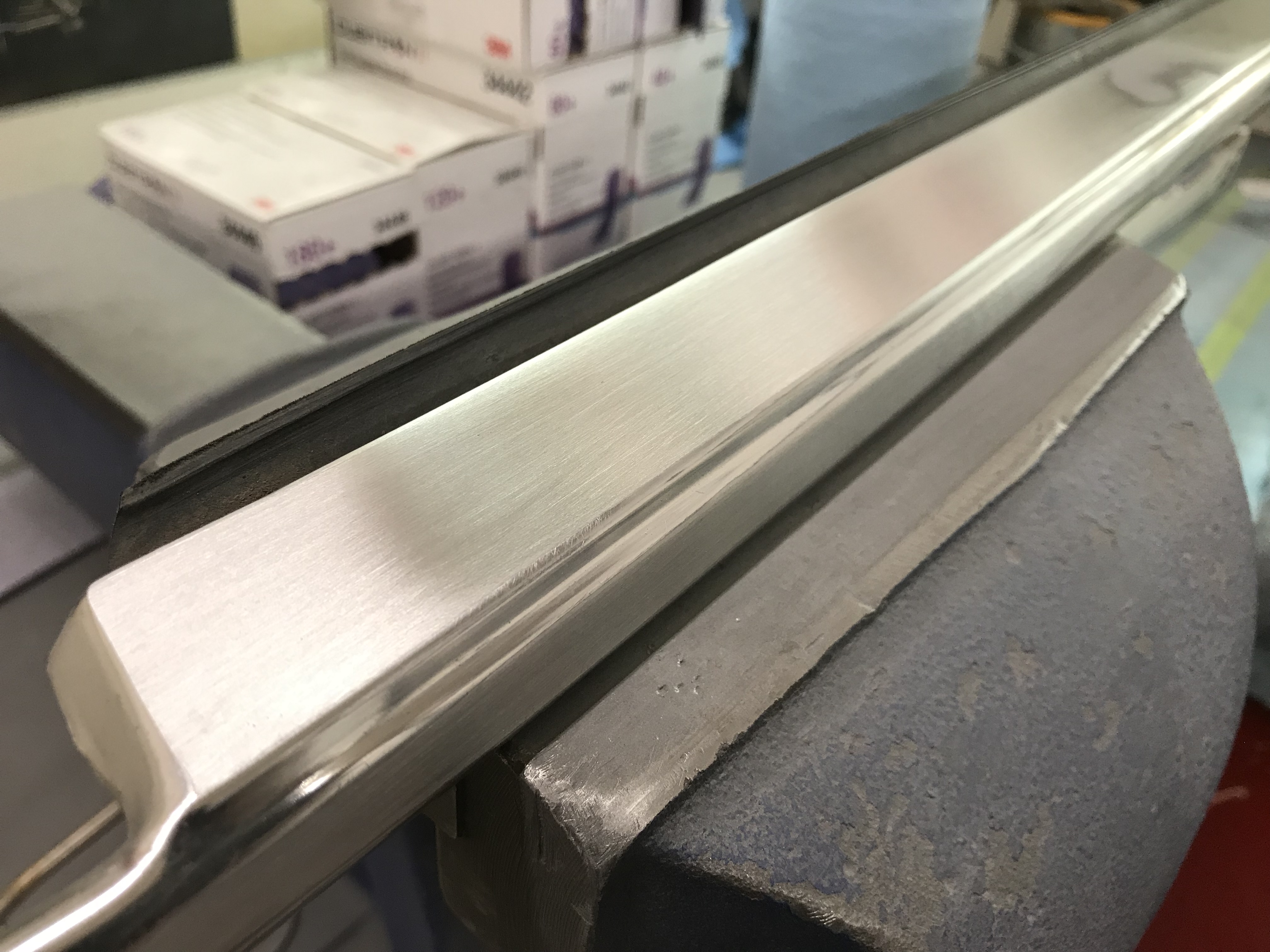

A look at this in the midst of the process:

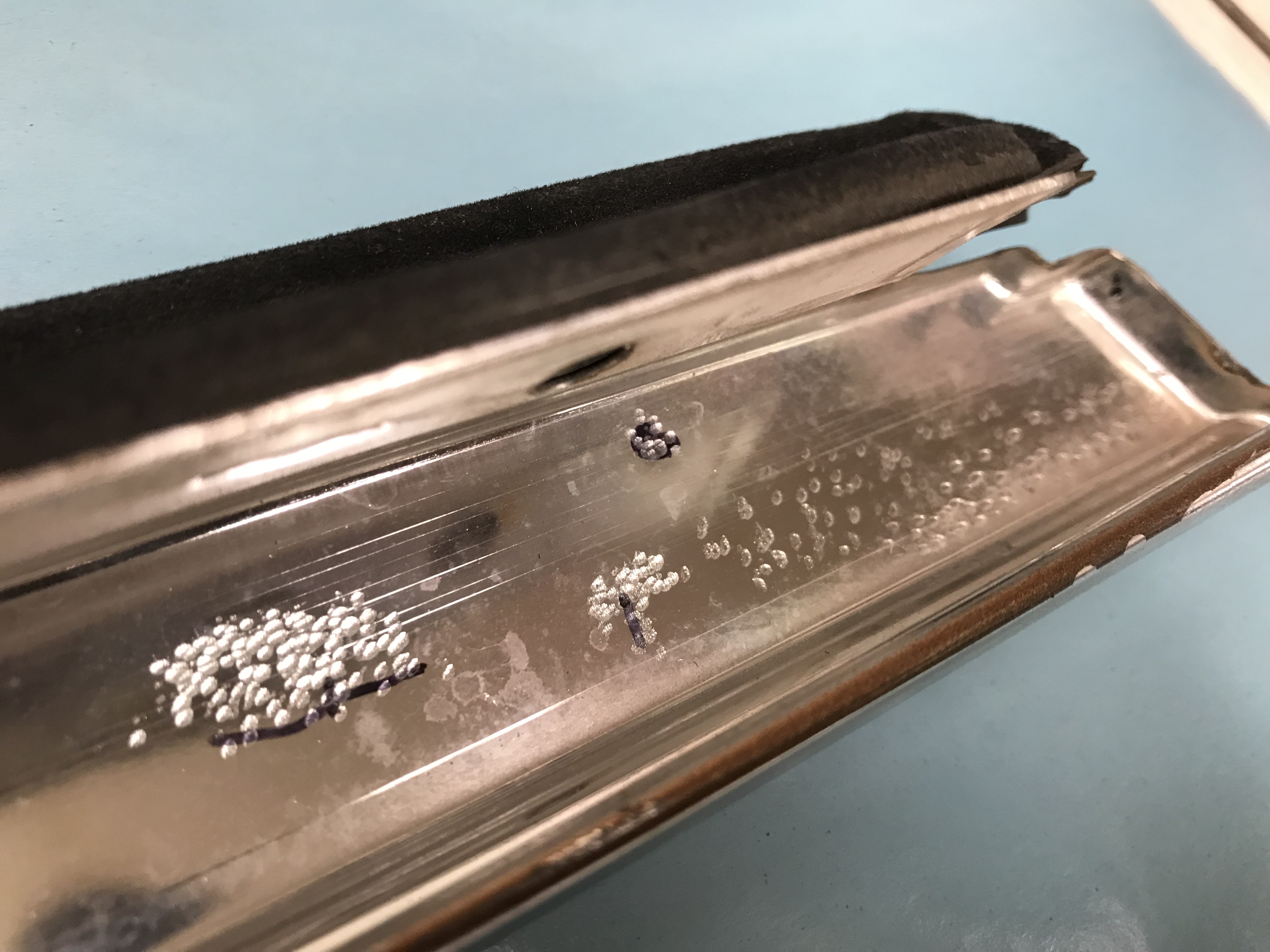

To give you some indication of just how time consuming this is, this is a roughly 8-10” finished section of the driver’s side moulding. There’s about 3 hours in this spot alone:

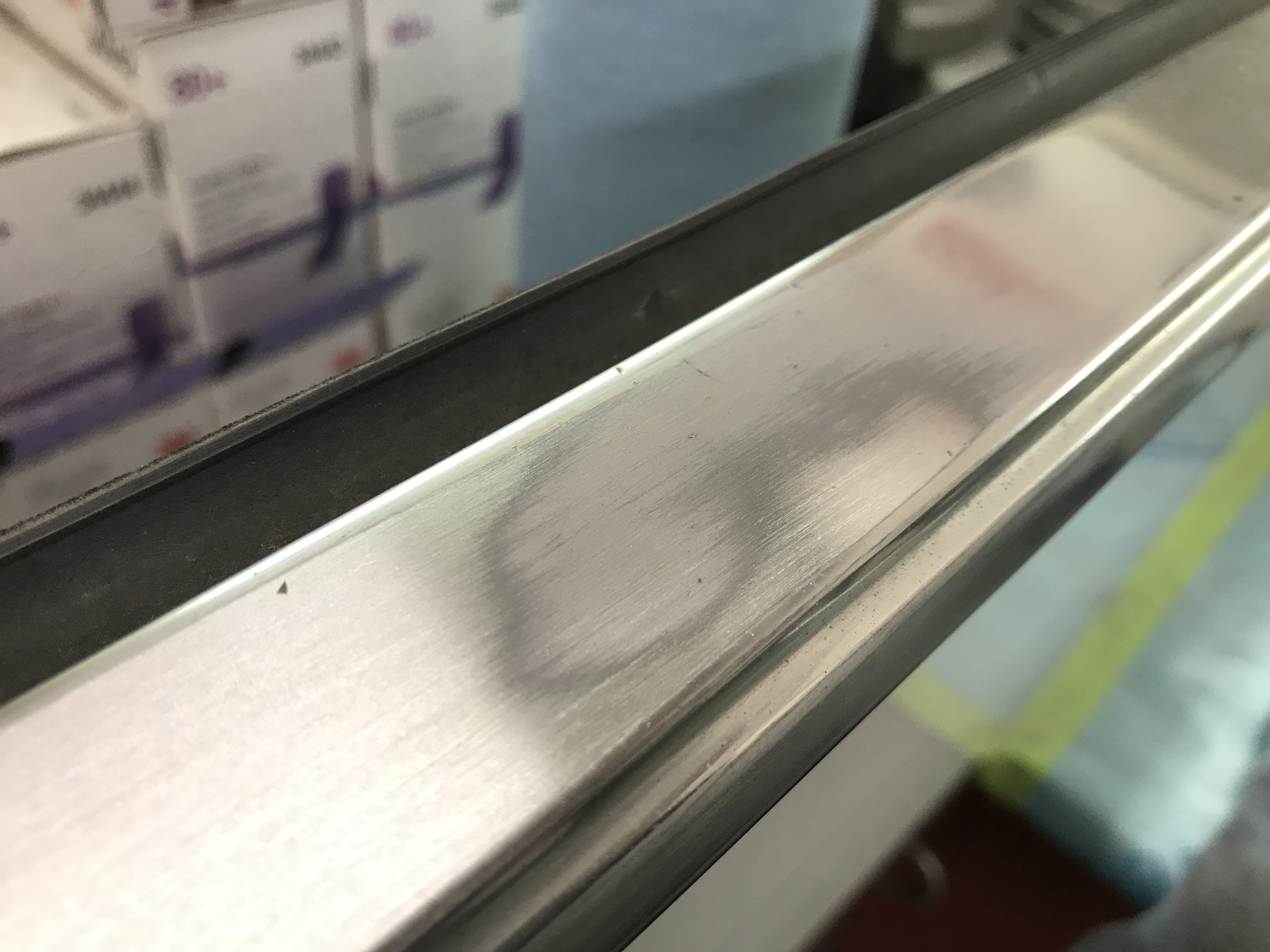

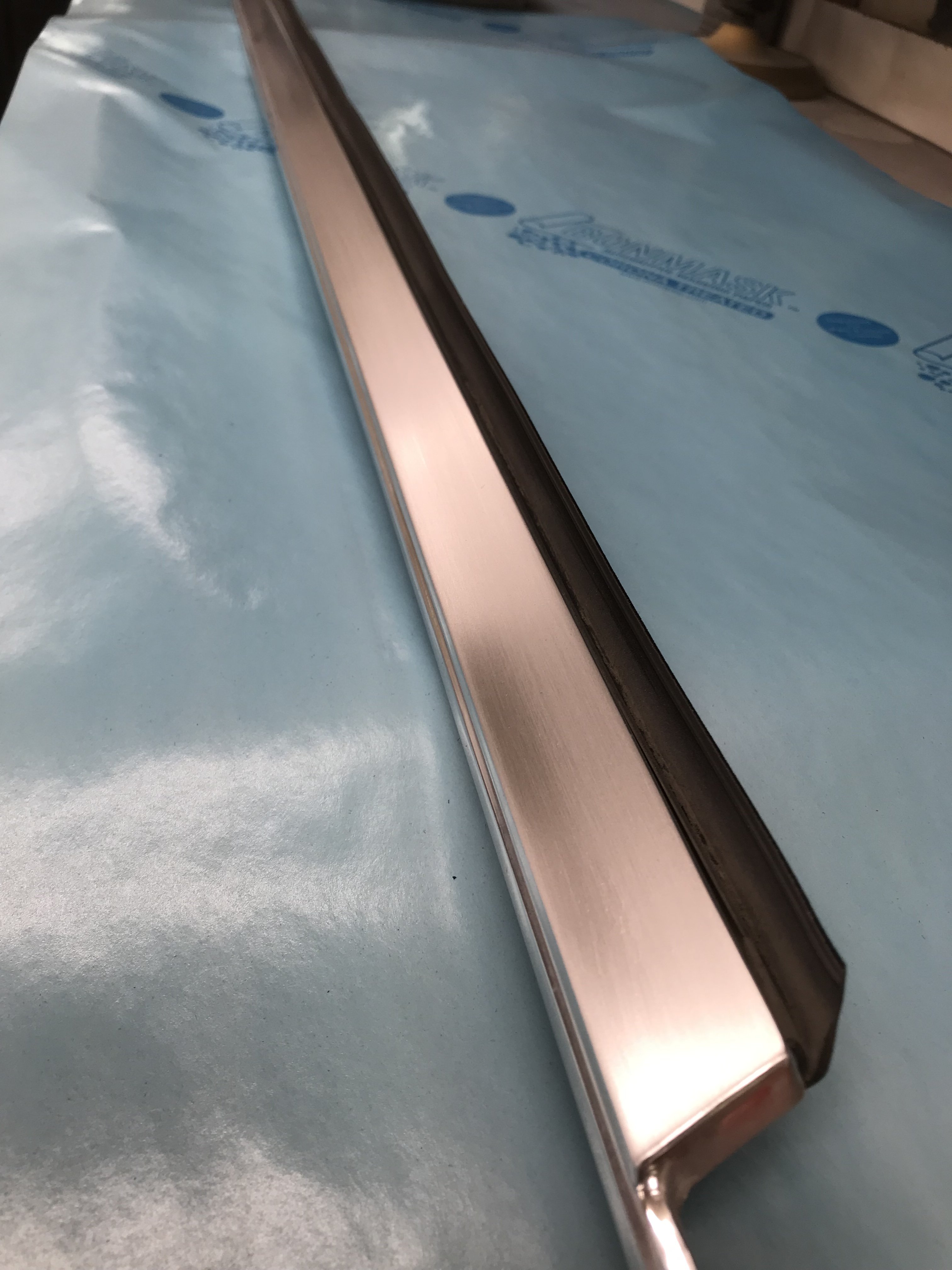

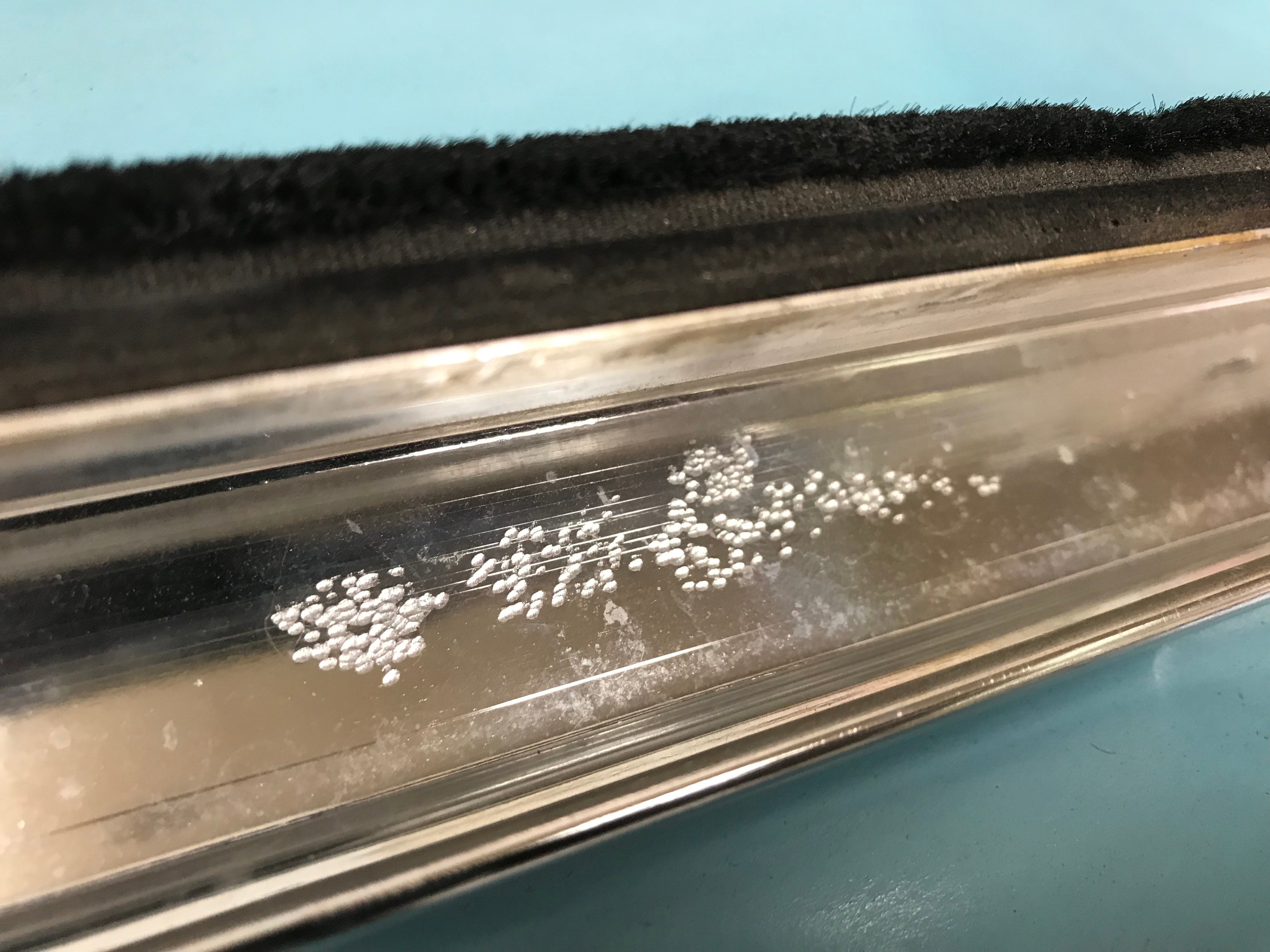

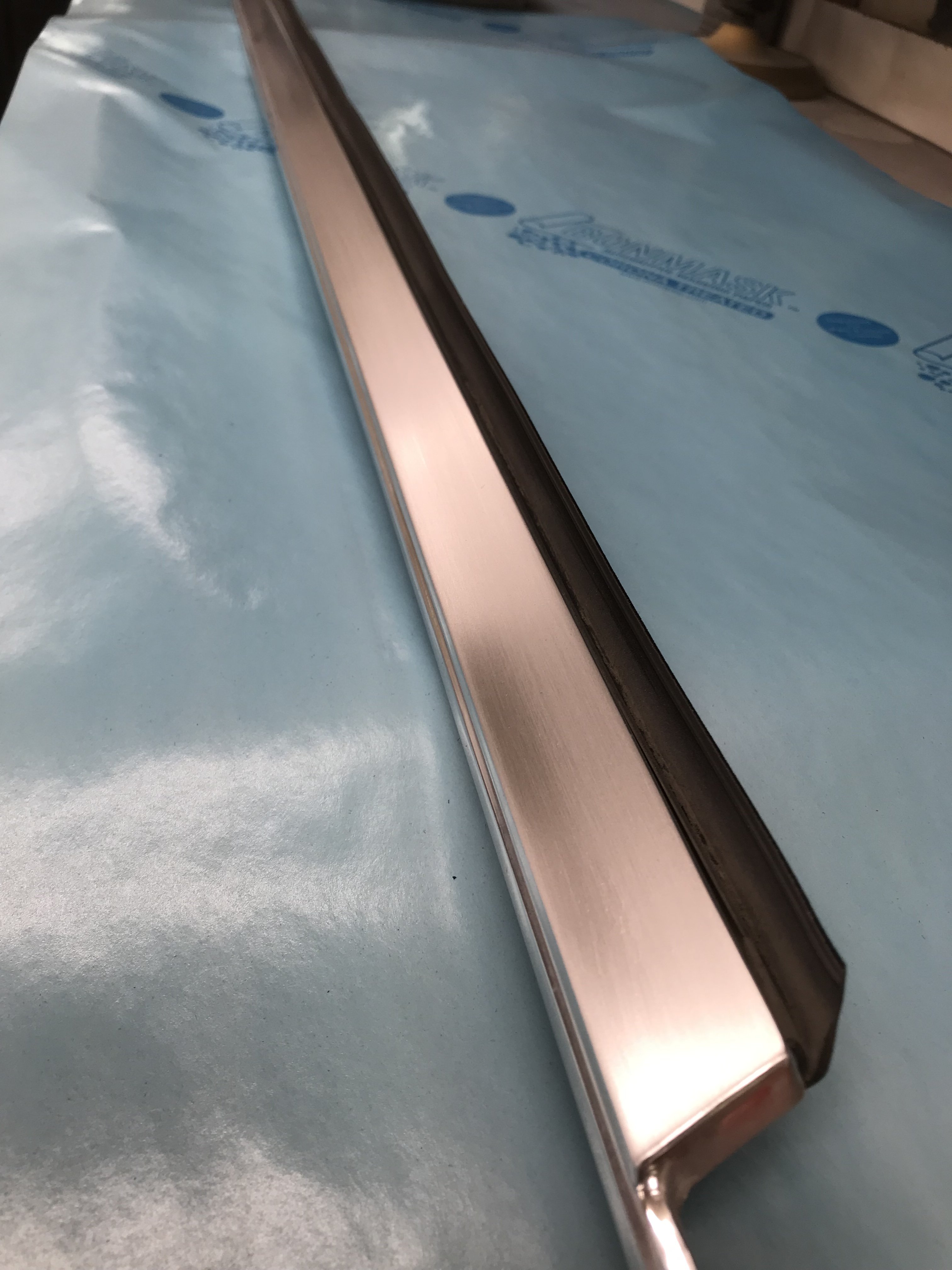

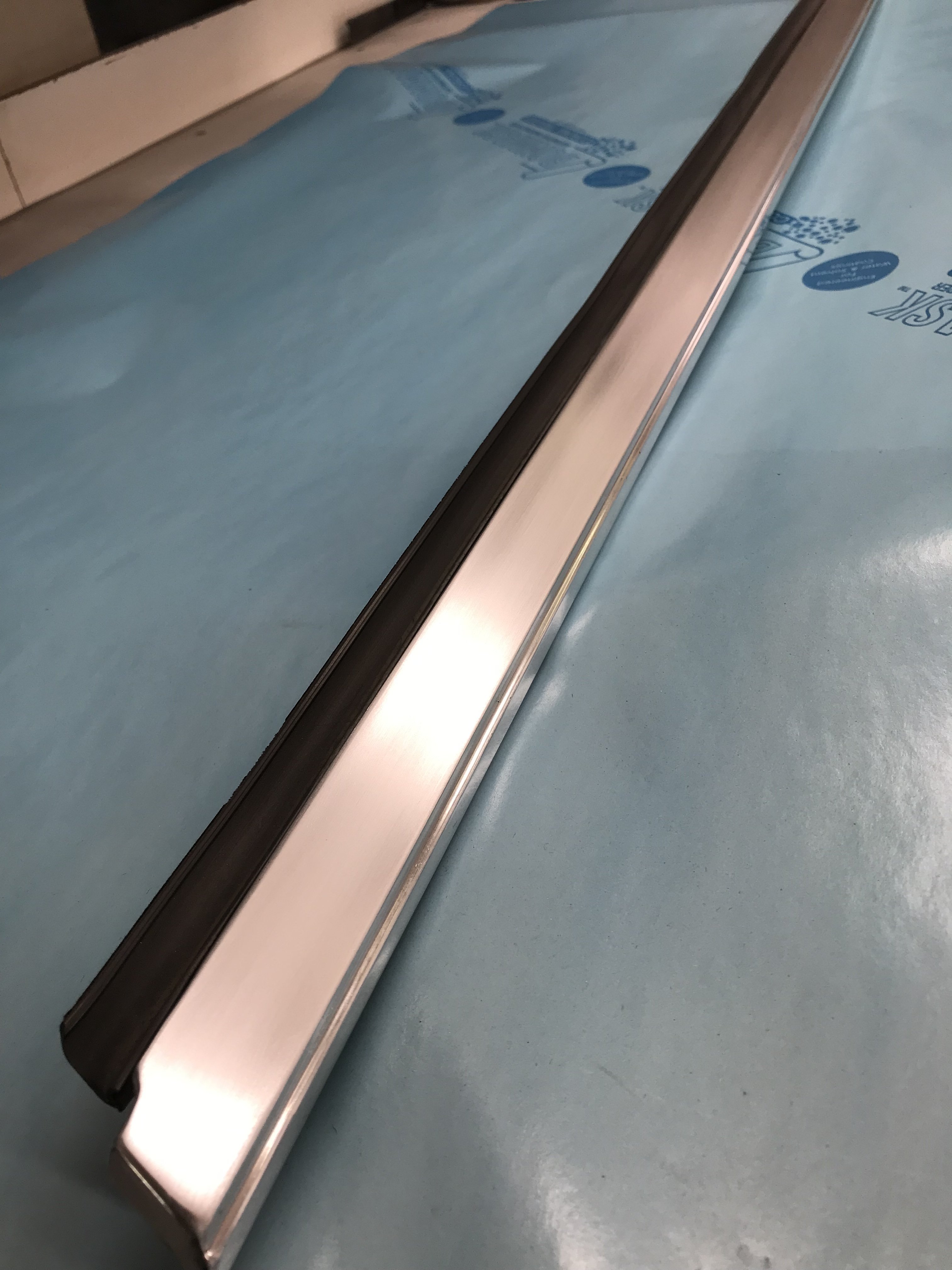

Eventually patience and perseverance pays off and you end up with a finished piece. Here’s the completed top of the second passenger side moulding:

I still have to strip the clear anodized coating from both mouldings with my oven cleaner trick, but I perform the straightening process before I strip them because it’s much easier to see the dents in the light with a shiny surface. Then afterwards there’s just a little cleanup with a light sanding and to ensure the brushed pattern is uniform.

That’s all for now, I gotta get back at it and finish straightening the other 3’-2” of driver’s moulding, but eh, who’s counting.

😏

V 2.0 because the on the first go-round I got a little aggressive on some of the deeper dents and over worked the material a bit too much.

Ok, a LOT too much.

I had the top surface so thin in spots I could literally move the material with nothing more than the force of a fingernail! Obviously unacceptable, so he we are on Versions 2.0.

I won’t bore y’all with the details of how I go about straightening and refinishing these unless it’s requested, but that doesn’t mean I can’t share a couple pictures of the progress.

As it stands as of right now, I have the top of the passenger’s side straightened and brushed, this is by far the hardest and most time consuming part. I’ve also started repeating the process now on the driver’s side moulding.

It all starts with choosing a suitable candidate, these are some of the ones that didn’t make the cut for obvious reasons:

From there and once I’ve chosen a suitable piece, nearly all the work gets done on the vise. Here’s my current work station, the towel is for cleaning out the pores of the sandpaper as the aluminum clogs up the 220 grit paper pretty quickly:

It’s pretty tough to see any of the dents, deep scratches, pits and multitude of imperfections in this pic, but trust me, after nearly 40 years of use and abuse, they’re there. This is actually a really good piece to start with:

The deepest dents and most extreme damage is always tackled first, if these areas can’t be repaired seamlessly, there’s no point in continuing with the rest of it. The process is less like paintless dent repair, and more like old school pick and filing technique. Sometimes hundreds of little tiny pick marks up from the underside depending on the severity of the damage...

...then carefully block sanded in a crosshatch pattern until it’s either flush and flat, or needs to be worked more.

A look at this in the midst of the process:

To give you some indication of just how time consuming this is, this is a roughly 8-10” finished section of the driver’s side moulding. There’s about 3 hours in this spot alone:

Eventually patience and perseverance pays off and you end up with a finished piece. Here’s the completed top of the second passenger side moulding:

I still have to strip the clear anodized coating from both mouldings with my oven cleaner trick, but I perform the straightening process before I strip them because it’s much easier to see the dents in the light with a shiny surface. Then afterwards there’s just a little cleanup with a light sanding and to ensure the brushed pattern is uniform.

That’s all for now, I gotta get back at it and finish straightening the other 3’-2” of driver’s moulding, but eh, who’s counting.

😏

I feel like such a hack when I read this thread.

Join the club.I feel like such a hack when I read this thread.

I feel like such a hack when I read this thread.

Join the club.

Thanks guys, I think.

Lol

I’m obviously not trying to make anyone feel like a hack, just trying to convey the amount of time and dedication to the end result these kinds of things require.

That’s why I wasn’t too worried about explaining the repair procedure, as I highly doubt anyone else is gonna attempt it. No one is likely as insane as me to do this nonsense, and if they are, my hat’s off to them. It’s a ton of work.

Thanks for the compliments.

Similar threads

- Replies

- 25

- Views

- 823

- Replies

- 14

- Views

- 723

- Replies

- 10

- Views

- 460

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.