Get some REST man!

Your killing me......I can't keep up this pace.

Your killing me......I can't keep up this pace.

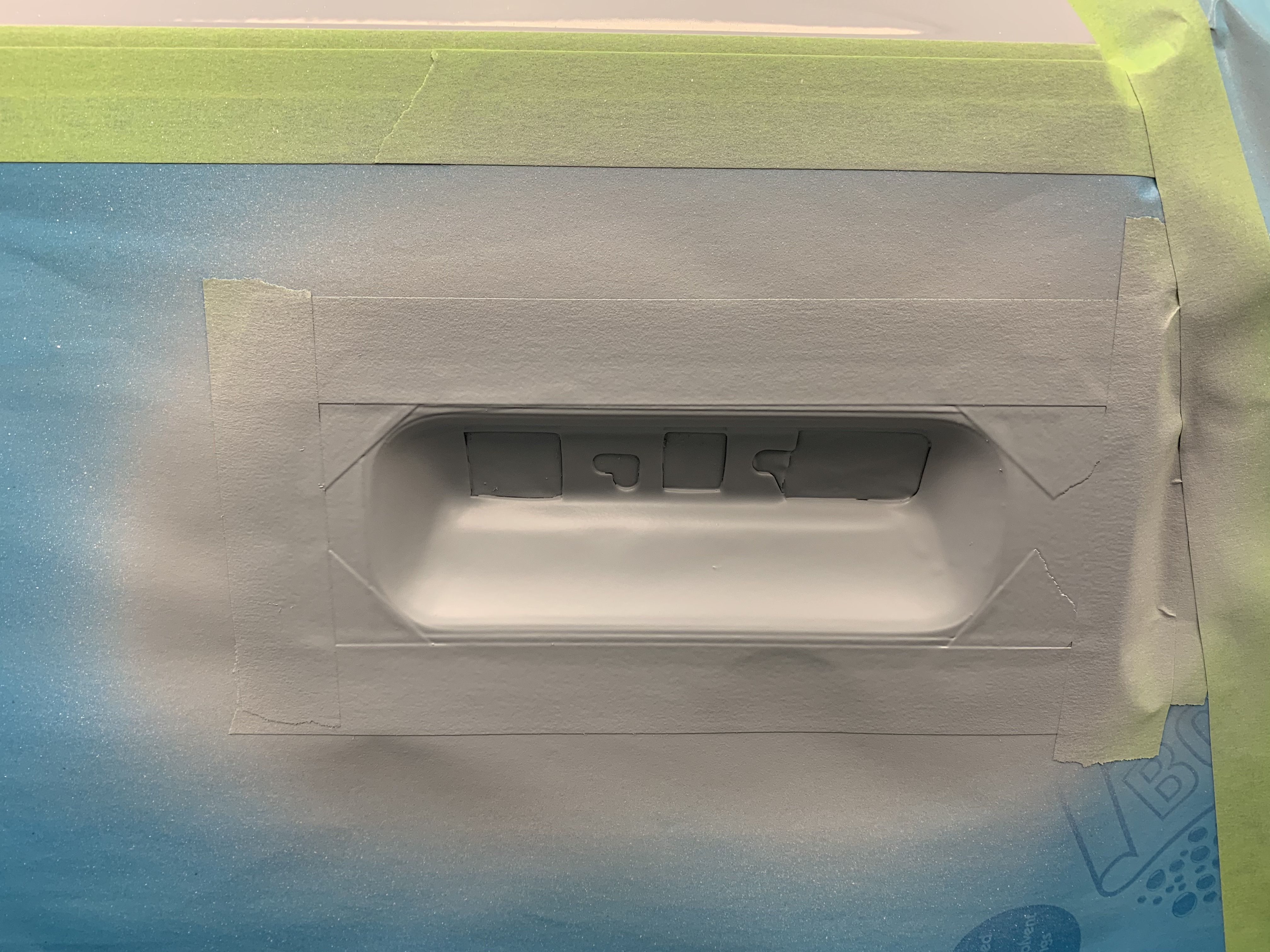

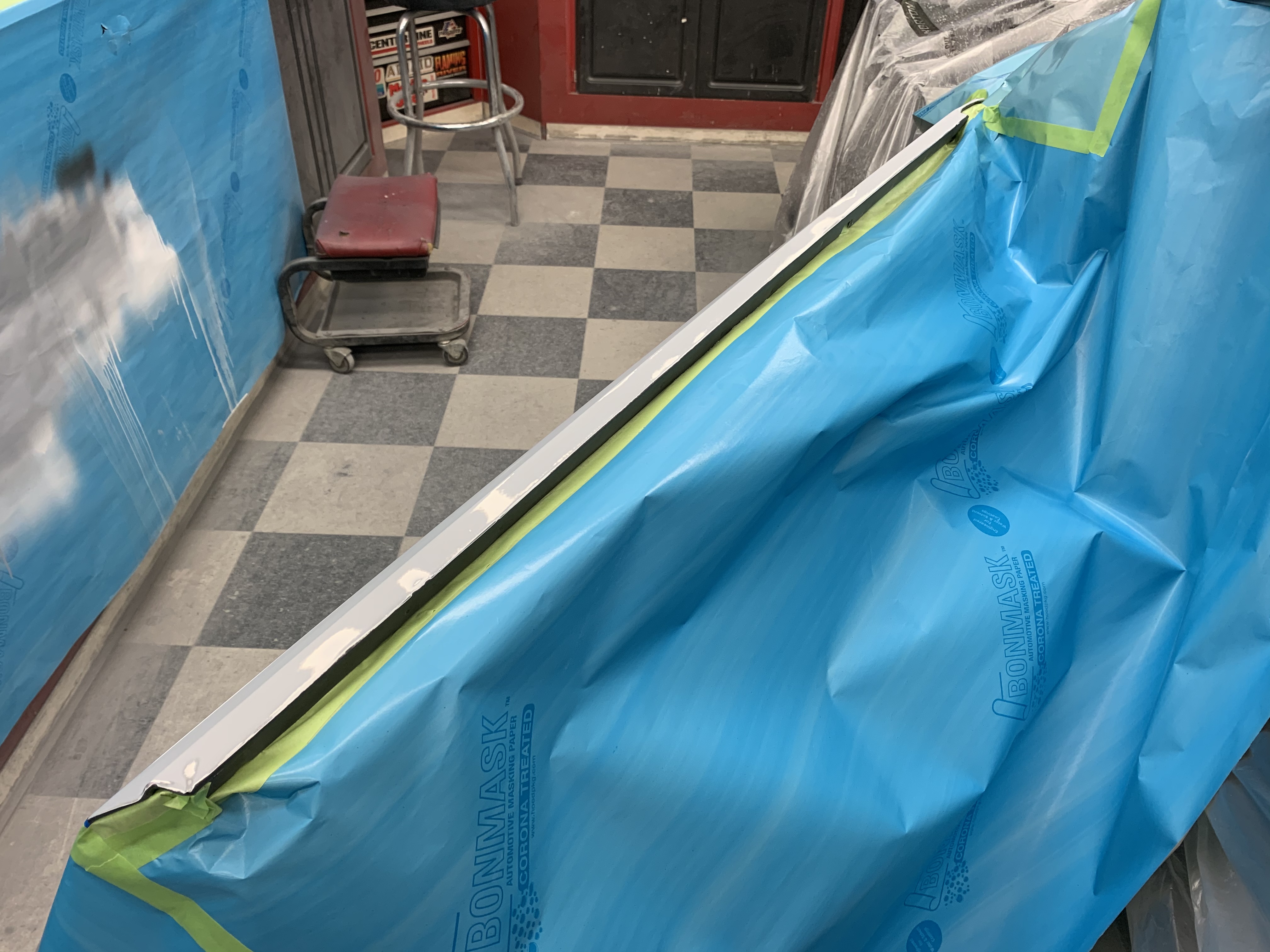

I’ve been a production painter for years and we use an ez edger to fold 3/4 masking tape for door jambs. When you put the tape in there properly it gives a softer edge than the foam. Sometimes the foam can leave a jagged edge from the paint build up. Some prep guys I know can fold the tape this way with their hands but unfortunately I can’t.

https://www.amazon.com/dp/B00BD455NE/?tag=gbody-20

Get some REST man!

Your killing me......I can't keep up this pace.

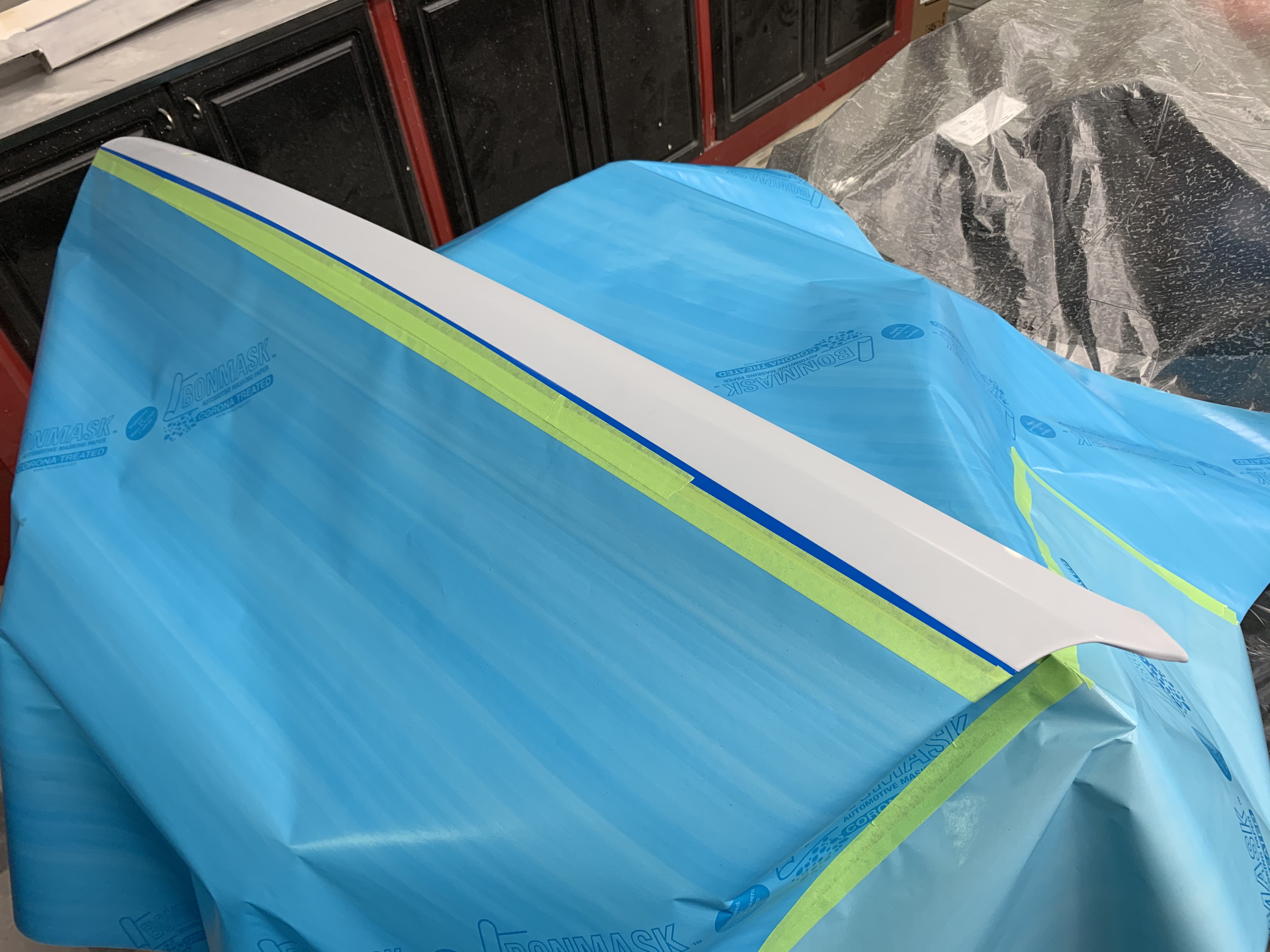

hi Donovan, Sure good to see you back in the shop, nothing like some sanding time to numb the senses a bit. Seeing you reference some high spots that mysteriously manifested, I just wanted to share a little thing we ran into while blocking the front fenders on my Monte. The inner fender wells were not installed at this stage because why would you. Once the guys started to block sand, the fenders started flexing, causing the bodyman to become somewhat agitated (pissed off). Installed inner fenders and flex problem disappeared. Kind of the same type of issue when blocking the cowl hood. When the hoods are built, foam (goop) is placed in the spaces between the inner and outer skins of the hood for support. Ever so slightly these spots can push up a bit more than other welded spots (pulled down). This will be evident when you first start sanding the hood. The shiny bare metal spots lined up directly above the foam placement under the hood. Thin metal can play lots of tricks on you. Once again, good to see you back at it!

So, when can I drop off my 78?

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.