BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I like your sense of humor. Well done.

Love this Donovan, your work keeps me motivated, bare minimum, entertained. 😀

D, it's good to hear you got through the slump and making progress again! We've all been there, I know I have. The constant grind of work everyday, then try to accomplish something on the car as the energy dimishes gets tough!!!!

Messing with these cars is sucky at times for sure, but being able to visualize the end result helps a bunch!

It's good therapy to "sweep" the slump away by cleaning up the shop or similar. A tidy garage helps charge the batteries to get goin, and you sure did it!

The patch looks great as is usual for your fab work!!! Nobody outside of the forum would ever know that part was eaten up with rust. Well done sir, carry on!

Scott

Messing with these cars is sucky at times for sure, but being able to visualize the end result helps a bunch!

It's good therapy to "sweep" the slump away by cleaning up the shop or similar. A tidy garage helps charge the batteries to get goin, and you sure did it!

The patch looks great as is usual for your fab work!!! Nobody outside of the forum would ever know that part was eaten up with rust. Well done sir, carry on!

Scott

I’m pleased to report that it fits like a glove. It uses the existing air filter I already had, fits the top of the QuadraBog to a tee, and even has perfect hood clearance!

Thank you GM for making so much stuff the same across different years and makes!

Okay, Donovan, when you crossposted the pictures of your freshly painted air filter housing to the "What did you do to your G-body today" thread, eagle eye pontiacgp noticed something fishy about an intake manifold bolt or something and you copped to the fact that your were running Vortec cylinder heads with clever Speedway adapter plates that allowed you to install old fashioned valve covers. Then I noticed you had roller rockers under those valve covers and asked "what else had you done to your engine" and you said "stay tuned I'll cover that maybe if I think about it on the Olds Cool build thread." So here's your reminder to let us know what kind of SBC beast you've got under the hood. Maybe you could fill us in when you get into the boring blocking and filling time when you're doing the final painting because the blocking and filling story is so boring. Sound good?

Some off those quotes are approximate

Cheers - Gary

Last edited:

What a superb job on the patch, Mr. D.

But would we expect anything less from you, Mr. Riddler?....I think not.

Glad you're feeling back to yourself again. I occasionally go thru the doldrums. It's best to take a break until your enthusiasm returns.

I know I've been there before...I guess many of us go thru it as well.

I'm starting to get feelings of selling the car and maybe taking on a different project.

I'm sure the feelings will pass.

Hey, great score on the swap meet goodies. The ram air dual snorkel air cleaner housing was an incredible find. It's nice finding cool vintage parts complete. It looks great in your engine compartment. It cleaned up nicely.

Most times when you're looking for particular parts, you're never able to find them.

Good scores all around, my friend.

But would we expect anything less from you, Mr. Riddler?....I think not.

Glad you're feeling back to yourself again. I occasionally go thru the doldrums. It's best to take a break until your enthusiasm returns.

I know I've been there before...I guess many of us go thru it as well.

I'm starting to get feelings of selling the car and maybe taking on a different project.

I'm sure the feelings will pass.

Hey, great score on the swap meet goodies. The ram air dual snorkel air cleaner housing was an incredible find. It's nice finding cool vintage parts complete. It looks great in your engine compartment. It cleaned up nicely.

Most times when you're looking for particular parts, you're never able to find them.

Good scores all around, my friend.

Looking good Donovan!

Thank you Kevin.

This project has snowballed on me much more than I ever expected, but don’t they all? I’ll just keep picking away at it and fixing the things that need it as I come across them.

Thanks for continuing to check in on it!

Donovan, I know that feeling all too well! Glad you were able to get out of it a bit, and get some more time on the car. I love doing metal work and fabrication, but it definitely takes a toll.

But back at the lab, it looks fantastic as always!

Appreciate the comment Jim.

I figured I’m not the only one that’s plain ‘ol burnt out on a project. Especially those of us that have these ongoing long term ones.

But onwards and upwards, gotta keep chipping away at it!

Love this Donovan, your work keeps me motivated, bare minimum, entertained. 😀

Thanks man. Likewise with you and your Malibu. I’d be a very happy camper if I could just get this thing to the point you’re currently at with yours!

D, it's good to hear you got through the slump and making progress again! We've all been there, I know I have. The constant grind of work everyday, then try to accomplish something on the car as the energy dimishes gets tough!!!!

Messing with these cars is sucky at times for sure, but being able to visualize the end result helps a bunch!

It's good therapy to "sweep" the slump away by cleaning up the shop or similar. A tidy garage helps charge the batteries to get goin, and you sure did it!

The patch looks great as is usual for your fab work!!! Nobody outside of the forum would ever know that part was eaten up with rust. Well done sir, carry on!

Scott

Scott

Thanks very much for the words of encouragement. You’ve always been in my corner and supported the decisions I’ve made. You’ve never been anything but enthusiastic with regards to the things I’ve done, and I truly value that.

You’re a true friend. Thank you.

What a superb job on the patch, Mr. D.

But would we expect anything less from you, Mr. Riddler?....I think not.

Glad you're feeling back to yourself again. I occasionally go thru the doldrums. It's best to take a break until your enthusiasm returns.

I know I've been there before...I guess many of us go thru it as well.

I'm starting to get feelings of selling the car and maybe taking on a different project.

I'm sure the feelings will pass.

Hey, great score on the swap meet goodies. The ram air dual snorkel air cleaner housing was an incredible find. It's nice finding cool vintage parts complete. It looks great in your engine compartment. It cleaned up nicely.

Most times when you're looking for particular parts, you're never able to find them.

Good scores all around, my friend.

Thanks so much Jack.

You hit the nail on the head, I just have to step away from it occasionally. Thinking back on it, I’ve been working on this thing nearly nonstop since late spring, and have had to fix some major issues along the way, many of them totally unexpected. No wonder I had a bit of a breakdown in motivation!

It’s nice to know I’m not alone in experiencing the “doldrums” as you say, and that many of us have gone through similar times. I really appreciate your comments, they definitely help boost the ‘ol morale.

Hopefully you decide not to sell the car, it would be a real shame after all the work you’ve put into it. But on the other hand, I know full well the appeal of starting a new project! Whatever you decide to do, you’ve got my support, and I will continue to look forward to seeing where the future takes you!

I’m very pleased with the swap meet find.

I’d been keeping an eye peeled for a dual snorkel housing for several months, and this one came at just the right time. A little spit and polish, and it’s got a new lease on life with me! It’s great that guys like us can spot diamonds in the rough, car guys were the original recyclers!

Appreciate the comments sir, again, thank you!

And another thank you all around to everyone on here that’s supported me and commented, followed, or gave me a like or two. This is the best forum around bar none, and you all are what make it that way.

Donovan

Alright, so it looks like we’re due for an unscheduled update on the drivetrain.

Why?

Because “Gary”.

😛

In all seriousness though, I really should’ve covered it here in the thread before embarking on the body repairs. That’s my own fault, and I take full responsibility for the flak you guys feel necessary to put me through!

Lol

Ok, to adequately describe what was done and why, we need to start near the beginning. When I purchased the car, part of the reason I got it for a song was because the engine was hurt. While fine at part throttle and below, the little 305 that was originally in it would pop, sputter and backfire through the carb with anything more.

Myself and friends tried everything we could think of to try and fix the problem. Rocker adjustments, ATF down the carb in case the valves were carboned up, timing, idle, you name it. But ultimately it was plain old worn out with a flat camshaft.

Scouring the online classifieds, I came across an ad for a supposedly low mile Gen I Chevy 350 for $350. Perfect. I know and understand these old motors, it was exactly what I was looking for. Only problem was, with nothing available locally, this one was a 3 hour drive north.

Road trip!

Loading my four legged buddy Tucker in the truck, we headed up early on Saturday morning. The seller was upfront and accommodating, explaining the engine came out of his brothers abandoned project truck. He claimed it was a Goodwrench 350, and although it hadn’t run in a couple years, it was in good condition with less than 60,000 miles on it.

Ever doubtful, I asked if he would mind if I pulled the plugs and rolled it over. He told me to do what I felt necessary, so after spinning it over on the engine stand a couple of times, I shone a flashlight in one of the plug holes and had a look at the top of a piston.

I couldn’t believe what I was seeing! Nice clean piston top, no carbon buildup, hell, I could even make out the valve reliefs perfectly!

Sold, done deal. Noting that it was just the bare long block, I asked if he had any of the peripherals that went along with it. After digging through his stash, I had nearly everything I’d need:

Balancer, flex plate, 3 water pumps, 2 starters. Pulleys, brackets, plus a few other things that went with, that he didn’t figure he’d need anymore. Score!

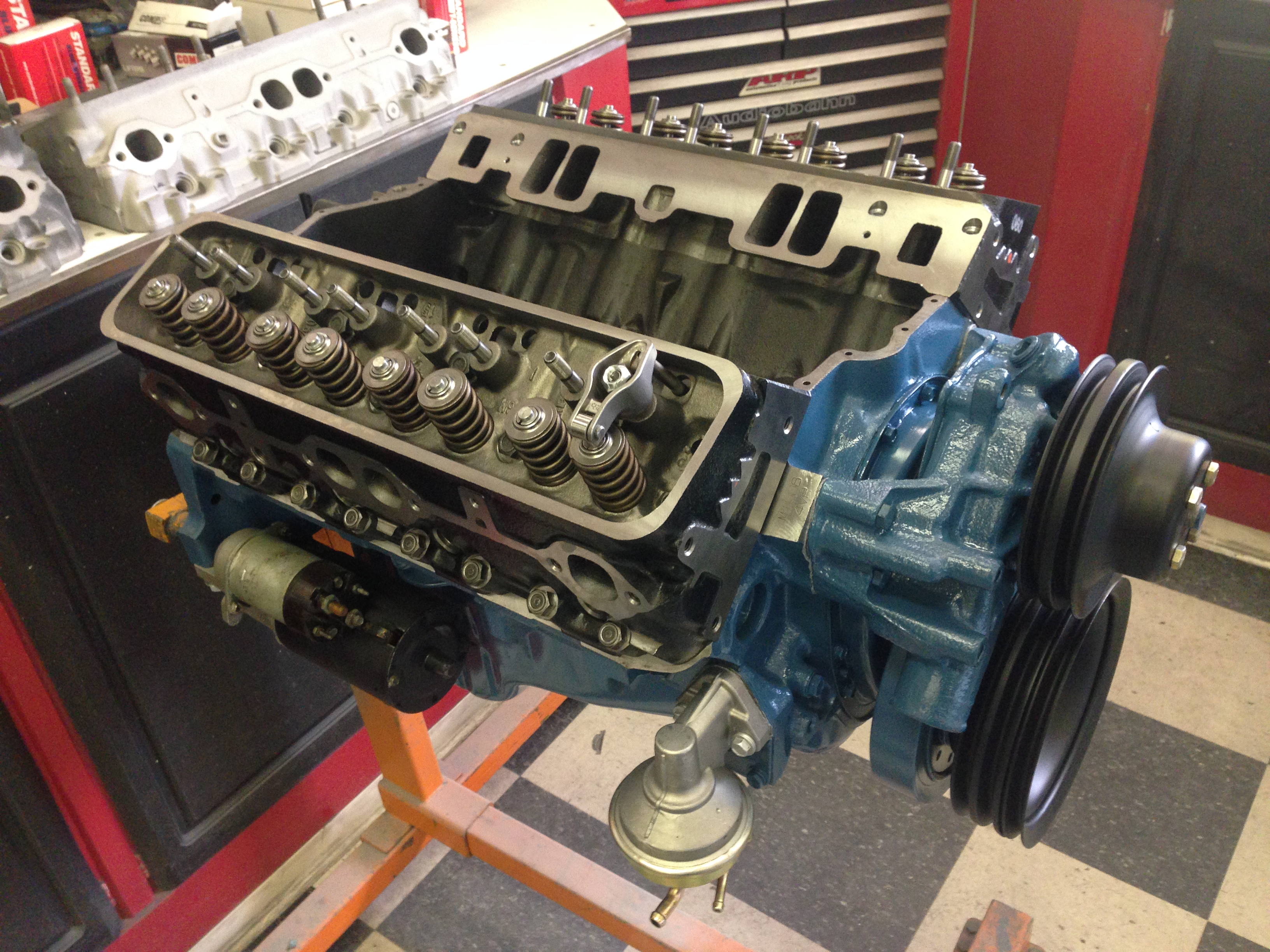

After getting it home and on the stand, I tore down the top end and pulled the oil pan. Here’s what it looked like at that point:

Imagine my pleasure at finding out it was a factory 4 bolt main block!

On the top end of things, this is the “as found” condition of the pistons and bores. While I’ve cleaned the block to head mating surfaces in these pics, the pistons and bores are untouched from the purchase:

Satisfied that things were looking really good so far, I yanked the timing chain and camshaft. This is where I found some oddities. While the lifter lobes on the cam all looked good, the fuel pump lobe was completely wiped out. I mean totally. It was round, it had worn down so far!

Odd...

You may have noticed in the pic above that the oil pump pickup had moved as well. It had somehow slumped down and the leading edge was resting on the bottom of the pan. None of these findings were a big deal tho, the cam was going to be replaced with something bigger anyways, and the oil pump was replaced with a better one as well.

After the oil pump was replaced, I tack welded the pickup to the pump body so it wouldn’t move again.

I pulled the bearing cap to replace the rear main seals, and the crankshaft bearing half looked great. Not feeling the need to reinvent the wheel, I left the bottom end completely alone. This was originally intended to be a budget build, so I didn’t want to completely blow the thing apart and spend a bunch of money on machine work, etc.

With the bottom end solid, I could concentrate on putting the money into the stuff that actually makes horsepower!

Knowing that factory Vortec cylinder heads were perhaps the best kept factory head secret, I decided to avoid getting a bunk set from the junkyard, and ordered a brand new set from my local GM performance parts dealer and his catalog.

🙂

Here’s one of the new heads fresh outta the box!

Gotta mock it up of course...

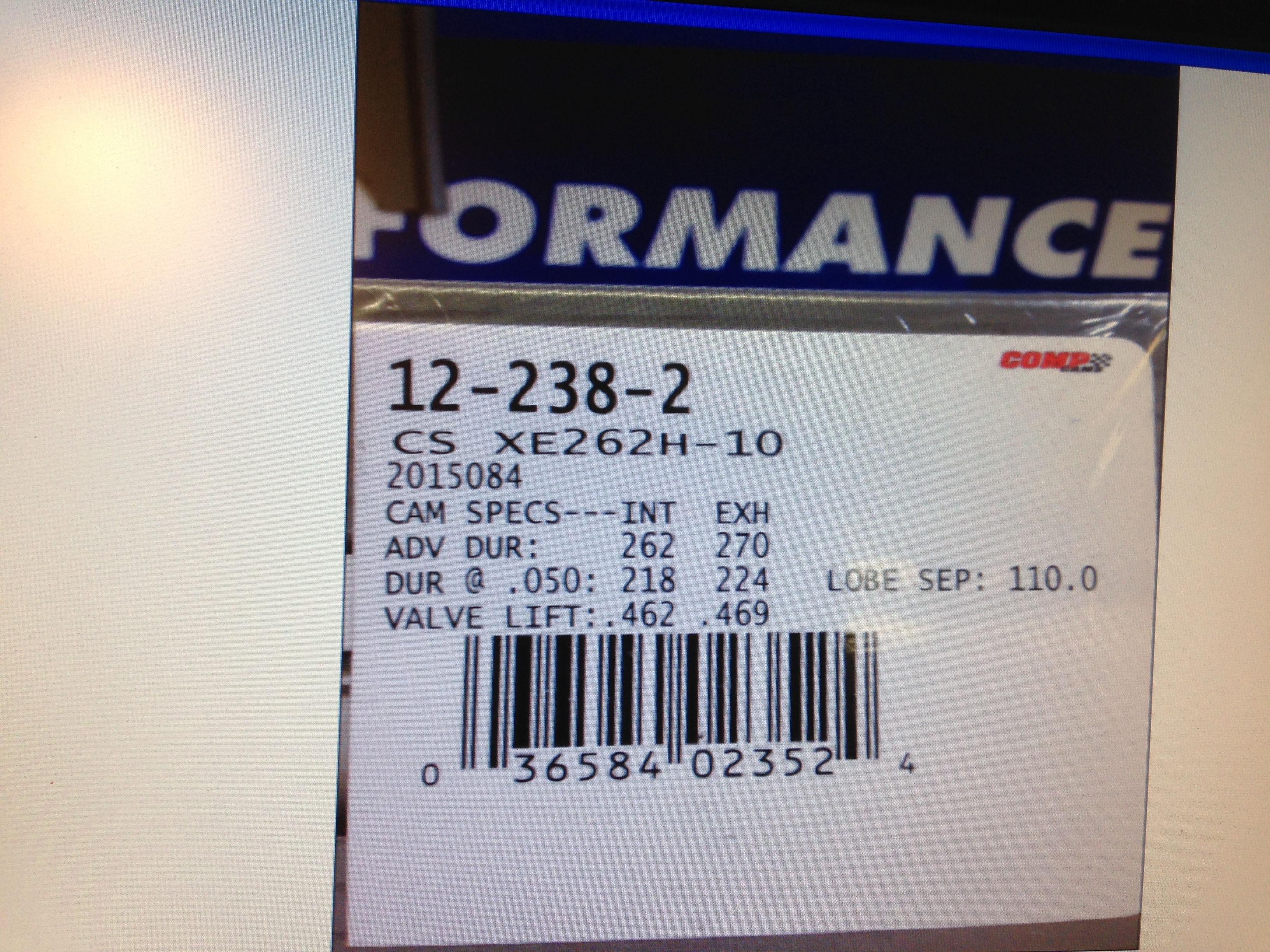

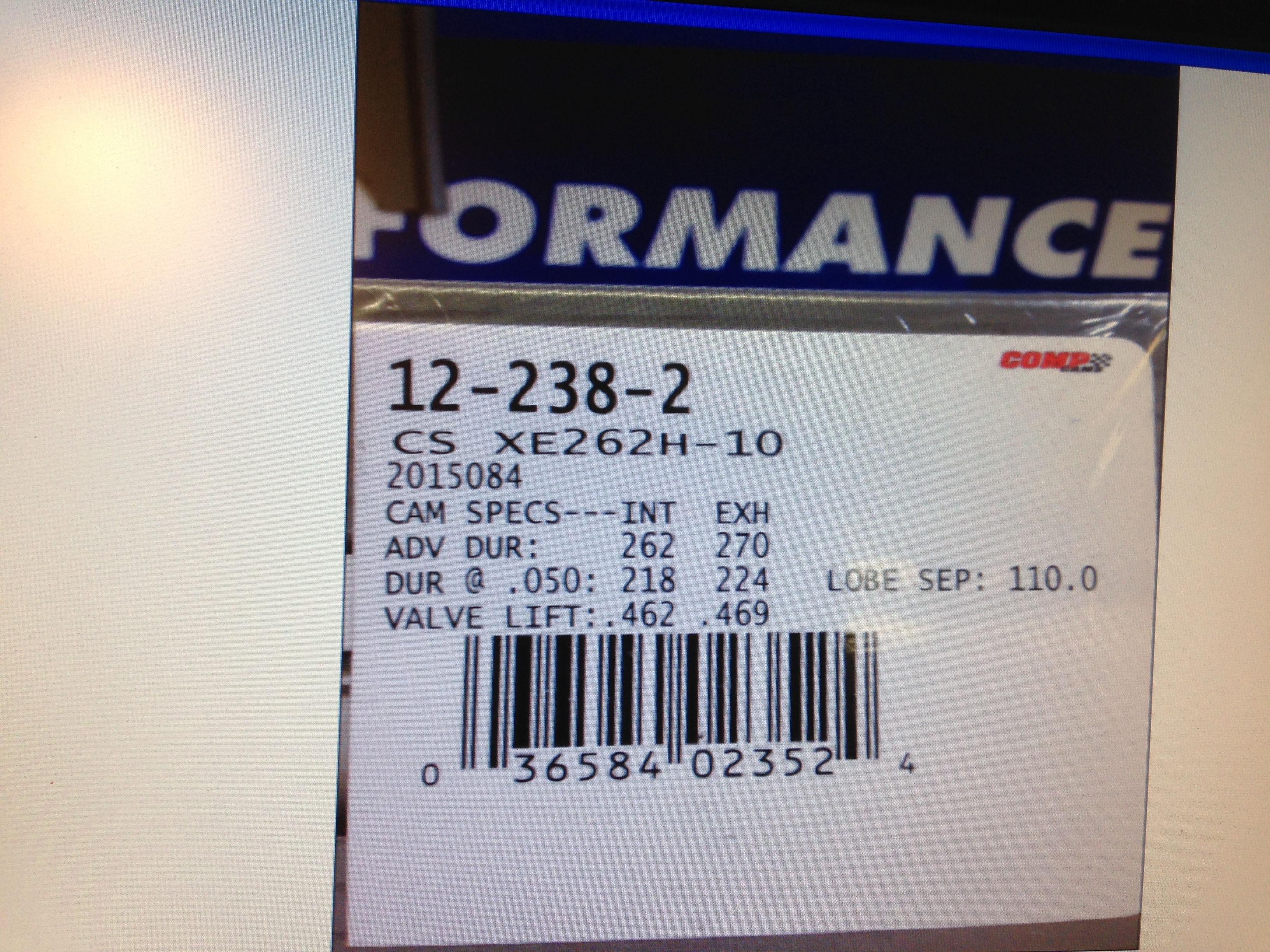

By this time, it was really starting to come together. I had the rear main seal replaced, the oil pump replaced, the pickup welded. The pan was back on, some of the accessories were installed, and it was bathed in GM corporate blue. After a brief conversation with Comp Cams, I went with their recommendation for a camshaft. It’s the biggest one I could go with for use with a stock stall converter:

After installing it in the block, it was degreed and installed “straight up”. Utilizing some old school cheap and easy tricks, I went with the thinnest head gaskets possible (to bump up the CR), and bought a set of Comp roller tip rocker arms. 1.6 ratio over the stock 1.5, to give me a little more lift.

With as much valve lift as I now had, I was getting close to the maximum I could run before I ran into coil bind. I don’t recall the exact number anymore, but with anything over that number, the spring bosses need to be milled down. Again in the spirit of saving money and being more “hands on”, I did it myself. Comp Cams sells the tool, and with a little patience and making many stops to measure, I did them all at home with nothing more than a hand drill.

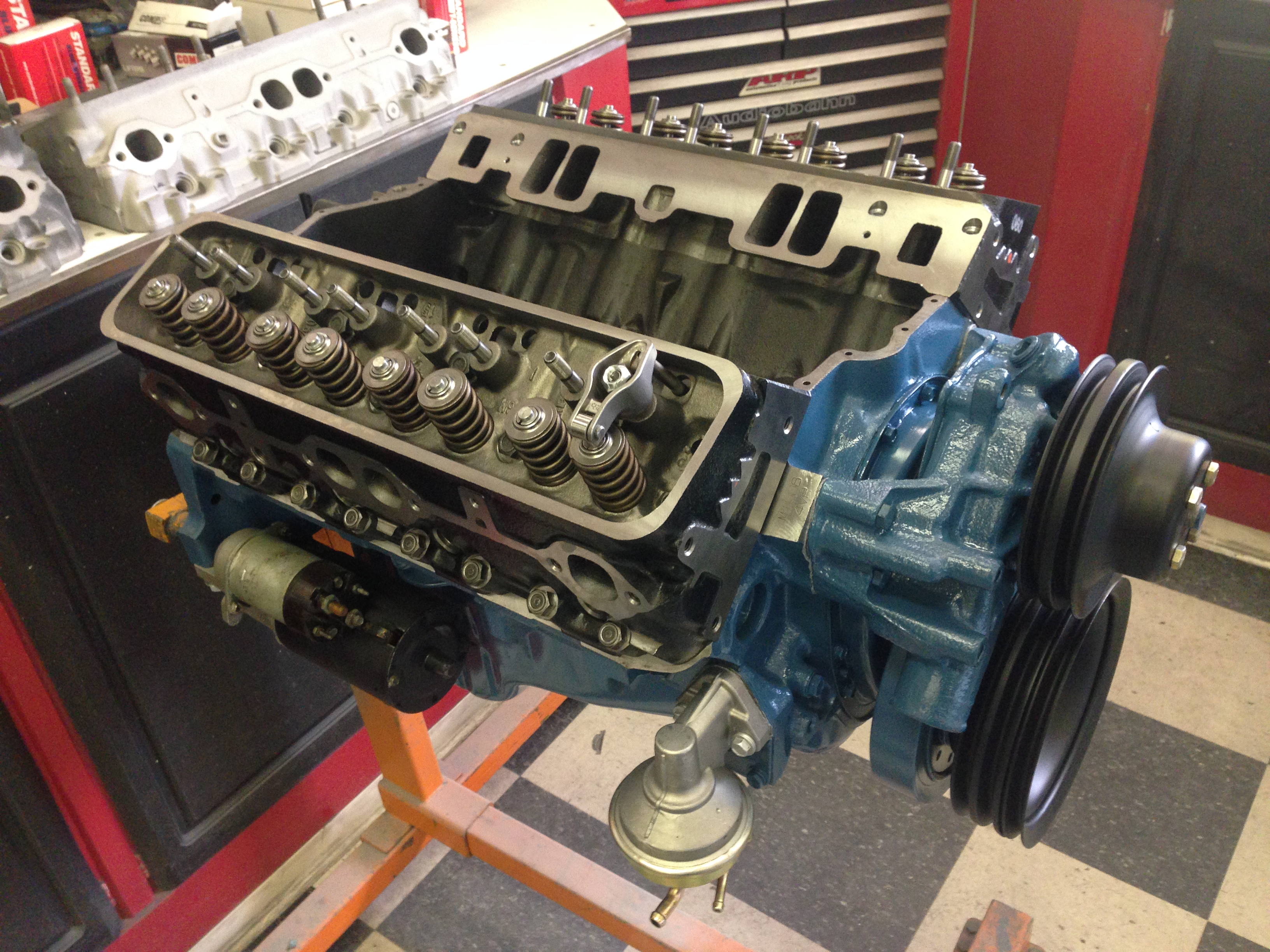

Once that was done, things could start to go together final:

Time to button up the top end. A buddy of mine had an aluminum Vortec intake manifold that I managed to talk him out of, I traded him a refrigerated dryer for his air system for it!

In keeping with the sleeper/stealth theme, it was installed and then carefully masked off and painted blue as well. I picked up an aluminum Weiand water pump and new aluminum thermostat housing, they were both given the exact same treatment.

As for the valve covers, I wanted to use a factory style as the center bolt ones are a dead giveaway that something’s been changed. A set of adapters were shipped from Speedway Motors, they seal to the heads with an o-ring on the head side, and use a conventional gasket on the top. They’re held in place at the center bolt locations.

Believe it or not, I actually had to go searching at the junkyard for a decent set of original valve covers. The ones that came on the 305 when I bought the car were M/T aftermarket ones, and leaked like a sieve.

The junkyard ones were cleaned up, sand blasted, painted and installed.

And that pretty much finishes off the long block assembly. There’s a bit more to cover on the engine yet but I’m going to leave that for now, and cover that in the next update. Which will hopefully be tomorrow.

Until then, here’s a few more pics as it was continuing to come together:

Thanks for following along everyone.

Until tomorrow...

D.

Why?

Because “Gary”.

😛

In all seriousness though, I really should’ve covered it here in the thread before embarking on the body repairs. That’s my own fault, and I take full responsibility for the flak you guys feel necessary to put me through!

Lol

Ok, to adequately describe what was done and why, we need to start near the beginning. When I purchased the car, part of the reason I got it for a song was because the engine was hurt. While fine at part throttle and below, the little 305 that was originally in it would pop, sputter and backfire through the carb with anything more.

Myself and friends tried everything we could think of to try and fix the problem. Rocker adjustments, ATF down the carb in case the valves were carboned up, timing, idle, you name it. But ultimately it was plain old worn out with a flat camshaft.

Scouring the online classifieds, I came across an ad for a supposedly low mile Gen I Chevy 350 for $350. Perfect. I know and understand these old motors, it was exactly what I was looking for. Only problem was, with nothing available locally, this one was a 3 hour drive north.

Road trip!

Loading my four legged buddy Tucker in the truck, we headed up early on Saturday morning. The seller was upfront and accommodating, explaining the engine came out of his brothers abandoned project truck. He claimed it was a Goodwrench 350, and although it hadn’t run in a couple years, it was in good condition with less than 60,000 miles on it.

Ever doubtful, I asked if he would mind if I pulled the plugs and rolled it over. He told me to do what I felt necessary, so after spinning it over on the engine stand a couple of times, I shone a flashlight in one of the plug holes and had a look at the top of a piston.

I couldn’t believe what I was seeing! Nice clean piston top, no carbon buildup, hell, I could even make out the valve reliefs perfectly!

Sold, done deal. Noting that it was just the bare long block, I asked if he had any of the peripherals that went along with it. After digging through his stash, I had nearly everything I’d need:

Balancer, flex plate, 3 water pumps, 2 starters. Pulleys, brackets, plus a few other things that went with, that he didn’t figure he’d need anymore. Score!

After getting it home and on the stand, I tore down the top end and pulled the oil pan. Here’s what it looked like at that point:

Imagine my pleasure at finding out it was a factory 4 bolt main block!

On the top end of things, this is the “as found” condition of the pistons and bores. While I’ve cleaned the block to head mating surfaces in these pics, the pistons and bores are untouched from the purchase:

Satisfied that things were looking really good so far, I yanked the timing chain and camshaft. This is where I found some oddities. While the lifter lobes on the cam all looked good, the fuel pump lobe was completely wiped out. I mean totally. It was round, it had worn down so far!

Odd...

You may have noticed in the pic above that the oil pump pickup had moved as well. It had somehow slumped down and the leading edge was resting on the bottom of the pan. None of these findings were a big deal tho, the cam was going to be replaced with something bigger anyways, and the oil pump was replaced with a better one as well.

After the oil pump was replaced, I tack welded the pickup to the pump body so it wouldn’t move again.

I pulled the bearing cap to replace the rear main seals, and the crankshaft bearing half looked great. Not feeling the need to reinvent the wheel, I left the bottom end completely alone. This was originally intended to be a budget build, so I didn’t want to completely blow the thing apart and spend a bunch of money on machine work, etc.

With the bottom end solid, I could concentrate on putting the money into the stuff that actually makes horsepower!

Knowing that factory Vortec cylinder heads were perhaps the best kept factory head secret, I decided to avoid getting a bunk set from the junkyard, and ordered a brand new set from my local GM performance parts dealer and his catalog.

🙂

Here’s one of the new heads fresh outta the box!

Gotta mock it up of course...

By this time, it was really starting to come together. I had the rear main seal replaced, the oil pump replaced, the pickup welded. The pan was back on, some of the accessories were installed, and it was bathed in GM corporate blue. After a brief conversation with Comp Cams, I went with their recommendation for a camshaft. It’s the biggest one I could go with for use with a stock stall converter:

After installing it in the block, it was degreed and installed “straight up”. Utilizing some old school cheap and easy tricks, I went with the thinnest head gaskets possible (to bump up the CR), and bought a set of Comp roller tip rocker arms. 1.6 ratio over the stock 1.5, to give me a little more lift.

With as much valve lift as I now had, I was getting close to the maximum I could run before I ran into coil bind. I don’t recall the exact number anymore, but with anything over that number, the spring bosses need to be milled down. Again in the spirit of saving money and being more “hands on”, I did it myself. Comp Cams sells the tool, and with a little patience and making many stops to measure, I did them all at home with nothing more than a hand drill.

Once that was done, things could start to go together final:

Time to button up the top end. A buddy of mine had an aluminum Vortec intake manifold that I managed to talk him out of, I traded him a refrigerated dryer for his air system for it!

In keeping with the sleeper/stealth theme, it was installed and then carefully masked off and painted blue as well. I picked up an aluminum Weiand water pump and new aluminum thermostat housing, they were both given the exact same treatment.

As for the valve covers, I wanted to use a factory style as the center bolt ones are a dead giveaway that something’s been changed. A set of adapters were shipped from Speedway Motors, they seal to the heads with an o-ring on the head side, and use a conventional gasket on the top. They’re held in place at the center bolt locations.

Believe it or not, I actually had to go searching at the junkyard for a decent set of original valve covers. The ones that came on the 305 when I bought the car were M/T aftermarket ones, and leaked like a sieve.

The junkyard ones were cleaned up, sand blasted, painted and installed.

And that pretty much finishes off the long block assembly. There’s a bit more to cover on the engine yet but I’m going to leave that for now, and cover that in the next update. Which will hopefully be tomorrow.

Until then, here’s a few more pics as it was continuing to come together:

Thanks for following along everyone.

Until tomorrow...

D.

glad you took a break from it for awhile, Donovan, I too know how constant work on the car and seeing a finish line, just to have another major hurdle thrown in your path, can have an effect on your energy and mental health. The Chief has driven me to that point and beyond (I actually had posted it on CL just before finding all the rust holes under the vynil), and has caused 2+year hold on the Regal. Now that your batteries are fresh, the excellent work has resumed, and the patch looks perfect (as always!).

nice write up so far on the secret under the hood! I've seen those cover adapters before, and had thought about getting a set, but never pulled the trigger.... maybe a future purchase for the Regal's 327 (have the same 062 heads), will have to see...

looking forward to more progress!

nice write up so far on the secret under the hood! I've seen those cover adapters before, and had thought about getting a set, but never pulled the trigger.... maybe a future purchase for the Regal's 327 (have the same 062 heads), will have to see...

looking forward to more progress!

Great score on the engine, D..That's a deal too hard to resist.

It's a good feeling when you find something that is what the seller claims it to be.

Good choice on the cam, too. I like the Comp Cams roller rockers. I've had a set in my engine since Comp Cams first came out with them. Yeah, I know...I'm dating myself again.

I also like that you kept the engine stock/ corporate in appearance. Stealth mode.

I'm glad you got your fiery enthusiasm back to the ole' Donovan we got to know and respect.

Be well my friend.

People like you make this forum interesting and the great forum that it is.

Keep on truckin'.

It's a good feeling when you find something that is what the seller claims it to be.

Good choice on the cam, too. I like the Comp Cams roller rockers. I've had a set in my engine since Comp Cams first came out with them. Yeah, I know...I'm dating myself again.

I also like that you kept the engine stock/ corporate in appearance. Stealth mode.

I'm glad you got your fiery enthusiasm back to the ole' Donovan we got to know and respect.

Be well my friend.

People like you make this forum interesting and the great forum that it is.

Keep on truckin'.

Similar threads

- Replies

- 25

- Views

- 915

- Replies

- 14

- Views

- 811

- Replies

- 10

- Views

- 486

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.