Very cool, good luck, I'm sure it'll turn out great, and I guarantee you'll love it once the cars on it!

Thanks Jim, I sure hope so. I’m looking forward to it for sure, but I know I’ll be on pins and needles the first time I go to roll it!

When you paint the steel, it must have flames.

Haha, but I’m not sure if I’m even going to ever paint it. It’s likely just going to get covered in overspray, undercoat etc anyways. But ordinarily, yeah I’d be all about some custom flames on that!

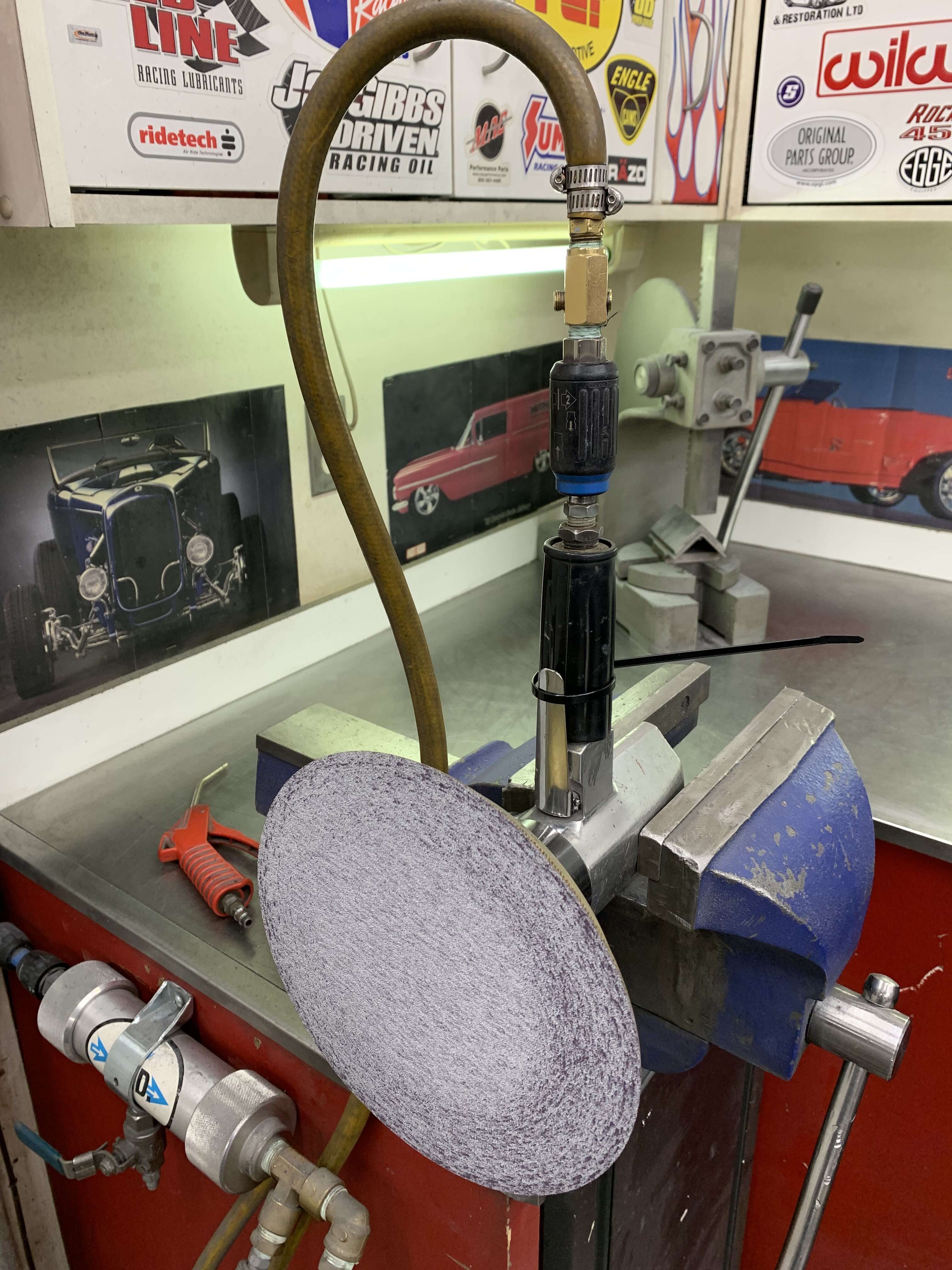

Awesome project Donovan. Thanks for sharing. It's amazing what you get done in that two car garage.

Thank you Jared. It would seem I’m constantly pushing my personal boundaries, and I don’t think that’s a bad thing. As for accomplishing what I do in this two car garage, I refuse to let my circumstances dictate my abilities. It’s all about trying to do more with less. A couple good tools and some effective space management definitely helps.

Will this be beefier than the store bought version?

At least equal to, if not more so IMO. This is the one I had my eye on before Covid, it’s virtually the exact same thing as what I’m building. You be the judge:

Link: https://www.kmstools.com/magnum-2-44-200lb-1-44-000-kg-car-rotisserie.html

Awesome stuff right here. And if you wanted when your done, you could sell it and probably make money on it.

Especially if it's got flamage.

Yep, my thoughts exactly, give or take the flames. Actually I’ve had several people tell me I should rent it out once I’m done with it, but I’m just not sure how that’d work. Be too hard to collect payment for the length of time that it’s in someone else’s possession I think. However I might make an exception for a certain couple of local forum members I know on here, Northernregal, Cauterize, you guys listening??

😉

And of course all those welds are going to be super clean looking like it all is one chunk of formed steel.

Nope, not on this one amigo. I’ll save all that effort for the actual car. Appreciate the thought though!

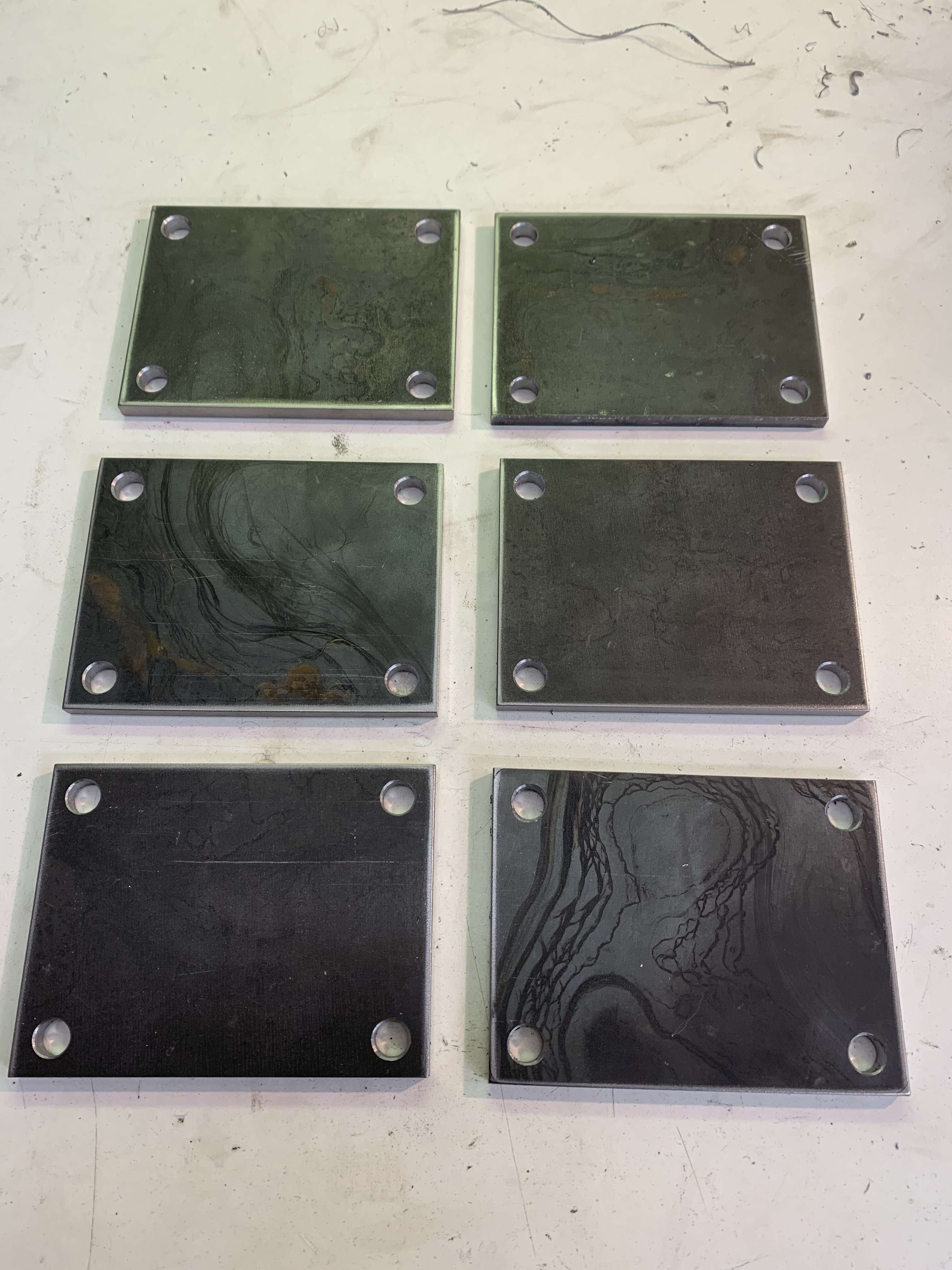

Another cool project Donovan! You never disappoint. Thanks for including the cost of the materials. Looking forward to seeing it all done. Looks pretty heavy-duty.

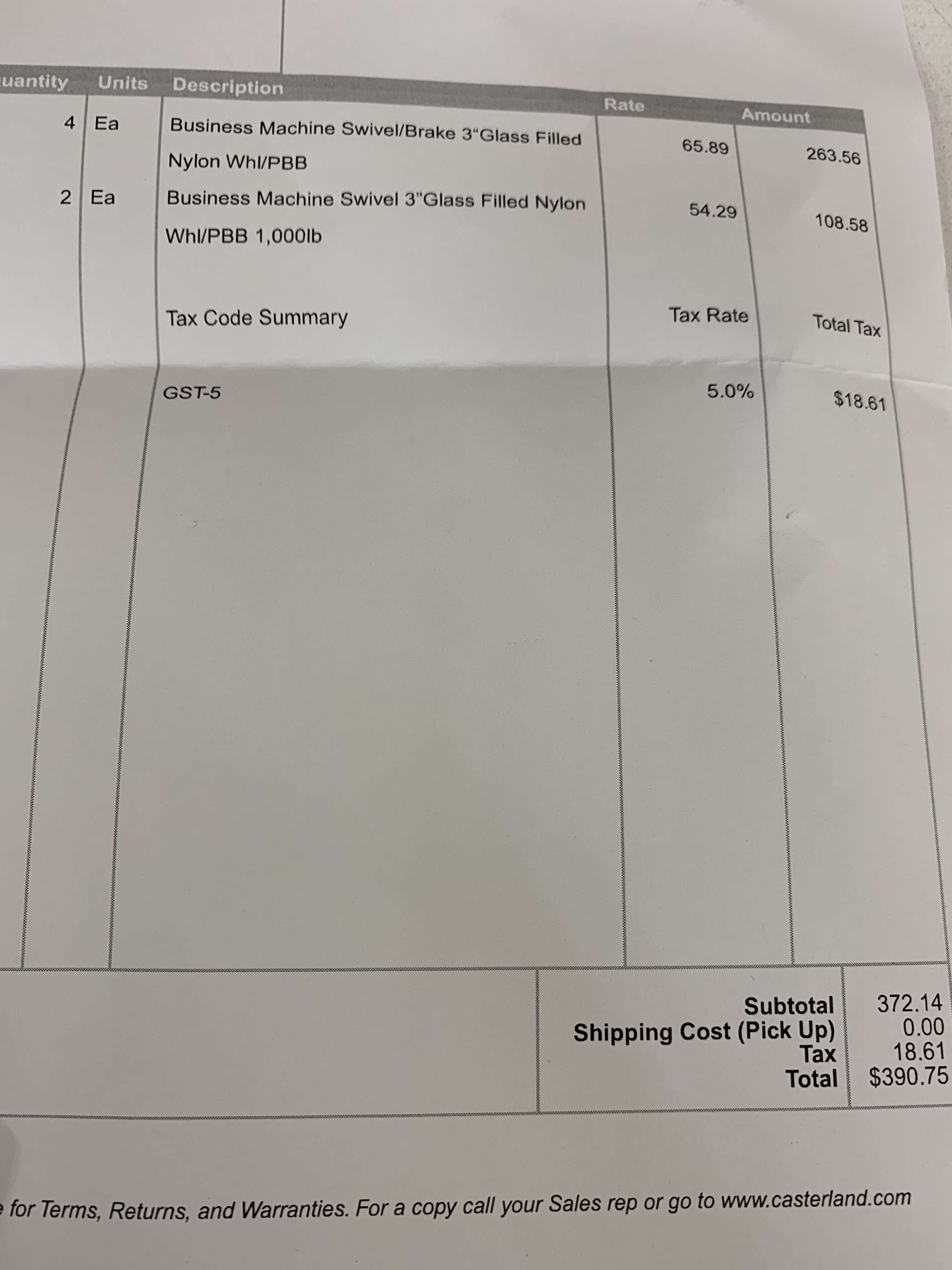

No problem Jeff, happy to share. So far I’m right on budget, but I have a nasty feeling that the casters and hydraulic jacks might put me over. Good quality casters with swivels and locks rated to carry that much weight are bloody expensive!

What’s Mike’s fee? I can already see you being his campaign manager as payment 😂

Ha! Mike knows which side his bread is buttered on, he knows I take care of him with the bodywork on his ‘57 Chevy. This is his chance to repay some of that extensive effort that’s gone into his car, and he knows it.

It all evens out between us in the end.

😏😎