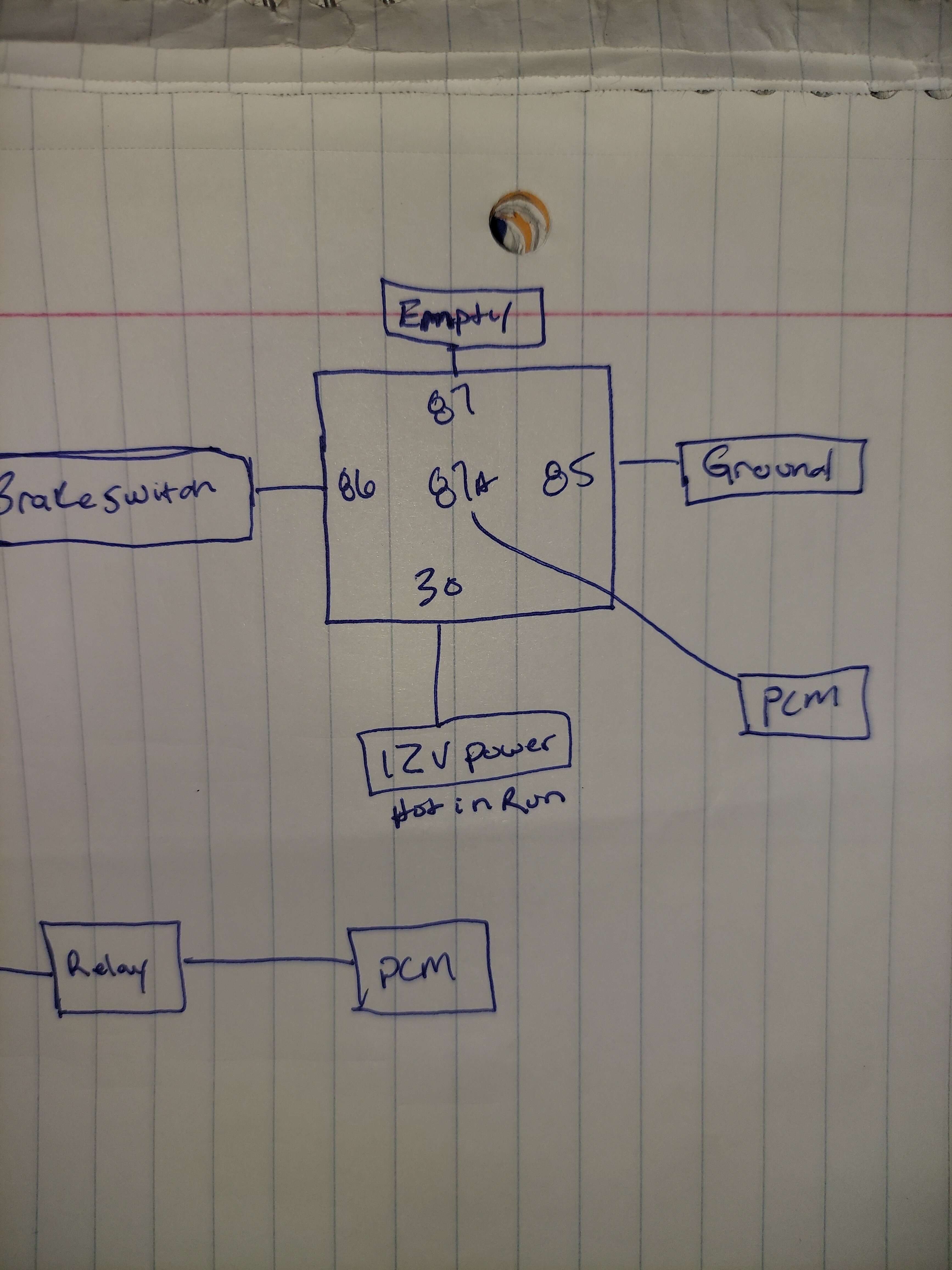

After spending the week finishing up the chassis, new bolts for the crossmember and brakes, verify transmission dipstick level is correct after shortening it, tightening down everything, I painted the crossmember with rattle can Duplicolor I had left over, installed the brake line flange gaskets

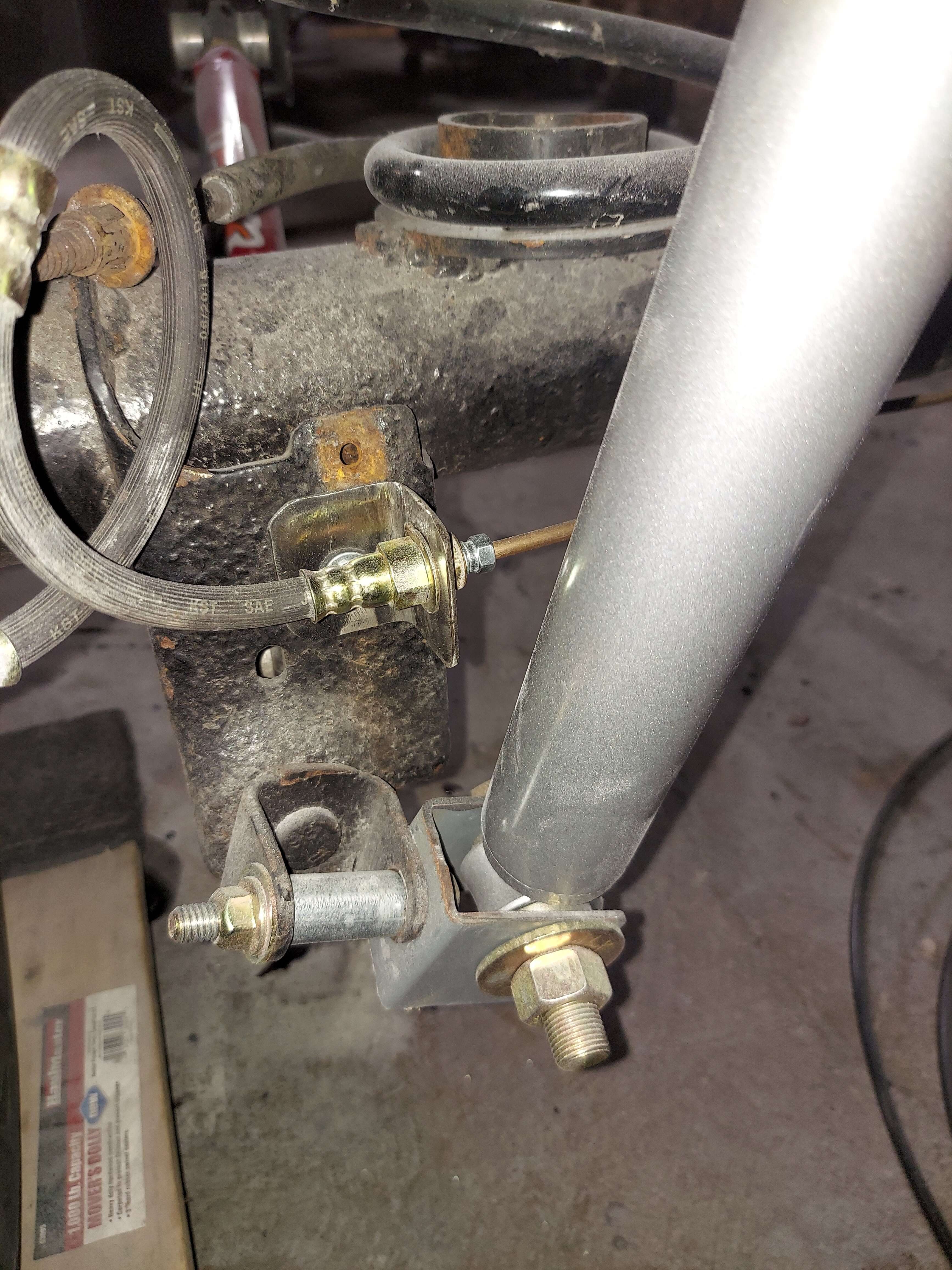

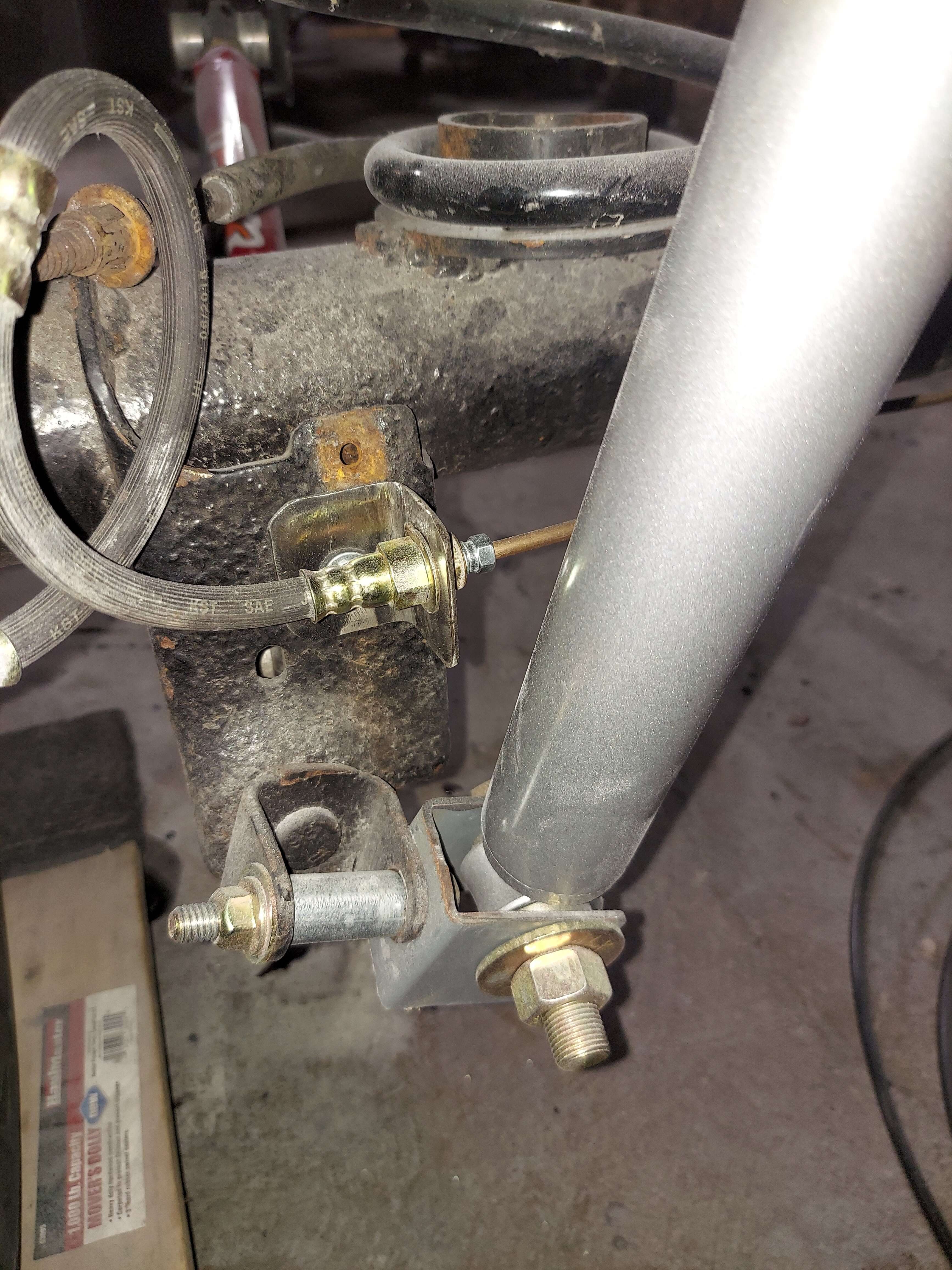

and made the rear brake lines, and some brackets to hold the rubber/metal line connection solid.

and made the rear brake lines, and some brackets to hold the rubber/metal line connection solid.

I tried to weld this bracket on the housing but I couldn't get it hot enough so I jb welded it on. I'll keep an eye on it but I tried to rip it off with vice grips and it didn't budge.

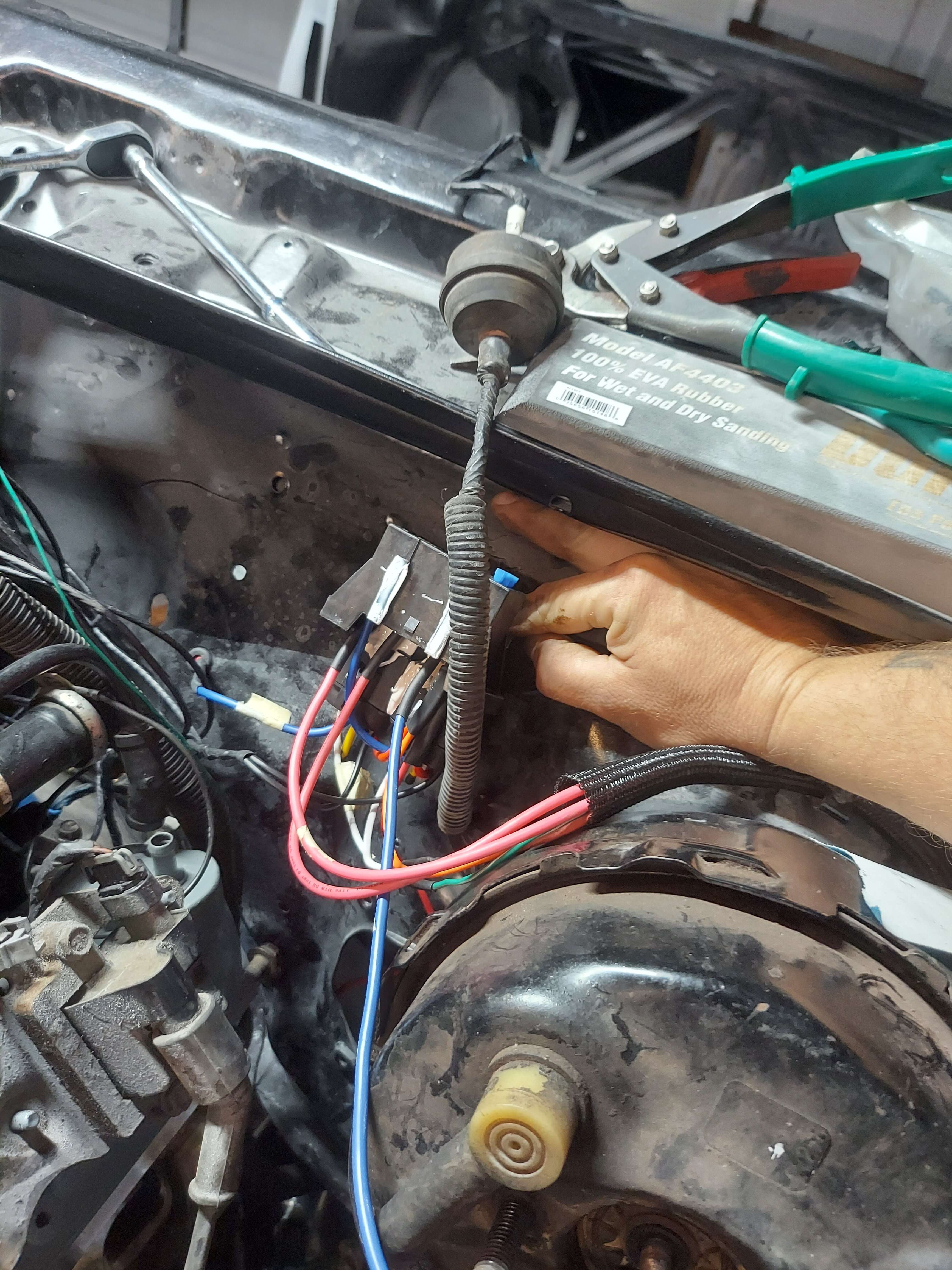

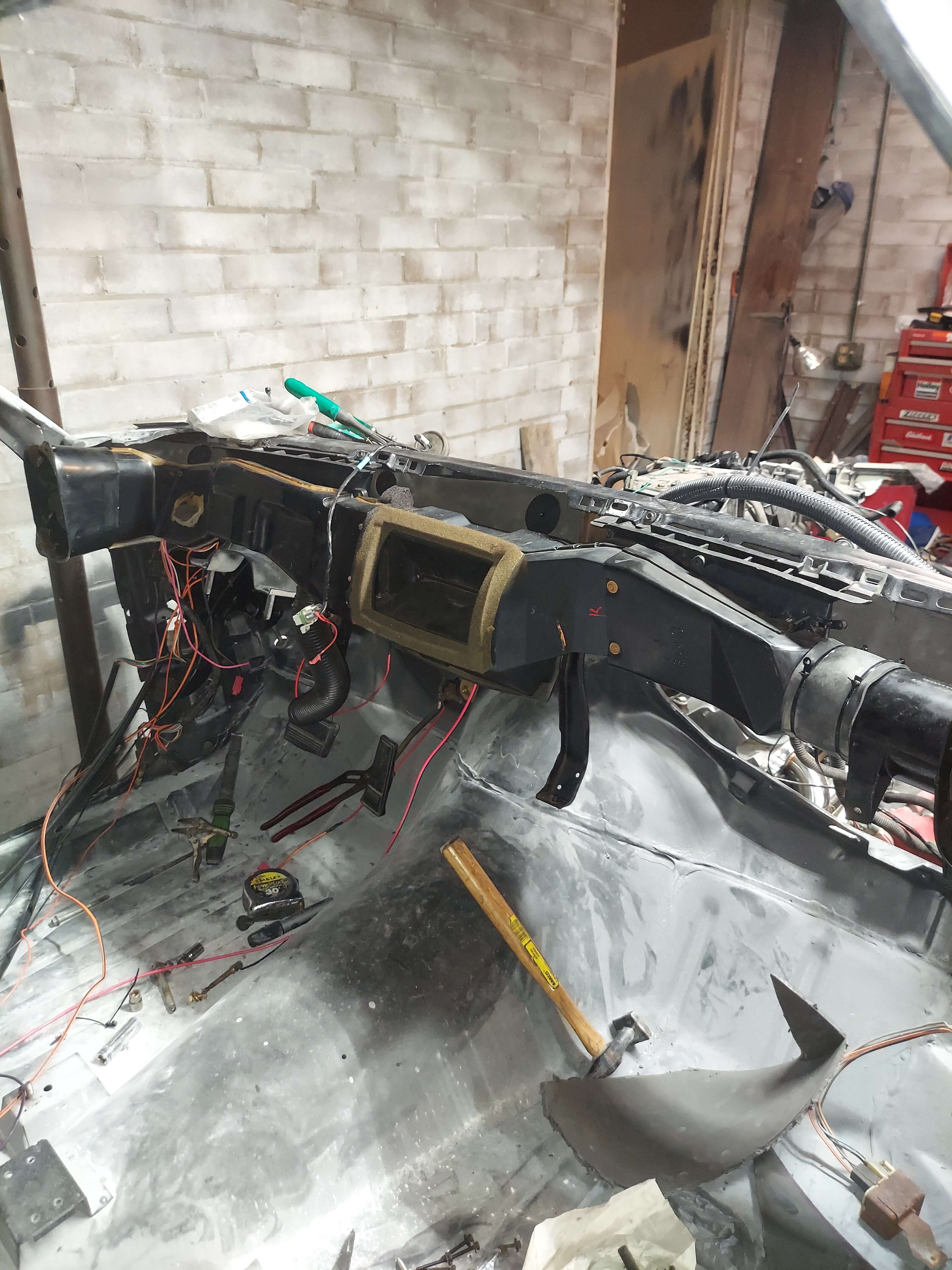

After all the double checking it was time to put the body back on. To say I was nervous is an understatement. To recap, I replaced the entire floor, entire roof, most of the backseat, both inner wheelhouse, 8 frame side body mounts. Both #2 ,#4, #5 and driver side #6 body side mounts. With a tape measure. Then put it on a redneck rotisserie for 2 yrs.So scared it wouldn't fit together right I was. My boy helped get it together and It was easy, dropped right on the guides and into place. Nothing hit, nothing needed cut out and moved. The hardest part was the washers in the prothane kit for #3 mounts holes weren't big enough. So the caged nut wouldn't fit into it. Once I figured that out it was smooth sailing.

I need a couple brackets for the rear brake lines still. 1 I'll buy for the axle tube. Then I'll make some for around the UCAs.

I need a couple brackets for the rear brake lines still. 1 I'll buy for the axle tube. Then I'll make some for around the UCAs.

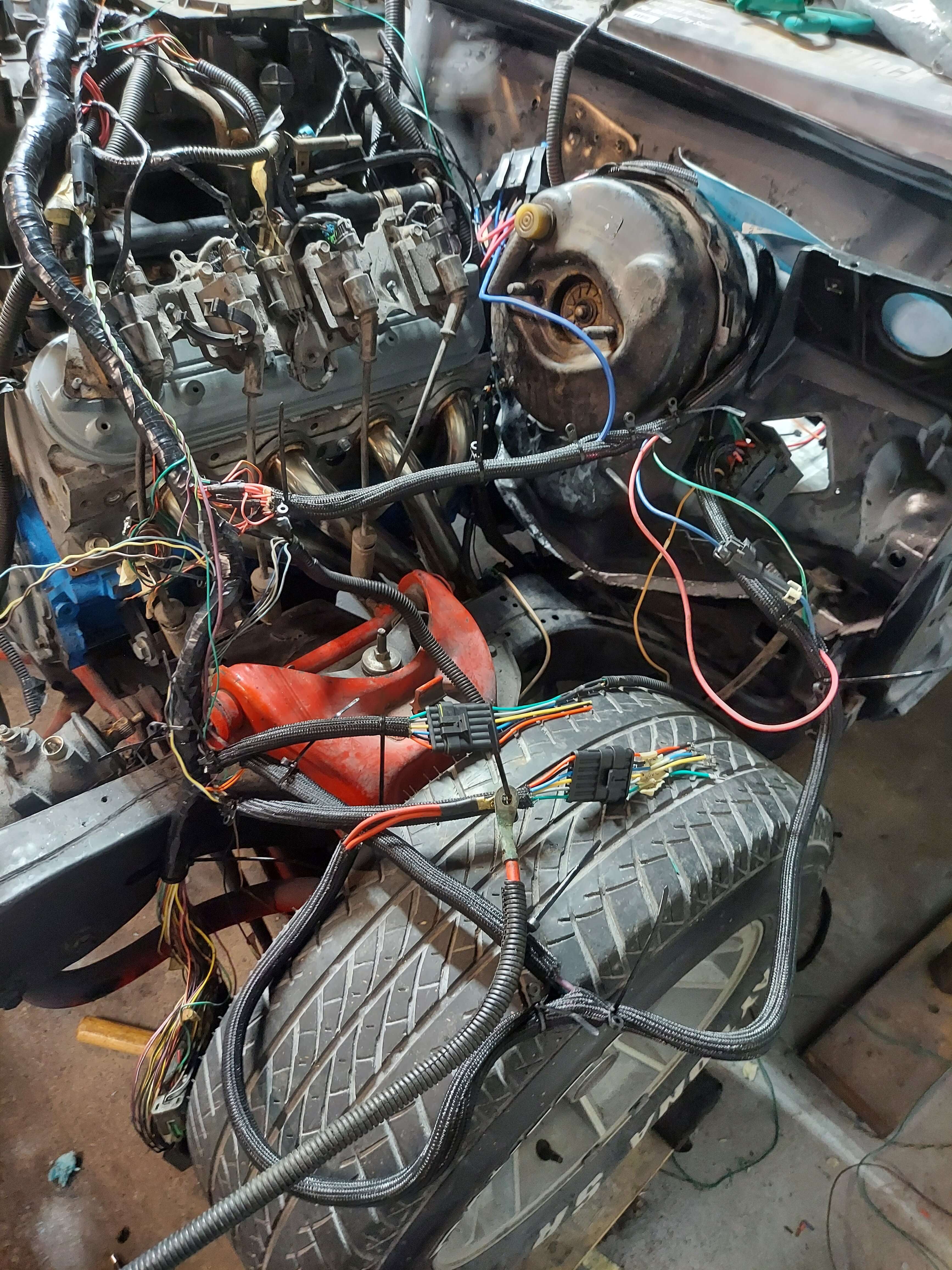

atleast 2" clearance for the crossmember and top of the transmission.

atleast 2" clearance for the crossmember and top of the transmission.

I'll admit it's kinda crappy spot for the dipstick, but I can reach it, it's out of sight and it was easy to make. I just cut it, and heated/bent it inward. The fuel line should tuck away nicely but im still gonna replace that loom with something better.

A/C box fits. Barely. It's been so long since this was together I found myself wandering if the ls sits back further then the sbc did. It looks like it , but I don't think it actually does.

My only issues is how high it sits in the back. It's a monster truck. I couldn't remember how it set but i found this old picture after i measured the spring(12")

so its stock in the back, and 2" drop spindles in the front. And the rear end+spacers are too wide. The tire sits right under the fender lip maybe a little outside of it.

so its stock in the back, and 2" drop spindles in the front. And the rear end+spacers are too wide. The tire sits right under the fender lip maybe a little outside of it.

Neither look is my thing. So I'm gonna get some new springs. I figure 9" springs would work. Also ill probably shorten/add 9" axle ends to an exploder axle this winter. Putting the doors and fenders on Today after family pictures. Hope to get it blocked out this weekend too.

Neither look is my thing. So I'm gonna get some new springs. I figure 9" springs would work. Also ill probably shorten/add 9" axle ends to an exploder axle this winter. Putting the doors and fenders on Today after family pictures. Hope to get it blocked out this weekend too.

I tried to weld this bracket on the housing but I couldn't get it hot enough so I jb welded it on. I'll keep an eye on it but I tried to rip it off with vice grips and it didn't budge.

After all the double checking it was time to put the body back on. To say I was nervous is an understatement. To recap, I replaced the entire floor, entire roof, most of the backseat, both inner wheelhouse, 8 frame side body mounts. Both #2 ,#4, #5 and driver side #6 body side mounts. With a tape measure. Then put it on a redneck rotisserie for 2 yrs.So scared it wouldn't fit together right I was. My boy helped get it together and It was easy, dropped right on the guides and into place. Nothing hit, nothing needed cut out and moved. The hardest part was the washers in the prothane kit for #3 mounts holes weren't big enough. So the caged nut wouldn't fit into it. Once I figured that out it was smooth sailing.

I'll admit it's kinda crappy spot for the dipstick, but I can reach it, it's out of sight and it was easy to make. I just cut it, and heated/bent it inward. The fuel line should tuck away nicely but im still gonna replace that loom with something better.

A/C box fits. Barely. It's been so long since this was together I found myself wandering if the ls sits back further then the sbc did. It looks like it , but I don't think it actually does.

My only issues is how high it sits in the back. It's a monster truck. I couldn't remember how it set but i found this old picture after i measured the spring(12")