You'll need a 80E specific crossmember, or modify your stocker to fit. Yoke should be the same, you'll need to have driveshaft shortened though. Aftermarket controller will control the converter.My th400 just kicked the bucket so I am looking in upgrading to the 4l80. I have a couple questions. First is do you have to get a new cross member or is there enough wiggle room on the stock one. Second is will I need a new driveshaft yoke. Third is do most aftermarket controllers run the lockup converter by themselves.

So you want to install a 4L80E? Learn from my mistakes (and successes!)

- Thread starter 454GrandPrix

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If your budget is of any concern, then I would strongly urge to have a long range plan. Swapping from TH400 to 80E with an aftermarket controller is, ummm, not real cheap.

Pros, trans is tough as nails and has overdrive; if you plan to stick to your current motor plan (carb), then fine and over 400hp; GREAT plan with a carb’d BB_ and want to swap gears.

Cons, heavier; new x member and driveshaft; if low power car, then this will just suck more power; if you plan to upgrade to EFI at some point then all money spent on controller and related goodies is money thrown away; have to swap gears.

P.s I’ll buy your 400 if you’re nearby 😉

Pros, trans is tough as nails and has overdrive; if you plan to stick to your current motor plan (carb), then fine and over 400hp; GREAT plan with a carb’d BB_ and want to swap gears.

Cons, heavier; new x member and driveshaft; if low power car, then this will just suck more power; if you plan to upgrade to EFI at some point then all money spent on controller and related goodies is money thrown away; have to swap gears.

P.s I’ll buy your 400 if you’re nearby 😉

Currently have a ls with about 475 hp and already have 4:10 and engine is carbureted. So gearing is not a worry and neither is power. I will probably eventually fuel inject the 6.0 for tuning and power reasons but have to do things in stages.If your budget is of any concern, then I would strongly urge to have a long range plan. Swapping from TH400 to 80E with an aftermarket controller is, ummm, not real cheap.

Pros, trans is tough as nails and has overdrive; if you plan to stick to your current motor plan (carb), then fine and over 400hp; GREAT plan with a carb’d BB_ and want to swap gears.

Cons, heavier; new x member and driveshaft; if low power car, then this will just suck more power; if you plan to upgrade to EFI at some point then all money spent on controller and related goodies is money thrown away; have to swap gears.

P.s I’ll buy your 400 if you’re nearby 😉

I used the same yoke from the 700r4 trans. Depending on tailshaft lengths driveshaft will need modified and crossmember is going to need moved back as well. If you are handy with a welder you might be able to move it the couple inches back for the mount. I have a rossler controller and a simple toggle switch for lock up, but it is a manual valve body by using the rosslock controller.

Thanks I am decent with a welder but I don’t have one so be crossmember it is. I am looking at getting the tci ez tcm.

That somewhat plugnplay other than you wed a tps input I believe. Do you have to get one wired in to your card throttle linkage.Thanks I am decent with a welder but I don’t have one so be crossmember it is. I am looking at getting the tci ez tcm.

Did you notice a change in your car's handling after the 454 swap? I once had plans for a Chevy BB for my Cutlass but I was told that my car would develop too much understeer (front heavy) and plow through corners, so I opted for a Chevy SBC 383 with a THM700R4.(Prologue: It seems that every time I mention my 4L80E transmission in this forum, somebody asks me for information about how I installed it. As I search around, I can find only one or two old threads with a few scraps of info... but it seems there isn't one all-inclusive thread to discuss the entire process. I'm hoping to change that now. Please remember that there is always more than one way to skin a cat. I tend to go for the low-buck Roadkill method whenever I modify my car, though I am not above spending a bit of money for something that is well engineered or that can save me significant amounts of time and/or headache. In other words, if you want to do something differently than I explain below, well, go right ahead--after all, it's your car. With that said, here we go.)

So you say you want to install a 4L80E into your G-body. Great! I put one in my 1980 Grand Prix, and I'm sure you can install one in your G-body as well. Let me guide you through the process--detailing the hijinks and heartaches, my failures and successes--so that you can pull this off with as little cursing as possible. There are a number of things you need to consider, and I'll attempt to address them all in a more-or-less systematic order.

Consideration #1: vehicle body prep

Good news: nothing outrageous is required. In fact, I did not hammer/dent/reshape any portion of my transmission tunnel or my firewall. I just dropped my 454/4L80E into the car and it fit. However, I later learned the transmission bell housing's left 'ear' contacts the trans tunnel--I should have cut that off. Oops. In my case, I've just been letting it "self-clearance" as I drive... which works, kinda, but it does transfer extra vibration to the interior. Cut the ear(s) off in advance and you should be golden.

Consideration #2: transmission prep

As I said above, my 4L80E is bolted to a 454. Both the transmission and the engine came out of a 1999 Chevy Express 3500. I already mentioned cutting off the ear(s) of the bell housing. Other than that, the only prep I performed on the transmission was a trans pan R&R to install a new internal filter, then I filled it with new fluid. I reused the stock converter.

Consideration #3: mounting it in the car

I used stock Monte Carlo SS frame mounts on the engine cross member + my donor van's stock engine clamshell brackets in order to mount the engine. For the rear transmission mount, I simply ordered the G-Force 4L80E crossmember. It bolted right into place, and the transmission bolted right to it. Because my G-body pre-dates the 4spd transmissions, I did need to also install the driver's side frame extension piece that they offer... but even that was a simple matter of drilling a couple holes and bolting it into position. You can see the extension here:

The G-Force piece is very well engineered, and it makes installing a 4L80E very simple (and it also perfectly cleared my dual 3" exhaust system). I am not a paid spokesman, but I endorse it completely.

Consideration #4: connecting it to your axle

This is as straightforward as it gets. I took some measurements, then went to a local driveline specialist and had him fab me a driveshaft. Easy.

Right behind the G-Force crossmember is the stock "driveshaft loop" bracket. When I installed my driveshaft, its u-joint was directly above that little bracket, and it would contact the bracket when the shaft spun. I quickly removed that bracket from the car. This didn't bother me, as I'm sure I'll install an NHRA-approved driveshaft loop at some point in the future.

Consideration #5: fluid cooling

There was no way I was going to try to adapt my stock V6 cooler lines to the 4L80E. Instead, I bought some lengths of steel brake line plus a handheld tubing bender, then I bent the lines into shapes that would work. At each end, I flared the tube and used rubber hose to connect it. At the transmission end, I needed some fittings to connect these rubber hoses to the housing. Because I had not modified my trans tunnel, I needed fittings with 90^ bends in them so I'd have room to attach the hoses. After looking at every part store in town, I found an old NAPA that came to my rescue: they had a dusty old cabinet with brass fittings--I literally blew the dust off the fittings as I took them out to inspect them. Here they are next to one of the transmission housing fittings:

DON'T do what I did and wait to install these after the transmission is in the car! I barely had enough room between the trans and the tunnel to install these. Attach them to the trans while it is still sitting on your shop floor and you'll be much happier. If you plan ahead and "massage" your trans tunnel with a large hammer, you'll be significantly better off than I was. 😉

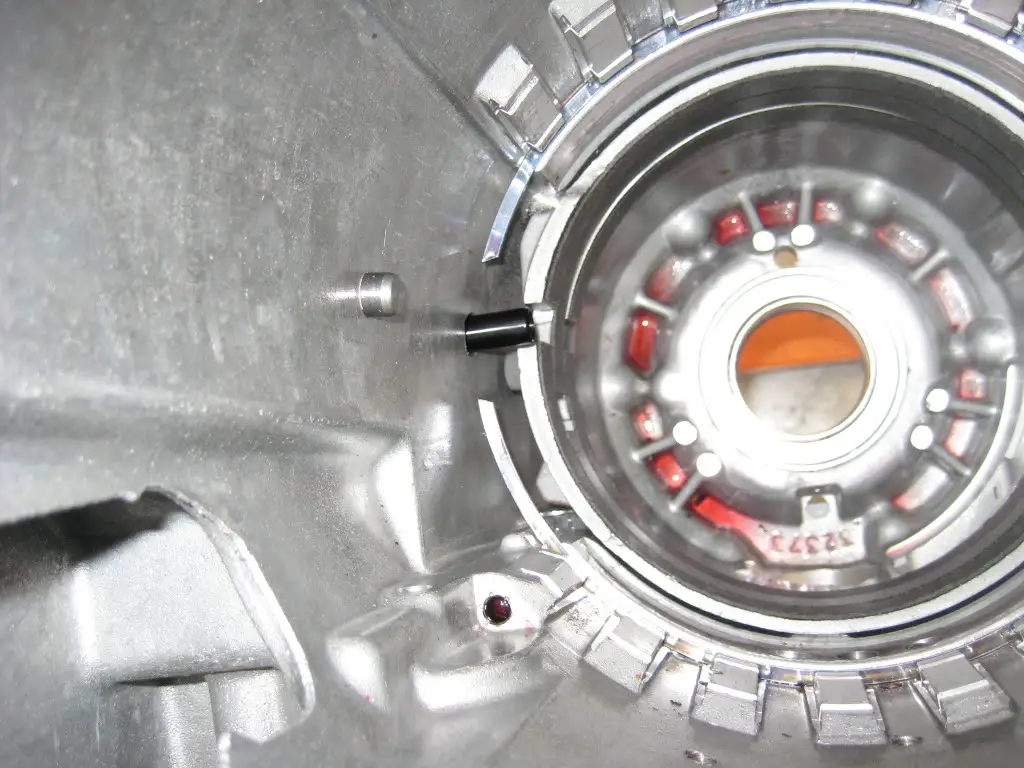

BE ADVISED: the early 4L80E transmission uses two identical fittings for the fluid cooler lines (they look like the one shown in the above photo). However, the 1997+ 4L80E transmission uses a rear fitting with a long 'nose' that protrudes into the housing. Here is a photo with two standard fittings and one long-nose fitting:

On that style of transmission, you must use this long-nose fitting in the rear. If you do not, fluid will not lubricate critical parts of the transmission and the entire unit will quickly die a horrible death. Here is an internal photo with an aftermarket black long-nose fitting installed to illustrate why this is so critical:

If you buy a working transmission and you simply re-use its stock fittings, you should be fine.

As for the actual heat exchange, I bought the largest bar and plate (or stacked plate) design cooler I could easily find--its core measures 12"x12". (This cooler design is much more efficient than the tube design!) I mounted it in front of the radiator but not attached to it; there is probably 4" or so between the two. As an old habit from my turbo minivan drag racing days, I also put an inline fluid filter in the inlet hose just before the cooler. I did not route my transmission fluid through the radiator at all; this external cooler is all I am using for temperature control. So far it has worked well; even in the peak of my summer desert heat, I have never seen the fluid temp go higher than 165^ at any time.

The 454 vs 383 weight issue is a bit misleading.Did you notice a change in your car's handling after the 454 swap? I once had plans for a Chevy BB for my Cutlass but I was told that my car would develop too much understeer (front heavy) and plow through corners, so I opted for a Chevy SBC 383 with a THM700R4.

A 454 with headers and aluminum parts like the intake and pulleys can weigh in as low as the 560-580lb zone.

A 383 with cast iron gm manifolds, a cast iron I take and misc parts also can easily tip the scales at 580 pounds.

It all depends how you outfit the motors there can be an overlap trending a good 100# away either direction.

Generally, a heavy small block and a lightened big block weigh about the same

Very good write up -

I think I have all the things I need based on this write up and another video.

I am still leaning towards getting the connect and cruise setup eventually but do not want to sink alot of money into the car right now.

I have a 1986 LS T-Top custom factory ordered Monte Carlo.

I did the LS 5.3 swap with a built 4L60E - runs out very nice kind of scary at times.

One thing I have to say about the G-Body is when putting any upgraded horse power in these - beef up the frame its extremely wonky and held togehter by ticky tacky - pulled the frame out and had it re-welded, boxed in and 3/16 steel bands across package tray and tied the rear coil spring towers together - now when I jack up right rear the right front and left front come up almost together... I noticed this when working on some Lexus and supra super sports the frames are tight with just enough play to avoid breaking. Also the rear end is Currie 9 inch tourino style bearing and 4-wheel disc brakes no 8 bolt of chincey 10 bolts or over priced 12 bolts.

was hoping to upgrade from suspension to big brakes and coil overs... the track on this car is wider with beefier tires while keeping a stock look.

The pics below is before the rear end upgrade and the digital dash - also I installed an RFID push button ignition - theft proof. the panel is integrated with engine management via wifi 5G and blue tooth 5 compoents Ada fruit and raspberry pie - plus the tesla panel from Ali Express.

That said the 4l60e has blown internal seals twice on me now so need a 4L80 or something beefy to hold up - BTW its so fun to walk away from those pesky Hell Kitties and loud obnoxious mustangs the only thing that is close is wife's P85 Tesla but its electric so makes sense.

Thanks for the write up...

I think I have all the things I need based on this write up and another video.

I am still leaning towards getting the connect and cruise setup eventually but do not want to sink alot of money into the car right now.

I have a 1986 LS T-Top custom factory ordered Monte Carlo.

I did the LS 5.3 swap with a built 4L60E - runs out very nice kind of scary at times.

One thing I have to say about the G-Body is when putting any upgraded horse power in these - beef up the frame its extremely wonky and held togehter by ticky tacky - pulled the frame out and had it re-welded, boxed in and 3/16 steel bands across package tray and tied the rear coil spring towers together - now when I jack up right rear the right front and left front come up almost together... I noticed this when working on some Lexus and supra super sports the frames are tight with just enough play to avoid breaking. Also the rear end is Currie 9 inch tourino style bearing and 4-wheel disc brakes no 8 bolt of chincey 10 bolts or over priced 12 bolts.

was hoping to upgrade from suspension to big brakes and coil overs... the track on this car is wider with beefier tires while keeping a stock look.

The pics below is before the rear end upgrade and the digital dash - also I installed an RFID push button ignition - theft proof. the panel is integrated with engine management via wifi 5G and blue tooth 5 compoents Ada fruit and raspberry pie - plus the tesla panel from Ali Express.

That said the 4l60e has blown internal seals twice on me now so need a 4L80 or something beefy to hold up - BTW its so fun to walk away from those pesky Hell Kitties and loud obnoxious mustangs the only thing that is close is wife's P85 Tesla but its electric so makes sense.

Thanks for the write up...

Attachments

Last edited:

Hi, do you have the part number for that B&M bracket and cable… I have the lightning rods in my hurst with a 4L60 and want to avoid buying/trying all different cables and brackets (I see a few options on Amazon)Nice write up. Thanks for sharing. I installed a 4L80E as part of my LS swap and cut off both ears with a sawz all to facilitate header clearance. For those searching for a used 4L80E keep in mind that GM made a few changes in 2004 you need to know about. Most notably the PRNDL is not a 7 position like most older overdrive transmissions. This means you cannot manually select gears 3-2-1 on the new models unless you have the BCM wired and paddle shifters to electronically change it. For those doing an LS swap I highly recommend using the factory transmission controller (they are plentiful in the junk yards and cheap!) For newer CANBUS ecm's like the E38 you can use a T42 transmission controller shown below. GM used them most every platform including 4 cylinder FWD cars. Most of the other 99-2003 ecm's have a built in transmission controller so no additional cost there.

I am using factory lightning rods with the 4L80E connected via a B&M cable and bracket kit. When installed with the 4L80 lever kit there is no fabrication required and it bolts up like GM would have installed it. Very clean and easy with no slop.

Im guessing the original cable is the wrong size?

Also we’re you able to connect that linkage from the column

Thank you in advance for any help

Similar threads

- Replies

- 3

- Views

- 307

- Replies

- 3

- Views

- 187

- Replies

- 0

- Views

- 62

- Replies

- 0

- Views

- 94

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.