Space City 1982 GP Build

- Thread starter Texas82GP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Thanks Eric. I appreciate it. I hope you catch a break on the Crew Cab. I know it's hard but take care of yourself. Both Sean and I had pretty bad bouts with Tennis Elbow (neither of us have ever played Tennis) and nothing will make it heal but time and rest. You only have one body. Take care of it buddy.Once again your work is impeccable and so is your attention to detail can't say much else great job

I thought the 3rd brake lights were mandated for 83 and up? I must be remembering that wrong? Anyway, the 'kit' from GM came with the wiring harness, complete with relay and convoluted tubing. It plugs in to the brake light switch, but I haven't accomplished that. It's funny because the ground for the harness uses the same screw that the ground for the taillight harness uses. The relay is mounted to the brace on the driver's side close to the taillight ground. Then the harness runs all the way to the front to pick up right off of the brake light switch. I wonder why it doesn't just tie into the taillight harness?Nice work getting everything to fit. For your third brake light kit, how does it wire in? Direct to the brake pedal switch? (Assume it's a add on kit for pre '86 cars.) I have an original used one with harness that I'm thinking about using in my '81.

Thanks for the suggestion. I had no idea the heat from the headers would be intense enough to melt that thing. Are your headers coated? I may have to find it a new home, but that's bad for my OCD. I want it to be where it is supposed to be. Hahaha!looks great. If I may suggest you might want to move the vacuum canister that hangs off the hvac box either up a little, to the fender or make a heat shield for it. I have melted 2 with the heat off the headers thus far.

Looks great and every little bit is progress !

Thanks Dan. It's good to have you following along. I still have February, March and April so there is still hope it will be running and driving for the summer but I don't know. I have some family commitments in the next few months and the progress just isn't the same as when I took a week off of work and worked on it every day, including Christmas. Also, I didn't intend to take the entire interior out of the car but the location of the shifter for the T5 was somewhat of a surprise. I had hoped to be driving it this summer with the granny split bench but that wasn't meant to be. Still, I'm glad to be getting rid of the pillow top seats, a great deal of the burgundy and the musty old car smell. Wherever I end up in May, I'm going to be really happy with how far the car has come since the beginning of November of 2017.Cars looking great Jared. So when do you think it will be driveable?

Thanks Jeff. Just like we call Donovan "Mr. Ridler", Sean is "Mr. Blue Tape". There's almost nothing he can't do with that blue tape. All kidding aside, he runs circles around me on masking. It's great having his help. I wouldn't be anywhere close to where I am without him. I'm glad you are happy with the pics. It is pretty tough to photograph those headers. I hope they helped you and others at least some.Excellent work Jared! Sean does awesome masking and taping. The closeup photos are great. Keep up the good work.

Thanks Jim. It's good to have you along in the thread. I'm very pleased with the progress. Hopefully the next few months will be just as productive.Jared, looks great man! Your moving right along!

Thanks Steve. I got those at Harbor Freight. If I remember correctly, they are sold in pairs. They are very affordable and well built. They were crucial when I had the smaller storage. I could move the car from one side to the other by myself. If anyone is in the market for some of these, I highly recommend them. I wish they were made in the USA.I don't know if it was mentioned before but I like the wheel dollys you have. What brand are they?

Thanks Mike. I hope you are enjoying the smaller file size pictures. You inspired me to reduce the size of the pictures so the thread would be friendlier.Awesome as always!

Thanks for all the replies guys. I didn't get over to the storage tonight so I wanted to get caught up on the thread. I'll update when there is progress to report. Until then...

Best,

Last edited:

Funny how things work, ever since I got rid of my 87 and bought the 84 I have wanted to put the 3rd brake light in. Growing up it was just something I liked the look of, so last week I got itching to get the pieces together since I have been buying some interior stuff to get my winter work rolling on the car. I ordered one out of a junkyard and just took what I could get when the first one said that they were not able to supply it at the end of the week after waiting to hear about shipment. Once I started getting rolling I ended up finding one with the correct light blue to match my interior so now have an extra but hope to be doing the same to mine soon.

I am really thinking of getting the LED upgrade since I have the Digitails but don't want to spend the $50 on the bulb itself when I think I could make something up myself. Guess I will be seeing in the next few weeks what I can come up with, I don't think I will like a single LED bulb replacement now that I have seen the board that goes in there.

I am really thinking of getting the LED upgrade since I have the Digitails but don't want to spend the $50 on the bulb itself when I think I could make something up myself. Guess I will be seeing in the next few weeks what I can come up with, I don't think I will like a single LED bulb replacement now that I have seen the board that goes in there.

Get the LED board upgrade, soooo worth it! I wish I still had the pic of mine lit up....it's bright as hell and was fairly easy to install.Funny how things work, ever since I got rid of my 87 and bought the 84 I have wanted to put the 3rd brake light in. Growing up it was just something I liked the look of, so last week I got itching to get the pieces together since I have been buying some interior stuff to get my winter work rolling on the car. I ordered one out of a junkyard and just took what I could get when the first one said that they were not able to supply it at the end of the week after waiting to hear about shipment. Once I started getting rolling I ended up finding one with the correct light blue to match my interior so now have an extra but hope to be doing the same to mine soon.

I am really thinking of getting the LED upgrade since I have the Digitails but don't want to spend the $50 on the bulb itself when I think I could make something up myself. Guess I will be seeing in the next few weeks what I can come up with, I don't think I will like a single LED bulb replacement now that I have seen the board that goes in there.

Get the LED board upgrade, soooo worth it! I wish I still had the pic of mine lit up....it's bright as hell and was fairly easy to install.

Oh trust me I am going to, I am doing LED everything on the car. Just trying to see if they have anything else that would fit

https://www.superbrightleds.com/mor...bulb-36-led-pcb-lamp-ba15s-retrofit-rvb/2368/

Update time. Last weekend wasn't that great. Everything was fighting and my attitude must have sucked because I didn't take the setbacks all that well.

First, I tried to install a new steering shaft I bought for a 95 Jeep Grand Cherokee. It wouldn't match up to the column so it went back in the box. Next, we installed the shifter in the car. I had bought a Pro 5.0 shifter for a 3rd Gen Camaro with a T5. I did this because the Pro 5.0 shifter has stops to keep you from over-shifting the T5. The T5 lacks internal stops so getting too rough with the shifter is one way to tear it up. The shifter went on fine. Next we looked at installing a boot to seal the shifter to the floor pan. I had bought a T5 lower shift boot out of a 4th gen Camaro (used). It would cover the area well and after trimming sealed to the new shifter well. The problem with it was it was a bit on the bulky side and is a bit wide. I don't want to have to pull the console, front seats and peel the carpet back to the back seat to get the boot out so I can pull the shifter to put a clutch in the car. So the boot was a strike out. Next we started looking at adapting the automatic transmission center console out of my brother's 78 Z28 to the car. The 2nd gen F body console fits our cars well in my opinion. We spent a fair amount of time jacking with it. The hole for the automatic shifter was well positioned for the T5. In the end, the shifter was hitting the side of the console in 1st gear and I decided it wasn't going to work. Strikeout on the console.

Next, I wanted to get the trim pieces that go along the side of the dash, from the A-Pillar trim to the kick panel out of the car. The passenger one is in bad shape and I want to paint the driver's side piece. I quickly realized that they were not going to come out without tearing the dash down and getting the dash basically ready to remove from the car. I didn't really want to tear into the dash so this was kind of the last straw for me last Saturday. It was time to get away from it and my brother had to leave a little early anyway. From there I went to a buddy's house and he and I machined a couple of spacers from 3/4" steel rod to space the shifter handle over to the right of the shifter. Using a 3rd gen Camaro shifter and a 3rd gen Camaro bellhousing with a T5 has the shifter way to the Driver's side. With the spacers, the handle is closer to the middle of the tunnel and I'm hoping this will work with the Monte console that I bought from Dixie.

Last Sunday I worked mostly on picking up and re-supplying the shop. I did go to the local True-Value hardware and found the M8x1.25x60mm allen head bolts that I needed to mount the shifter handle to the shifter with the spacers my buddy and I had machined the night before. After the resupply mission, I came home and Sean and I tried to make the new Jeep Cherokee shaft I had bought a few years ago work. We got it in the press and got it to collapse but it did not want to move freely. I was worried about heating it because I had read it would ruin a plastic bushing. I ended up with it in the vice and hammering on it with a hammer and big wrench to try to get it to expand. It was getting boogered up, I was getting frustrated and one of the ends was starting to come off of the splined shaft. I lost my temper and put it in the recycle bin. Strike out steering shaft. That was last weekend. This is why I didn't have an update last week.

First, I tried to install a new steering shaft I bought for a 95 Jeep Grand Cherokee. It wouldn't match up to the column so it went back in the box. Next, we installed the shifter in the car. I had bought a Pro 5.0 shifter for a 3rd Gen Camaro with a T5. I did this because the Pro 5.0 shifter has stops to keep you from over-shifting the T5. The T5 lacks internal stops so getting too rough with the shifter is one way to tear it up. The shifter went on fine. Next we looked at installing a boot to seal the shifter to the floor pan. I had bought a T5 lower shift boot out of a 4th gen Camaro (used). It would cover the area well and after trimming sealed to the new shifter well. The problem with it was it was a bit on the bulky side and is a bit wide. I don't want to have to pull the console, front seats and peel the carpet back to the back seat to get the boot out so I can pull the shifter to put a clutch in the car. So the boot was a strike out. Next we started looking at adapting the automatic transmission center console out of my brother's 78 Z28 to the car. The 2nd gen F body console fits our cars well in my opinion. We spent a fair amount of time jacking with it. The hole for the automatic shifter was well positioned for the T5. In the end, the shifter was hitting the side of the console in 1st gear and I decided it wasn't going to work. Strikeout on the console.

Next, I wanted to get the trim pieces that go along the side of the dash, from the A-Pillar trim to the kick panel out of the car. The passenger one is in bad shape and I want to paint the driver's side piece. I quickly realized that they were not going to come out without tearing the dash down and getting the dash basically ready to remove from the car. I didn't really want to tear into the dash so this was kind of the last straw for me last Saturday. It was time to get away from it and my brother had to leave a little early anyway. From there I went to a buddy's house and he and I machined a couple of spacers from 3/4" steel rod to space the shifter handle over to the right of the shifter. Using a 3rd gen Camaro shifter and a 3rd gen Camaro bellhousing with a T5 has the shifter way to the Driver's side. With the spacers, the handle is closer to the middle of the tunnel and I'm hoping this will work with the Monte console that I bought from Dixie.

Last Sunday I worked mostly on picking up and re-supplying the shop. I did go to the local True-Value hardware and found the M8x1.25x60mm allen head bolts that I needed to mount the shifter handle to the shifter with the spacers my buddy and I had machined the night before. After the resupply mission, I came home and Sean and I tried to make the new Jeep Cherokee shaft I had bought a few years ago work. We got it in the press and got it to collapse but it did not want to move freely. I was worried about heating it because I had read it would ruin a plastic bushing. I ended up with it in the vice and hammering on it with a hammer and big wrench to try to get it to expand. It was getting boogered up, I was getting frustrated and one of the ends was starting to come off of the splined shaft. I lost my temper and put it in the recycle bin. Strike out steering shaft. That was last weekend. This is why I didn't have an update last week.

This weekend was much better. I had been looking for a replacement for the lower windshield stainless trim piece that the wipers park on. I had one lined up to buy from a fellow member on here. During the week I received a notification that an 81 Caballero had hit the Pick-A-Part that is on my way home from work. Friday afternoon I left the office and went by to see what was there. My luck had changed. It had a pretty nice trim piece on it. Better than that, the hood and wipers had already been removed for me....

The trim piece had one vertical crease in it on the extreme passenger end. I'm guessing it was a result of the passenger fender being removed from the car. I don't know what the picker in question was after. The passenger fender was in the bed. The inner fender was on the ground. The hood was leaning against the driver's side. The header panel was in the bed. The bumper was on the ground in front of the car. I looked at the car wondering what I could save but it was pretty rough. It had a V-6. It was very rusty. Check out the rust damage hiding under the trim piece...

So I came out of the Pick-A-Part with a trim piece much nicer than mine for $10.87 total. I have to tell you, it felt like a win. When I got home, I worked on the crease with a hammer and dolly, and then sanded the scratches and the general area starting with 400 grit and working my way up to 1000 grit. I went over the entire piece two times with Mother's Mag and Aluminum polish. My repair did not turn out perfect but it turned out very good, especially for a worm like me...

Here is a close up on the repair area.....

Saturday morning, the refurbished trim piece went on the car first thing. It is a huge improvement over what I had.....

The glass on the car is dirty at this point. The car looks dirty but it was really humid that morning and I had drug the California Car Duster over it and the result was streaky and hazy. I need to go over the whole car with quick detailer and a micro-fiber.

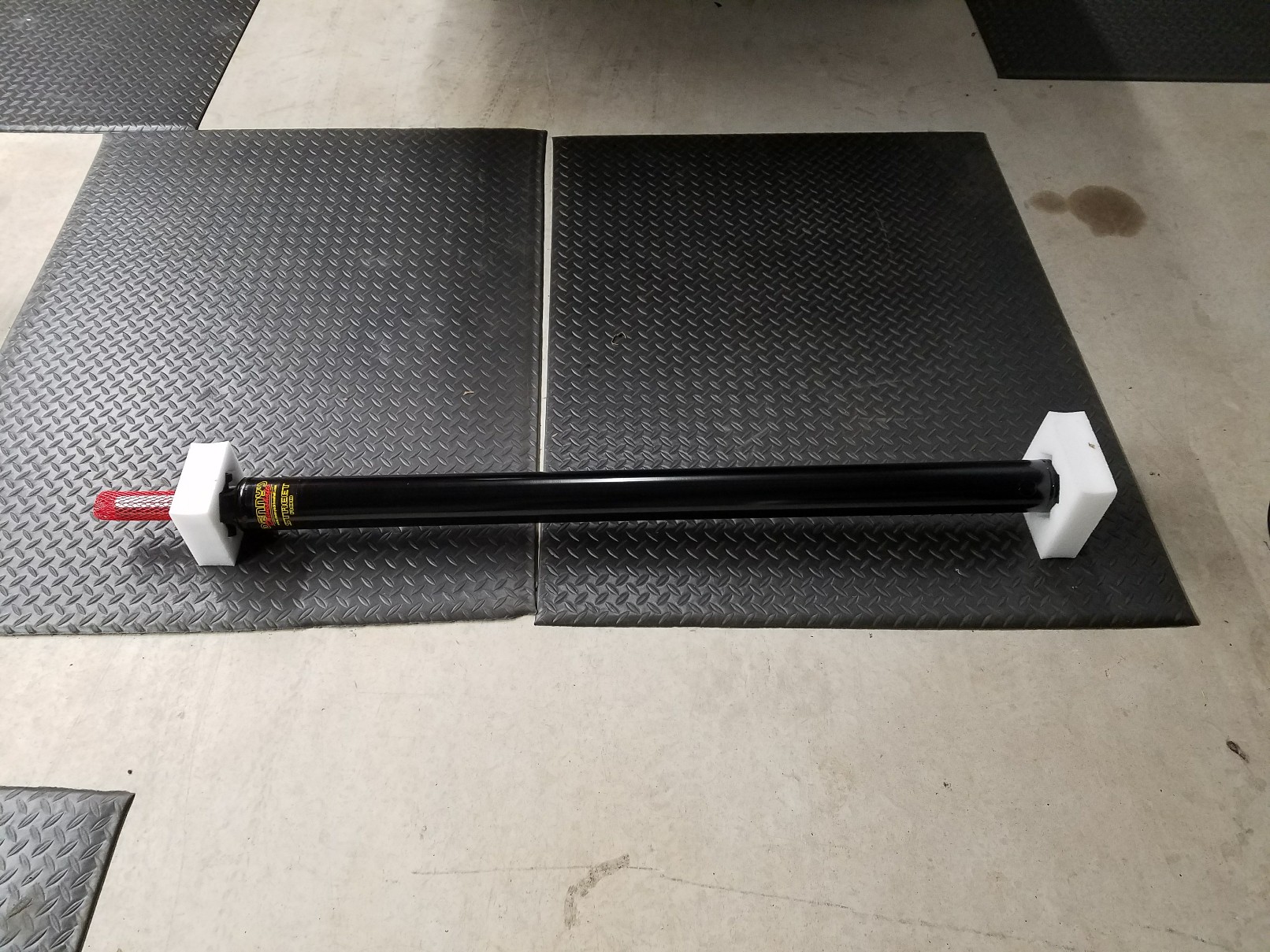

My driveshaft from Denny's had come in last Thursday. They do a great job. Here it is fresh out of the box....

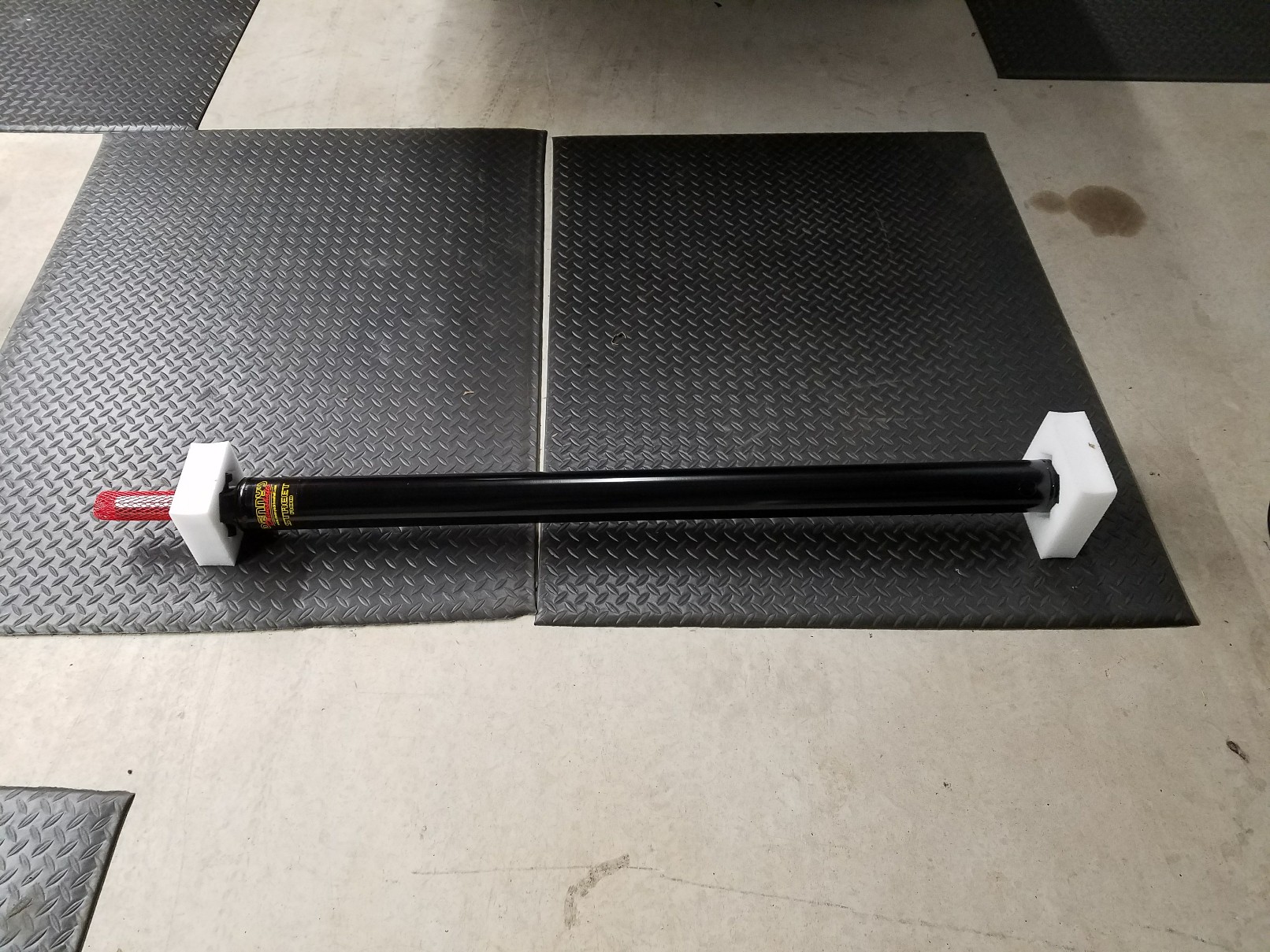

After installing the new windshield trim piece, Sean and I got right on installing the driveshaft. It went in with no drama...

Also visible in the pics above is the driveshaft loop I bought from JT Raceshop. Steve (pontiacgp) had warned me that the stock floor brace was not going to work with the T5. The longer T5 or 700R4 causes the front U-joint and the stock floor brace to compete for the same real estate. I'm really happy with the quality of the loop.

To be continued.....

The trim piece had one vertical crease in it on the extreme passenger end. I'm guessing it was a result of the passenger fender being removed from the car. I don't know what the picker in question was after. The passenger fender was in the bed. The inner fender was on the ground. The hood was leaning against the driver's side. The header panel was in the bed. The bumper was on the ground in front of the car. I looked at the car wondering what I could save but it was pretty rough. It had a V-6. It was very rusty. Check out the rust damage hiding under the trim piece...

So I came out of the Pick-A-Part with a trim piece much nicer than mine for $10.87 total. I have to tell you, it felt like a win. When I got home, I worked on the crease with a hammer and dolly, and then sanded the scratches and the general area starting with 400 grit and working my way up to 1000 grit. I went over the entire piece two times with Mother's Mag and Aluminum polish. My repair did not turn out perfect but it turned out very good, especially for a worm like me...

Here is a close up on the repair area.....

Saturday morning, the refurbished trim piece went on the car first thing. It is a huge improvement over what I had.....

The glass on the car is dirty at this point. The car looks dirty but it was really humid that morning and I had drug the California Car Duster over it and the result was streaky and hazy. I need to go over the whole car with quick detailer and a micro-fiber.

My driveshaft from Denny's had come in last Thursday. They do a great job. Here it is fresh out of the box....

After installing the new windshield trim piece, Sean and I got right on installing the driveshaft. It went in with no drama...

Also visible in the pics above is the driveshaft loop I bought from JT Raceshop. Steve (pontiacgp) had warned me that the stock floor brace was not going to work with the T5. The longer T5 or 700R4 causes the front U-joint and the stock floor brace to compete for the same real estate. I'm really happy with the quality of the loop.

To be continued.....

Once we finished with the driveshaft install, Sean and I set about measuring the driveline angle. Results: From the perspective of front to back, the transmission is pointing down 5-1/2 degrees. The driveshaft is pointing down 6 degrees. The rear end is pointing down 4 degrees. This gives an operating angle of 1/2 degree at the front U-joint and 2 degrees at the rear. Based on what I've read so far, this seems like it is in the acceptable range? Feedback? We had the car pretty level and out of curiosity I put the angle finder on the pad for the carburetor and it is virtually horizontal. Please give me some feedback on this guys.

After the driveshaft install Sean and I split up. I started tearing down the dash. I pulled the column. Then I pulled the bezel. Then the cluster and the gauges. Then the radio. Then the glove box door. Then the upper center grille. I patiently worked to loosen up the dash enough to get the side trim pieces out that I referenced earlier. While I was doing all this, Sean installed the Eastwood X-Mat (think Dynamat) in the trunk. When he finished the trunk, he moved into the cab of the car. When we left Saturday evening I had the trim pieces out and had almost everything I pulled off the car boxed up. Sean had the X-Mat in the trunk done and had 3/4 of the cab of the car done. We went back over there this morning. I pulled the front seat seatbelt retractors out and installed the block-off plates. I also pulled the trim loose from the front seat belts where they mount to the inner rocker. I did some more boxing of parts pulled off of the dash. Meanwhile Sean finished the X-Mat install in the cab of the car. I also started working on stowing the jack and tire tool in the trunk of the car. When I bought the car it didn't have a jack, a spare, a tire tool. I didn't get anything. I'm going to let the pictures do some talking now...

Sean does awesome work doesn't he? He didn't put the X-Mat on the tunnel because we need to install the mounts for the new console and they haven't come in yet. I'm either dumb or I don't have the right stuff to stow my jack. I have two clip-in 'studs' to mount the jack. I have the long one in the forward location in the quarter panel brace. I have the short one in the trunk floor, just in front of the tail panel. With it set up like this there doesn't seem to be enough stud at the back for the clip that secures the tire tool. I bought the jack, tool and hardware a few years ago on ebay I think. I might not have the right stuff. I'm working on that.

That's pretty much the progress for now. Thanks as always for tuning in guys. I'll update again when there is more progress to report. Until then...

Best,

Jared

After the driveshaft install Sean and I split up. I started tearing down the dash. I pulled the column. Then I pulled the bezel. Then the cluster and the gauges. Then the radio. Then the glove box door. Then the upper center grille. I patiently worked to loosen up the dash enough to get the side trim pieces out that I referenced earlier. While I was doing all this, Sean installed the Eastwood X-Mat (think Dynamat) in the trunk. When he finished the trunk, he moved into the cab of the car. When we left Saturday evening I had the trim pieces out and had almost everything I pulled off the car boxed up. Sean had the X-Mat in the trunk done and had 3/4 of the cab of the car done. We went back over there this morning. I pulled the front seat seatbelt retractors out and installed the block-off plates. I also pulled the trim loose from the front seat belts where they mount to the inner rocker. I did some more boxing of parts pulled off of the dash. Meanwhile Sean finished the X-Mat install in the cab of the car. I also started working on stowing the jack and tire tool in the trunk of the car. When I bought the car it didn't have a jack, a spare, a tire tool. I didn't get anything. I'm going to let the pictures do some talking now...

Sean does awesome work doesn't he? He didn't put the X-Mat on the tunnel because we need to install the mounts for the new console and they haven't come in yet. I'm either dumb or I don't have the right stuff to stow my jack. I have two clip-in 'studs' to mount the jack. I have the long one in the forward location in the quarter panel brace. I have the short one in the trunk floor, just in front of the tail panel. With it set up like this there doesn't seem to be enough stud at the back for the clip that secures the tire tool. I bought the jack, tool and hardware a few years ago on ebay I think. I might not have the right stuff. I'm working on that.

That's pretty much the progress for now. Thanks as always for tuning in guys. I'll update again when there is more progress to report. Until then...

Best,

Jared

Smokin’ right along!

Great progress Jared. Thanks for the update. Glad you were able to step back from it for a bit and regroup. It happens to us all at times. Keep it up brother, it’s looking great!

Great progress Jared. Thanks for the update. Glad you were able to step back from it for a bit and regroup. It happens to us all at times. Keep it up brother, it’s looking great!

Awesome progress Jared! It's coming along nicely!

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 151

- Replies

- 9

- Views

- 586

- Replies

- 15

- Views

- 3K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.