Space City 1982 GP Build

- Thread starter Texas82GP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mobile tint, interesting, I have to get the wagon to tint first thing.

The trunk looks great, the extra effort shows.

Thanks Jim. Yeah, mobile tint was the only way it was going to work for me. Some of the tint guys around here don't know how to work on older cars and don't want to mess with it. There is a tint shop in a shopping center right next door to the storage facility where my car is and the guy just turned me away. I wanted to get the windows tinted while the interior was out. I don't want my freshly painted plastic and brand new package shelf getting soaking wet. Also, my tinter told me that having the car apart like that made his life much easier. Thanks for the kind words on the trunk. It looks ok as long as you don't look too close. I'm going to work on it a bit more to improve it. It looks a lot better than what I started with anyway.

The trunk looks good. I may have to do that.

Thanks Zach. I can't recommend going the route I did. The lack of instructions and the poor fitment of this kit make me recommend against it. It was way overpriced for what you get. My suggestion is buy a new mat and glue it down yourself. Buy some bulk trunk carpet and make your own boards. It will be less expensive and fit better.

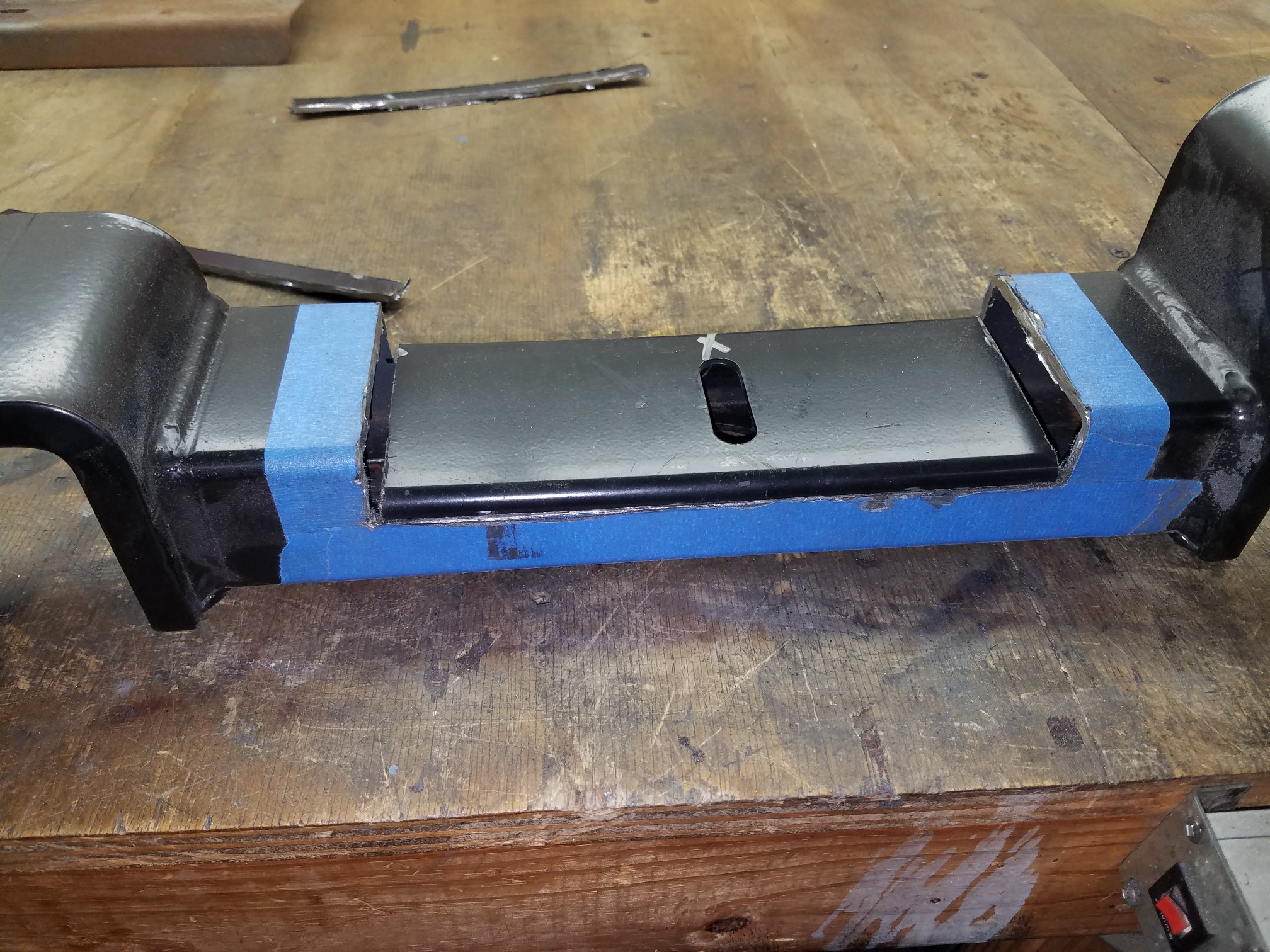

Update time. If any of you saw my thread where I was searching for a non-existent 1" tall transmission mount, you know that I decided to modify my G-Force crossmember to correct my driveline angle and improve clearance between the tunnel and the top of the transmission. I'm using the RCG700 crossmember from G-Force and it is really for a 700R4 but works for a T5, lengthwise. They note on their website that a custom transmission mount may be required for a T5. To correct the driveline angle and use the crossmember as it was, I needed a 1" tall mount. Those don't seem to exist. Moving forward, I decided to use the 'short' Energy Suspension mount (part number 3.1158G) that I already had in there and modify the crossmember. The 'short' Energy Suspension mount is 1-5/8" tall. My plan was to cut 5/8" out of the center section of the crossmember to get me in the same place as if I had a 1" tall mount with the unmodified crossmember. Tuesday night I pulled the crossmember out of the car and brought it home for surgery. Wednesday night my brother Sean came out with me and helped me lay out the proposed cuts. We started out by laying out the top of the center section that I wanted to move down....

We did the cutting with a pneumatic rotary tool with a 2-1/2" or 3" cutoff wheel in it. This was really a little bit of a big job for it. I probably would have been better off using a 4" or 6" angle grinder. Still, we got the center section cut out Wednesday night....

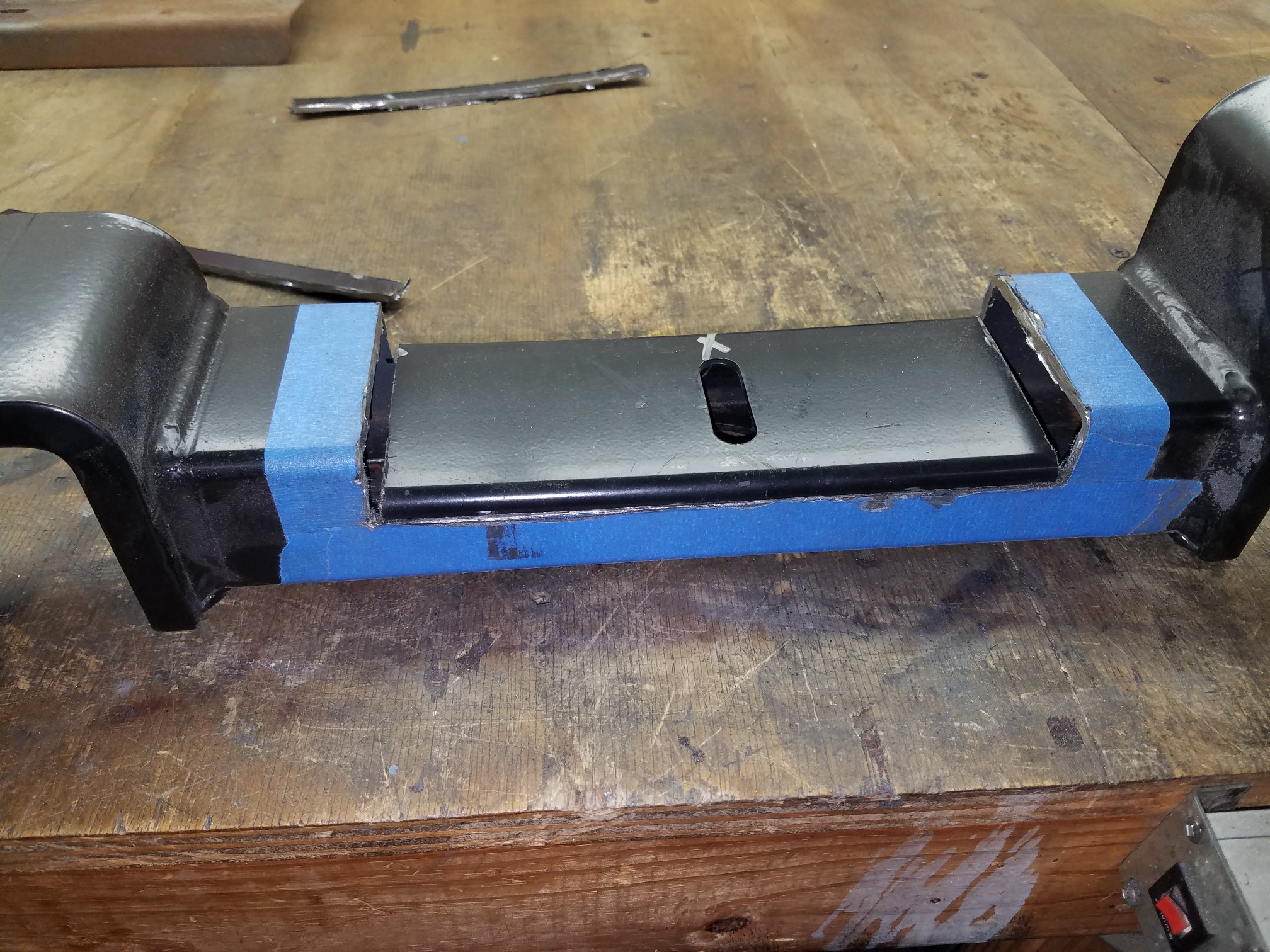

In the picture above, you can see how we have a tape line below our cut along the front edge. This represents what we would cut away to lower the top plate 5/8". We made those cuts Thursday night and worked on chamfering the pieces for the welding...

And here's a look at the intended outcome....

In the picture above, you may see some warpage of that top plate. I guess the heat from cutting it out caused it to warp a little. I placed it on the anvil portion of our vice and was able to hammer it out of it easily.

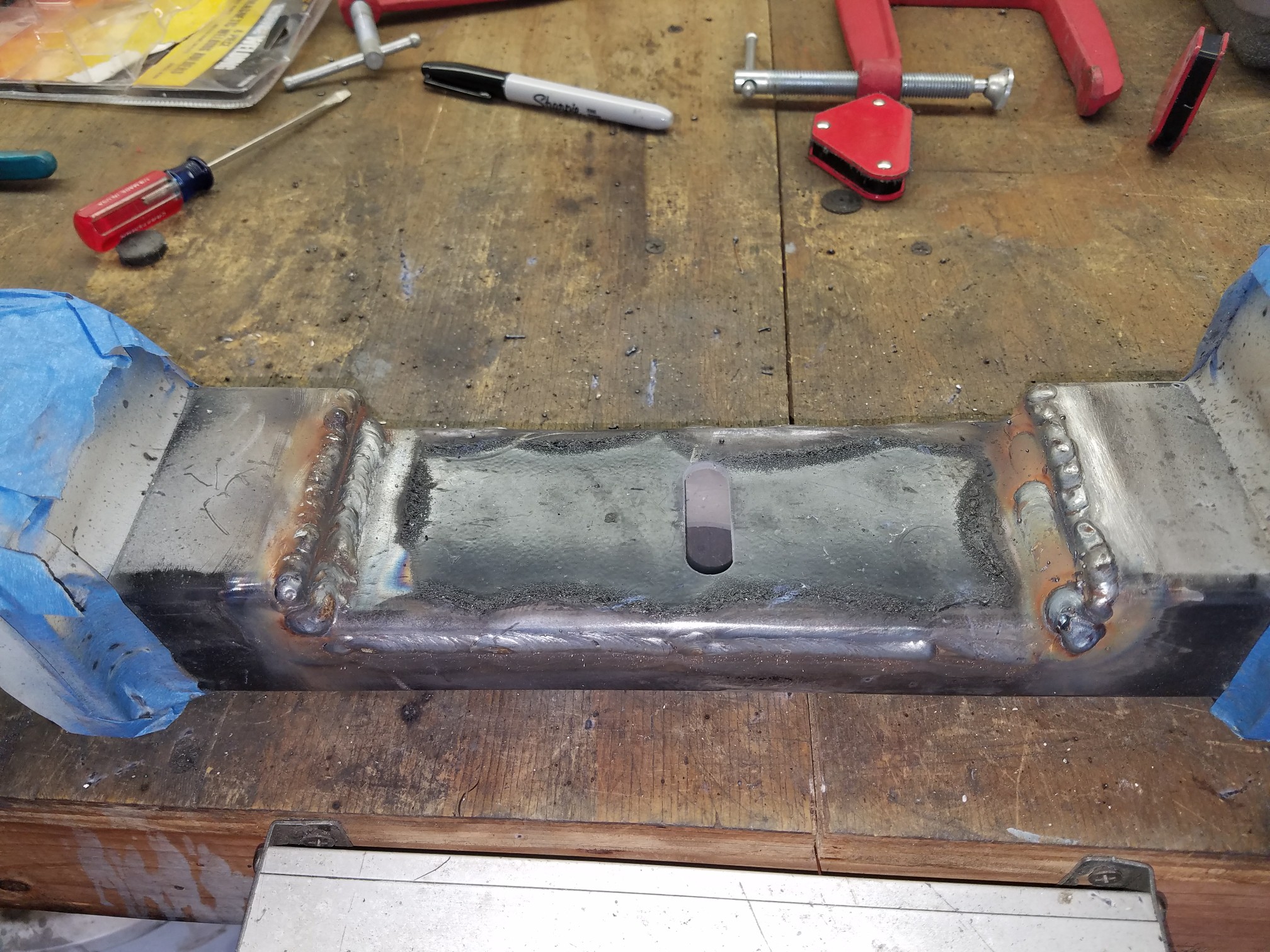

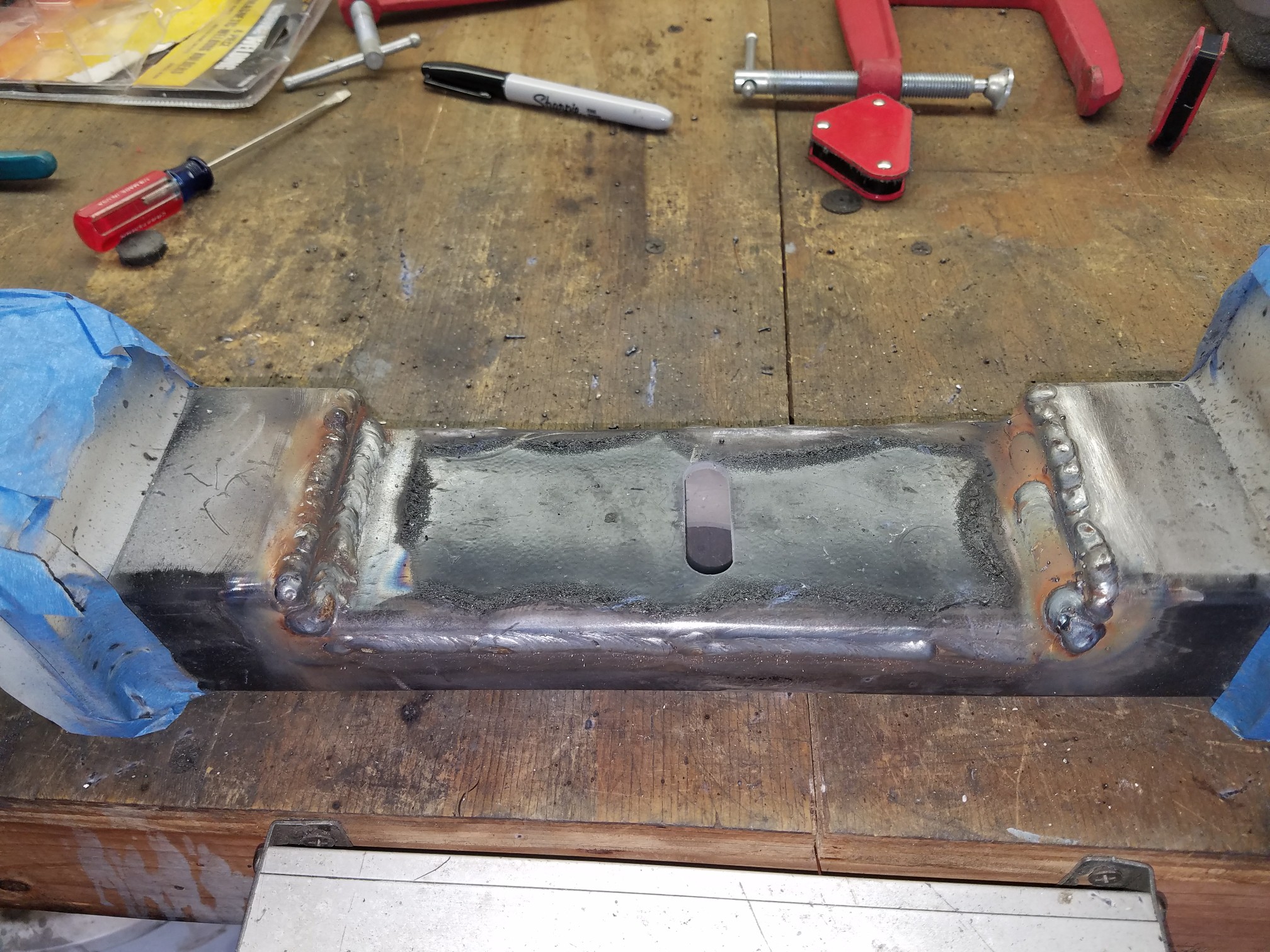

Now, I wouldn't call myself a welder. I'm not a total novice but I have plenty to learn. Most of my experience is welding sheet metal. I wanted this thing to turn out pretty nice so I had a buddy of mine come over to the house on Saturday to watch me and give me some pointers. I learned a lot about how to get good penetration on this thicker (1/8") material and even got some of it to look pretty decent. You guys that are more accomplished welders than me may think this is funny looking but I'm pretty proud of how it went...

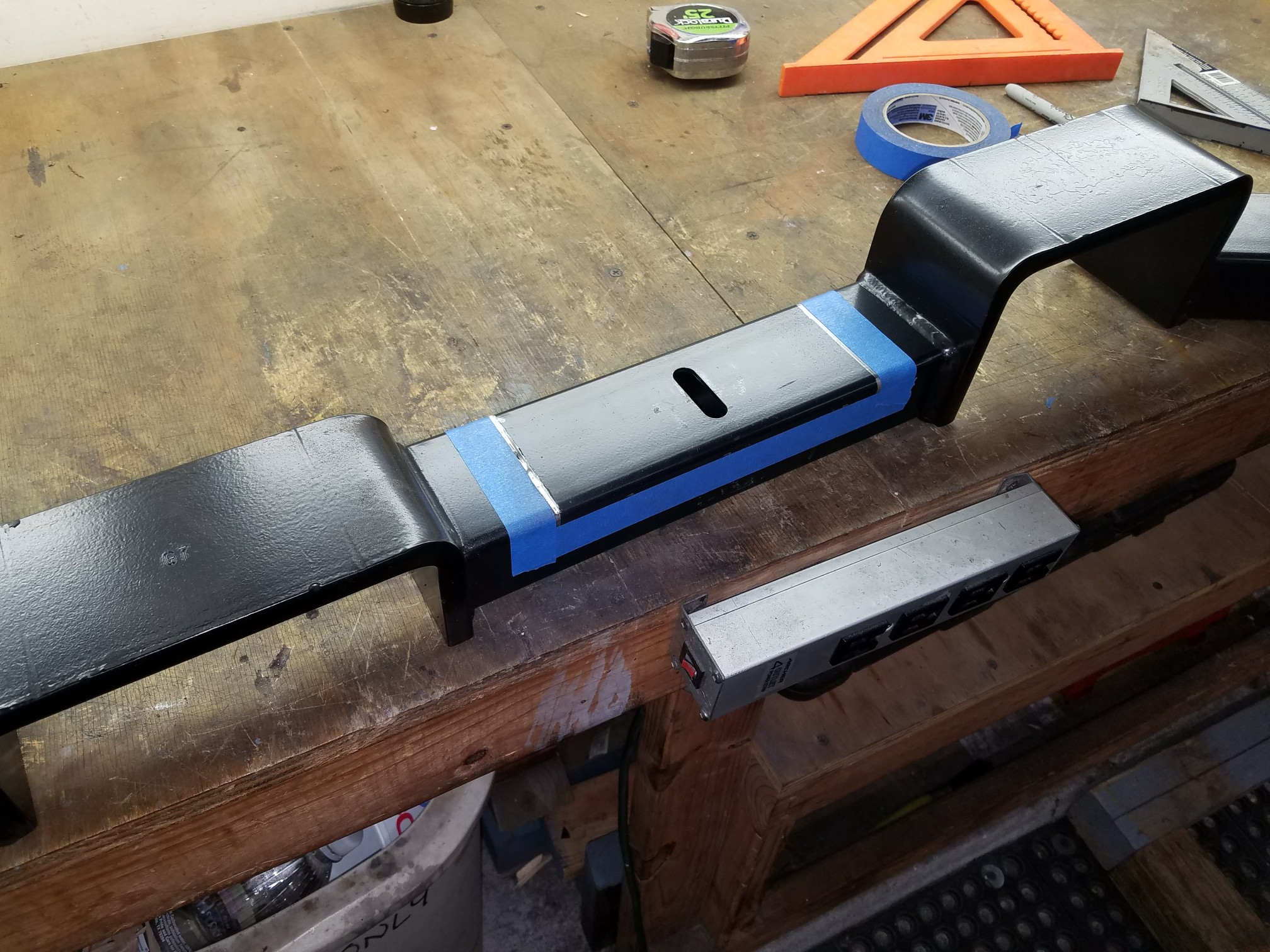

After some grinding to make it prettier....

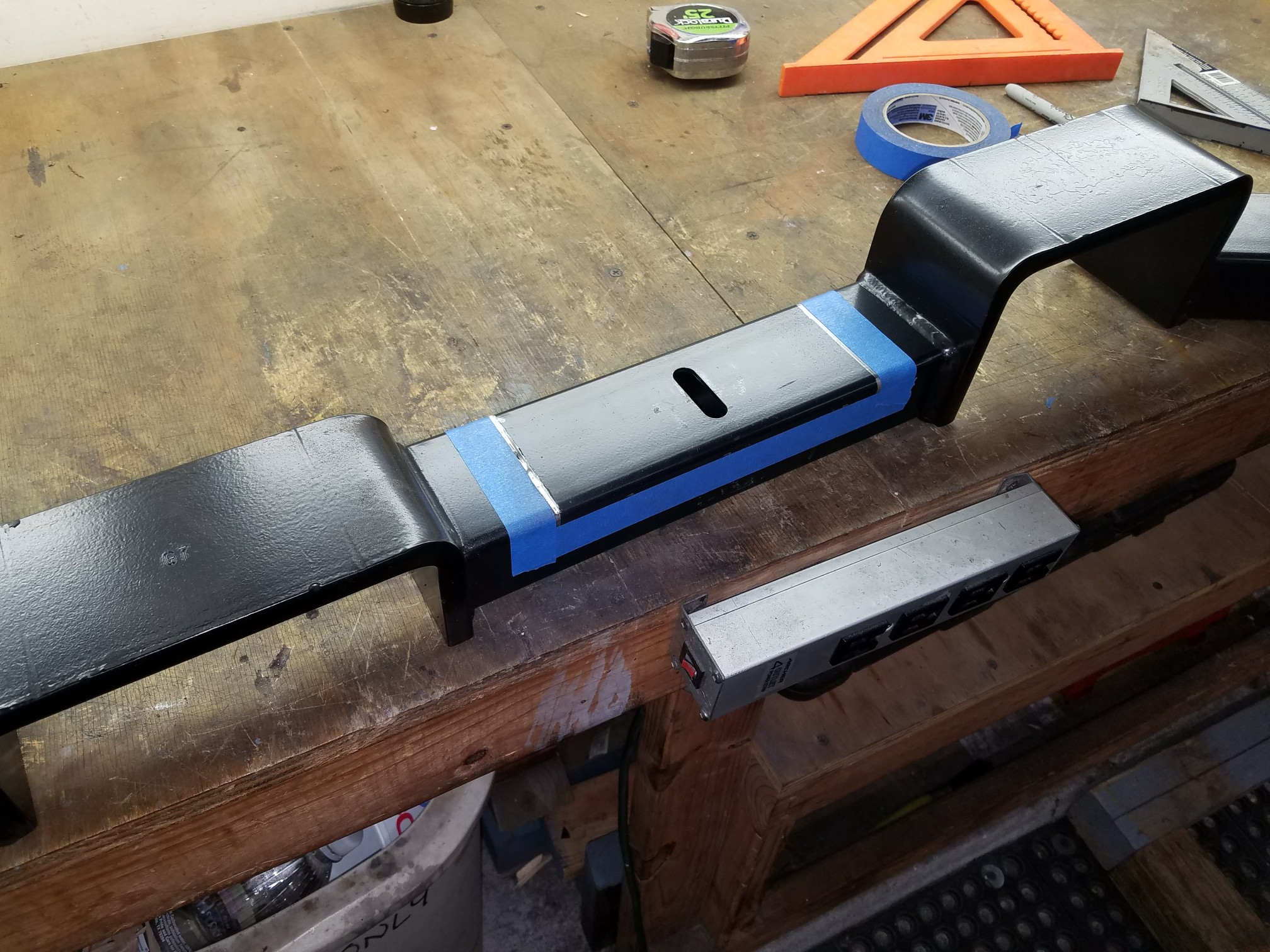

Here it is Saturday evening, painted and ready to install. I only primed and painted the areas we disturbed. I used Duplicolor Engine Enamal as that's what I had on hand. It's amazing how good the semi-gloss black matched the original powdercoat. Just a little bit shinier than the powdercoat. Saturday was a good car day...

To be continued.....

We did the cutting with a pneumatic rotary tool with a 2-1/2" or 3" cutoff wheel in it. This was really a little bit of a big job for it. I probably would have been better off using a 4" or 6" angle grinder. Still, we got the center section cut out Wednesday night....

In the picture above, you can see how we have a tape line below our cut along the front edge. This represents what we would cut away to lower the top plate 5/8". We made those cuts Thursday night and worked on chamfering the pieces for the welding...

And here's a look at the intended outcome....

In the picture above, you may see some warpage of that top plate. I guess the heat from cutting it out caused it to warp a little. I placed it on the anvil portion of our vice and was able to hammer it out of it easily.

Now, I wouldn't call myself a welder. I'm not a total novice but I have plenty to learn. Most of my experience is welding sheet metal. I wanted this thing to turn out pretty nice so I had a buddy of mine come over to the house on Saturday to watch me and give me some pointers. I learned a lot about how to get good penetration on this thicker (1/8") material and even got some of it to look pretty decent. You guys that are more accomplished welders than me may think this is funny looking but I'm pretty proud of how it went...

After some grinding to make it prettier....

Here it is Saturday evening, painted and ready to install. I only primed and painted the areas we disturbed. I used Duplicolor Engine Enamal as that's what I had on hand. It's amazing how good the semi-gloss black matched the original powdercoat. Just a little bit shinier than the powdercoat. Saturday was a good car day...

To be continued.....

Looks so familiar. Also, no one is judging your welds - good work.

Sunday morning Sean and I went over to the storage and installed the crossmember. Big improvement!

Before....

After.....

Before....

After....

Before.... (notice how the flange where the shifter bolts is protruding through the tunnel)......

After....(now the mounting flange of the shifter is below the tunnel)....

I have to tell you it feels great to have this issue resolved. The engine and transmission went in the car on January 2nd. Now, nearly two months later, the driveline angle issue has been finally put to bed.

Moving from there I finished the stowing of the jack and the tire tool. A big thank you to Timo22 for providing a replacement for the broken wing nut I had and for providing pictures and feedback for how the jack is stowed in his two cars....

I might go back later and repaint the jack and the hardware but it is not a priority for me now. With the finishing kit, you don't even see it so I'm not worried about it for now. I went to lock down my new spare tire but the J-bolt I bought along with the jack and the rest of the hardware (not from Tim) a few years ago was way too short. It must have been for a compact spare. Sean and I headed to the house and I fabbed a new J-bolt from some stock we had on hand....

I plan to go by the storage tonight and try it out. Then I have a little more work to do on the trunk finishing kit and I need to put my jacking decal on my trunk lid. At that point, I'm going to call the trunk done and I'm going to latch the lid. Yesterday evening I cleaned up and painted the bracket that goes between the top of the steering column and the bottom of the dash. The factory put it in bare and it had surface rust all over it. I also painted the two brackets to mount the console to the tunnel. This week I'll be working to come up with the hardware to attach the brackets to the console so we can get it mocked up and get the brackets attached to the tunnel. Once we get those brackets in place we need to finish the X-mat install on the tunnel, reroute the reverse light wiring through the tunnel (the previous owner had it routed through the speedometer cable grommet) and then we can install the carpet. If we could get some painting weather and get some of the interior plastic trim painted, some of the interior could go back together.

Anyways, it's been a good car week. That's the update for now. I'll update again as progress warrants. Until then, thanks as always for checking in.

Best,

--Jared

Before....

After.....

Before....

After....

Before.... (notice how the flange where the shifter bolts is protruding through the tunnel)......

After....(now the mounting flange of the shifter is below the tunnel)....

I have to tell you it feels great to have this issue resolved. The engine and transmission went in the car on January 2nd. Now, nearly two months later, the driveline angle issue has been finally put to bed.

Moving from there I finished the stowing of the jack and the tire tool. A big thank you to Timo22 for providing a replacement for the broken wing nut I had and for providing pictures and feedback for how the jack is stowed in his two cars....

I might go back later and repaint the jack and the hardware but it is not a priority for me now. With the finishing kit, you don't even see it so I'm not worried about it for now. I went to lock down my new spare tire but the J-bolt I bought along with the jack and the rest of the hardware (not from Tim) a few years ago was way too short. It must have been for a compact spare. Sean and I headed to the house and I fabbed a new J-bolt from some stock we had on hand....

I plan to go by the storage tonight and try it out. Then I have a little more work to do on the trunk finishing kit and I need to put my jacking decal on my trunk lid. At that point, I'm going to call the trunk done and I'm going to latch the lid. Yesterday evening I cleaned up and painted the bracket that goes between the top of the steering column and the bottom of the dash. The factory put it in bare and it had surface rust all over it. I also painted the two brackets to mount the console to the tunnel. This week I'll be working to come up with the hardware to attach the brackets to the console so we can get it mocked up and get the brackets attached to the tunnel. Once we get those brackets in place we need to finish the X-mat install on the tunnel, reroute the reverse light wiring through the tunnel (the previous owner had it routed through the speedometer cable grommet) and then we can install the carpet. If we could get some painting weather and get some of the interior plastic trim painted, some of the interior could go back together.

Anyways, it's been a good car week. That's the update for now. I'll update again as progress warrants. Until then, thanks as always for checking in.

Best,

--Jared

That's about the same position at my T5 is at the opening in the tunnel. You guys did a real nice job on the welding and I hope you saved the Gforce sticker. When you are ready to fill the transmission I find it easier to remove the shifter and fill it from from there. I remove the fill plug and fill it till it drips out of the fill hole. Another thing I do is to replace the 3/8" square fill and drain plugs with allen plugs.

Where did you get your driveshaft hoop?

Where did you get your driveshaft hoop?

Last edited:

Jared,

Nice job modifying the crossmember. I could see what a bear it would be to cut metal that thick. It's hard enough slicing bumpers...but that's thicker and takes more time to cut through. An angle grinder would have come in handy, but sometimes we have to use what's available in our arsenal.

All in all, great work. It's always a feeling of elation when you can cross off another task from your "to-do" list.

Does your spare tire fit nicely in the well? I would like to eliminate the original 14" spare with a 15" rim and a lower profile tire. I know it won't quite equal the diameter of the 235/60 X 15.

Keep up the great work as always. 👍

Nice job modifying the crossmember. I could see what a bear it would be to cut metal that thick. It's hard enough slicing bumpers...but that's thicker and takes more time to cut through. An angle grinder would have come in handy, but sometimes we have to use what's available in our arsenal.

All in all, great work. It's always a feeling of elation when you can cross off another task from your "to-do" list.

Does your spare tire fit nicely in the well? I would like to eliminate the original 14" spare with a 15" rim and a lower profile tire. I know it won't quite equal the diameter of the 235/60 X 15.

Keep up the great work as always. 👍

Last edited:

That crossmember turned out nice. I couldn't have done it any better. I am anxious to see you tinted windows. Keep up the good work!

That's about the same position at my T5 is at the opening in the tunnel. You guys did a real nice job on the welding and I hope you saved the Gforce sticker. When you are ready to fill the transmission I find it easier to remove the shifter and fill it from from there. I remove the fill plug and fill it till it drips out of the fill hole. Another thing I do is to replace the 3/8" square fill and drain plugs with allen plugs.

Where did you get your driveshaft hoop?

Thanks Steve! Sean saved the G-Force sticker. It now adorns his air compressor. I already applied a little RTV between the shifter and the top of the transmission so I won't be filling it through the top, though that was my original plan. I have allen plugs I could use to replace the square ones. Thanks for the feedback, especially regarding how your transmission is sitting in the tunnel. I was pretty sure you had said as much earlier. Thanks for the kind words and thanks for looking in on my thread buddy.

Jared,

Nice job modifying the crossmember. I could see what a bear it would be to cut metal that thick. It's hard enough slicing bumpers...but that's thicker and takes more time to cut through. An angle grinder would have come in handy, but sometimes we have to use what's available in our arsenal.

All in all, great work. It's always a feeling of elation when you can cross off another task from your "to-do" list.

Does your spare tire fit nicely in the well? I would like to eliminate the original 14" spare with a 15" rim and a lower profile tire. I know it won't quite equal the diameter of the 235/60 X 15.

Keep up the great work as always. 👍

Thanks Jack! I'm pretty happy with the fit of the spare tire. I actually had Sean close me in the trunk with a flashlight and a tape measure so I could see just what would fit. It was obvious that a 26" tire would not fit. I had bought a 15"x6" steel wheel when I first bought the car but I became so overwhelmed with the drivetrain swap that I never did anything with it. Recently I decided I wanted to button up the trunk and have something that was 'done' on the car. Since a 26" tire wouldn't fit, my first question was, what was the stock full size tire on a G-Body? The answer I came up with was a 205/70/14, which translates to an 8" wide, 25.3" tall tire. I already had a 15" rim so I went with a 195/65/15 which translates to a 7.7" wide, 25" tall tire. Based on my measurements, I knew I wanted to be around 25" tall for the height. When I got the tire mounted and balanced on my rim, it looked really small. Keep in mind I'm used to the 275/55/20's on my truck. The tire didn't look small as soon as I put it in the trunk. It doesn't need to be much bigger. The shorter tire will not be ideal if I get a flat on the back of the car with the posi but it will get me off the side of the road, out of harm's way. I'd rather hurt the posi from having two different sized tires on the back of the car rather than get killed on the side of the road. Thanks for the feedback and thanks for looking in on my build my friend.

That crossmember turned out nice. I couldn't have done it any better. I am anxious to see you tinted windows. Keep up the good work!

Thanks Zach. I posted a few pictures of the tinted windows (opera windows and rear window) in post number 399 on page 40. I didn't go very dark. I just went with 35%, which is the legal limit here for the front side windows. I wanted the tint on all the windows to match and I wanted it to be a little understated. I also want to be able to see out the back of this thing when I back it in at night and I'm not getting any younger. I've daily driven pickup trucks since 2000 and my first vehicle was an S10 Blazer so the small mirrors on the G-Body are an adjustment for me. Thanks for the kind words and thanks for following along.

Small update:

I went over to the storage last night and tried the J-bolt I fabbed up Sunday. It worked pretty well. I had to tweak it slightly. The spare is now secure in the trunk....

Next, I worked on the trunk finishing kit a little more. I trimmed the panel that goes against the tail panel on the passenger side to make it fit a little better. I added a little more Velcro here and there and tweaked the shape of a few of the panels. It's fitting pretty decent at this point. Then I went ahead and put the jacking decal on the deck lid. I took Hutch's advice in my other thread and put the sticker where I wanted it. I had mixed feelings on this but in the end I couldn't put the sticker on overlapping the inner structure webbing of the deck lid and I didn't like it turned sideways so I put it here....

I'm calling the trunk 'done' at this point. I'll have to be looking for something to do to go back to it. I'm happy to have a spare and a jack. I'm happy with how the trunk looks finished out.

After that I started looking at securing my lower shifter boot to the tunnel. A month or so back I bought a used lower boot from a 4th generation Camaro with a T5....

I've trimmed it and now it fits the base of my shifter very well...

This is probably the best picture I have right now showing the boot sitting on the tunnel. It fits the tunnel well....

When I was looking to use the 2nd gen Camaro console out of Sean's car, this boot was too wide but it fits under the Monte console quite well. Last night I went to the auto parts store and found some nice short, black automotive trim screws that will work nicely for securing the boot to the tunnel. I practiced on a piece of sheet metal to determine the best drill bit size and then I ran out of time. Tonight I will drill the holes and get the boot secured to the tunnel. I think I'm going to use strip caulk between the boot and the tunnel for insurance. Then I can put the dust boot over the shifter. You can see it in the picture above to the right of the shifter itself. It keeps trash out of the top of the shifter mechanism.

Beyond that, the immediate focus is to get the console mounting brackets attached, at least temporarily to the console so the console can be mocked up and the mounts attached to the tunnel. I didn't get any hardware when I bought the mounts and the console from Dixie. I did some looking online but didn't find a hardware kit specific to a Monte, so I bought one for an older GM application. I think it will work well. Based on the size of the holes in the mounts it takes two different sizes/types of fasteners to attach the console to its mounts.

That's it for now gents. I'll update as progress warrants. Thanks for following along.

Best,

--Jared

I went over to the storage last night and tried the J-bolt I fabbed up Sunday. It worked pretty well. I had to tweak it slightly. The spare is now secure in the trunk....

Next, I worked on the trunk finishing kit a little more. I trimmed the panel that goes against the tail panel on the passenger side to make it fit a little better. I added a little more Velcro here and there and tweaked the shape of a few of the panels. It's fitting pretty decent at this point. Then I went ahead and put the jacking decal on the deck lid. I took Hutch's advice in my other thread and put the sticker where I wanted it. I had mixed feelings on this but in the end I couldn't put the sticker on overlapping the inner structure webbing of the deck lid and I didn't like it turned sideways so I put it here....

I'm calling the trunk 'done' at this point. I'll have to be looking for something to do to go back to it. I'm happy to have a spare and a jack. I'm happy with how the trunk looks finished out.

After that I started looking at securing my lower shifter boot to the tunnel. A month or so back I bought a used lower boot from a 4th generation Camaro with a T5....

I've trimmed it and now it fits the base of my shifter very well...

This is probably the best picture I have right now showing the boot sitting on the tunnel. It fits the tunnel well....

When I was looking to use the 2nd gen Camaro console out of Sean's car, this boot was too wide but it fits under the Monte console quite well. Last night I went to the auto parts store and found some nice short, black automotive trim screws that will work nicely for securing the boot to the tunnel. I practiced on a piece of sheet metal to determine the best drill bit size and then I ran out of time. Tonight I will drill the holes and get the boot secured to the tunnel. I think I'm going to use strip caulk between the boot and the tunnel for insurance. Then I can put the dust boot over the shifter. You can see it in the picture above to the right of the shifter itself. It keeps trash out of the top of the shifter mechanism.

Beyond that, the immediate focus is to get the console mounting brackets attached, at least temporarily to the console so the console can be mocked up and the mounts attached to the tunnel. I didn't get any hardware when I bought the mounts and the console from Dixie. I did some looking online but didn't find a hardware kit specific to a Monte, so I bought one for an older GM application. I think it will work well. Based on the size of the holes in the mounts it takes two different sizes/types of fasteners to attach the console to its mounts.

That's it for now gents. I'll update as progress warrants. Thanks for following along.

Best,

--Jared

Similar threads

- Replies

- 4

- Views

- 206

- Replies

- 9

- Views

- 635

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.