That sounds right. I am thinking the new lock was not so good. Or the tumbler pins were not fitted properly. When re-keying a cylinder, even with the called-for correct pins, I often need to file the pins down flush with the cylinder. If the pins are even a tiny bit above or below the surface of the cylinder- problems. I think before you drill, try wiggling and inserting/removing the key while trying to turn the wing. Squirt some WD-40 in there. You may get lucky, it opens, and then you can get at it from inside.When this assembly was previously working, the key cylinder never turned independently of the wings. When the key was in, the wings would turn and glass would open. Turn wings opposite direction, gate would open. The locking function would happen by simply removing the key.

Tailgate lock

- Thread starter JD1964

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I’ve done a substantial amount of tinkering including lubricant, key wiggling and tapping area with a hammer while simultaneously trying to turn the wings. No go thus far

The interior panel is in pretty rough condition and I can see in there partially. It is already cracked around that opening and from the inside I can pull the plastic back and poke around in there. I tried to push down on the lever you see in the picture but it wouldn’t budge. If I knew exactly how I should be probing in there I might be able to get lucky and have it open

I found my 1983 FSM. The door will not unlock unless the glass is unlocked first. The optional electrical opener unlocks the glass, not the door. It also says in '83 they used plastic trim fasteners instead of screws. You could snap them off and get at the insides. What does yours have?

An idea for a backup release. If you remove the tag light you can reach up and feel a flat surface that could be drilled for access. A trip wire made from a bent coat hanger could hang down in that area with a loop. Then if you needed a back up to open you could remove the tag light, hook the loop and pull down to release the latch.

In an extreme case, could you unbolt the glass hinges from inside the car, then slim-jim the latches on either side of the gate. With help, then you could let the latched glass and gate down, prop it carefully and remove the inner panel.

Crafty thinking for sure. I can walk my brain through how that would work but I’d be terrified about breaking the glass. I’d probably drill and replace the lock before I did that.

Last edited:

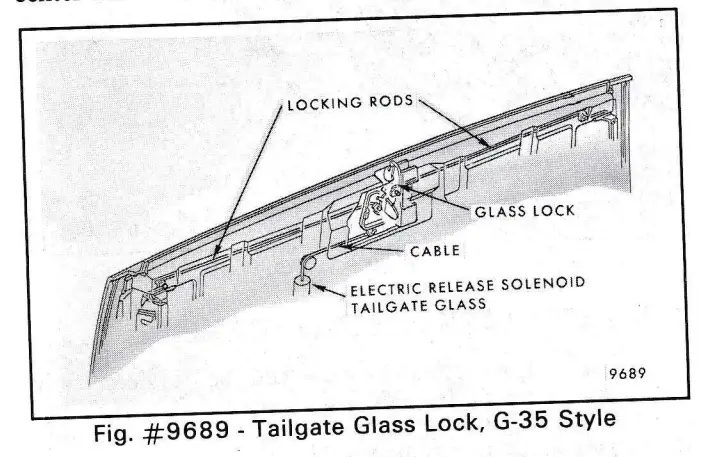

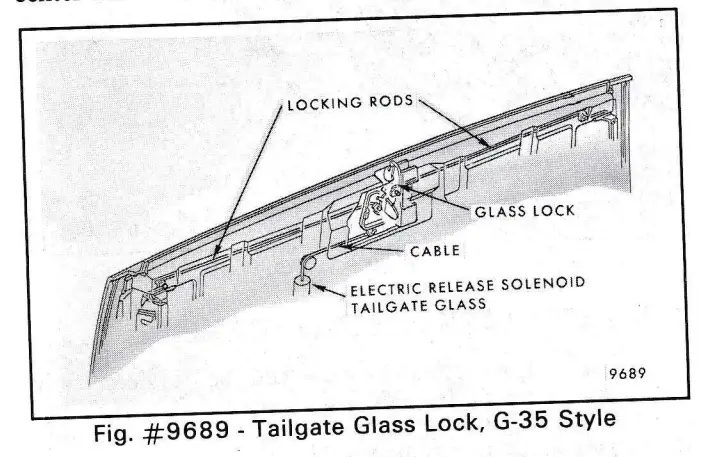

I also noticed that the provision for the electrical release uses a cable that goes to the bottom of the glass latch. If you can peer in there, look for a hole at the bottom where that cable would go if it had that option. That is your way to unlatch the glass. You could probably get a bent coat hanger with a hook at the end to engage that hole.

My interior panel is in bad enough condition and it’s also covered with a fabric which was adhered with weatherstrip adhesive I think. I can pull the fabric off, cut an access opening in the panel to get it open. Then I can make a patch panel and cover it back up with the fabric. Seriously, the panel is in bad enough condition that cutting it is no big deal really.

If I can get in there and get it apart I might be able to fix the lock cylinder without spending any money. After re-adhering the fabric it would not look any different than it already does

If I can get in there and get it apart I might be able to fix the lock cylinder without spending any money. After re-adhering the fabric it would not look any different than it already does

I’ll try that, thanksI also noticed that the provision for the electrical release uses a cable that goes to the bottom of the glass latch. If you can peer in there, look for a hole at the bottom where that cable would go if it had that option. That is your way to unlatch the glass. You could probably get a bent coat hanger with a hook at the end to engage that hole. View attachment 234499

Looking at the rear hatch glass handle. You could try unbolting the handle from the glass (two flat hexed 14mm ? bolts) and lift the hatch for better access.

You then could work inside the tailgate to release the tailgate lock.

I forgot about the small cable that attaches to the release solenoid. As Mark suggested, that might be a good place to grab hold of the latch and release it.

I later added the tailgate lock release solenoid to my car, which wasn't equipped with it originally.

or, if you can access the inside of the tailgate, you can remove the lock assembly by releasing the clip and you can then gain access thru the outside with a large screw driver to unlatch the tailgate.

You then could work inside the tailgate to release the tailgate lock.

I forgot about the small cable that attaches to the release solenoid. As Mark suggested, that might be a good place to grab hold of the latch and release it.

I later added the tailgate lock release solenoid to my car, which wasn't equipped with it originally.

or, if you can access the inside of the tailgate, you can remove the lock assembly by releasing the clip and you can then gain access thru the outside with a large screw driver to unlatch the tailgate.

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 4

- Views

- 158

- Replies

- 2

- Views

- 175

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.