Texas82GP's GMT900

- Thread starter Texas82GP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I don't like how the 6 speed trucks drive. I've driven/ridden in half ton and 3/4 ton variants. It just isn't for me. In traffic (which I live in), it seems like you are perpetually going too fast for 2nd and too slow for 3rd and the transmission is constantly hunting. I never considered a 6 speed (automatic) swap. I guess for 43, I'm stodgy and like the good old 4 speed automatic.Any reason you went with a 80e vs a 6L80e considering you have an NNBS pickup?

I know not all 09+ NNBS GM's got a 6 speed but since it was a factory option just curious your reasoning.

I've heard the same. I work for a Land Surveying company. We have 12 trucks running the 6L90 ranging between 2009 and 2016. To be fair, we haven't had a bit of trouble.I can't answer for the OP but from my reading-light at that-the 6L80e has more problems than the 80e, and the gear spread isn't much different. Ironically I learned this when doing the research for the OD transmission I want to end up with in the aerocoupe.

That's definitely taking place Mike. Thanks again for your advice on the converter and your comments about the driveshaft, flexplate, and swap harness in my other thread. I appreciate the help.Uh oh! I am seeing a little bit of "since I am in there anyway..." going on.

Good ol' project creep. 😉

That's a great looking truck. I had an 89 regular cab long bed. It had the 305 TBI as well. I always wanted to put something better in it but I was a poor 20 something back then. I'd like to have another GMT400. I'd want a 95 up though. I like the later dash better.I really like shortbed, regular cab trucks. If i could even kind of justify one again I would totally do it. Sold mine a couple years ago but it only had the lowly 305 TBI engine and I didn't want to swap it to something good.View attachment 107125

Thanks Greg. Glad to have you aboard.Nice

Thanks. Glad to have you along for the ride. Yeah, they have rust beat down here. When the roads freeze, we stay home. This truck has sat outside virtually every day I've had it since new. Down here if they aren't sitting around, especially on unpaved ground, they don't rust. Thanks for the compliment and the reassurance I'm headed in the right direction. I appreciate it.You're going to love the 80E. Good decision. Nice looking truck! The tunnel also looks clean. That Texas weather is really hard on vehicles. Keep us posted.

Looking to see how this one works out for you Jared. Knowing your perseverance and attention to detail, I expect to work out well.

See, I don't care for the '95 and newer dash/interior. Always broken hockey stick interior door handles, the speed sensitive power steering thing behind the steering wheel craps out and goes full John Deere, no return to center, ultra vague feeling. Radio is in a better place though. Hideous steering wheel too.

That car under the cover in the back looks familiar...🤔, I just don't remember from where.

My wife's *cough* Toyota has a 6 speed. It's great until you fill the car with people and gear or try to tow, then it hunts like mad. I usually just slap the shifter left into 4 and it calms right down. 4 speeds solve everything.

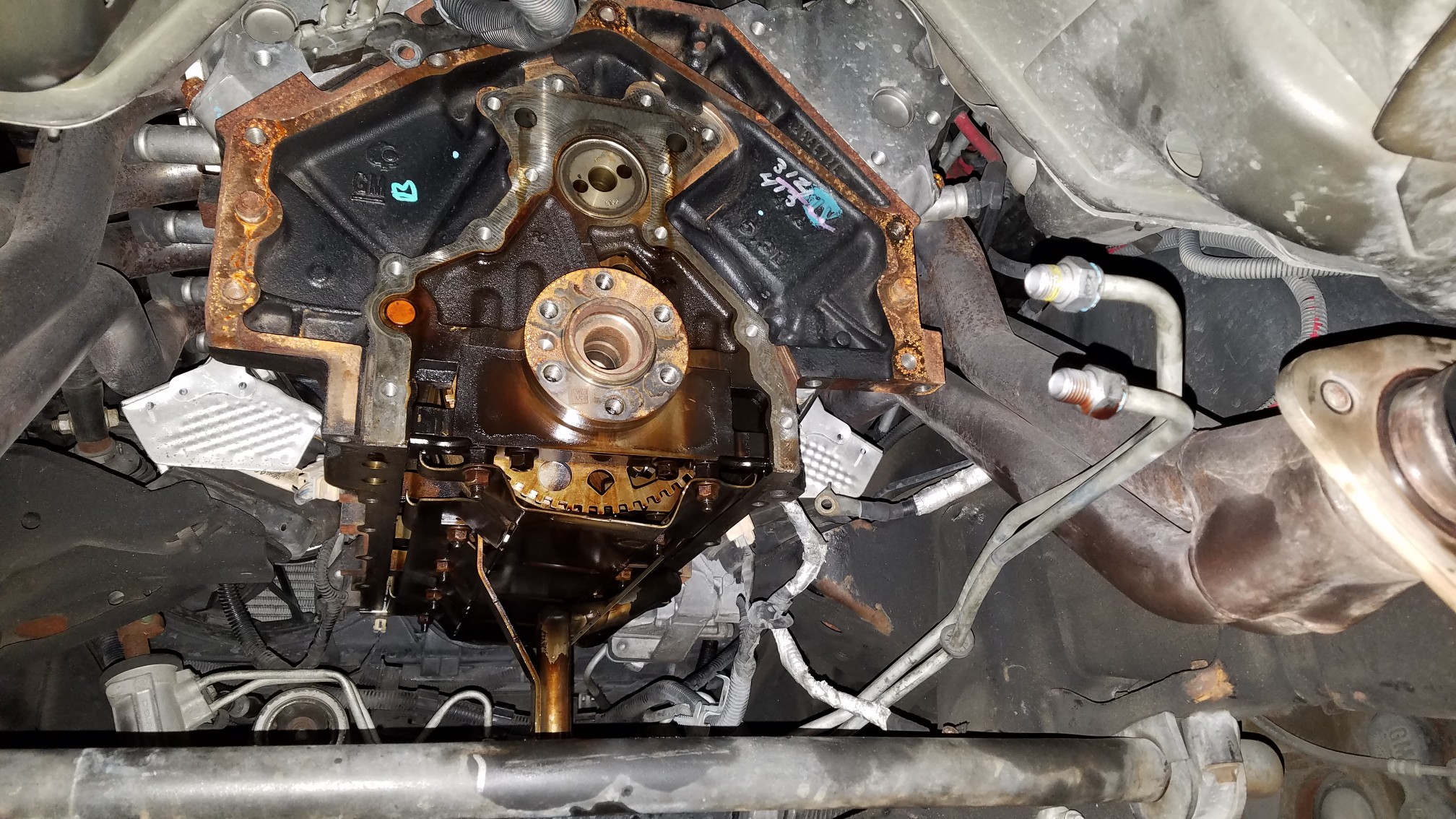

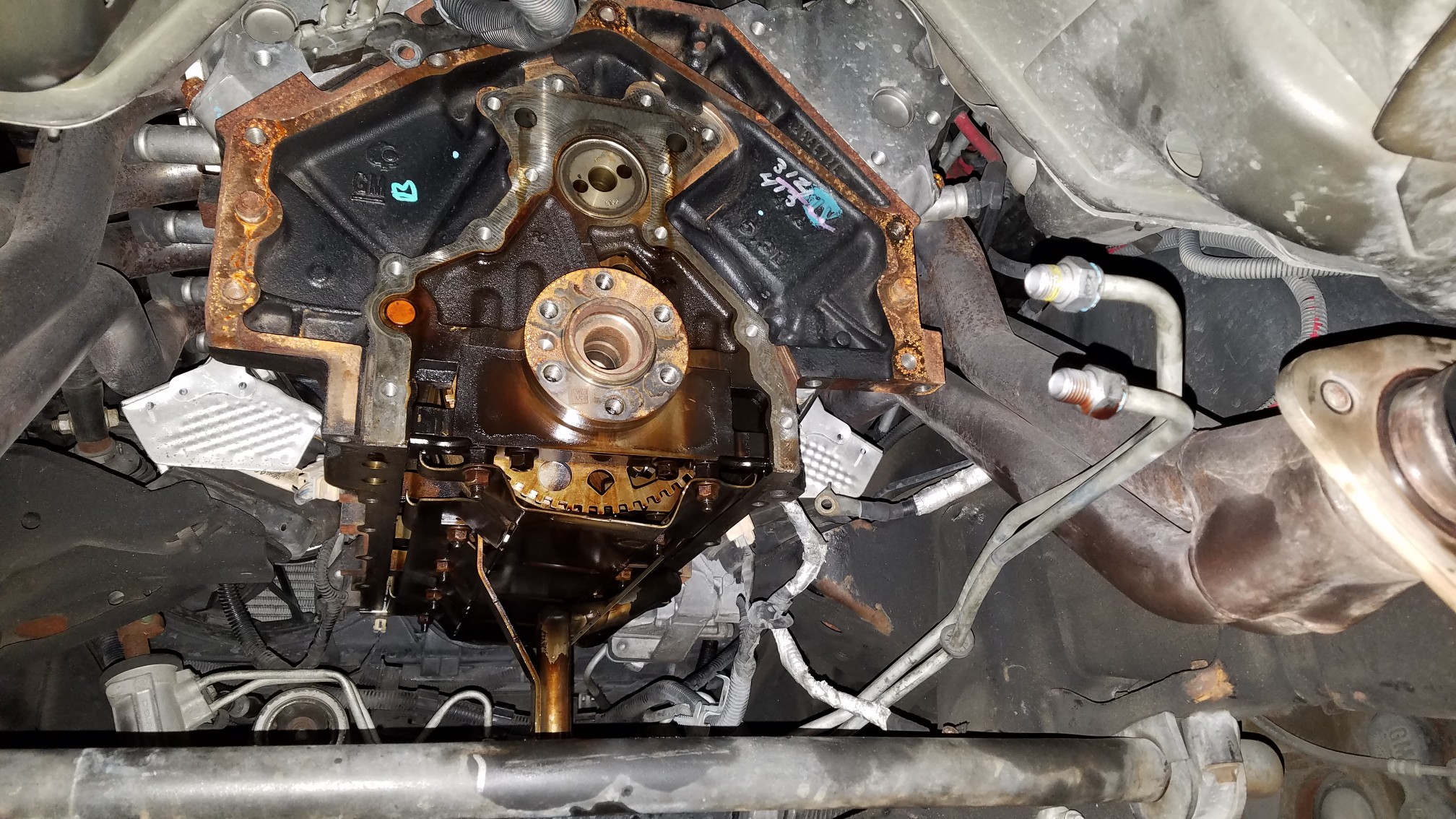

Made some progress on the swap over the weekend. Dad and I went over to the storage Saturday morning. The main goal was to replace the rear main seal on the 5.3. It might have been possible to replace the seal without pulling the pan or the rear cover but I elected to pull both and do both gaskets while I'm in there and it is this far apart. Here's a look with everything apart. Notice the engine crossmember is out under the pan. This was a good design on GM's part (for once).....

Dad cleaned up the rear cover for me and I cleaned up the pan (inside and out). It went back together nice. I didn't have the special tool to align the rear cover so left the plastic insert in the new rear seal. I used it to guide the seal and cover on. Then I put all the bolts in and just left them a 1/4 turn from snug so the cover could still move. Then I put on the pan and snugged all the bolts. Then I torqued the rear cover. Next, I broke the pan back loose and installed the bellhousing for the 65E to align the pan with the rear flange of the block. Everything got torqued to spec. I hope the new seal doesn't leak. Here's a look with everything cleaned up and mostly back together....

Believe it or not, this took most of the day. I finished up by installing the new 6.0/4L80E style flexplate and torqueing the bolts...

Sunday, I was on my own. I got over to the storage around 10, after doing chores at the house. My goal was to test fit the transmission for a variety of reasons. Among them: to test fitment, to measure for the crossmember modifications, to look at transmission cooler line modifications, to see if the exhaust is going to work, and I wanted to be able to pull the pan and look inside the transmission.

I got started by pulling stuff off of the 85E including, the vent hose, the shift cable bracket, the heat shield, the "gear shift position switch" (not sure what its proper name is), the lower bellhousing cover and the torque converter. I was surprised to find that the torque converter didn't seem to have any fluid in it. I got the transmission on the jack and got it under the truck. I started jacking it up into position and it wasn't going to go. The 'ear' on the passenger side was interfering with the header big time.

I pulled it back out. The truck is sitting pretty high on the stands but I still have to jack the front up quite a bit to be able to roll the transmission in and out from under the truck on the jack. I decided I would trim the ears on both sides even though I didn't really need to on the driver's side. I did this for symmetry and perhaps the added clearance will help me sometime in the future when I'm under there working on it. I started by cleaning up the lower bellhousing cover and then looking at what I could trim off of it without weakening or hacking it.....

Then I installed the pan on the transmission to mark the cut line on it....

Then I pulled the cover and made the cuts on the transmission. I made all these cuts with a fiberglass reinforced cutoff wheel in my HF rotary tool. I'm sure it wasn't the best way to do it but it was what I had on hand at the storage. A hacksaw might have been cleaner. Still, I think the cuts turned out pretty good....

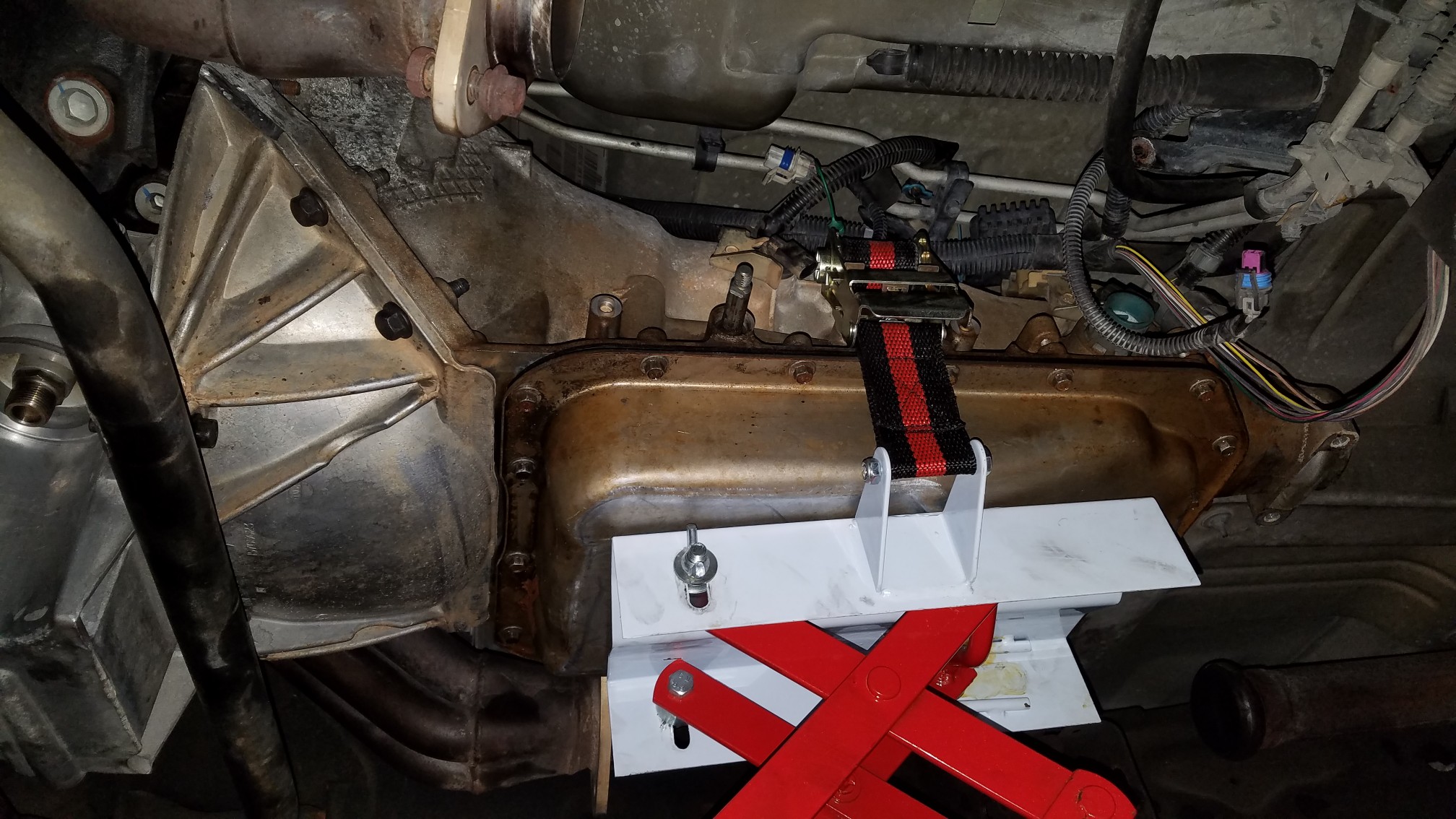

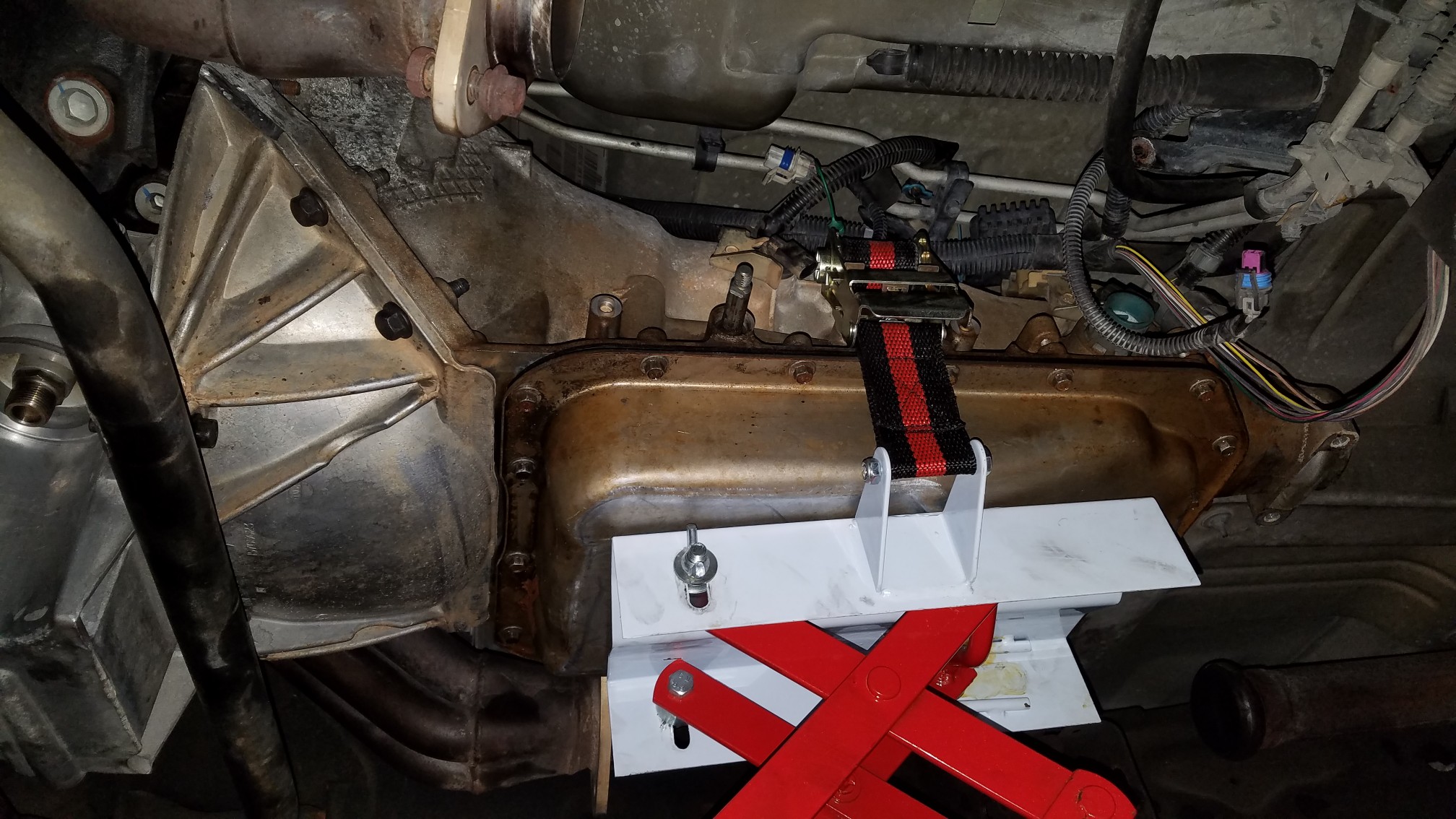

Moments after taking the picture above, I did something stupid. I wound the jack down part way. I wanted to turn the transmission around on the jack so the ratchet would be at the tail (as intended) and so I could use the pitch adjustment to match up to the engine better. Half way down or so, I stopped to undo the ratcheting strap while it was still up part way since it was easier. Mistake. I ended up with the transmission spilling off of the jack towards me. There was no damage to the transmission but I took a little. I was able to get out of the way pretty much but I got a decent gash on the heel of my left hand, below the thumb. I think one of the cut off cooler lines got me. The gash is only about a 1/2" long but it must have been a little deep because it was tough to get it to stop bleeding. I was prepared. I have hydrogen peroxide, alcohol wipes, triple-antibiotic ointment and band-aids over at the storage, not to mention soap and bottled water. I got it cleaned up and dressed. It took the wind out of my sails for a few minutes. The hand is bruised as well so my enthusiasm waned. I picked up all the tools and got everything straightened up and organized. Then I thought to myself, "Well, I didn't get to where I wanted to". Then I got mad. I decided "F. U. hand". I picked that heavy b*tch up and put it on the transmission jack. I got it back under the truck and jacked it up into place. I was babying my left hand. Still, I got it up in there. It went relatively easily considering I was one handed and by myself. Here it is bolted in place...

That's a beefy unit and I have a new found respect for it. That is pretty much where I called it for the day. My hand was pretty pissed and it was getting cold in the storage (not cold to our friends up north but cold to a Houstonian). I had forgot to bring another big jack stand from the house. My intention is to put it under the tailhousing of the 85E so I can pull the transmission jack out. Then I want to pull the pan and take a peek inside.

The next big push will be towards doing the crossmember modifications. I have all the measurements and a buddy of mine, who is a better welder than me and has a bigger welder is going to help me. Here is a look at what needs to happen. The center section of the crossmember needs to move back 5-3/4"....

Once I get it on the crossmember, I can install the deep aluminum pan I bought for it and can see if the exhaust will go on or if it needs to be modified. I have a plan on what to do with this end of the cooler lines. Between now and getting the crossmember in, I'm going to work towards figuring out what I'm going to do on the cooler end. The truck has the auxiliary transmission cooler that a truck with the towing package would have. I put it in when I put the higher stall speed torque converter in, at the same time I did the cam swap. It proved to not be big enough though. I have a much larger aftermarket cooler to go in its place. I'll be working towards figuring out mounting and plumbing it.

That's it for now gents. Thanks for the likes and responses. I'll update as progress warrants. Until then....

Best,

Jared

Dad cleaned up the rear cover for me and I cleaned up the pan (inside and out). It went back together nice. I didn't have the special tool to align the rear cover so left the plastic insert in the new rear seal. I used it to guide the seal and cover on. Then I put all the bolts in and just left them a 1/4 turn from snug so the cover could still move. Then I put on the pan and snugged all the bolts. Then I torqued the rear cover. Next, I broke the pan back loose and installed the bellhousing for the 65E to align the pan with the rear flange of the block. Everything got torqued to spec. I hope the new seal doesn't leak. Here's a look with everything cleaned up and mostly back together....

Believe it or not, this took most of the day. I finished up by installing the new 6.0/4L80E style flexplate and torqueing the bolts...

Sunday, I was on my own. I got over to the storage around 10, after doing chores at the house. My goal was to test fit the transmission for a variety of reasons. Among them: to test fitment, to measure for the crossmember modifications, to look at transmission cooler line modifications, to see if the exhaust is going to work, and I wanted to be able to pull the pan and look inside the transmission.

I got started by pulling stuff off of the 85E including, the vent hose, the shift cable bracket, the heat shield, the "gear shift position switch" (not sure what its proper name is), the lower bellhousing cover and the torque converter. I was surprised to find that the torque converter didn't seem to have any fluid in it. I got the transmission on the jack and got it under the truck. I started jacking it up into position and it wasn't going to go. The 'ear' on the passenger side was interfering with the header big time.

I pulled it back out. The truck is sitting pretty high on the stands but I still have to jack the front up quite a bit to be able to roll the transmission in and out from under the truck on the jack. I decided I would trim the ears on both sides even though I didn't really need to on the driver's side. I did this for symmetry and perhaps the added clearance will help me sometime in the future when I'm under there working on it. I started by cleaning up the lower bellhousing cover and then looking at what I could trim off of it without weakening or hacking it.....

Then I installed the pan on the transmission to mark the cut line on it....

Then I pulled the cover and made the cuts on the transmission. I made all these cuts with a fiberglass reinforced cutoff wheel in my HF rotary tool. I'm sure it wasn't the best way to do it but it was what I had on hand at the storage. A hacksaw might have been cleaner. Still, I think the cuts turned out pretty good....

Moments after taking the picture above, I did something stupid. I wound the jack down part way. I wanted to turn the transmission around on the jack so the ratchet would be at the tail (as intended) and so I could use the pitch adjustment to match up to the engine better. Half way down or so, I stopped to undo the ratcheting strap while it was still up part way since it was easier. Mistake. I ended up with the transmission spilling off of the jack towards me. There was no damage to the transmission but I took a little. I was able to get out of the way pretty much but I got a decent gash on the heel of my left hand, below the thumb. I think one of the cut off cooler lines got me. The gash is only about a 1/2" long but it must have been a little deep because it was tough to get it to stop bleeding. I was prepared. I have hydrogen peroxide, alcohol wipes, triple-antibiotic ointment and band-aids over at the storage, not to mention soap and bottled water. I got it cleaned up and dressed. It took the wind out of my sails for a few minutes. The hand is bruised as well so my enthusiasm waned. I picked up all the tools and got everything straightened up and organized. Then I thought to myself, "Well, I didn't get to where I wanted to". Then I got mad. I decided "F. U. hand". I picked that heavy b*tch up and put it on the transmission jack. I got it back under the truck and jacked it up into place. I was babying my left hand. Still, I got it up in there. It went relatively easily considering I was one handed and by myself. Here it is bolted in place...

That's a beefy unit and I have a new found respect for it. That is pretty much where I called it for the day. My hand was pretty pissed and it was getting cold in the storage (not cold to our friends up north but cold to a Houstonian). I had forgot to bring another big jack stand from the house. My intention is to put it under the tailhousing of the 85E so I can pull the transmission jack out. Then I want to pull the pan and take a peek inside.

The next big push will be towards doing the crossmember modifications. I have all the measurements and a buddy of mine, who is a better welder than me and has a bigger welder is going to help me. Here is a look at what needs to happen. The center section of the crossmember needs to move back 5-3/4"....

Once I get it on the crossmember, I can install the deep aluminum pan I bought for it and can see if the exhaust will go on or if it needs to be modified. I have a plan on what to do with this end of the cooler lines. Between now and getting the crossmember in, I'm going to work towards figuring out what I'm going to do on the cooler end. The truck has the auxiliary transmission cooler that a truck with the towing package would have. I put it in when I put the higher stall speed torque converter in, at the same time I did the cam swap. It proved to not be big enough though. I have a much larger aftermarket cooler to go in its place. I'll be working towards figuring out mounting and plumbing it.

That's it for now gents. Thanks for the likes and responses. I'll update as progress warrants. Until then....

Best,

Jared

Last edited:

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.