Made some more progress on the swap, though it's going slower than I would like. I got the crossmember painted up one evening last week....

I didn't work on the truck on Saturday. There was too much other stuff going on. I had new glasses to pick up that day so I made Saturday an all chores day. I did buy a new tool box for the storage. It was on sale at Harbor Freight. I'm thinking once I buy the top box, this will be last toolbox I buy. We'll see....

Sean took me to Harbor Freight to buy it. They loaded it in his pickup with a fork lift. It wasn't that fun unloading it. It doesn't look like 300 pounds. It's really well built. That picture was actually taken Sunday morning. That heater is my friend's Mr. Heater Big Buddy that he lent me to try. It worked really well. I'll be getting one for next winter. Sunday morning I did work on the swap. First I got the crossmember in and got the transmission sitting on it. Everything lines up perfectly....

Next, I pulled the transmission pan to get a look inside.....

It looks really clean. Obviously the salvage yard pulled the pan and drained the fluid before they shipped it. Also, they drained the torque converter. What I can't decide is if they cleaned out the pan. I'm guessing yes since there was no clutch mud and nothing on the magnet. What do you guys think? Can it look this good with 118k miles on it? It was behind a diesel in a totally stock application.

Is that a stock pan gasket with the torque limiters? I'm wondering if the transmission got serviced recently (like at 100k miles) and that's why it looks so good.

Next, I wanted to fit the deep aluminum pan I bought. The stock pan was a little rough and I wanted a drain plug for easier maintenance. Also, I wanted the extra fluid capacity. It's a nice piece, made by PML. Made in the U.S.A.......

Here's a look at the pan installed (just hanging by a few bolts) on the transmission. No clearance issues with the crossmember. All bolts are accessible with the crossmember in....

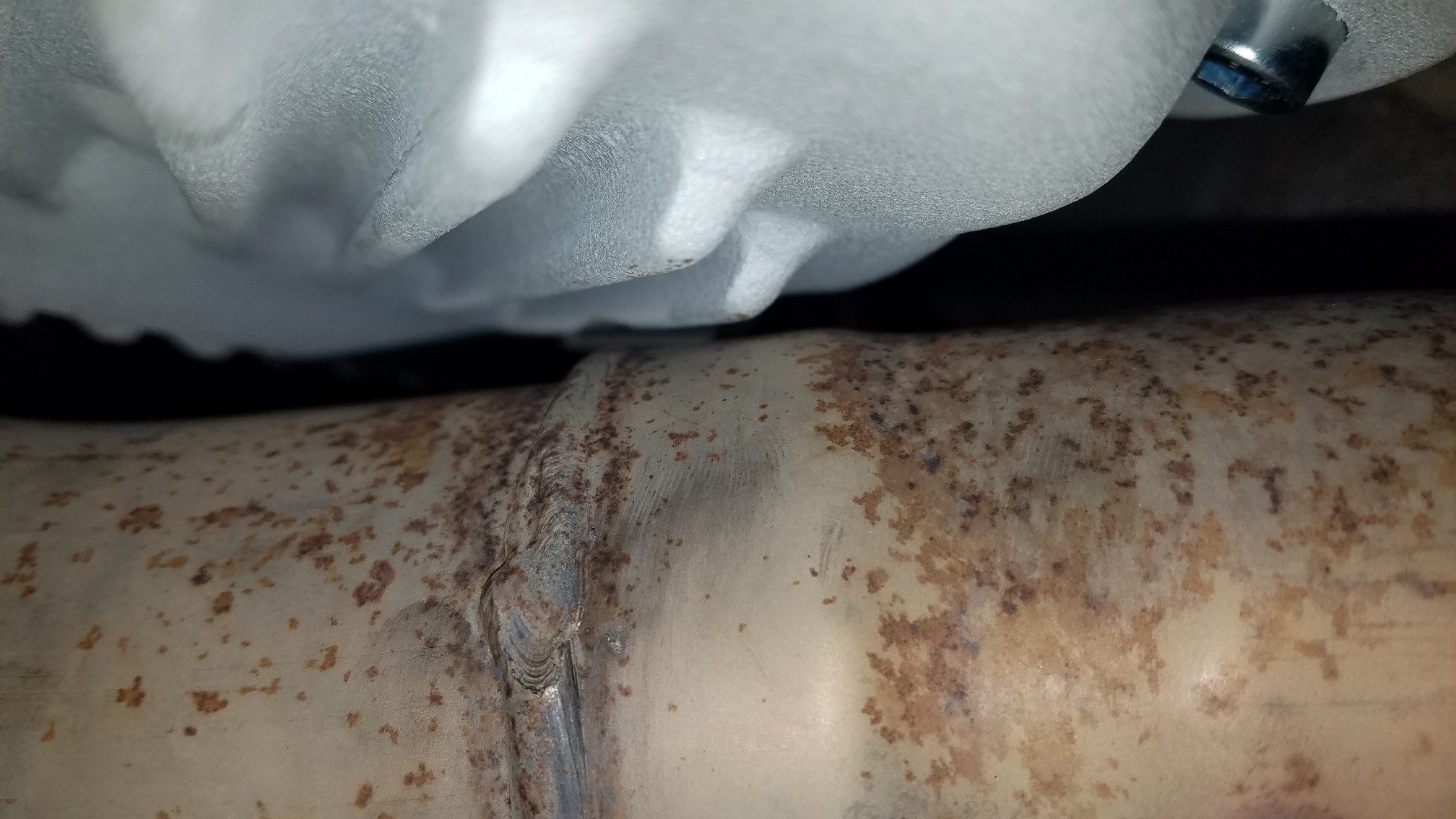

I'm going to have to paint it or clear it. It was getting dirty just hanging it under there. Next, I wanted to see if the mid section of my exhaust system was going to work, and if not, what I was going to need to modify it or rebuild it to make it work. This was really my main goal for the weekend. To my surprise, the exhaust fits, and fits better now with the modified crossmember than it ever did before....

I had long had trouble with the inside curve of the Y rubbing on the transmission crossmember. You can see the mark in this picture. Now, with that section of the crossmember moved back 5-3/4", that is no longer a problem.....

A different angle....

And another, lots of clearance on the crossmember. The pipe is a little tight on one of the fins on the transmission pan. I may grind some of it off.....

Once I got the exhaust all tight and realized it was going to fit without modification, I was in a bit of a quandary as to what to do next, so I picked up all the tools. I entertained thoughts of putting in the driveshaft but I know it is going to fit, so why? At this point everything needs to come back out (I didn't have a torque converter when the transmission went in) and I need to decide if I'm going to have the transmission overhauled/upgraded or if I'm going to just put a shift kit in it myself and go with it.

I've gotten a lot of advice on here to just put a shift kit in it and go with it. From a financial standpoint, I like that thinking. I'm just having trouble with going with a transmission that has 118k miles on it. That may be an old way of thinking though. My engine only makes maybe 400 ft. lbs., which is well below the transmission's factory rated capacity of 460 ft. lbs. in a much heavier vehicle. I'd be satisfied with getting 100k miles out of this install behind the 5.3. That would put 270k miles total on the 5.3 and would buy me about 6.5 years. I'm thinking that if I were to build something with substantially more torque before then, I could freshen up the 85E at that time. The only thing that scares me is I think the salvage yard cleaned out the pan so I really don't know what I have. It has to come back out anyway so maybe I should have it freshened up? What do you guys think? Any strong opinions?

I'm going to try to get over there weeknights this week and work towards getting it all pulled back out but we're busy at work so we'll see. That may all happen on Saturday. Moving forward, here is what is left:

- Transmission lines

- Replace transmission cooler

- Re-pin main transmission wiring connector (two wires)

- Add wiring for second speed sensor, run to TCM and pin into TCM connector

- Tuning

I'm going to do the wiring, cooler lines and cooler while the transmission is out.

That's it for now gents. I'll update when there is progress to report. Thanks in advance for your feedback requested above. Thanks for following along and thanks for the likes.

Best,

Jared