This is escalating quickly.... I likey!

BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Very, very cool. Someone was a good boy in '22.

Meh, no more or less than any other time/year. Just in a much better financial situation finally to be able to afford some of the nicer additions and amenities.

Very nice Donovan! I can't wait to see the work that these tools will enable you to do. That English wheel looks pretty cool. Is that a Princess Auto product?

Thanks Jeff. I’m obviously very excited about these too. Using the English wheel will be a very steep learning curve, but will be worth it if I can get half-azzed proficient with it.

It is indeed a Princess Auto brand. I drool over the much larger ones at KMS Tools every time I go in there, but at 2K +, they’re very expensive and way overkill for what I’d do with them. Especially being a novice with one, so this much smaller one seems like a good option to get my feet wet.

Oh hell yeah. Can't wait to see what you have planned with the dimple dies! Also what you can cook up with an English wheel.

Agreed! I don’t yet have any projects planned for the English wheel, but you never know. I could come across something that it would be the right tool for the job for. Who knows, maybe something on the planned smooth front firewall will call for the use of the English wheel.

As for the dimple dies, I’m pretty sure now that I have some I’ll be able to find all kinds of cool areas and things to use them for!

This is escalating quickly.... I likey!

Absolutely, but I (so far) regret nothing. I really enjoy the custom fabrication aspect of this hobby, so investing in these tools only makes sense to me. And as I outgrow things like the entry level English wheel, I can always sell them and upgrade as I go.

ahh get ready to start smashing your finger tips while learning the English wheel. But I got a feeling you will master it here pretty quickly!Posting this in The Juggernaut thread and not in the “What did you do to your shop today” thread, because I’m going to be trying to step up my fabrication game in 2023 BIG TIME.

Spent a lot of $$$ this holiday break, and have got some really cool new toys with more on the way. Already picked up a full set of dimple dies, in sizes of 1/2”, 3/4”, 1”, 1 1/4”, 1 1/2”, and 1 3/4”…

View attachment 213611

View attachment 213609

View attachment 213610

…and found a really good deal on an entry level English wheel I can use in my vise:

View attachment 213612

View attachment 213613

View attachment 213614

Looks like I’m going to be learning how to wheel!

I was going to stop there, but decided this morning to pull the trigger on a couple more things. Got onto the @eastwood.com website, and ordered a powered drive system for my bead roller…

View attachment 213616

View attachment 213617

…as well as a table for it:

View attachment 213615

These two accessories will make my bead rolling operations much easier and more efficient/comfortable/convenient. No more having to recruit a second person for anything, I’m especially stoked about the drive motor. Speed adjustable, and foot pedal controlled, this is going to be a huge game changer.

So excited about these new tools, and can’t wait to start putting them to use!

Can you say hand made fender flares? 🤩 Can't wait to see you excell with the new tools Donovan!

Decided to tackle a project a little different than what I’ve been working on lately (can’t reveal that just yet, it’s still a work in progress), figuring out the flexible fuel lines between the tank and hard lines.

This is one of the last things that needs to be addressed before the body comes off the frame, so no time like the present to get after it.

Last weekend, Mike and I got underneath the car and put our heads together to come up with a plan. Specifically the routing of said flexible lines. I don’t know if I covered it in detail way back when, but I purchased and installed an Aeromotive Phantom 340 universal in-tank fuel pump and pickup system. I had also bought a brand new Spectra fuel tank, and had already mated the two together. The stock sending unit is the only thing that still needs a little tweaking, I have to manipulate the float arm slightly so that it clears the Aeromotive assembly.

Enough backstory, the tank has been installed up in place since the Aeromotive install, and bits of mock-up stainless hardline were placed running towards the rear of the car. It was time to decide where the hardlines should terminate, and the flexible ones should start to connect to the top of the tank. The connections at the Aeromotive unit are return, vent, and supply, in that order, from left to right when looking at it from the front of the tank underneath the car.

I’m running half inch -8AN supply and return lines, while the vent is -6AN. Mike and I figured out the best routing of the two -8 lines, but the vent direct in the middle of the two was kind of a PITA. But let’s start at where the stainless hardlines are going to terminate, shall we?

These are the two dummy mock-up pieces we made and clamped into place. The outboard one is supply, the inboard one is return.

A couple different angles of it, so you can get a better idea:

I’m currently waiting on a Summit order to arrive, it’ll have the male -8AN hose ends and the 5/8” Made 4 You nylon clamps on it that I need to terminate and firmly attach the hoses.

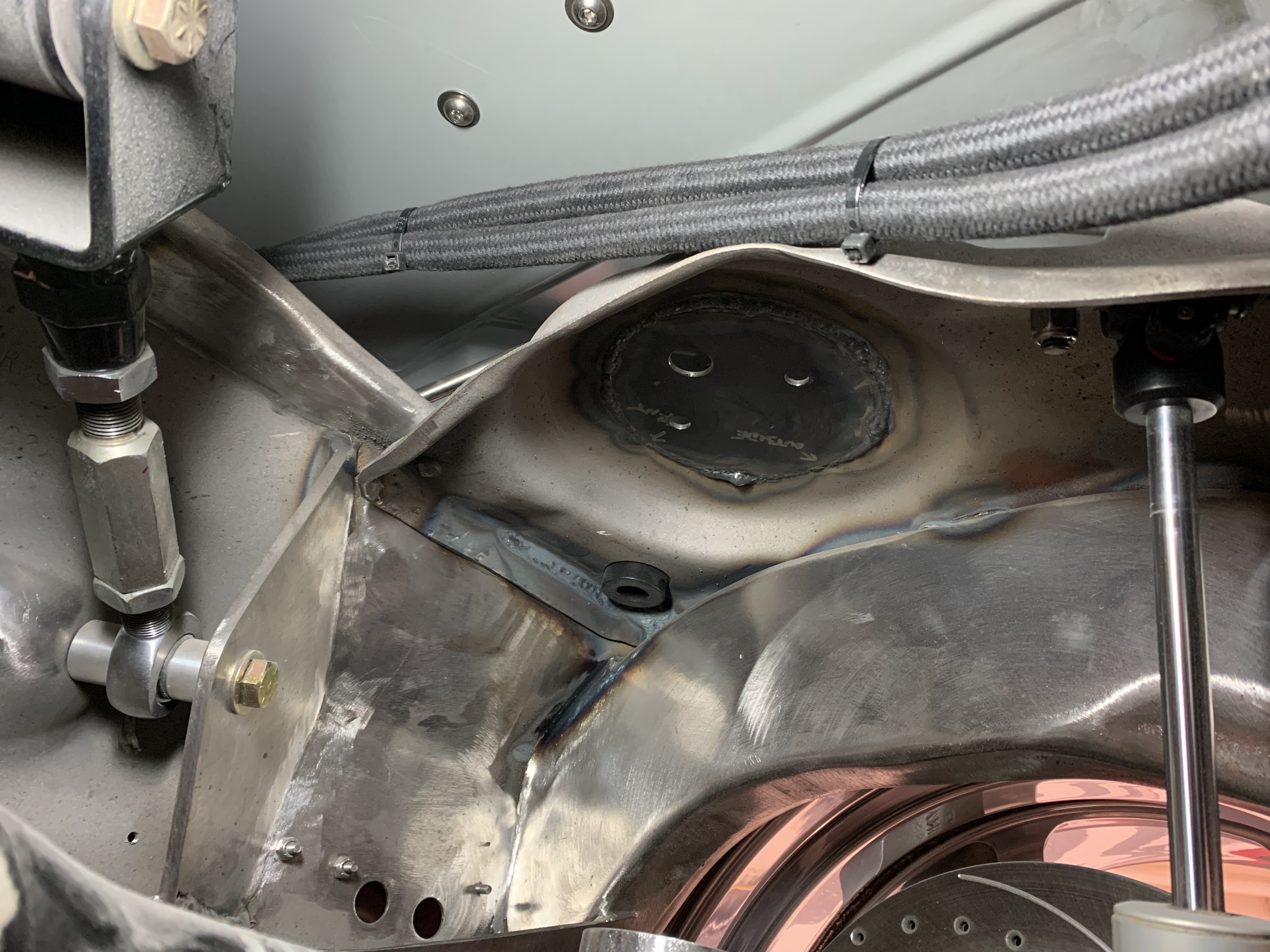

From this point, the hoses are routed over top of the rear crossmember. This picture is taken from behind the crossmember, looking forward now:

The zip ties are temporary, again, until I get the Summit order later next week.

Once over the crossmember, they continue on to the trunk floor kickup, then neatly tuck behind the passenger’s side tank strap.

The connections to the tank are as clean as I could make them with the stupid vent port right in the middle. I think I did not too bad.

The vent hose I routed over towards the driver’s side, and across the top of the tank inside a groove that ran the full length of the tank.

I also spaced the front of the tank down slightly, for a little additional clearance to the hose end fittings. It wasn’t completely necessary, but it makes me feel a little better about it. I simply cut two pieces of 1/2” stainless tube, placed them between the body tabs and the tank straps, and ran the bolts through them. No pictures as I didn’t feel it was really necessary.

That brings me up to today. I now had to drop the rear of the tank to give me access to the top of the filler neck where I planned to route the vent line into.

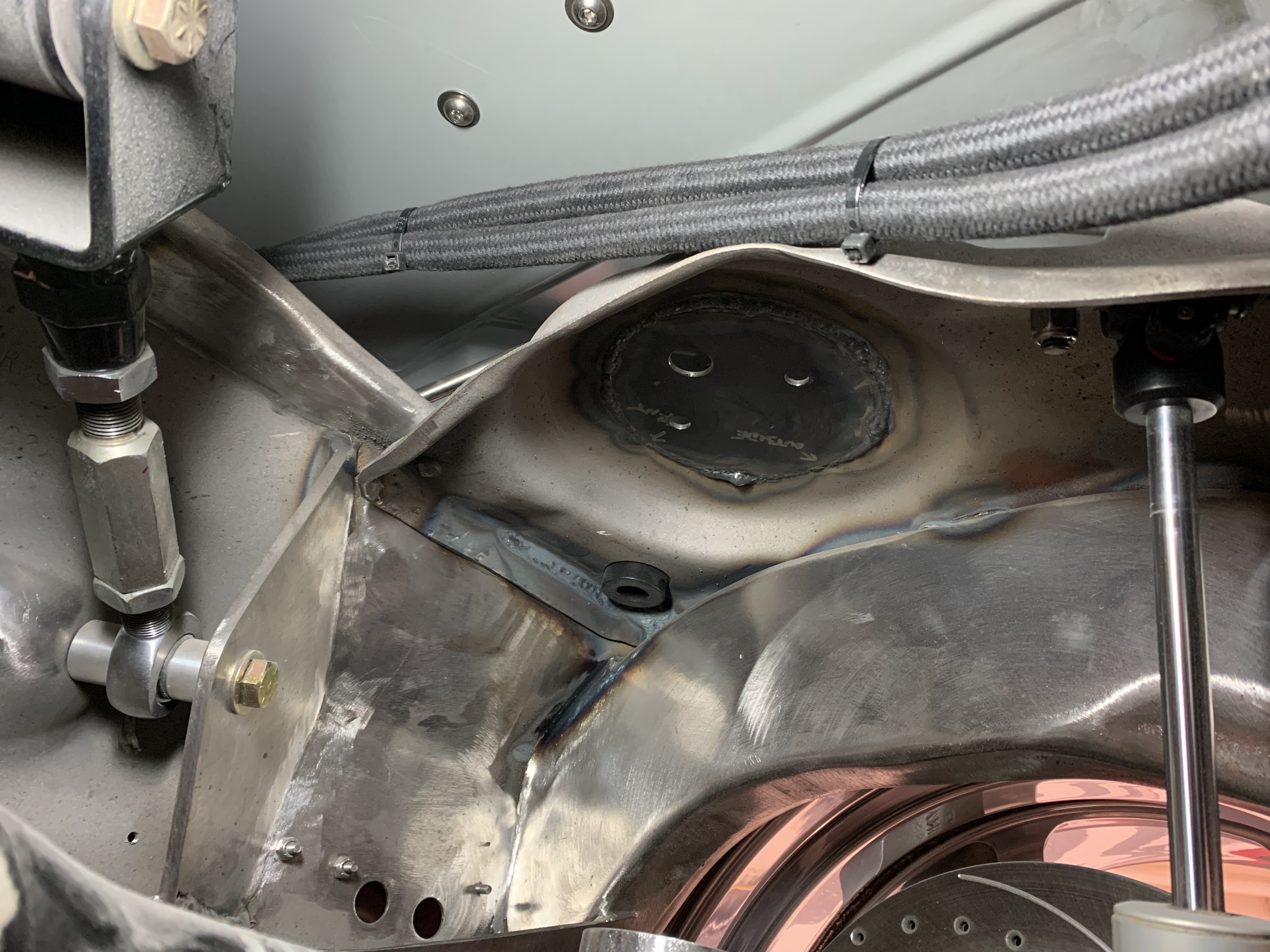

Here’s a good look at the top of the Aeromotive unit in place. Note it’s positioned at the deepest part of the tank, in the deep wide recess, and right by the front for good access to the hose connections.

Here you can also see the routing of the vent line in the front to back groove:

Next was to mark out a location for the vent line fitting, I chose the very top and as close to the top of the filler neck as I could get.

I actually had to change the location slightly after that picture was taken, this point wasn’t far enough back from the filler neck flapper when it was in the “up” position. I moved it down slightly, just enough for it to clear afterwards.

Time to make a hole, and cut some threads. A 1/4” NPT tap did the trick.

I purposely chose NPT (National Pipe Taper), I had briefly considered ORB (O-Ring Boss), but decided against it for a couple of reasons. Firstly, because I didn’t trust the O-ring to seal fully on a round surface, and secondly because I don’t have a tap for the fine thread ORB threads.

A generous application of Loctite 567 thread sealer, and the -6AN 90 got tightened down in the filler neck. I cut the NPT threads quite deep to keep the 90 degree fitting as low profile as possible.

After lifting the back of the tank back up into place, I adjusted the orientation of the 90 until I could comfortably thread the hose fitting on it.

Cut the vent line to length, assemble the hose end, feed it back through above the tank, and connect the ends. Done deal.

It’s tucked up nice and high, out of the way of everything, and should work nicely. Once I get the -8 male hose ends and clamps from Summit next week, I can wrap this up entirely.

The other thing that I bought on that Summit order was Aeromotive’s deluxe heavy duty fuel pump wiring kit. When it arrives, I’ll drop the tank again to make the wiring connections to the pickup, and have another look at tweaking that float arm so I can install the factory pickup (which is now only needed for the float for the gas gauge).

All for now gents, till next week.

D.

This is one of the last things that needs to be addressed before the body comes off the frame, so no time like the present to get after it.

Last weekend, Mike and I got underneath the car and put our heads together to come up with a plan. Specifically the routing of said flexible lines. I don’t know if I covered it in detail way back when, but I purchased and installed an Aeromotive Phantom 340 universal in-tank fuel pump and pickup system. I had also bought a brand new Spectra fuel tank, and had already mated the two together. The stock sending unit is the only thing that still needs a little tweaking, I have to manipulate the float arm slightly so that it clears the Aeromotive assembly.

Enough backstory, the tank has been installed up in place since the Aeromotive install, and bits of mock-up stainless hardline were placed running towards the rear of the car. It was time to decide where the hardlines should terminate, and the flexible ones should start to connect to the top of the tank. The connections at the Aeromotive unit are return, vent, and supply, in that order, from left to right when looking at it from the front of the tank underneath the car.

I’m running half inch -8AN supply and return lines, while the vent is -6AN. Mike and I figured out the best routing of the two -8 lines, but the vent direct in the middle of the two was kind of a PITA. But let’s start at where the stainless hardlines are going to terminate, shall we?

These are the two dummy mock-up pieces we made and clamped into place. The outboard one is supply, the inboard one is return.

A couple different angles of it, so you can get a better idea:

I’m currently waiting on a Summit order to arrive, it’ll have the male -8AN hose ends and the 5/8” Made 4 You nylon clamps on it that I need to terminate and firmly attach the hoses.

From this point, the hoses are routed over top of the rear crossmember. This picture is taken from behind the crossmember, looking forward now:

The zip ties are temporary, again, until I get the Summit order later next week.

Once over the crossmember, they continue on to the trunk floor kickup, then neatly tuck behind the passenger’s side tank strap.

The connections to the tank are as clean as I could make them with the stupid vent port right in the middle. I think I did not too bad.

The vent hose I routed over towards the driver’s side, and across the top of the tank inside a groove that ran the full length of the tank.

I also spaced the front of the tank down slightly, for a little additional clearance to the hose end fittings. It wasn’t completely necessary, but it makes me feel a little better about it. I simply cut two pieces of 1/2” stainless tube, placed them between the body tabs and the tank straps, and ran the bolts through them. No pictures as I didn’t feel it was really necessary.

That brings me up to today. I now had to drop the rear of the tank to give me access to the top of the filler neck where I planned to route the vent line into.

Here’s a good look at the top of the Aeromotive unit in place. Note it’s positioned at the deepest part of the tank, in the deep wide recess, and right by the front for good access to the hose connections.

Here you can also see the routing of the vent line in the front to back groove:

Next was to mark out a location for the vent line fitting, I chose the very top and as close to the top of the filler neck as I could get.

I actually had to change the location slightly after that picture was taken, this point wasn’t far enough back from the filler neck flapper when it was in the “up” position. I moved it down slightly, just enough for it to clear afterwards.

Time to make a hole, and cut some threads. A 1/4” NPT tap did the trick.

I purposely chose NPT (National Pipe Taper), I had briefly considered ORB (O-Ring Boss), but decided against it for a couple of reasons. Firstly, because I didn’t trust the O-ring to seal fully on a round surface, and secondly because I don’t have a tap for the fine thread ORB threads.

A generous application of Loctite 567 thread sealer, and the -6AN 90 got tightened down in the filler neck. I cut the NPT threads quite deep to keep the 90 degree fitting as low profile as possible.

After lifting the back of the tank back up into place, I adjusted the orientation of the 90 until I could comfortably thread the hose fitting on it.

Cut the vent line to length, assemble the hose end, feed it back through above the tank, and connect the ends. Done deal.

It’s tucked up nice and high, out of the way of everything, and should work nicely. Once I get the -8 male hose ends and clamps from Summit next week, I can wrap this up entirely.

The other thing that I bought on that Summit order was Aeromotive’s deluxe heavy duty fuel pump wiring kit. When it arrives, I’ll drop the tank again to make the wiring connections to the pickup, and have another look at tweaking that float arm so I can install the factory pickup (which is now only needed for the float for the gas gauge).

All for now gents, till next week.

D.

So the parts that you're getting from Summit will replace the zip ties that are holding the feed and return hoses that are going to the tank now Donovan? I'd like to see it after its all finished with the new parts you have coming. I think I will like it much more then. Thanks for posting the explanation and photos up to now. I'm assuming that there won't be any kind of vapour canister on the car, and that's why you ran the vent hose to the filler neck?

So the parts that you're getting from Summit will replace the zip ties that are holding the feed and return hoses that are going to the tank now Donovan? I'd like to see it after its all finished with the new parts you have coming. I think I will like it much more then. Thanks for posting the explanation and photos up to now. I'm assuming that there won't be any kind of vapour canister on the car, and that's why you ran the vent hose to the filler neck?

Yes, that is correct Jeff. Any sort of emissions equipment was eliminated long, long ago. There’s not even any provisions for any of them on the 455 engine combination any more.

Any mention of utilization of the vent port in the Aeromotive instructions were vague at best, but I recalled reading a post or two on here about how guys had run the vent line into the filler neck in similar applications. So I thought that would be the best course of action for mine as well. Of course, I welcome any input from others that may have different suggestions.

I will do a follow up post once the new clamps and hose ends have been installed, and connected to the mock-up hard lines. I’m sure it will look a little better. Underneath the car in person, it actually looks pretty good. I guess the pictures don’t exactly do it justice. I just wish the feed and return line ports were side by side on the Aeromotive pickup, with the vent port off to one side, it would have made the hose routing much simpler and cleaner.

I have done this in the past and never had any problems (edit. This was in a diesel oem tank and really doesn't apply here) My current setup is a Holley tank and all their instructions want the vent going to a roll over valve that they supplied. I am unsure about a few things. Since your vent is going back into the tank, does this make it a sealed system? In other words the vent isn't really venting and with pump running and fuel levels dropping, will you run into turning tank into a vaccum condition? If so that obviously is not ideal. If I am wrong please tell me. I still haven't completed this part of my system.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.