Hey guys, there's been some requests to cover the suspension and Air ride section next, so here goes.

Some of you may be wondering "why air ride?" Yes, there's no doubt it looks cool when it's aired down, but the main factor behind choosing to go this way was actually two fold:

1) Stance and attitude.

Stance and wheels and tires can make or break an otherwise nice car. With air ride, the stance can be almost infinitely adjusted and changed to suit your wants and needs (within their operating limits of course). Killer slammed height at the show, stock ride height for the drive home!

2) Versatility and performance.

Air suspension has come a long ways since the old air shocks we remember from the 70's and 80's. The technology has finally caught up enabling us to have that nice comfortable ride for the Sunday drive, yet with a few tweaks, can be made to handle and perform on the track if desired. (Google some air suspended vehicles auto crossing sometime!) With an air suspension, ride height can be changed instantly from inside the car. Try doing that with a set of coil overs! I've always liked the aggressive look of a lowered vehicle and early on, I went with a set of dropped spindles. I can tell you from personal experience, a front heavy car with a big block and railroad tracks or even parking lot entrances and drop spindles equal pancaked headers. Not good. So, then it was back to stock height spindles, once again fighting with coil spring compressors and the dangers associated with all that. With air suspension, easy in, easy out. No dangerous compressed springs to wrestle with. You may disagree, but for me and my intended driving, air ride was a no-brainer.

I apologize in advance, I don't have quite as many pics of the individual parts before they went on, I never anticipated I'd be doing a build thread on the car one day. Anyways...

FRONT SUSPENSION

Global West "F" body spindle conversion tubular upper control arms

The decision to go this route was to improve on the factory suspension geometry with the added benefit that big brake selection is far greater for the "F" body spindle.

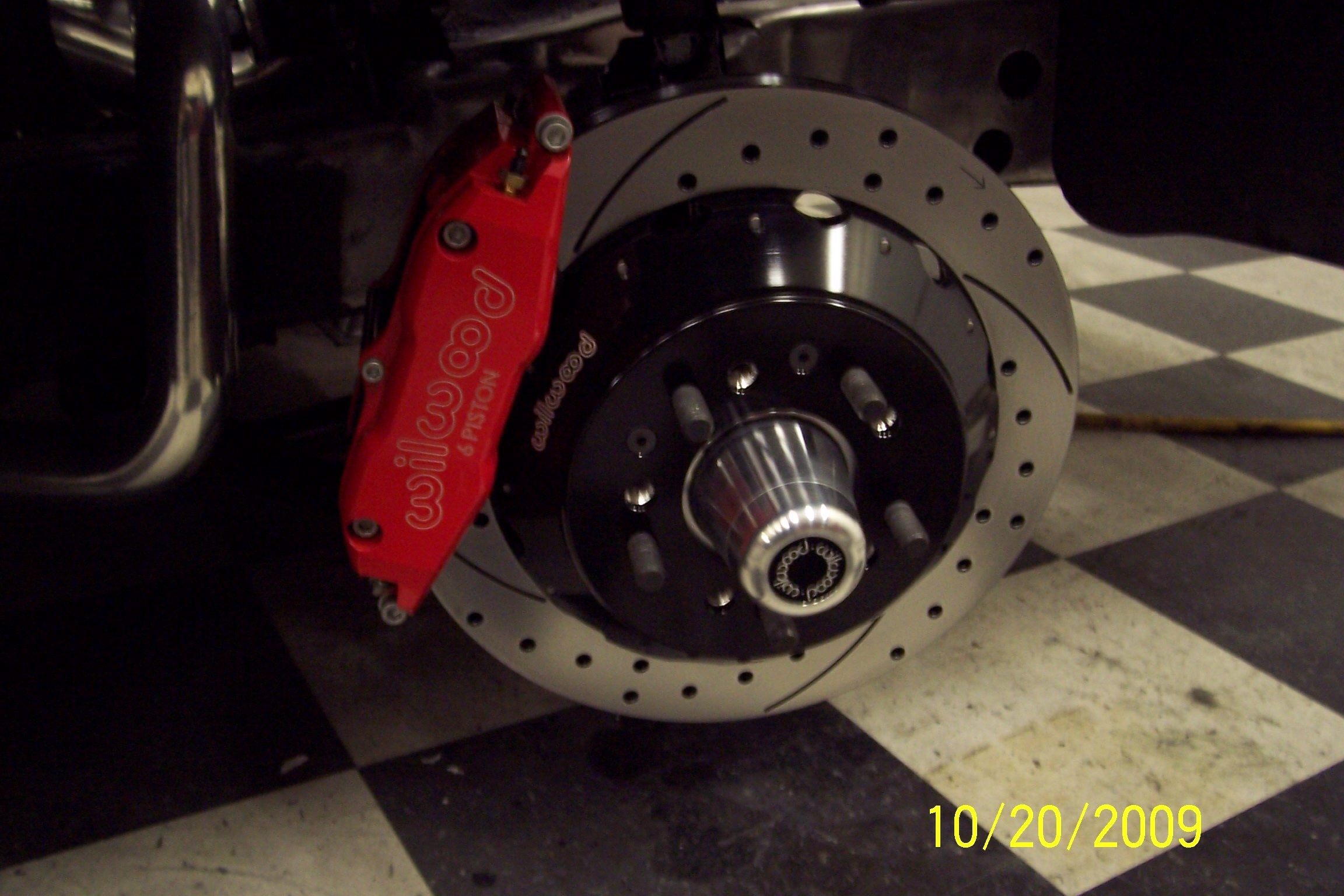

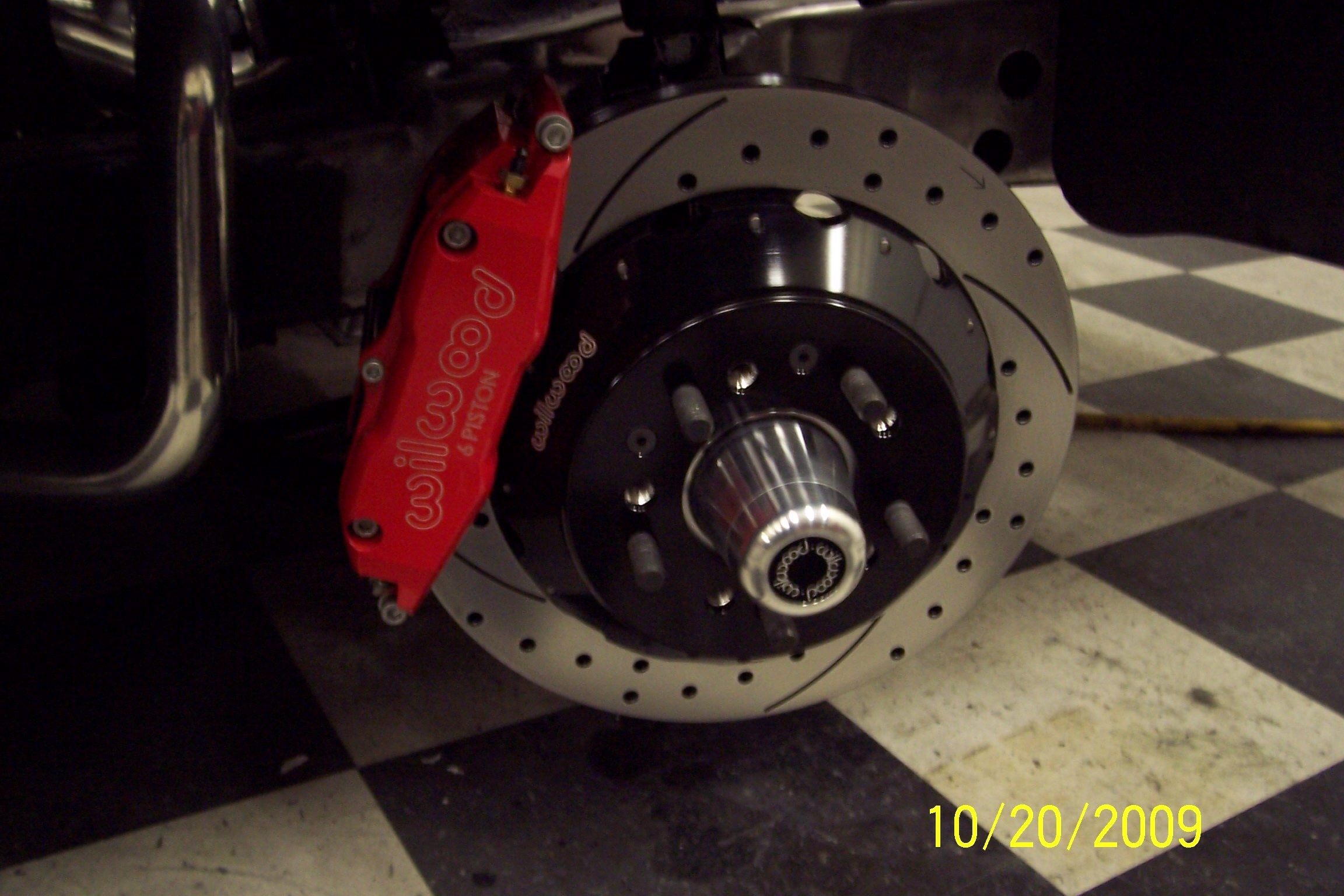

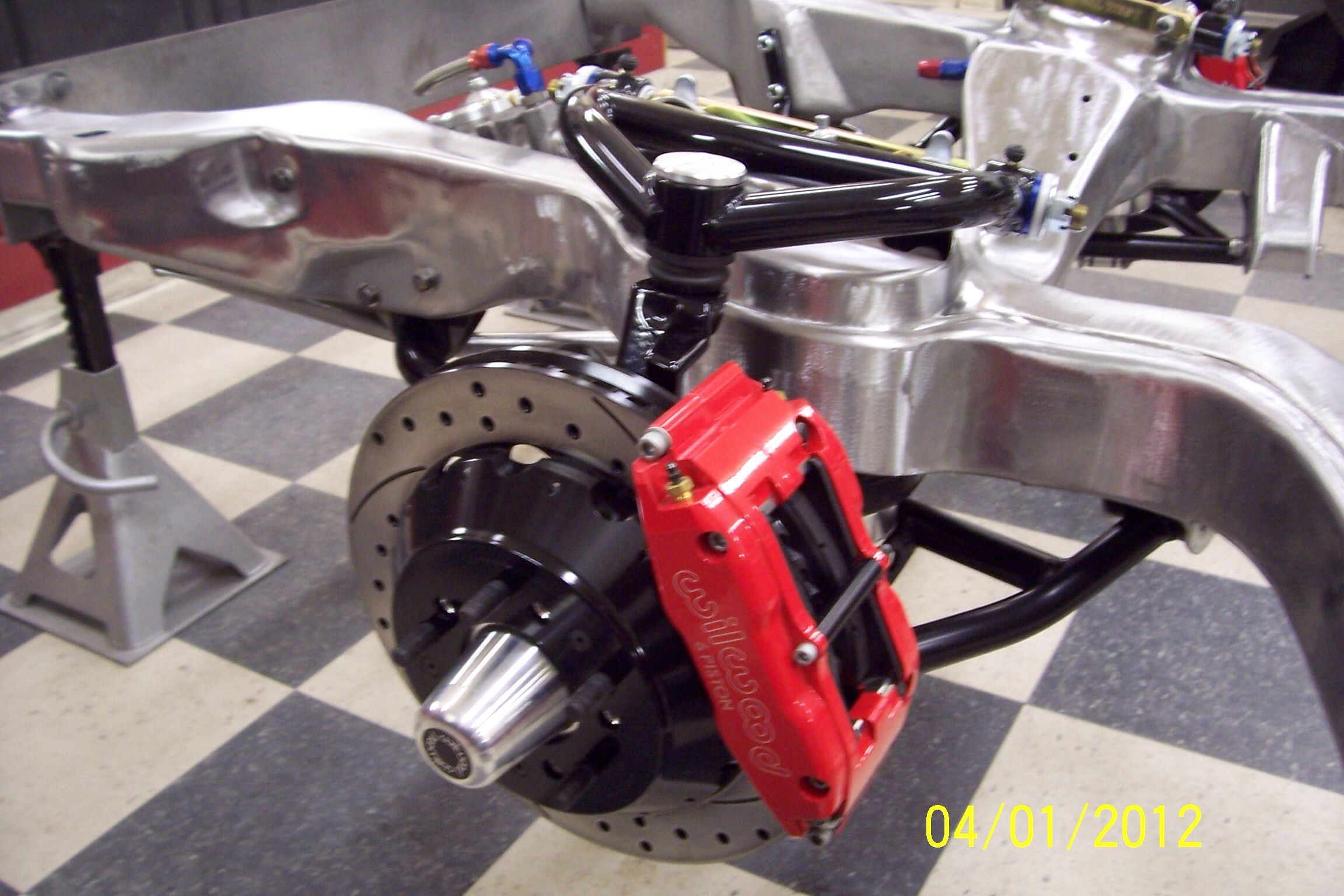

1979 Camaro spindles, smoothed, powder coated, steering stops trimmed to clear lower control arms, and trimmed for installation of Wilwood brakes

Wilwood "Big Brake" kit for F body.

Rotors are 12.9" slotted and cross drilled

Calipers are red powdercoated radial mount 6 piston with stainless pistons. Really nice pieces. Pricey tho...

Ride Tech "Strong Arm" tubular lower control arms with provision for mounting either coil overs or "ShockWave" air springs

Ride Tech "ShockWave" air springs. These are a combination air bag and shock together in one. Brilliant, and about time. No more separate 'bags and relocating shocks.

New Hotchkis steering components. These include the idler arm and inner and outer tie rod ends. Center link and pitman arm are stock, but new. Hotchkis black powdercoated billet tie rod adjusters. All steering components painted gloss black with PPG "Delfleet" industrial paint.

Hotchkis monster 1 3/8" hollow tubular front sway bar. I'm also using factory front lower frame jounce bars, and these needed to be tweaked to be used with the Hotchkis bar.

Hotchkis billet front sway bar mounts with polyurethane bushings. (Just cause they look cooler than the stockers)

Ride Tech "Posi Link" sway bar end links.

If you've never seen these, they are the ticket for replacing your end links. They're essentially two miniature ball joints that can swivel and move independently of each other as the suspension moves thru it's arc. The stock design is constantly in bind in any other position other than straight and level, and these solve that issue.

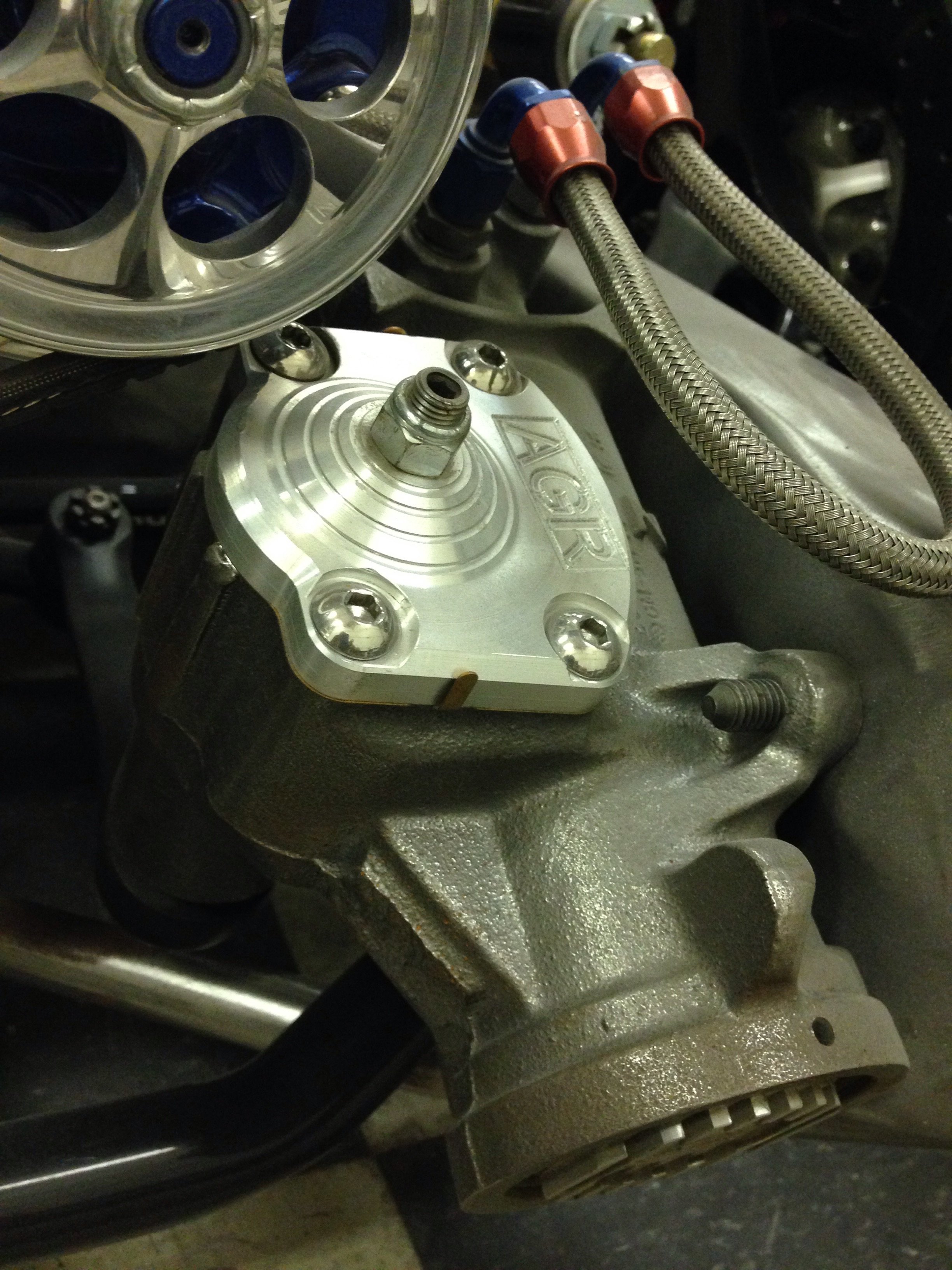

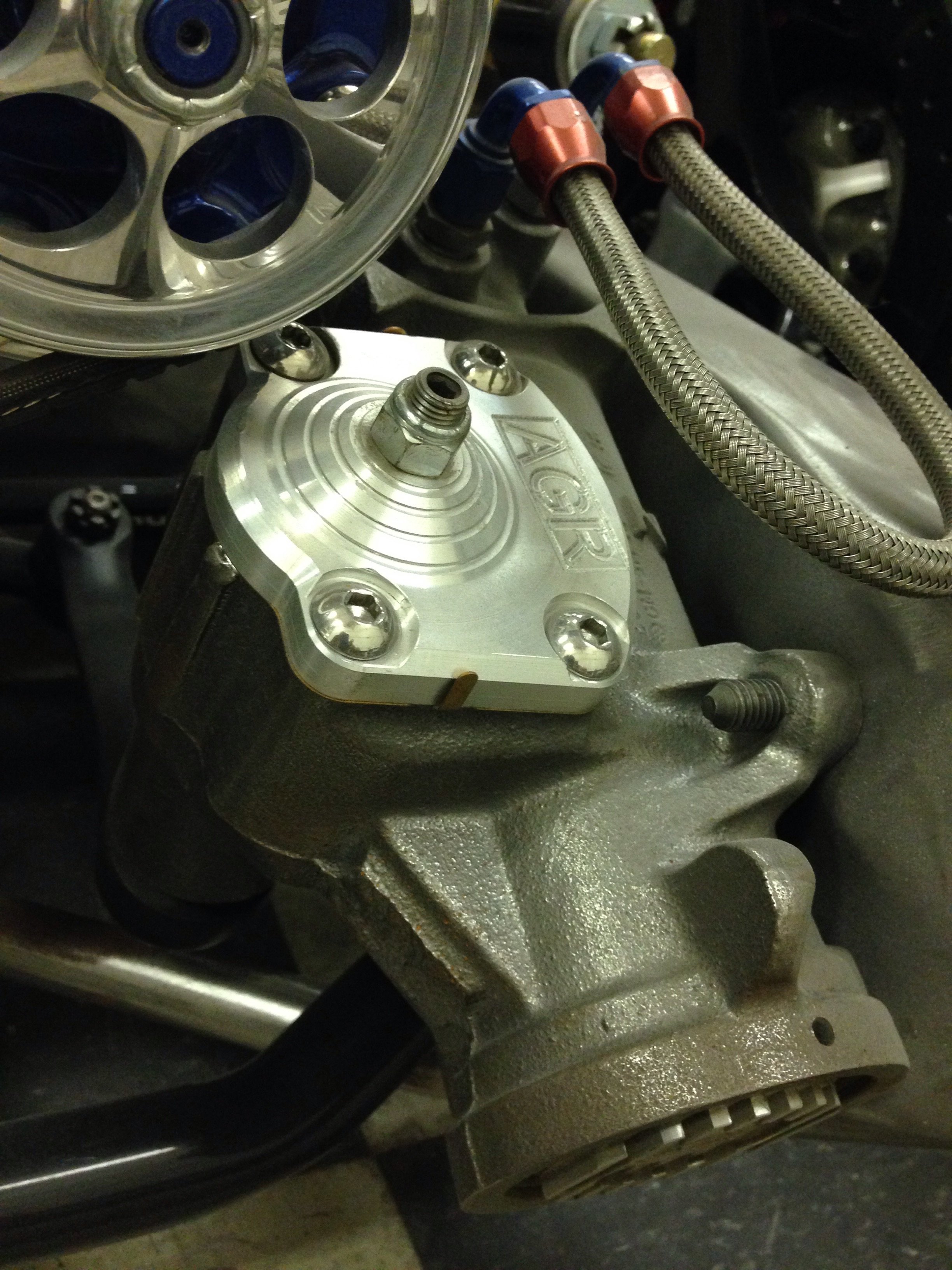

AGR 12.7:1 quick ratio power steering box

This is a GM box with the internals and valving changed by AGR to increase the ratio.

View attachment 38371

View attachment 38371

Some of you may be wondering "why air ride?" Yes, there's no doubt it looks cool when it's aired down, but the main factor behind choosing to go this way was actually two fold:

1) Stance and attitude.

Stance and wheels and tires can make or break an otherwise nice car. With air ride, the stance can be almost infinitely adjusted and changed to suit your wants and needs (within their operating limits of course). Killer slammed height at the show, stock ride height for the drive home!

2) Versatility and performance.

Air suspension has come a long ways since the old air shocks we remember from the 70's and 80's. The technology has finally caught up enabling us to have that nice comfortable ride for the Sunday drive, yet with a few tweaks, can be made to handle and perform on the track if desired. (Google some air suspended vehicles auto crossing sometime!) With an air suspension, ride height can be changed instantly from inside the car. Try doing that with a set of coil overs! I've always liked the aggressive look of a lowered vehicle and early on, I went with a set of dropped spindles. I can tell you from personal experience, a front heavy car with a big block and railroad tracks or even parking lot entrances and drop spindles equal pancaked headers. Not good. So, then it was back to stock height spindles, once again fighting with coil spring compressors and the dangers associated with all that. With air suspension, easy in, easy out. No dangerous compressed springs to wrestle with. You may disagree, but for me and my intended driving, air ride was a no-brainer.

I apologize in advance, I don't have quite as many pics of the individual parts before they went on, I never anticipated I'd be doing a build thread on the car one day. Anyways...

FRONT SUSPENSION

Global West "F" body spindle conversion tubular upper control arms

The decision to go this route was to improve on the factory suspension geometry with the added benefit that big brake selection is far greater for the "F" body spindle.

1979 Camaro spindles, smoothed, powder coated, steering stops trimmed to clear lower control arms, and trimmed for installation of Wilwood brakes

Wilwood "Big Brake" kit for F body.

Rotors are 12.9" slotted and cross drilled

Calipers are red powdercoated radial mount 6 piston with stainless pistons. Really nice pieces. Pricey tho...

Ride Tech "Strong Arm" tubular lower control arms with provision for mounting either coil overs or "ShockWave" air springs

Ride Tech "ShockWave" air springs. These are a combination air bag and shock together in one. Brilliant, and about time. No more separate 'bags and relocating shocks.

New Hotchkis steering components. These include the idler arm and inner and outer tie rod ends. Center link and pitman arm are stock, but new. Hotchkis black powdercoated billet tie rod adjusters. All steering components painted gloss black with PPG "Delfleet" industrial paint.

Hotchkis monster 1 3/8" hollow tubular front sway bar. I'm also using factory front lower frame jounce bars, and these needed to be tweaked to be used with the Hotchkis bar.

Hotchkis billet front sway bar mounts with polyurethane bushings. (Just cause they look cooler than the stockers)

Ride Tech "Posi Link" sway bar end links.

If you've never seen these, they are the ticket for replacing your end links. They're essentially two miniature ball joints that can swivel and move independently of each other as the suspension moves thru it's arc. The stock design is constantly in bind in any other position other than straight and level, and these solve that issue.

AGR 12.7:1 quick ratio power steering box

This is a GM box with the internals and valving changed by AGR to increase the ratio.

Last edited:

Seriously tho, I'm just like most other guys on this forum, blue collar, and bustin' my hump for every dollar. More than once I've settled for Kraft dinners to save up and afford that next "must have" part. In fact, most of the "big dollar" parts that you see have taken me quite a while to save up for. In some cases, years! I'm not sure our American friends fully appreciate the availability and price of their aftermarket parts. I just brought up a back window from another member on here, and paid an additional 30% in exchange alone due to our crappy dollar. If you were to carry that across, in theory it would cost us 30% more for us to build our cars up here. Grrr!

Seriously tho, I'm just like most other guys on this forum, blue collar, and bustin' my hump for every dollar. More than once I've settled for Kraft dinners to save up and afford that next "must have" part. In fact, most of the "big dollar" parts that you see have taken me quite a while to save up for. In some cases, years! I'm not sure our American friends fully appreciate the availability and price of their aftermarket parts. I just brought up a back window from another member on here, and paid an additional 30% in exchange alone due to our crappy dollar. If you were to carry that across, in theory it would cost us 30% more for us to build our cars up here. Grrr!