I forgot to mention when I covered the front suspension, that the Ride Tech Shockwaves are single adjustable units. The adjustment is for the "rebound" on the singles, and "compression" and "rebound" on the double units. Double adjustables would've been nice for sure, but I just couldn't justify the additional cost.

REAR SUSPENSION

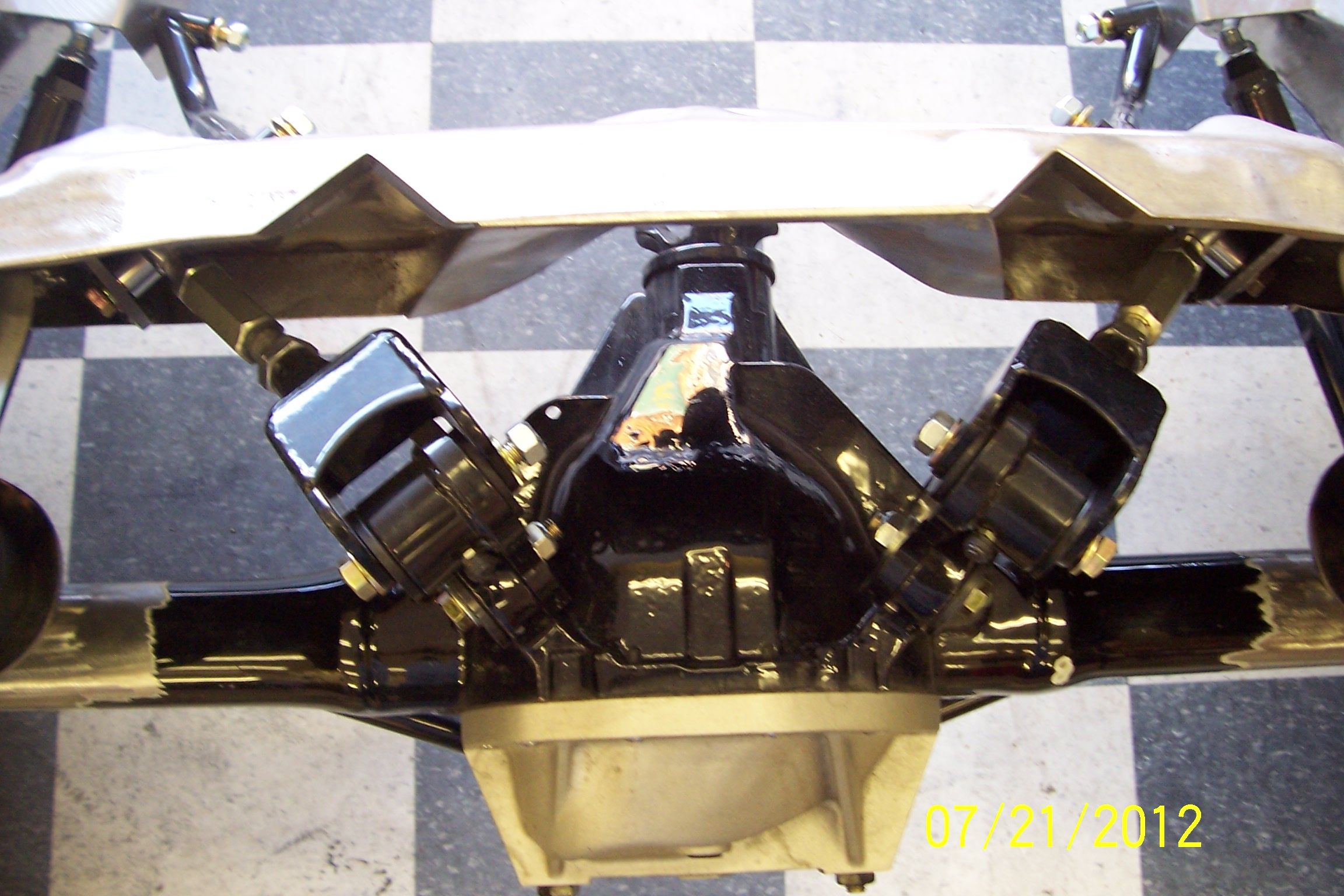

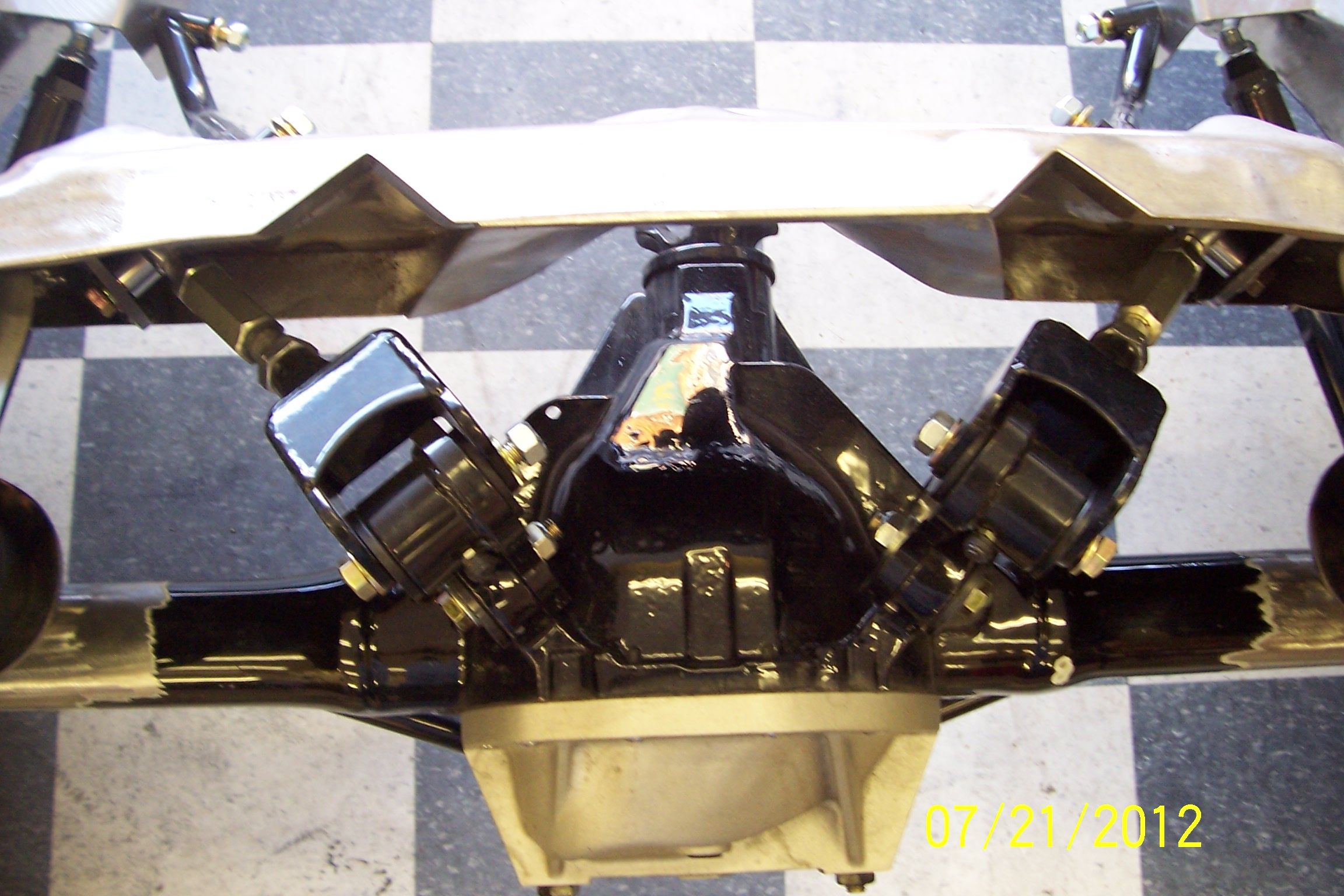

Housing: Chevrolet car 12 bolt, 8.875" ring gear diameter, Richmond 3.73:1 gear set, with rebuilt GM positraction. "Appropriated" from my dads scrapped '71 Chevelle Malibu project, minus the posi and gears. Lower trailing arm brackets removed, narrowed to G body width, new Ford 9" big bearing Torino ends welded on, and the factory 12 bolt lower trailing arm brackets re-welded back on.

The decision to go to Ford 9" housing ends was primarily to avoid the need for C clip eliminators. They are notorious for leaking, and the factory C clips aren't strong or reliable enough for extreme duty. Over a certain power level, most sanctioned tracks won't let you run without some form of positive axle retention over and above the factory C clips. The 9" ends provide that, and the bigger bearings help distribute the weight better.

Axles: Moser custom alloy, custom length, 28 spline count with bearing and retainer package, and 1/2" wheel studs

Girdle: T/A performance, aluminum with adjustable bolts for setting preload on the bearing caps.

Brakes: Wilwood disc. Rotors are 12.1" Slotted, crossdrilled, and vented. Calipers are red powdercoated, stainless 4 piston, with internal drum parking brake assembly hidden under the rotor hat.

Upper rear trailing arms: UMI performance, black powdercoated double adjustable specific for the 12 bolt swap into a G body. When I first came across these, UMI was just starting up, and virtually unknown. I'm pretty sure I was one of the first to order a set from them...

Lower rear trailing arms: UMI Performance black powdercoated double adjustable with offset heim joint spacers, and holes to incorporate sway bar mounting in the factory location

Sway Bar: Hotchkis 1" solid, black powdercoated

Misc: QA1 lift bars. These install in the upper trailing arm bushing holes on the diff, and relocate the upper arms' mounting points higher up. This changes the cars "instant center", allowing more leverage to be forced on the rear tires during launch, improving traction. Energy Suspension polyurethane pinion stop and axle housing bump stops, Lokar stainless steel parking brake cables

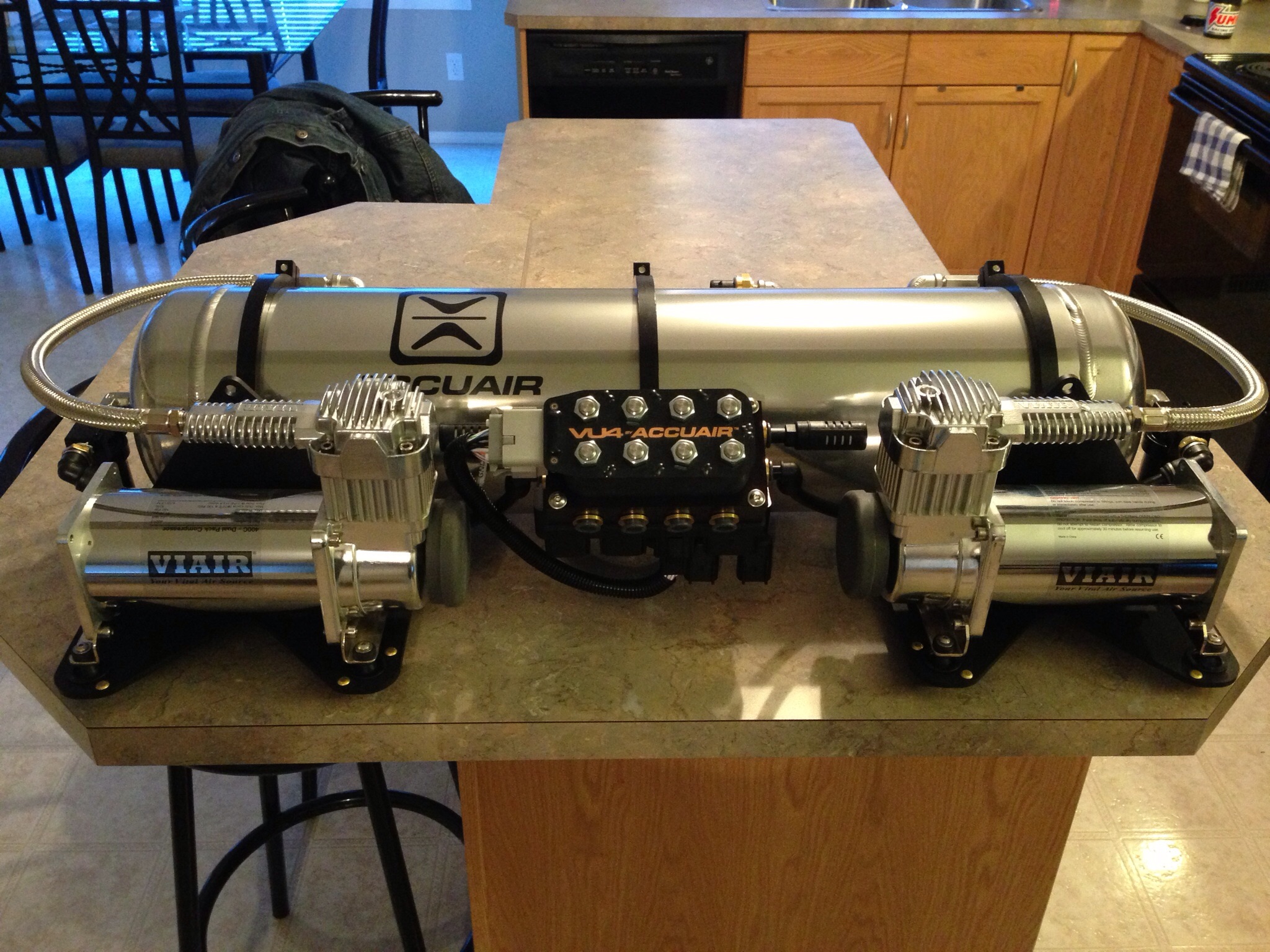

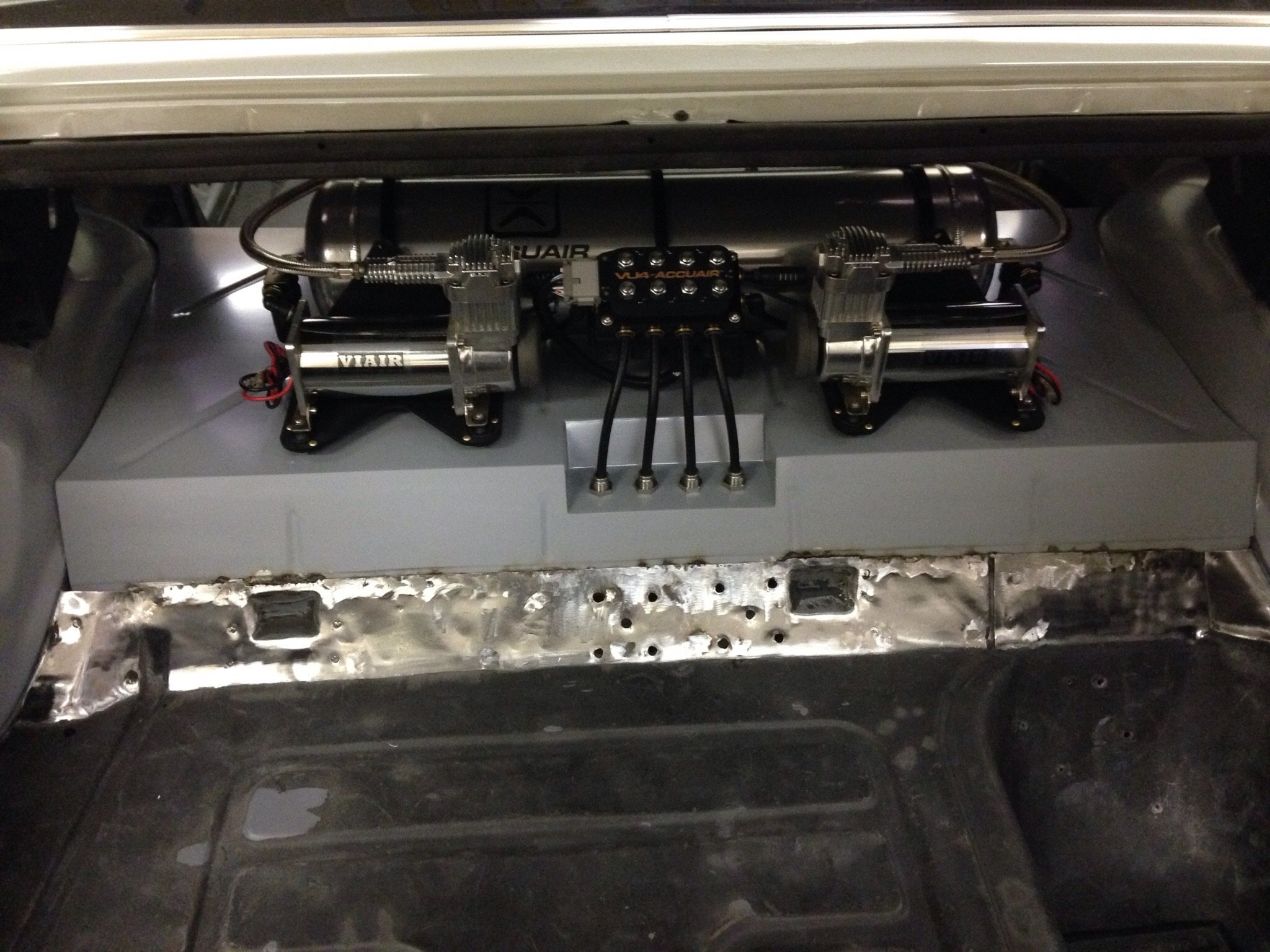

Rear air bags: Ride Tech "Cool Ride" kit for G bodies. Shortly after I purchased the rear kit, lighter duty versions of the ShockWaves became available for rear suspension applications for G bodies and others. However unlike the fronts, I felt the natural motion of the rear axle would benefit more from a separate bag and shock combination. After all, that's the way the General designed it.

Shocks: Ride Tech/Fox Racing single adjustable units. It took me forever to get these, but unfortunately now I can't remember any of the details for them...

REAR SUSPENSION

Housing: Chevrolet car 12 bolt, 8.875" ring gear diameter, Richmond 3.73:1 gear set, with rebuilt GM positraction. "Appropriated" from my dads scrapped '71 Chevelle Malibu project, minus the posi and gears. Lower trailing arm brackets removed, narrowed to G body width, new Ford 9" big bearing Torino ends welded on, and the factory 12 bolt lower trailing arm brackets re-welded back on.

The decision to go to Ford 9" housing ends was primarily to avoid the need for C clip eliminators. They are notorious for leaking, and the factory C clips aren't strong or reliable enough for extreme duty. Over a certain power level, most sanctioned tracks won't let you run without some form of positive axle retention over and above the factory C clips. The 9" ends provide that, and the bigger bearings help distribute the weight better.

Axles: Moser custom alloy, custom length, 28 spline count with bearing and retainer package, and 1/2" wheel studs

Girdle: T/A performance, aluminum with adjustable bolts for setting preload on the bearing caps.

Brakes: Wilwood disc. Rotors are 12.1" Slotted, crossdrilled, and vented. Calipers are red powdercoated, stainless 4 piston, with internal drum parking brake assembly hidden under the rotor hat.

Upper rear trailing arms: UMI performance, black powdercoated double adjustable specific for the 12 bolt swap into a G body. When I first came across these, UMI was just starting up, and virtually unknown. I'm pretty sure I was one of the first to order a set from them...

Lower rear trailing arms: UMI Performance black powdercoated double adjustable with offset heim joint spacers, and holes to incorporate sway bar mounting in the factory location

Sway Bar: Hotchkis 1" solid, black powdercoated

Misc: QA1 lift bars. These install in the upper trailing arm bushing holes on the diff, and relocate the upper arms' mounting points higher up. This changes the cars "instant center", allowing more leverage to be forced on the rear tires during launch, improving traction. Energy Suspension polyurethane pinion stop and axle housing bump stops, Lokar stainless steel parking brake cables

Rear air bags: Ride Tech "Cool Ride" kit for G bodies. Shortly after I purchased the rear kit, lighter duty versions of the ShockWaves became available for rear suspension applications for G bodies and others. However unlike the fronts, I felt the natural motion of the rear axle would benefit more from a separate bag and shock combination. After all, that's the way the General designed it.

Shocks: Ride Tech/Fox Racing single adjustable units. It took me forever to get these, but unfortunately now I can't remember any of the details for them...