Well, guess I had better do an update on here before I get too much further along.

First of all, let me say THIS HOOD IS GOING TO BE THE DEATH OF ME!

Lol

Well ok, it's not quite that bad, but the underside of it is definitely challenging every aspect of my OCD tendencies. There's just a lot of areas that require attention, and it's all über time consuming stuff.

I should backtrack a little bit here so the pics make sense with the timeline.

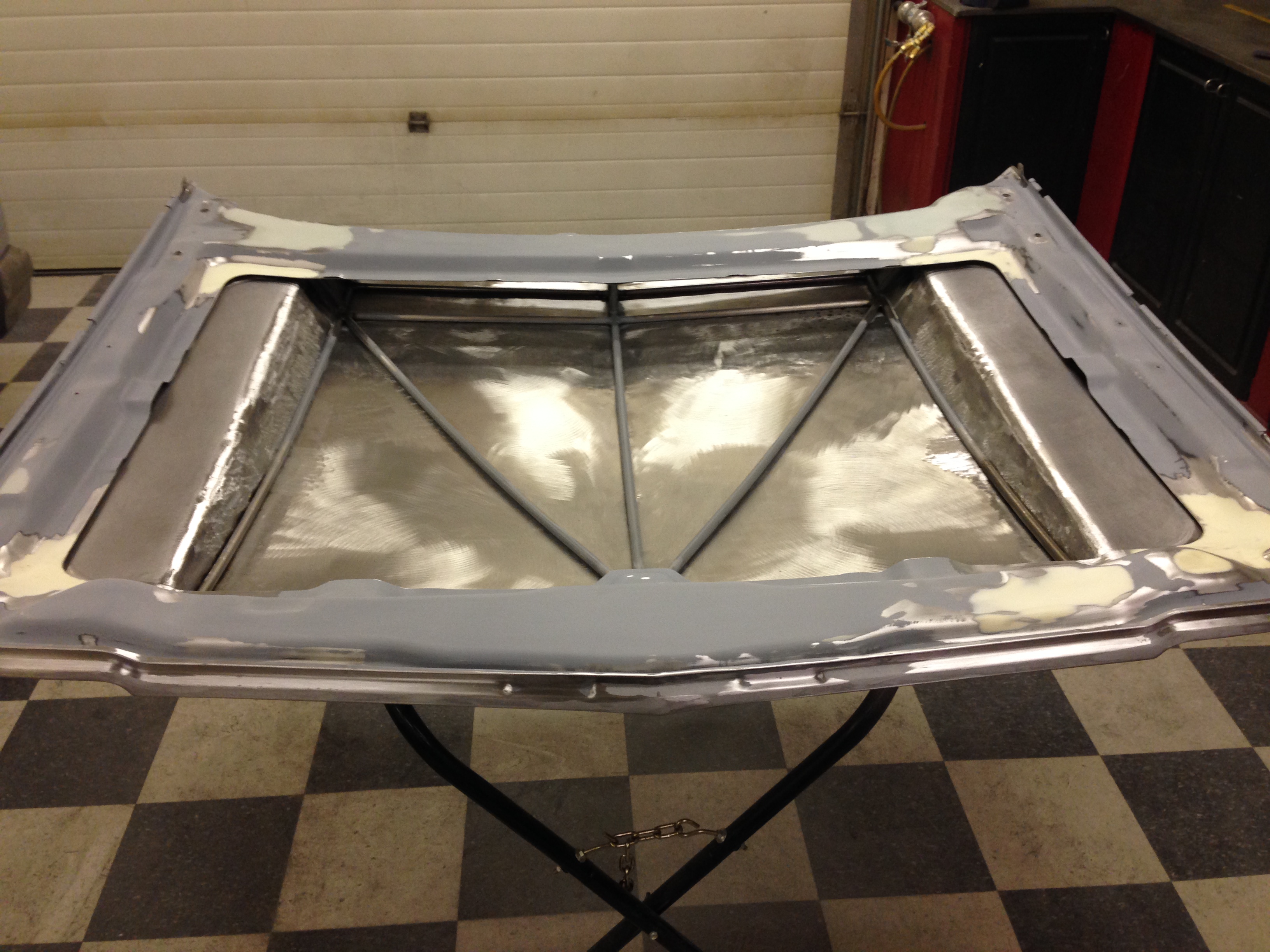

Shortly before work stopped on the hood a couple years ago, the underside was epoxy primed as we thought we were to the point we were ready for it, and to protect the bare metal from oxidation.

After the hood was epoxied, Scottie took it to his shop and did a bunch of shrinks with a torch and some hammer and dolly work to tighten up the sheetmetal.

Once that was done, I ground off the epoxy on the underside of the hood skin inbetween the round support tubing in preparation for skimming and blocking some putty.

Well, I never quite got to the putty stage before the progress stopped.

Unfortunately, and as expected, after several years of sitting around and being bumped and moved, the underside was a bit worse for wear when I got back to it here a couple weeks ago.

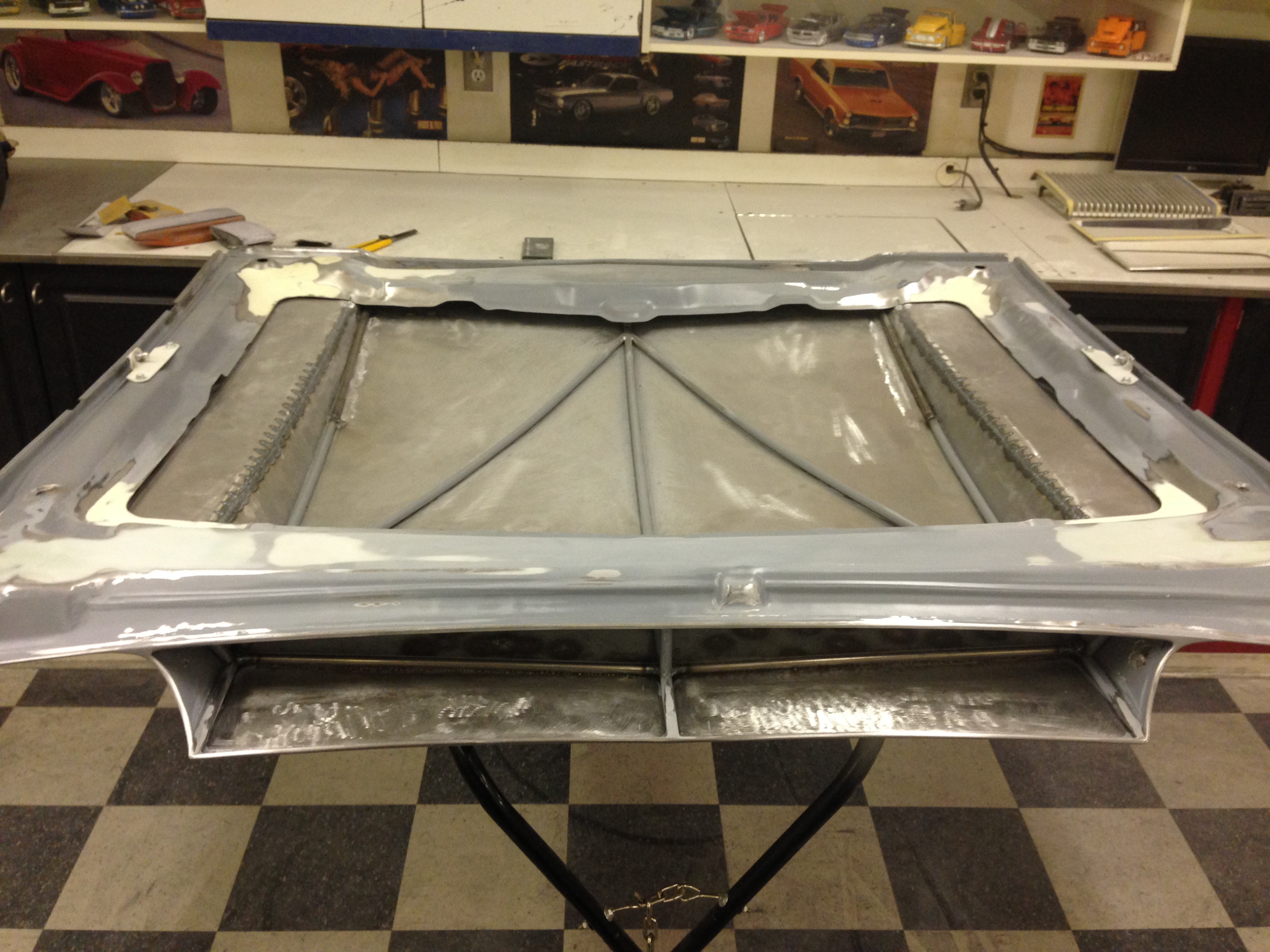

Here's some of the good, the bad, and the downright UGLY that I was faced with once I got it upside down on the stand.

One of the hood corners where I added weld to fix the gaps:

Some cracked and chipping filler on the backside of the cowl section in between the tubing. I had skimmed this area prior to welding in the tube uprights because I knew it would be extremely difficult to get in there and do it afterwards.

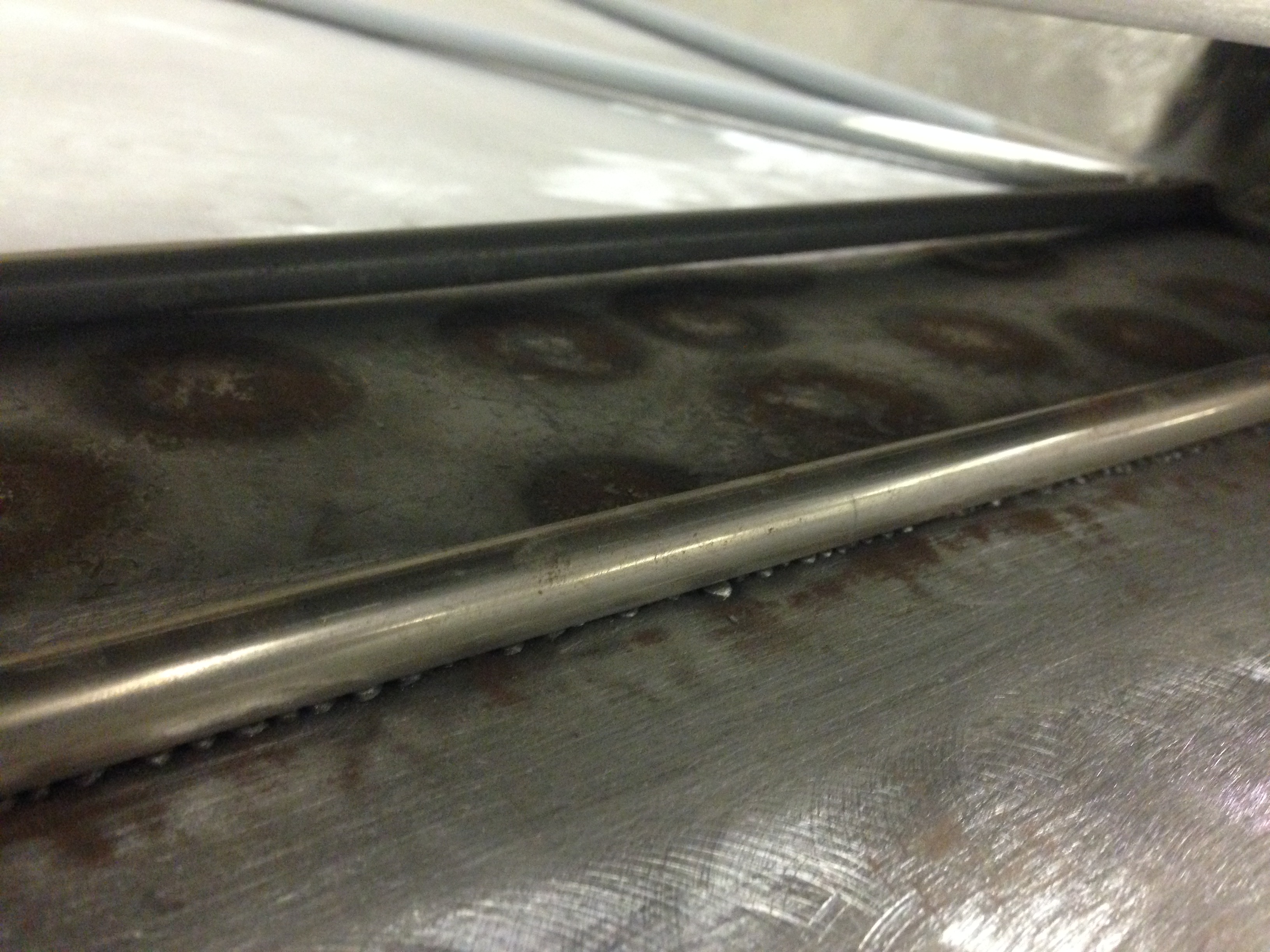

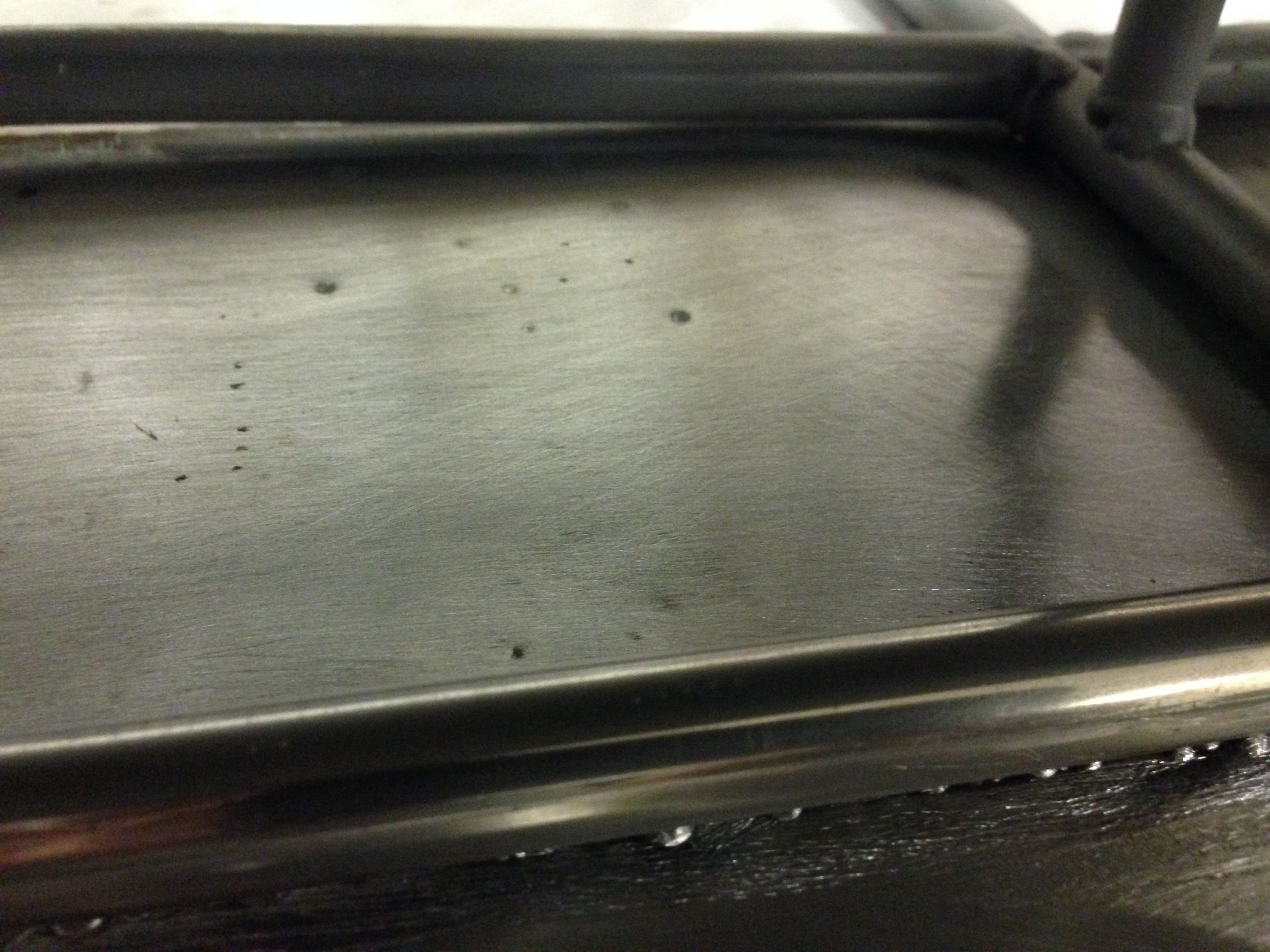

This was really ugly. Burnt epoxy and wrinkles from the shrinks, and surface rust from sitting so long. This is the underside of the skin above the hood bracing:

Then there was this: despite getting the skin tightened up as much as we could with the shrinks, there was still an air gap between the tubing and the hood skin.

When Scott started blocking the filler on the topside, I remember him saying he was having a difficult time because the hood skin was flexing and moving around on him. That would explain why.

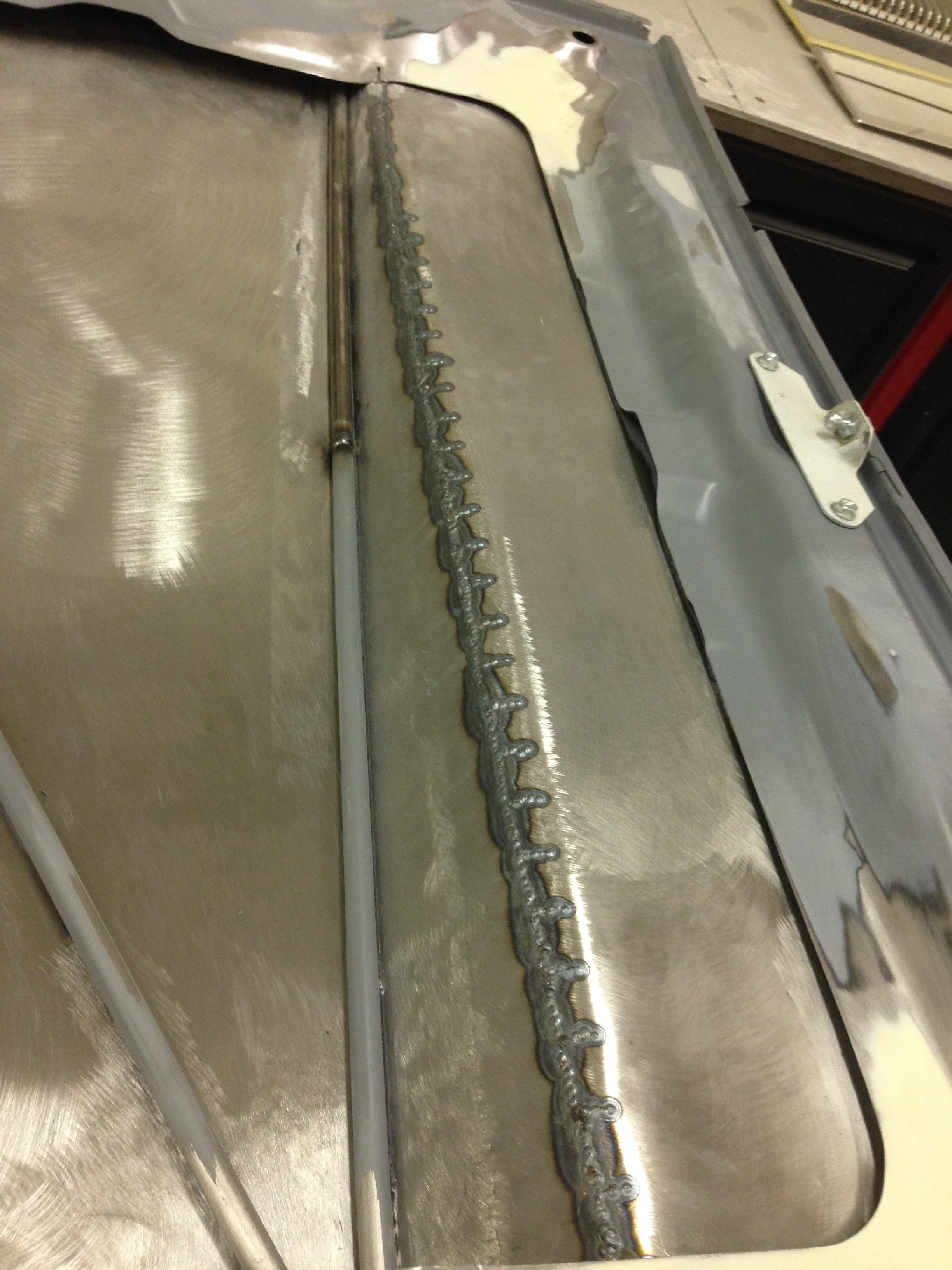

Some more nastiness awaiting me, the long welds from when I repaired the hood curvature:

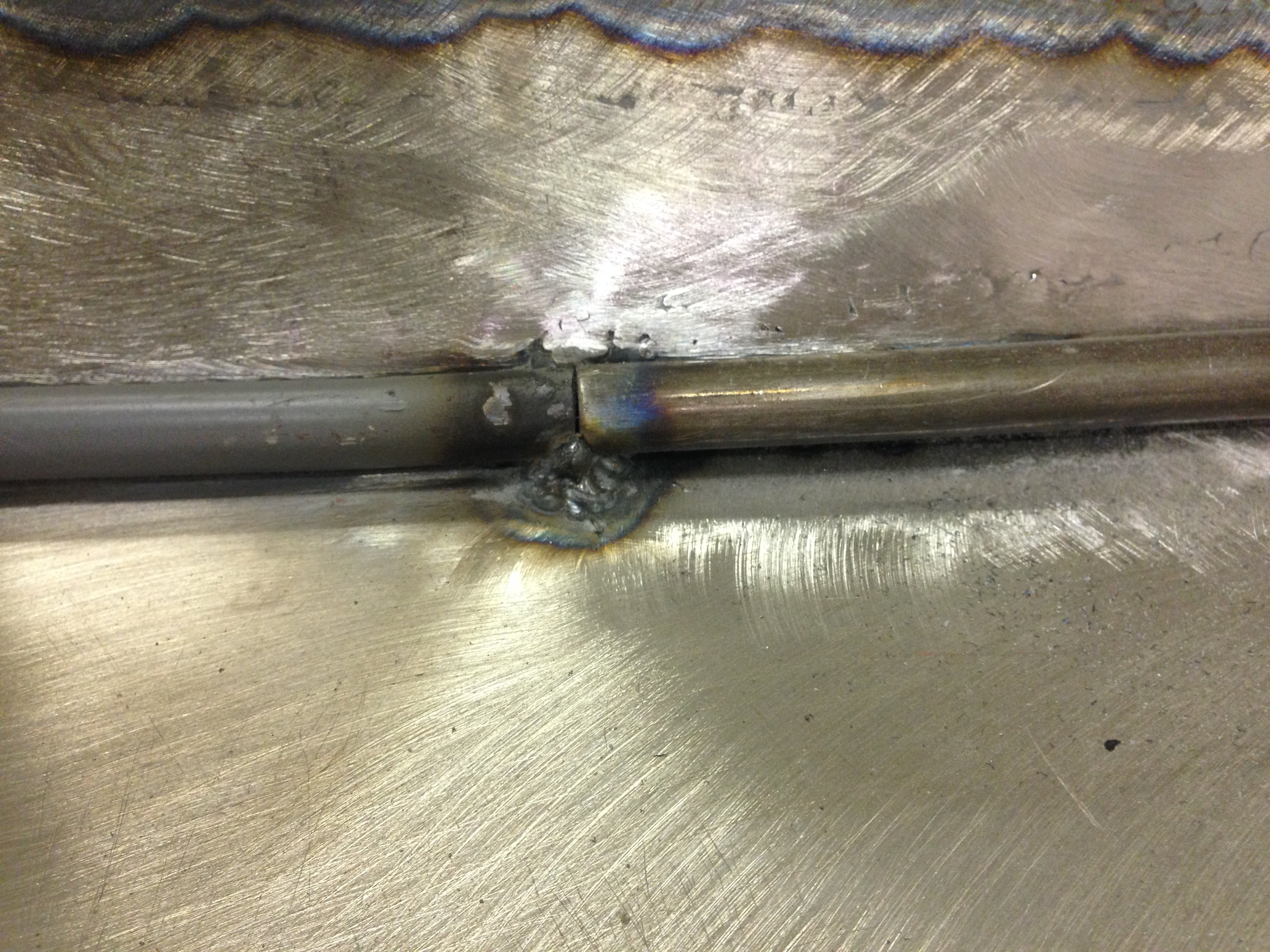

Incomplete and unfinished welds where I replaced the front tube structure:

The front of the factory hood structure where I got a little deep cutting the old stuff out:

Continued >>>