You’ll be blowing by everyone too fast to see if it’s actually pretty or not...

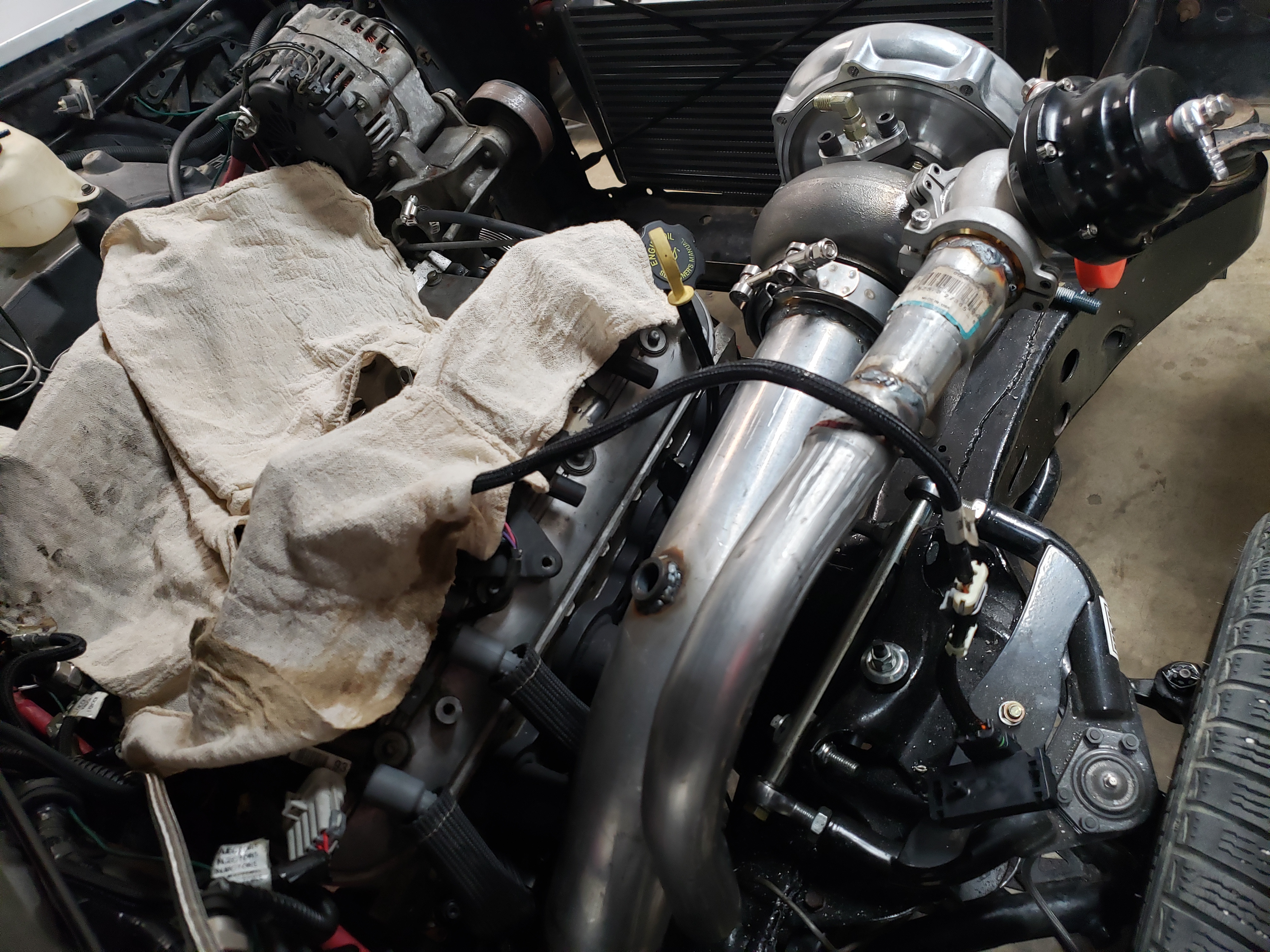

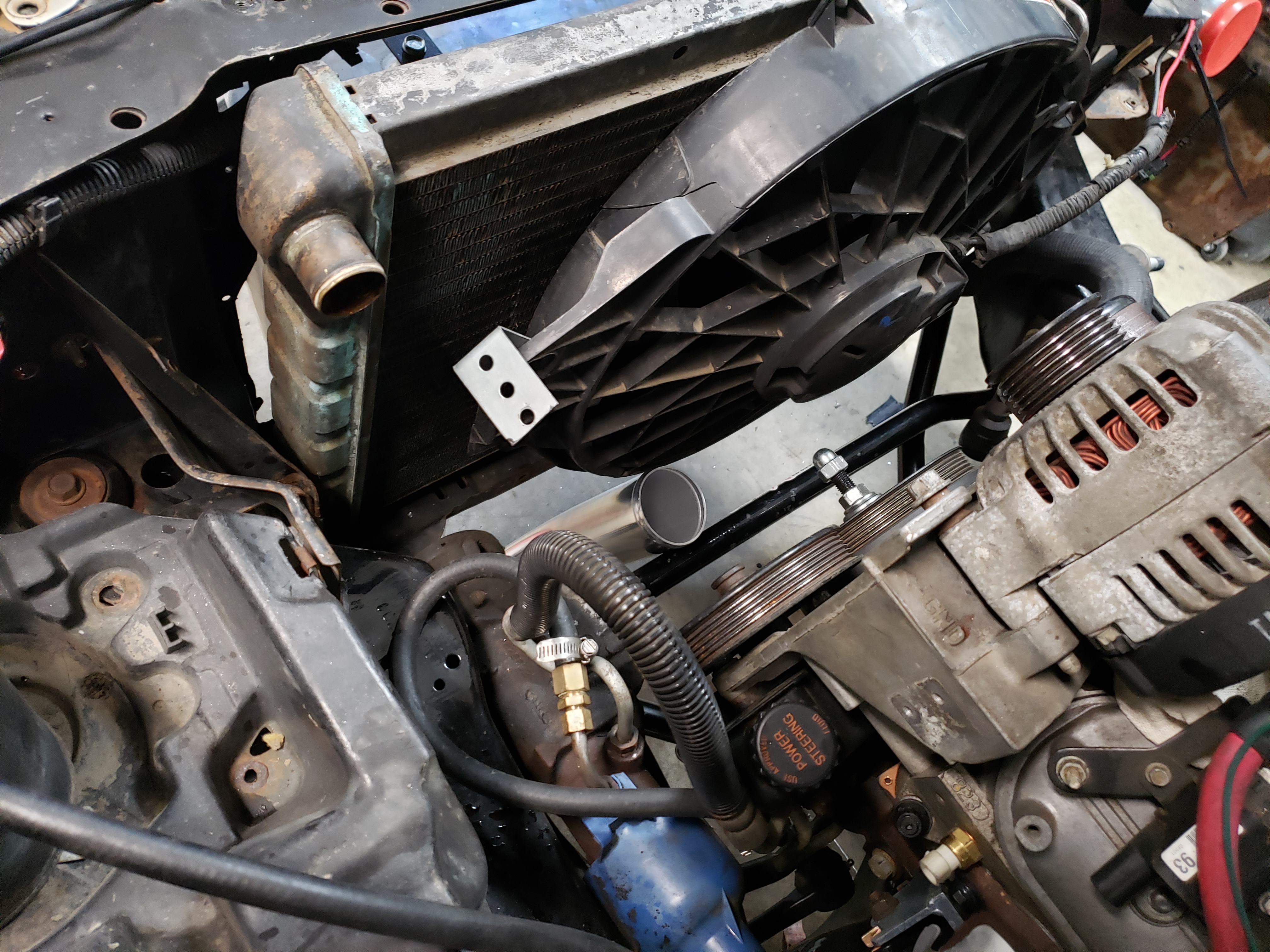

That IS low Duke, too low in my opinion. I’d be plenty nervous too. I don’t like to have anything hanging lower than the lowest scrub point, in your case either the front engine cradle crossmember or the trans crossmember. I would seriously be looking at finding a way to get it up higher, possibly angling it back and up more. That might just buy you enough clearance. Otherwise I think you’re asking for trouble.

The driver’s side header collector on my 455 hangs lower than the passenger’s side, but doesn’t hang anywhere near as low as that, and I’ve pancaked it several times on railroad tracks.

I’d hate to see you tear that pipe off unexpectedly.

That IS low Duke, too low in my opinion. I’d be plenty nervous too. I don’t like to have anything hanging lower than the lowest scrub point, in your case either the front engine cradle crossmember or the trans crossmember. I would seriously be looking at finding a way to get it up higher, possibly angling it back and up more. That might just buy you enough clearance. Otherwise I think you’re asking for trouble.

The driver’s side header collector on my 455 hangs lower than the passenger’s side, but doesn’t hang anywhere near as low as that, and I’ve pancaked it several times on railroad tracks.

I’d hate to see you tear that pipe off unexpectedly.