So Monday I got to the Body Shop supply store and got real black dry guide coat, some 220 sand paper and some more polyester glazing putty and my regular place is out.

I dont recognize this brand, it's a different color and I found the work time to be shorter than I'm used to. I'll stick with USC from now on....

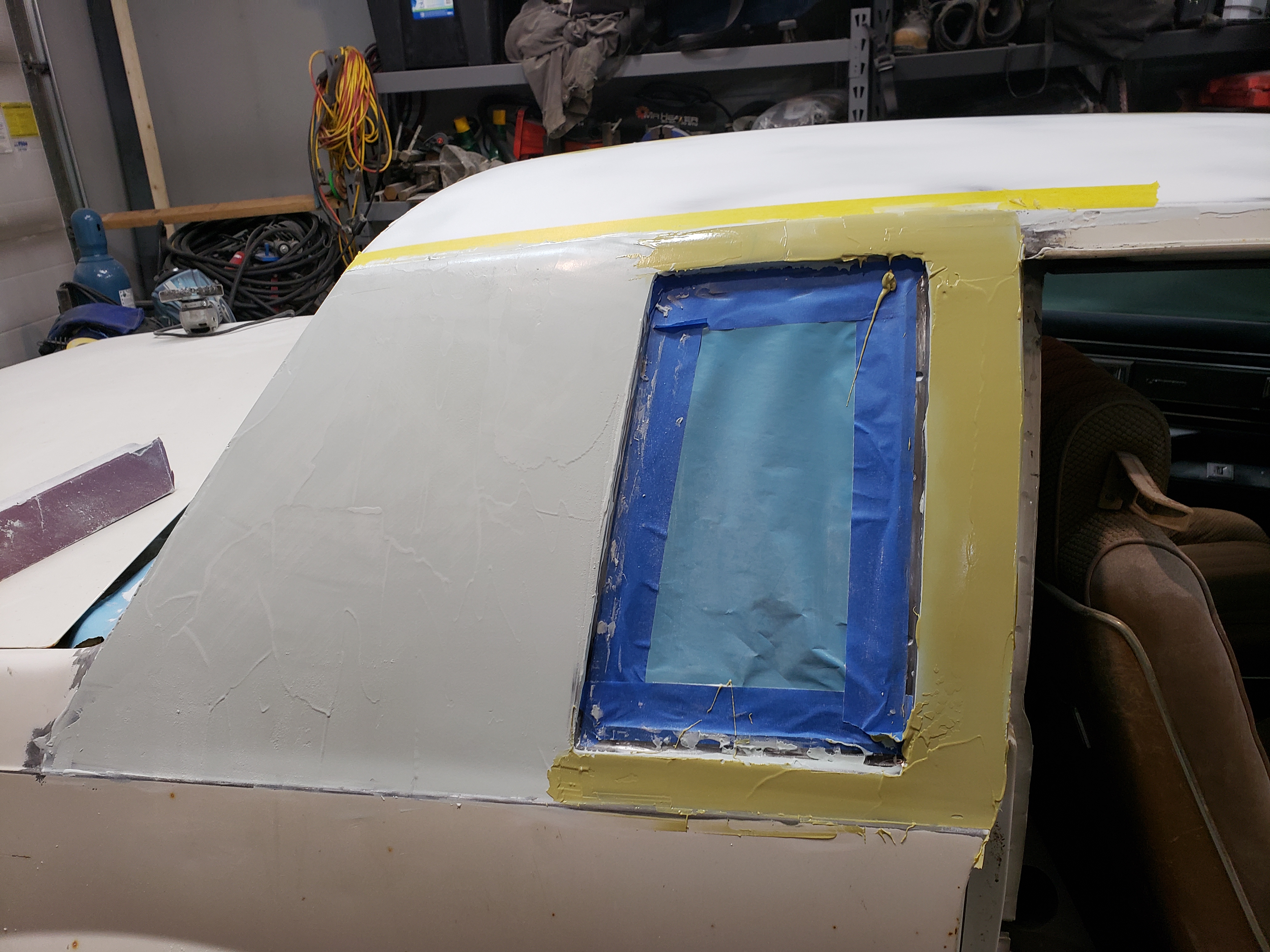

Anyway, seeing as I have done my C pillars wrong twice already Donovan said start over.

So I did.

Used the DA sander and took it most of the way to metal, except for the kitty hair in the seam. Hit with 40 grit and started round 2.

First coat of filler, put on correctly and blocked out. I had taped off the roof line as it was blocked to 180 and the edges to make it easier to hold the edges on the body line.

Blocked out rough with 80 grit and apply the smooth stuff.

I'm finding this to be a pretty easy way to get the filler depth right, since I dont have any real experience I dont always know if I have enough down for what I'm doing. But fill, block to 80, and you have a pretty idea where your lows are so you can apply correction before it's too late and you've over sanded.

Put that fancy new guide coat to work at the 120 and 180 stage. Makes leveling up with the block much easier.

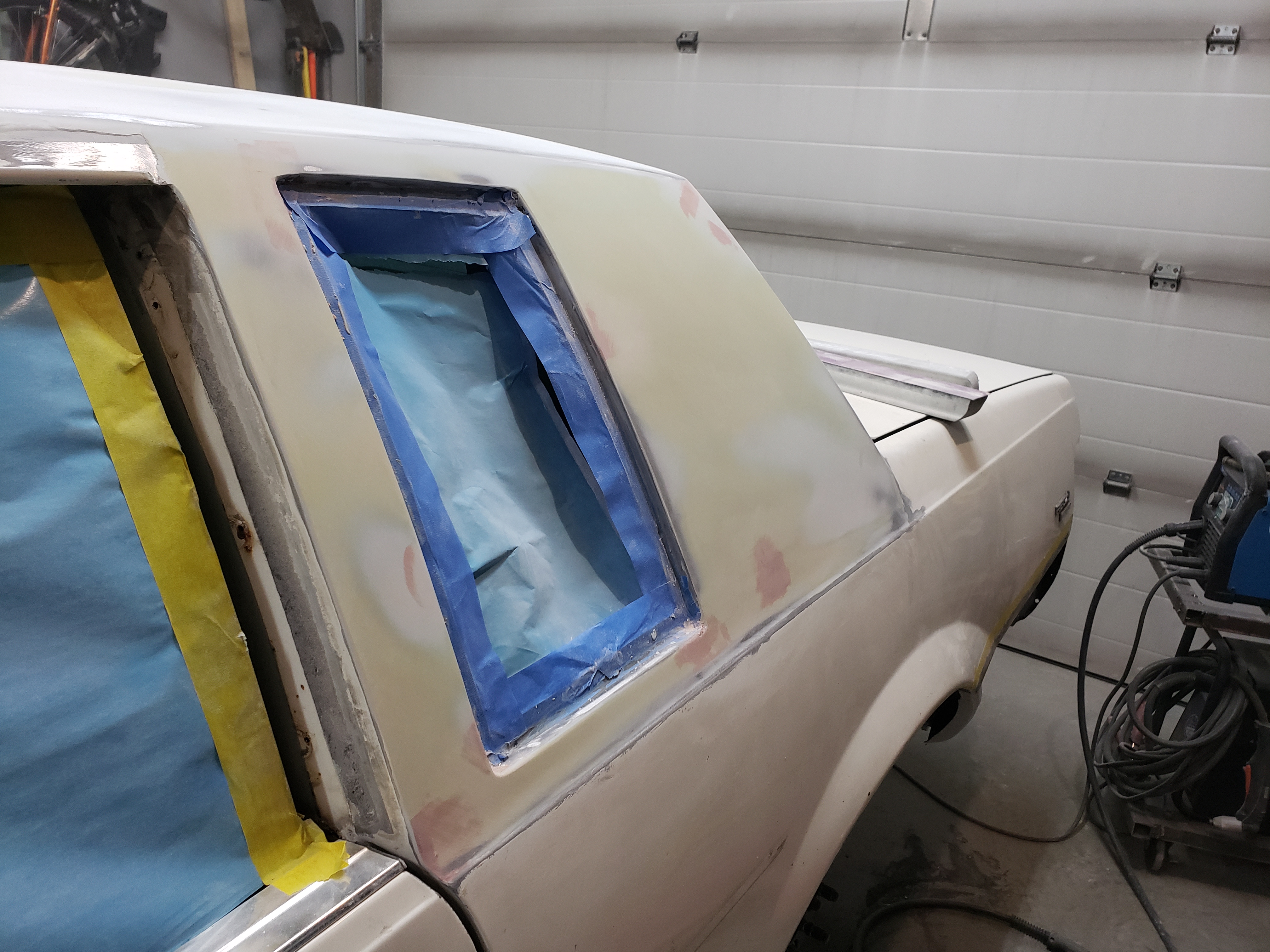

I did the B pillars at the same time so when I'm done I can fit the quarter windows and see how that's all gonna play together. This time I blocked it out to 220 it isn't even comparable to the hack job I did last time. Had a couple small details to touch up on the drivers side with putty but I'm really happy with the end product. it's super straight and smooth.

I took the opportunity when I was using the glazing putty to touch up the couple spots on the roof that needed some attention, then I finished it out to 220 also.

I'm pretty happy with the results. Considering how un-fun the roof was, I feel pretty good about the easier panels with what I've learned from this. The roof builds a lot of character, it sucked a lot. Haha.