Got it mostly welded in.

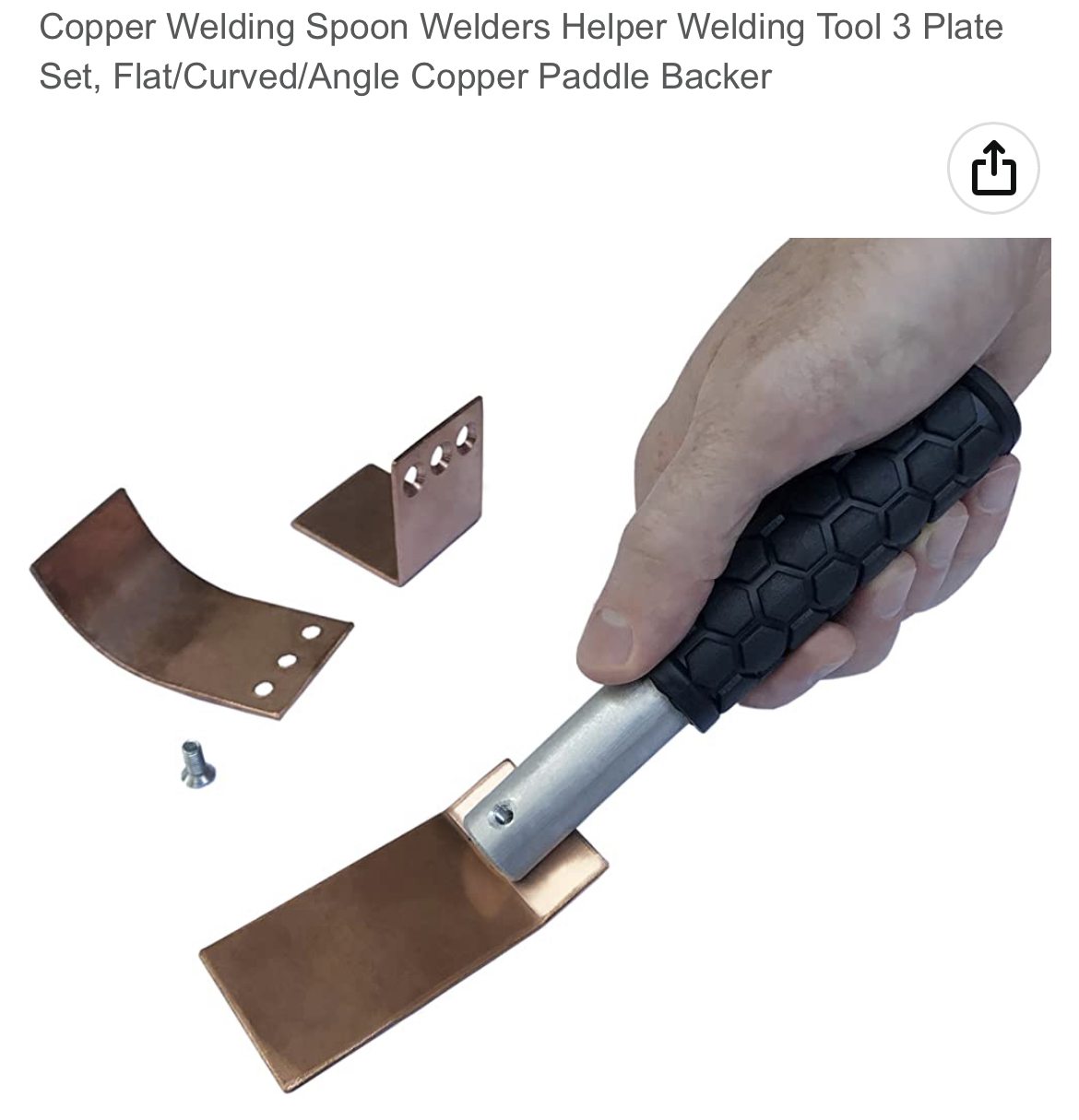

At first I had to be really careful that those little beads didn't fall through. As I laid down more and more beads, I found that the pan was more and more tolerant of heat. Eventually the welds took more time to penetrate so I held the trigger just a little longer. But some places didn't like that, it was a dynamic experience for sure. Once a problem area was bookended with a couple beads though it was super easy to glue it back shut. That top right corner got cut a little too sloppy so that's gonna be fun. I tried dropping little chunks of welding wire in and then zapping it to no avail. I really need something to help hold the heat. Anyone got any tricks up their sleeve they care to share here?

At first I had to be really careful that those little beads didn't fall through. As I laid down more and more beads, I found that the pan was more and more tolerant of heat. Eventually the welds took more time to penetrate so I held the trigger just a little longer. But some places didn't like that, it was a dynamic experience for sure. Once a problem area was bookended with a couple beads though it was super easy to glue it back shut. That top right corner got cut a little too sloppy so that's gonna be fun. I tried dropping little chunks of welding wire in and then zapping it to no avail. I really need something to help hold the heat. Anyone got any tricks up their sleeve they care to share here?