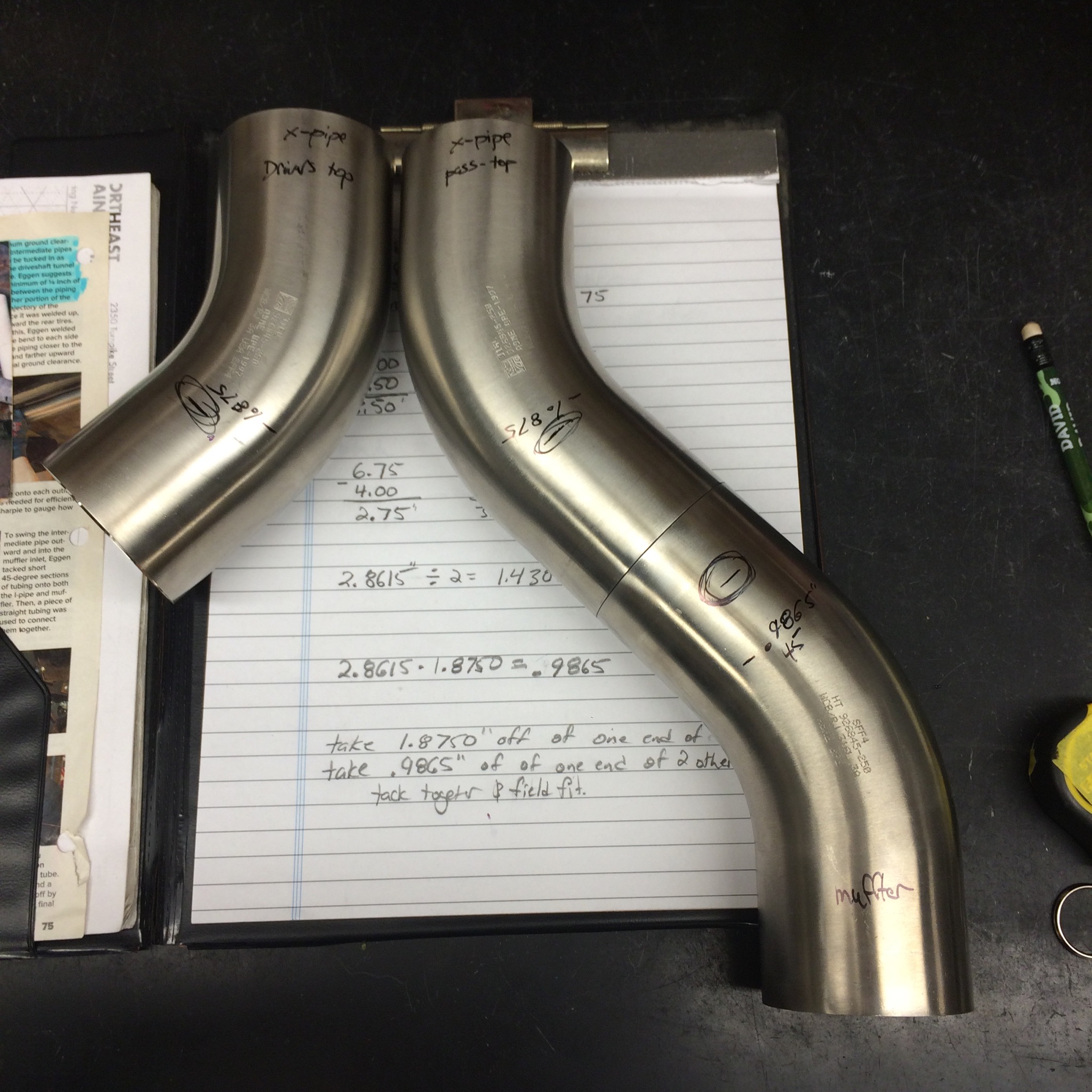

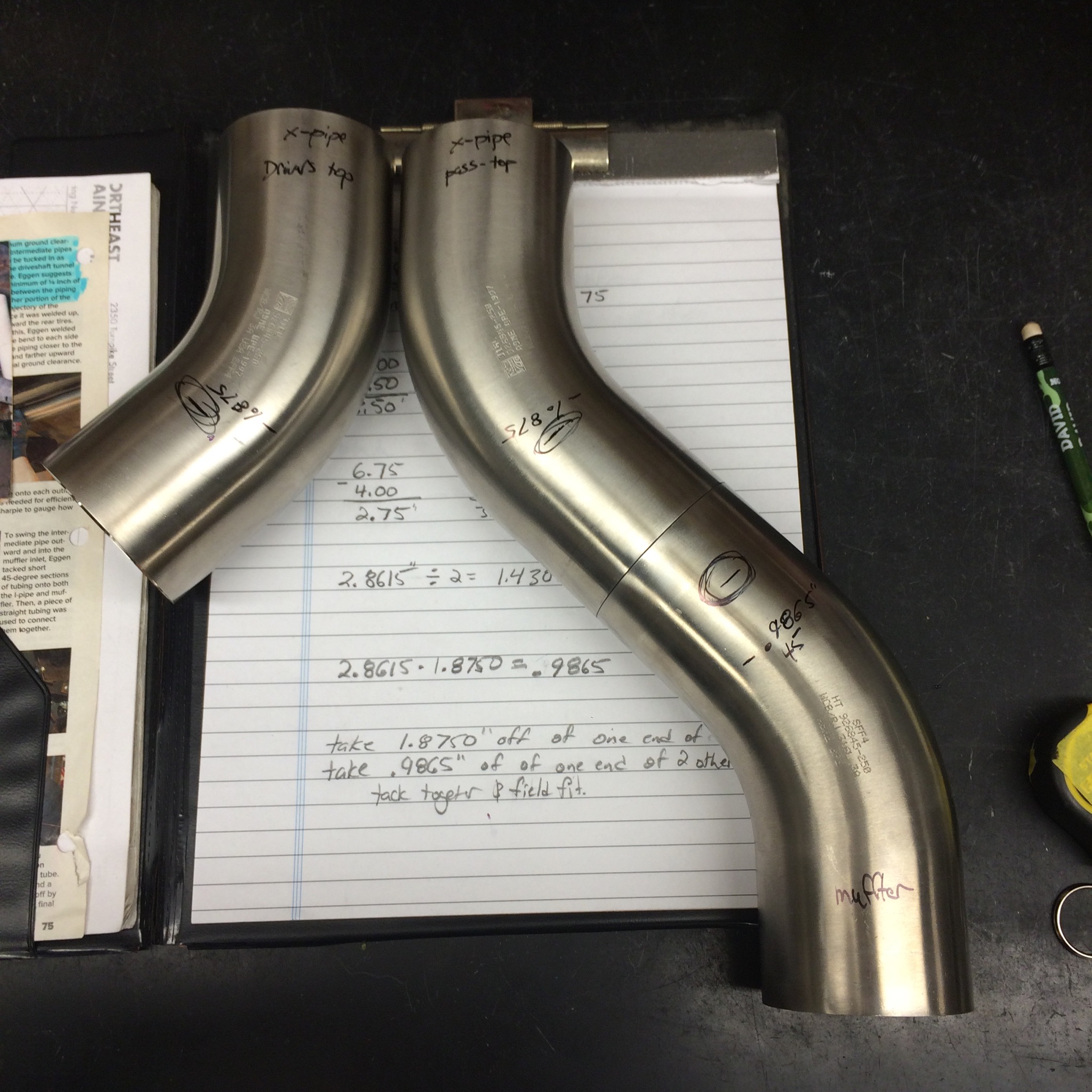

Also, what diameter driveshaft is that and what size exhaust piping. Asking for a friend.they're a pain to work around,i don't think i'd do it again.the v-band's are worthy investmentView attachment 117089View attachment 117090

X pipe

- Thread starter dickeymoore

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

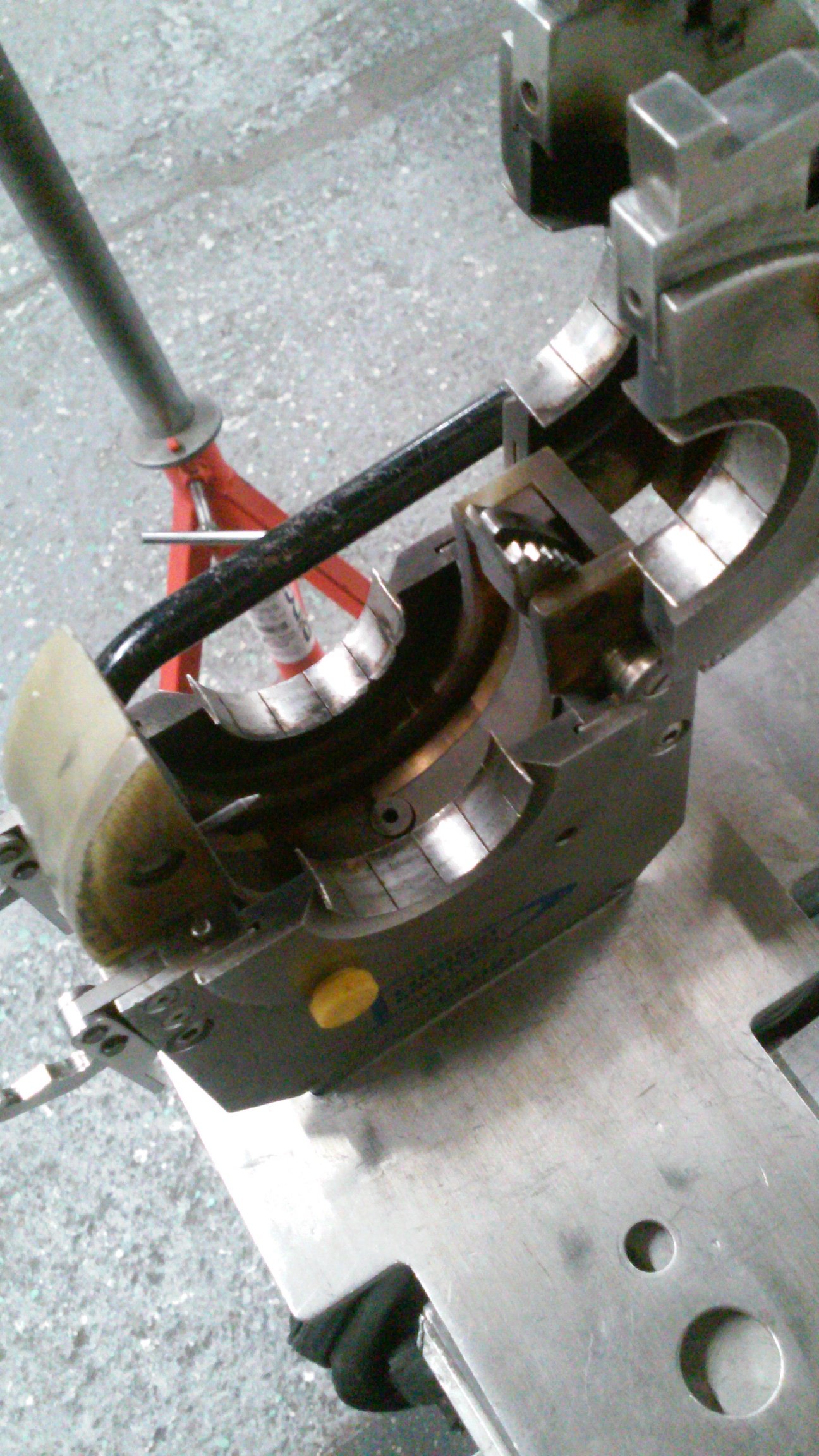

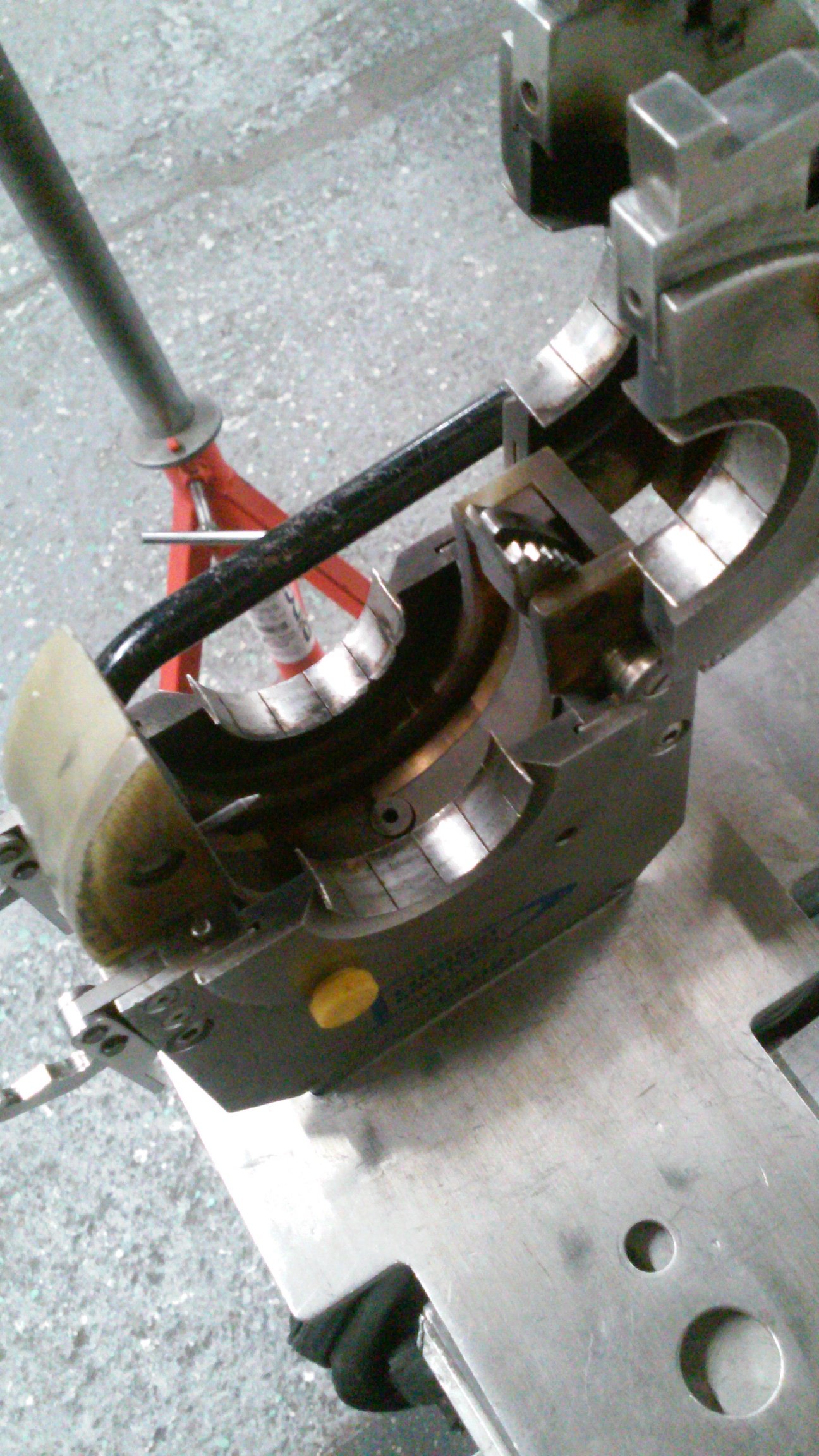

thanks,it's a 3.5"driveshaft.the exhaust is 2.5" 316 pharmaceutical stainless.it was automatic tig welded.i wish i had a video of that machine running,it's wildest thing.here's a picture of the welding head.

Last edited:

Ok, that's badass but even I'm not that OCD lol!!! It looks super clean and methodical like all of your stuff, and those sizes help me determine what stuff might fit with my 3.5" driveshaft.thanks,it's a 4"driveshaft.the exhaust is 2.5" 316 pharmaceutical stainless.it was automatic tig welded.i wish i had a video of that machine running,it's wildest thing.here's a picture of the welding head. View attachment 117093View attachment 117094

it was a giant pita.that shaft is a little closer to the left muffler but there's room.

That's an absolute work of art! When I was attempting my 180 degree header project, a friend in the med equipment field told me about that method. I was really tempted, but didn't know anyone certified to rent one. I have to ask why you kept the 3 bolt flange after all that, though.

Yeah, on our roads here, not a good idea. Surgical Stainless Steel and tight welded wow. Worth more than my 88, everything in total I bet.

honestly it didn't cross my mind until i was done with the v-bands on the tailpipes.wish i had they're slick.That's an absolute work of art! When I was attempting my 180 degree header project, a friend in the med equipment field told me about that method. I was really tempted, but didn't know anyone certified to rent one. I have to ask why you kept the 3 bolt flange after all that, though.

I don't care if an X pipe was worth 50 horsepower, I absolutely WON'T have another on any car let alone a daily driver like this car is. Once this system rots away it will be stock manifolds and true duals all the way back.

[/QUOTE

Not even for 50 horsepower? Dang

- Status

- Not open for further replies.

Similar threads

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.