Congrats on the completion of the mirror saga! They look excellent

BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I know how tedious wiring can be and you've knocked it out of the park again! Perfectly laid out and explained. Also the lines of your hood and the mirrors look great. Like they were made with each other in mind. Very very cool 😎.

Wiring sucks, looks great as always. Got to love how the bean counters decided properly working mirrors weren't necessary. I have the same dilemma with my 70, having only a factory driver side mirror. Do I really want to reinforce the passenger door just to upgrade to shitty cable ran mirrors? No, not really. I might have to figure out something similar. Good to know, nothing good is easy.

Nice work, as always Donovan. Just curious here, but what are you using for mirror mounting gaskets on the car now? They look pretty good (at least in your photos).

Congrats on the completion of the mirror saga! They look excellent

Thank you! I’m slowly getting used to them, after having the stock mirrors shaved off for so many years I got used to how it looked without them. I’m more than happy with the look of these, and now having the modern convenience of power adjustable mirrors is just icing on the cake.

I know how tedious wiring can be and you've knocked it out of the park again! Perfectly laid out and explained. Also the lines of your hood and the mirrors look great. Like they were made with each other in mind. Very very cool 😎.

Keen observation Tony! I never really noticed how the shapes and angles of the mirrors match the cowl so closely until you mentioned it. It’s especially evident in this picture…

…where the angled part of the mirror matches the shape of the back of the cowl almost perfectly. Thanks for the compliments!

Wiring sucks, looks great as always. Got to love how the bean counters decided properly working mirrors weren't necessary. I have the same dilemma with my 70, having only a factory driver side mirror. Do I really want to reinforce the passenger door just to upgrade to shitty cable ran mirrors? No, not really. I might have to figure out something similar. Good to know, nothing good is easy.

Thanks Christian. We’ve gotten spoiled over the years with all the modern conveniences in our cars nowadays, but if we revisit the point in time when these cars were built, just having remotely operated mirrors, manual or otherwise, was a pretty big deal at the time. So to bring this car into the 21st century with something as simple as power mirrors is something that most people won’t think twice about. They’ll just take it for granted as that’s how they came, and that’s fine with me. That tells me I’ve pulled off the upgrade successfully.

As for wiring, I really don’t mind it. In fact I find it relaxing and rewarding. It’s slow, tedious and time consuming work, and requires thinking ahead for a lot of things, but when you’re done it’s very satisfying. For me anyways.

Nice work, as always Donovan. Just curious here, but what are you using for mirror mounting gaskets on the car now? They look pretty good (at least in your photos).

Jeff, the gaskets that are currently installed in those pictures are the second version of the 3D printed ones I’m having made. They’re much closer to the required shape than the first attempt, but they’re still not quite right and need a bit more refining. I’m very eagerly awaiting version 3 as the guy I’m having design the file seems to think he’s got all the adjustments to the computer file for them aced.

It’s been somewhat frustrating because it’s my boss at work that has the actual printer, but he’s not proficient with the design software for creating the file from scratch. A fellow technician coworker of mine has much more experience with the software, but he’s been struggling with creating the revisions I’ve asked for between versions. So, I sit in limbo at the mercy of these two guys, a position I despise being in. I’ve been let down so many times in the past by other people, I much prefer doing everything myself. At least that way I know it’ll get done, and done right.

Unfortunately I don’t have the option of doing this myself, so I have to just be patient and wait. I guess it helps me to learn patience, understanding and trust, but I still don’t like it.

Been a slow week on the forum here by the looks of things, and a slow week in The Skunkworks too due to fulfilling other obligations for my dad and his motorcycle.

But, I’ve already started making plans for the next item on the hit list, I’ll be going after the front bumper and related filler panel again. The front bumper has already undergone an absolute massive amount of work, it’s been narrowed several inches, the end caps have been lengthened, capped and straightened, the front license plate recess has been shaved and smoothed out, and the multitude of trim holes have all been welded up to name a few of the modifications. Not visible in the pictures below is the Kirban aluminum shock absorber substitutions that have been shortened a couple inches to tuck the bumper in closer to the body. All these subtle little tweaks have made a dramatic improvement in the overall appearance of the front of the car.

I had originally planned on rechroming it once all the modifications had been completed, but with my latest envisioning of the car, I have since abandoned that idea. For several reasons. Firstly, chrome plating nowadays has become prohibitively expensive. Secondly, there is no chrome plater locally that can do a really nice, PROPER job of making a custom modified bumper look like it came that way. And thirdly, as I mentioned before, I don’t think chrome will look right in the re-envisioning I have pictured for it. So, to that end, the work I had already done to the bumper was with an old school method called “pick and filing” whereby the low spots in the metal is hammered up from behind with the pick end of a body hammer, and then filled down flush.

Way overkill for regular bodywork, but it gives a nice starting point for resuming the work. The new plan for both bumpers is to bodywork, prime and paint them body color. This will have the effect of modernizing the overall look of the entire car.

The reason I stopped and didn’t finish it several years ago is because I got a little frustrated with the required modifications for the signal lights that I’m planning on using. They are G Body Buick Regal lights. Why? Because unlike the original ‘80 Cutlass lights, the Regal ones are reproduced new in the aftermarket, and sequential LED lights are available for them from DigiTails. So that should give you a little idea of the direction I’m headed with this.

Unfortunately after sitting around in bare metal for several years, it was looking a little worse for wear. I had to spend a couple hours just sanding off all the surface flash rust, oxidation, water spots, and miscellaneous dirt and grime.

I knew I wouldn’t be done with the modifications just yet, so fortunately I had hung onto two other spare stock bumpers that’ll be good for cannon fodder.

Here’s all three together on the stand:

Once you start comparing the stock bumpers to the modified one, the alterations become quite evident. Here’s a comparison of the extended end caps that tuck into the recesses in each fender:

Here, the modified bumper has the front tag pocket removed, the stock bumper is below it for comparison:

And a look at the amount that it has been narrowed over stock:

You may notice how much cleaner it’s looking too, much better than before. I never should’ve let it get that bad.

Also visible in the picture of all three bumpers together is a length of 1” x 1/8” angle iron. This will be for the “new” plan for the signal lights. It will entail building “boxes” out of the angle iron to house the lights, then welding those into the bumper, that’s the plan at least.

Stay tuned to see that all plays out over the next couple days. Until then,

D.

But, I’ve already started making plans for the next item on the hit list, I’ll be going after the front bumper and related filler panel again. The front bumper has already undergone an absolute massive amount of work, it’s been narrowed several inches, the end caps have been lengthened, capped and straightened, the front license plate recess has been shaved and smoothed out, and the multitude of trim holes have all been welded up to name a few of the modifications. Not visible in the pictures below is the Kirban aluminum shock absorber substitutions that have been shortened a couple inches to tuck the bumper in closer to the body. All these subtle little tweaks have made a dramatic improvement in the overall appearance of the front of the car.

I had originally planned on rechroming it once all the modifications had been completed, but with my latest envisioning of the car, I have since abandoned that idea. For several reasons. Firstly, chrome plating nowadays has become prohibitively expensive. Secondly, there is no chrome plater locally that can do a really nice, PROPER job of making a custom modified bumper look like it came that way. And thirdly, as I mentioned before, I don’t think chrome will look right in the re-envisioning I have pictured for it. So, to that end, the work I had already done to the bumper was with an old school method called “pick and filing” whereby the low spots in the metal is hammered up from behind with the pick end of a body hammer, and then filled down flush.

Way overkill for regular bodywork, but it gives a nice starting point for resuming the work. The new plan for both bumpers is to bodywork, prime and paint them body color. This will have the effect of modernizing the overall look of the entire car.

The reason I stopped and didn’t finish it several years ago is because I got a little frustrated with the required modifications for the signal lights that I’m planning on using. They are G Body Buick Regal lights. Why? Because unlike the original ‘80 Cutlass lights, the Regal ones are reproduced new in the aftermarket, and sequential LED lights are available for them from DigiTails. So that should give you a little idea of the direction I’m headed with this.

Unfortunately after sitting around in bare metal for several years, it was looking a little worse for wear. I had to spend a couple hours just sanding off all the surface flash rust, oxidation, water spots, and miscellaneous dirt and grime.

I knew I wouldn’t be done with the modifications just yet, so fortunately I had hung onto two other spare stock bumpers that’ll be good for cannon fodder.

Here’s all three together on the stand:

Once you start comparing the stock bumpers to the modified one, the alterations become quite evident. Here’s a comparison of the extended end caps that tuck into the recesses in each fender:

Here, the modified bumper has the front tag pocket removed, the stock bumper is below it for comparison:

And a look at the amount that it has been narrowed over stock:

You may notice how much cleaner it’s looking too, much better than before. I never should’ve let it get that bad.

Also visible in the picture of all three bumpers together is a length of 1” x 1/8” angle iron. This will be for the “new” plan for the signal lights. It will entail building “boxes” out of the angle iron to house the lights, then welding those into the bumper, that’s the plan at least.

Stay tuned to see that all plays out over the next couple days. Until then,

D.

That bumper is going to look bad and I mean that in the best possible way. Cannot imagine the amount of time spent getting it to this point. I must have missed those posts or just so long ago my memory fails me. Keep on keeping on D.

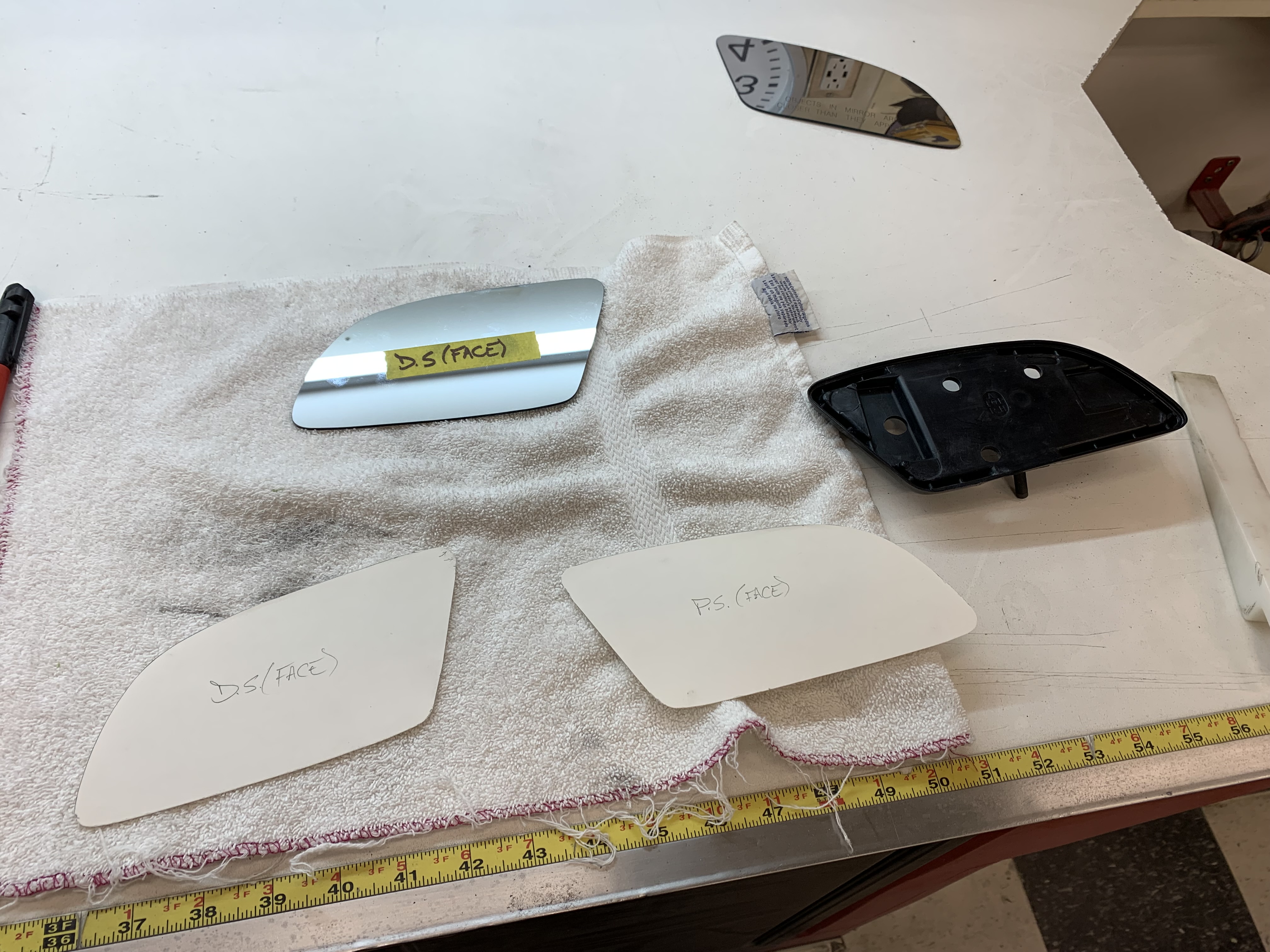

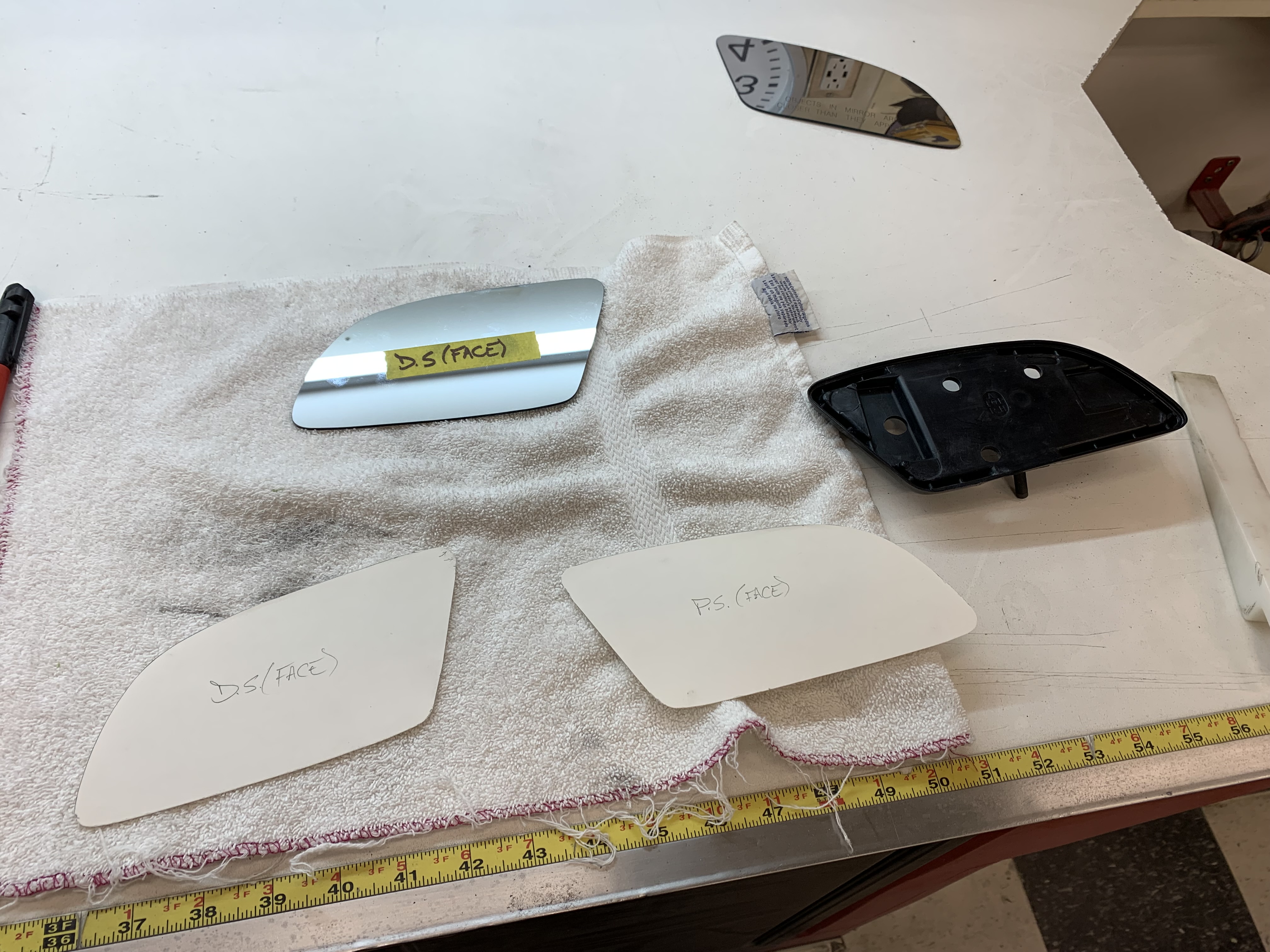

Mirror update!

Some of you might remember how the aftermarket replacement mirror glass I got from Rock Auto didn’t really fit very well. The driver’s side was slightly oversized and didn’t fit inside it’s plastic carrier, and the cut of the passenger’s side was completely wrong and shy material in the upper left corner:

Yeah, you can call me anal retentive, overly fussy or just plain picky, but it’s either right or it’s not. Anything worth doing is worth doing properly IMO.

So after setting this little issue aside for a few weeks, last week I visited a glass fabrication company for work and it occurred to me that they might be able to help. I outlined the issue I was having, and they said that they would be able to grind down oversize edges of mirror glass without issue.

Having this brought to the forefront of my attention, that night I jumped on the interwebz and ordered two more replacement mirror glass inserts, this time as oversized as I could get from Rock Auto. When they arrived today, I grabbed the passenger’s side and immediately tried fitting it into the carrier. Much to my surprise, it not only wasn’t oversized, it actually dropped right in and fit great without any modification.

Great news, already halfway there.

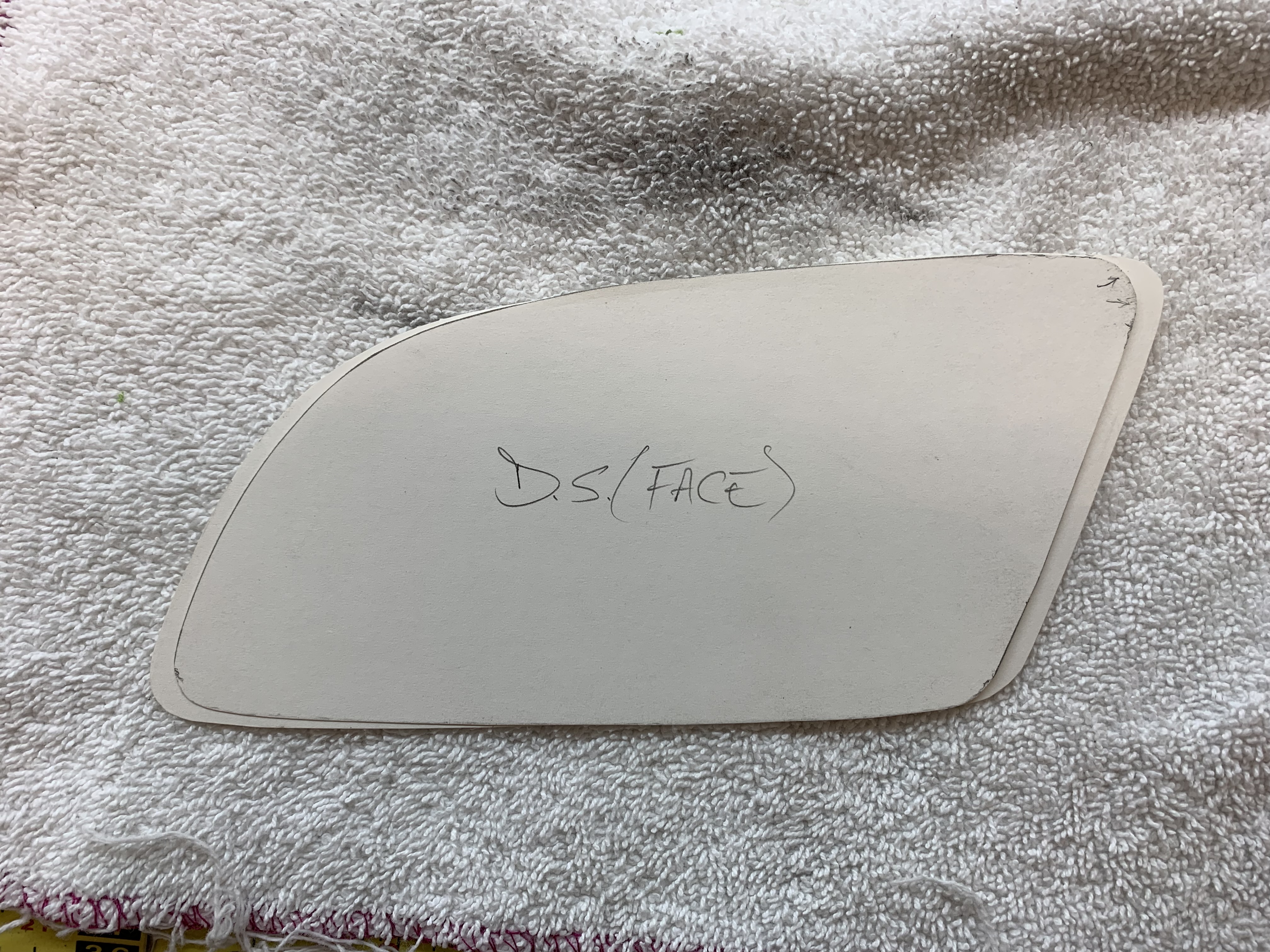

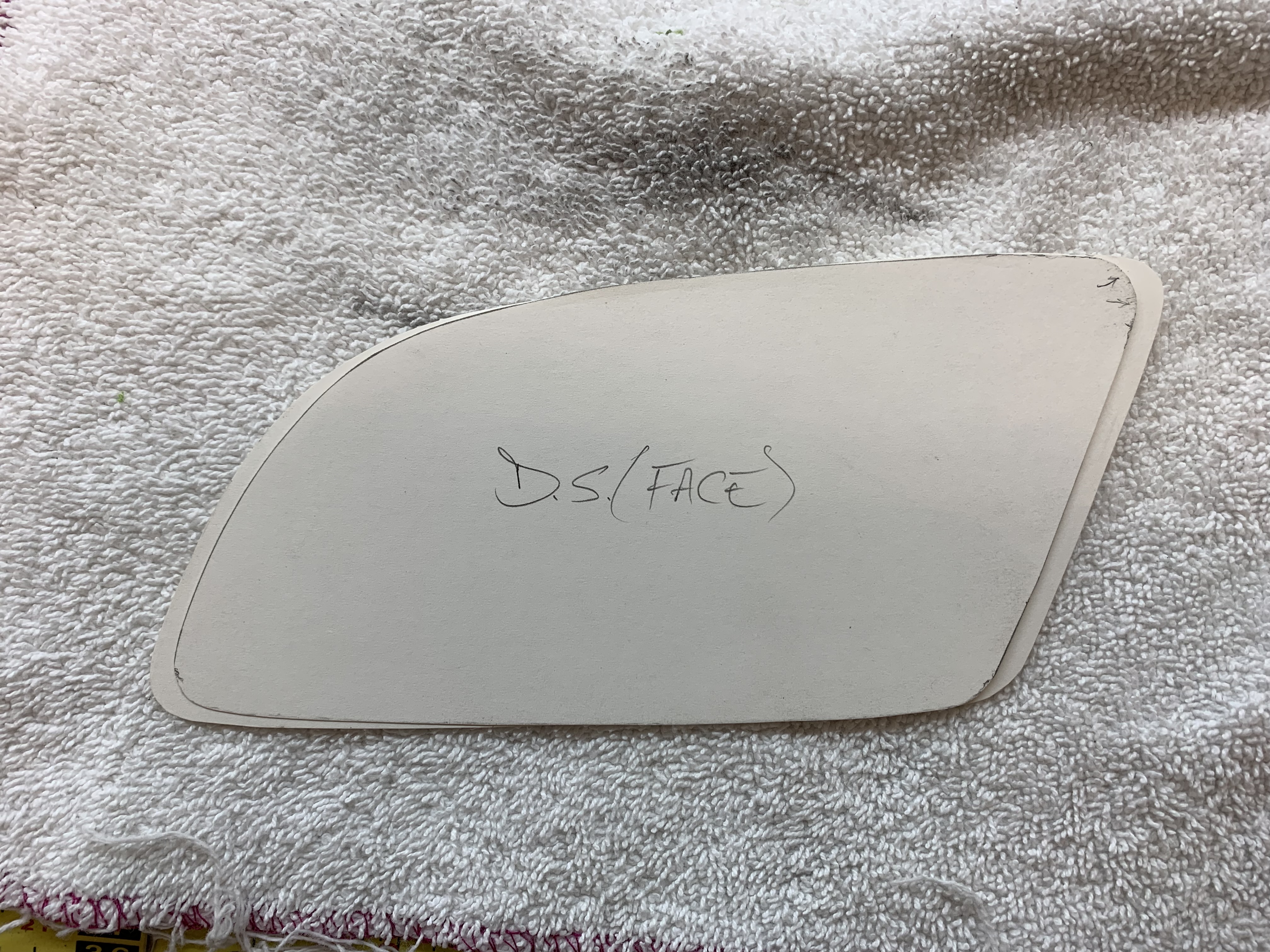

For the driver’s side, I carefully removed the previously installed mirror glass and made a cardboard template for the actual size it should be.

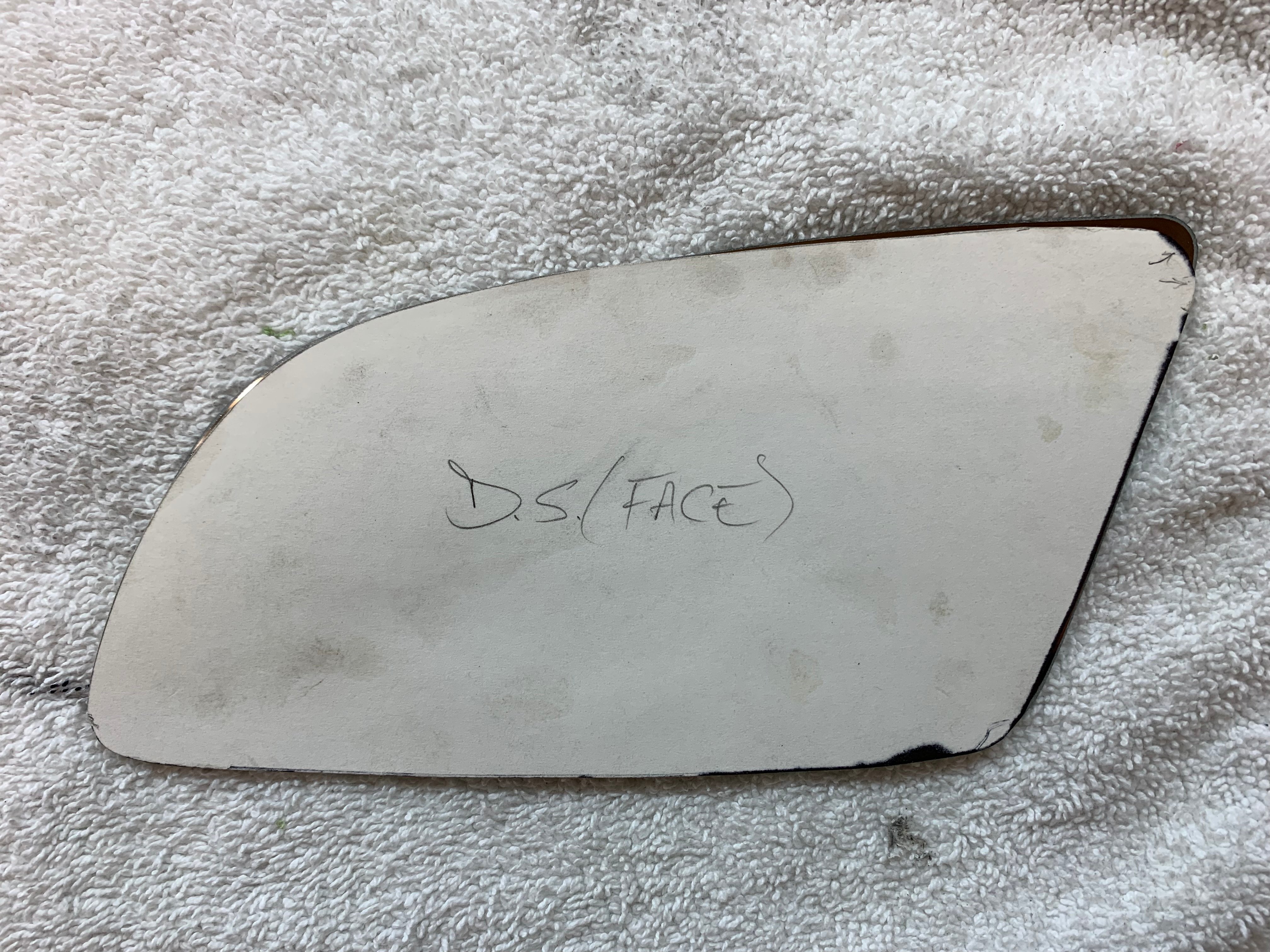

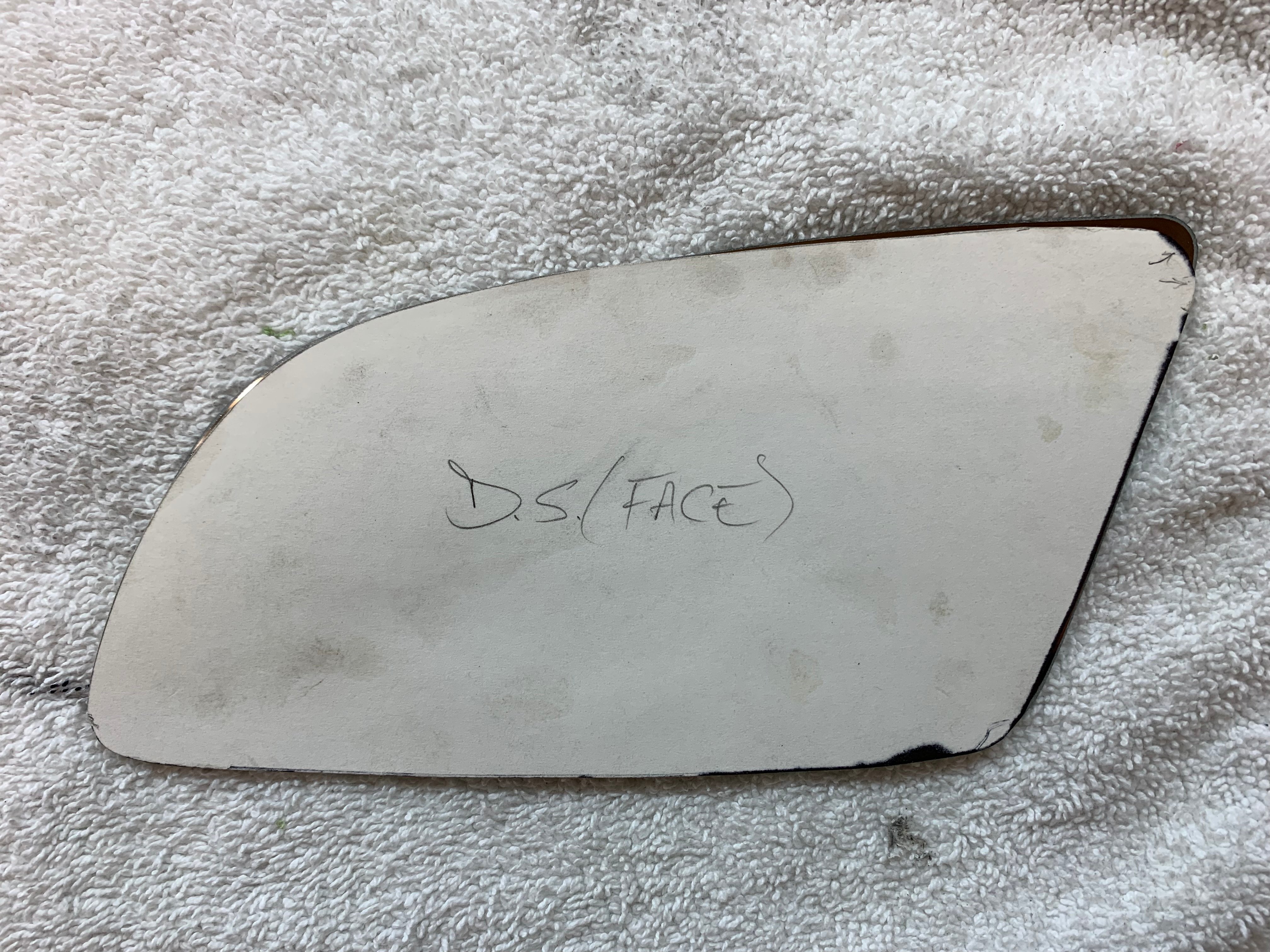

Now keep in mind, this is the original one I had installed in the mirror, disappointingly the driver’s side mirror replacement I got today was cut even worse.

This is how much material needs to be removed, not terrible, and mostly off the bottom:

An interesting observation, you’d think both sides would be the same size right? Surprisingly not, the passenger’s side is actually considerably larger as evidenced in this picture of the driver’s side template overlaid on the passenger’s side:

The new Burco brand replacements that arrived today:

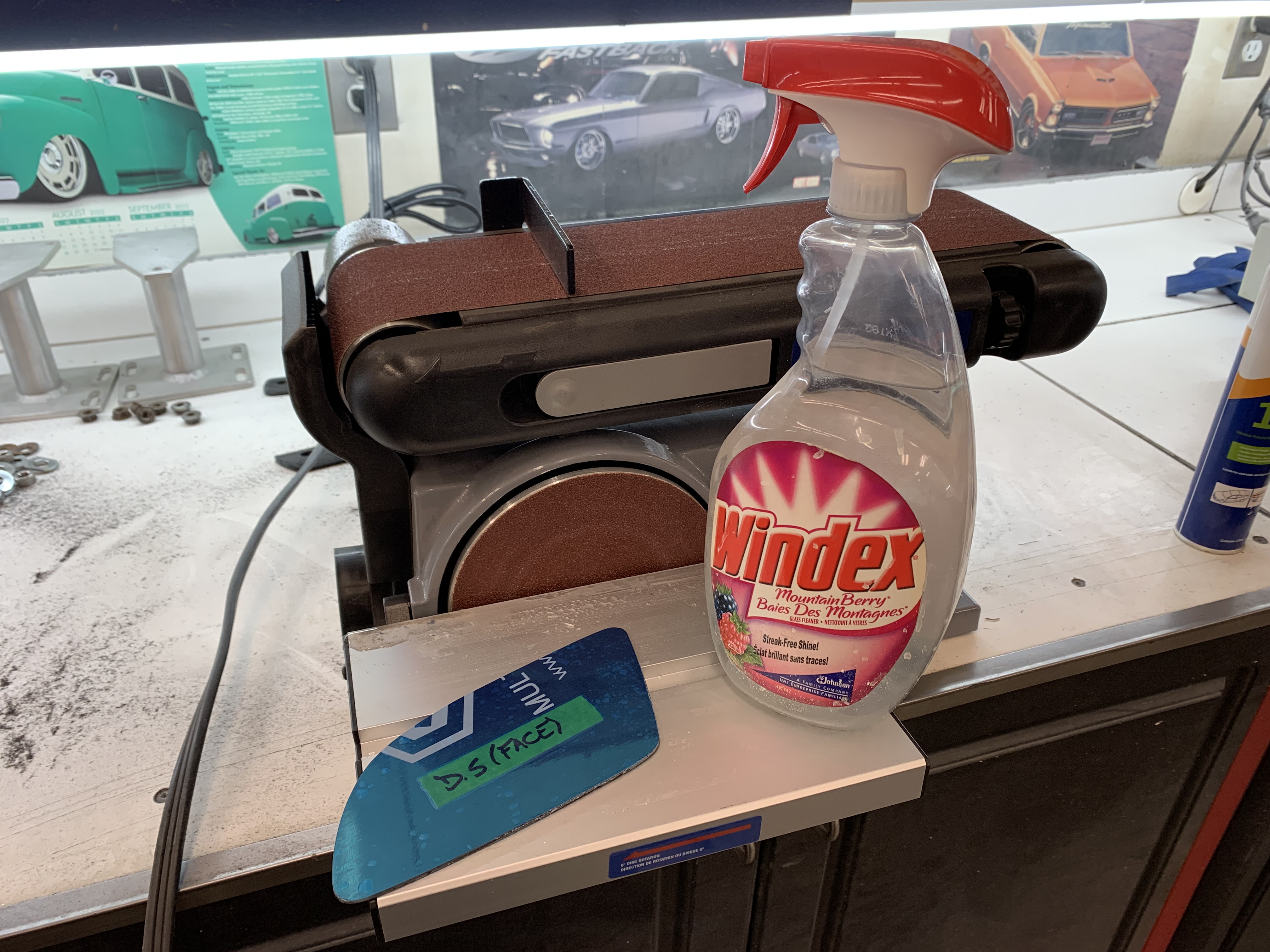

Armed with the template for the driver’s side and the original mirror glass, I headed up to see my glass contact. He has a large vertical water lubricated belt sander that they use for this purpose, and after applying a thin plastic sheet to protect the mirror, he carefully removed the excess material until it closely matched the template. Upon returning home, I immediately tried it in the carrier but was dismayed to find it was still a bit too big.

Rather than making the hour-long round trip to see him again, I thought to myself, I can probably do this myself here at home. I overlaid the template on the glass and marked out the areas that needed a little more removal with a black Sharpie.

It just so happens that I recently picked up a combination belt/disc sander, so with a spray bottle of water, I should be able to duplicate the process.

Aaaaand, voilà. With a little time and several test fits, I had it fitting perfectly!

In fact, I got it fitting so snugly that I actually had to lightly pry it back out of the carrier.

So there ya go guys, if you have this issue with any of your rides, it’s totally do-able at home in your own shop.

One more little thing off the list. This actually isn’t what I’ve been working feverishly on lately, that would be the front bumper. Lots to update on with that next time.

Some of you might remember how the aftermarket replacement mirror glass I got from Rock Auto didn’t really fit very well. The driver’s side was slightly oversized and didn’t fit inside it’s plastic carrier, and the cut of the passenger’s side was completely wrong and shy material in the upper left corner:

Yeah, you can call me anal retentive, overly fussy or just plain picky, but it’s either right or it’s not. Anything worth doing is worth doing properly IMO.

So after setting this little issue aside for a few weeks, last week I visited a glass fabrication company for work and it occurred to me that they might be able to help. I outlined the issue I was having, and they said that they would be able to grind down oversize edges of mirror glass without issue.

Having this brought to the forefront of my attention, that night I jumped on the interwebz and ordered two more replacement mirror glass inserts, this time as oversized as I could get from Rock Auto. When they arrived today, I grabbed the passenger’s side and immediately tried fitting it into the carrier. Much to my surprise, it not only wasn’t oversized, it actually dropped right in and fit great without any modification.

Great news, already halfway there.

For the driver’s side, I carefully removed the previously installed mirror glass and made a cardboard template for the actual size it should be.

Now keep in mind, this is the original one I had installed in the mirror, disappointingly the driver’s side mirror replacement I got today was cut even worse.

This is how much material needs to be removed, not terrible, and mostly off the bottom:

An interesting observation, you’d think both sides would be the same size right? Surprisingly not, the passenger’s side is actually considerably larger as evidenced in this picture of the driver’s side template overlaid on the passenger’s side:

The new Burco brand replacements that arrived today:

Armed with the template for the driver’s side and the original mirror glass, I headed up to see my glass contact. He has a large vertical water lubricated belt sander that they use for this purpose, and after applying a thin plastic sheet to protect the mirror, he carefully removed the excess material until it closely matched the template. Upon returning home, I immediately tried it in the carrier but was dismayed to find it was still a bit too big.

Rather than making the hour-long round trip to see him again, I thought to myself, I can probably do this myself here at home. I overlaid the template on the glass and marked out the areas that needed a little more removal with a black Sharpie.

It just so happens that I recently picked up a combination belt/disc sander, so with a spray bottle of water, I should be able to duplicate the process.

Aaaaand, voilà. With a little time and several test fits, I had it fitting perfectly!

In fact, I got it fitting so snugly that I actually had to lightly pry it back out of the carrier.

So there ya go guys, if you have this issue with any of your rides, it’s totally do-able at home in your own shop.

One more little thing off the list. This actually isn’t what I’ve been working feverishly on lately, that would be the front bumper. Lots to update on with that next time.

Things like that make all the difference in the world to those who are detail oriented. The mirror looks so much better now that it has uniform black trim around it.

After literally months and months of fabrication, cutting, welding, grinding, test fitting, tweaking, reworking, modifying, adjusting, and countless other things, all the fabrication on the front bumper is finally done.

Still have to get the aluminum bumper shock substitutions shortened a half inch and welded back together again, but at least now I can start on the filler and bodywork process.

Video on Instagram:

Don’t have Instagram? It should still be visible. Otherwise, too bad, suck it up buttercup. It’s the 21st century, time to get with the times.

🤣🤣🤣

For those of you who miss my old school long update posts, I’ll do one of those too, but it’s going to take some time. I literally have 3 months worth of pictures, work, procedures, and modifications done to it to cover. And with me working on it nearly every day over those 3 months, trust me - it’s a lot.

D.

Still have to get the aluminum bumper shock substitutions shortened a half inch and welded back together again, but at least now I can start on the filler and bodywork process.

Video on Instagram:

Don’t have Instagram? It should still be visible. Otherwise, too bad, suck it up buttercup. It’s the 21st century, time to get with the times.

🤣🤣🤣

For those of you who miss my old school long update posts, I’ll do one of those too, but it’s going to take some time. I literally have 3 months worth of pictures, work, procedures, and modifications done to it to cover. And with me working on it nearly every day over those 3 months, trust me - it’s a lot.

D.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.