Rear sway bar mounted, end links on order.

Front sway bar was a bit of a challenge. Not much real estate to work with.

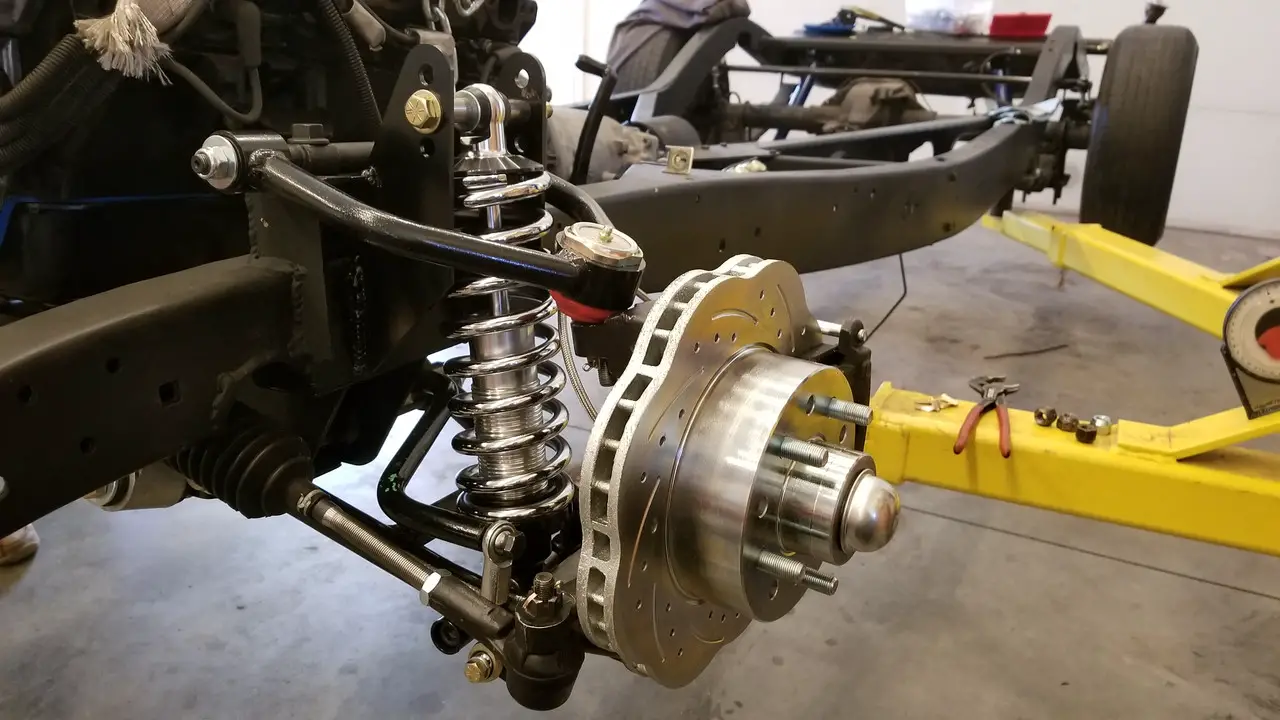

We also modified the crossmember to lower the rack mounts. The tie rods aren't exactly parallel to the lower control arms but certainly much closer.

We dropped the engine and transmission in (hopefully for the last time) and set the ride height then mocked up a fender just to see how it sits.

Next time we'll probably start on the upper coilover mounts and the brake lines.

Front sway bar was a bit of a challenge. Not much real estate to work with.

We also modified the crossmember to lower the rack mounts. The tie rods aren't exactly parallel to the lower control arms but certainly much closer.

We dropped the engine and transmission in (hopefully for the last time) and set the ride height then mocked up a fender just to see how it sits.

Next time we'll probably start on the upper coilover mounts and the brake lines.