I remembered the last two new trans seals, the TV and dipstick tube.

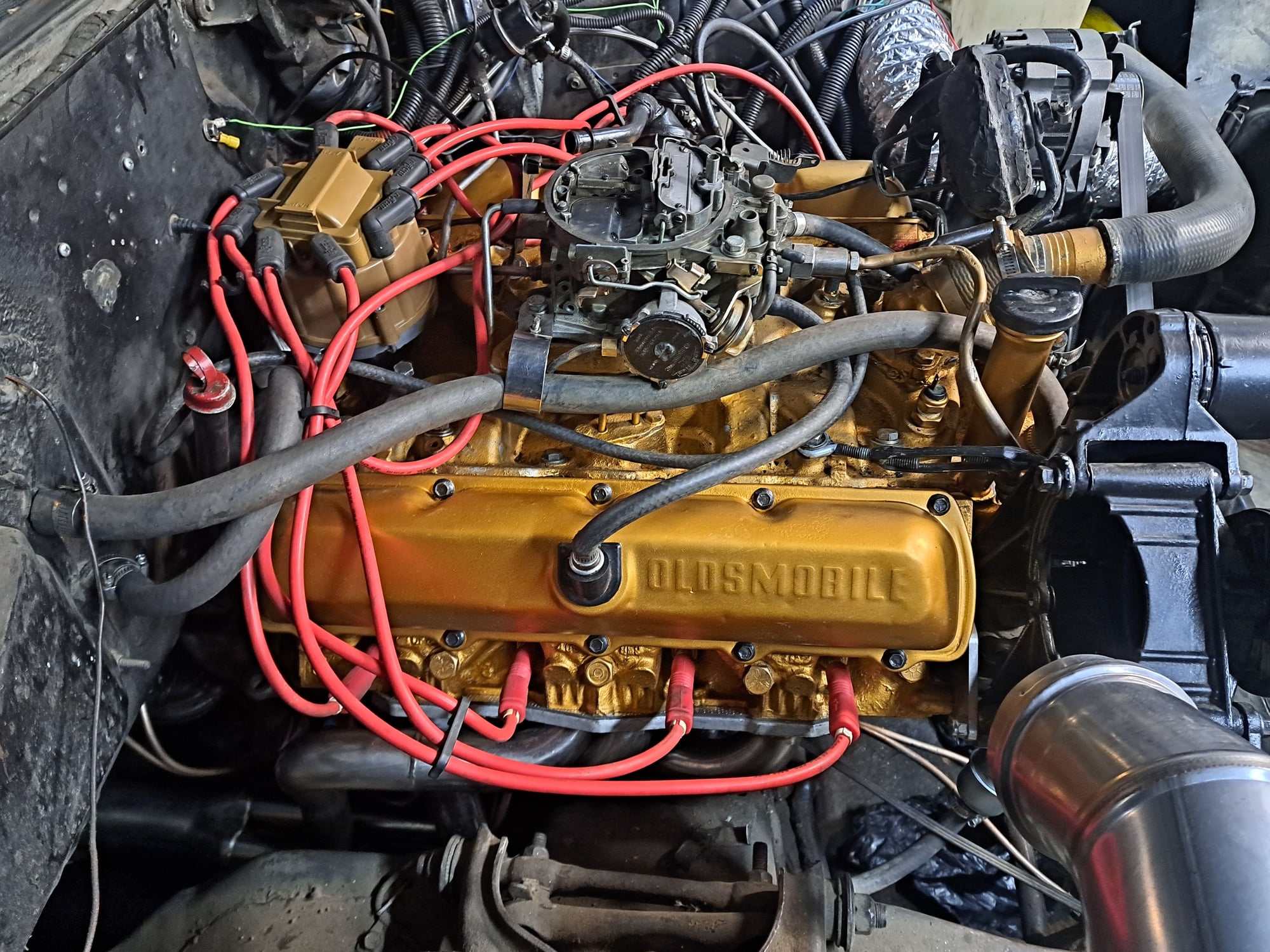

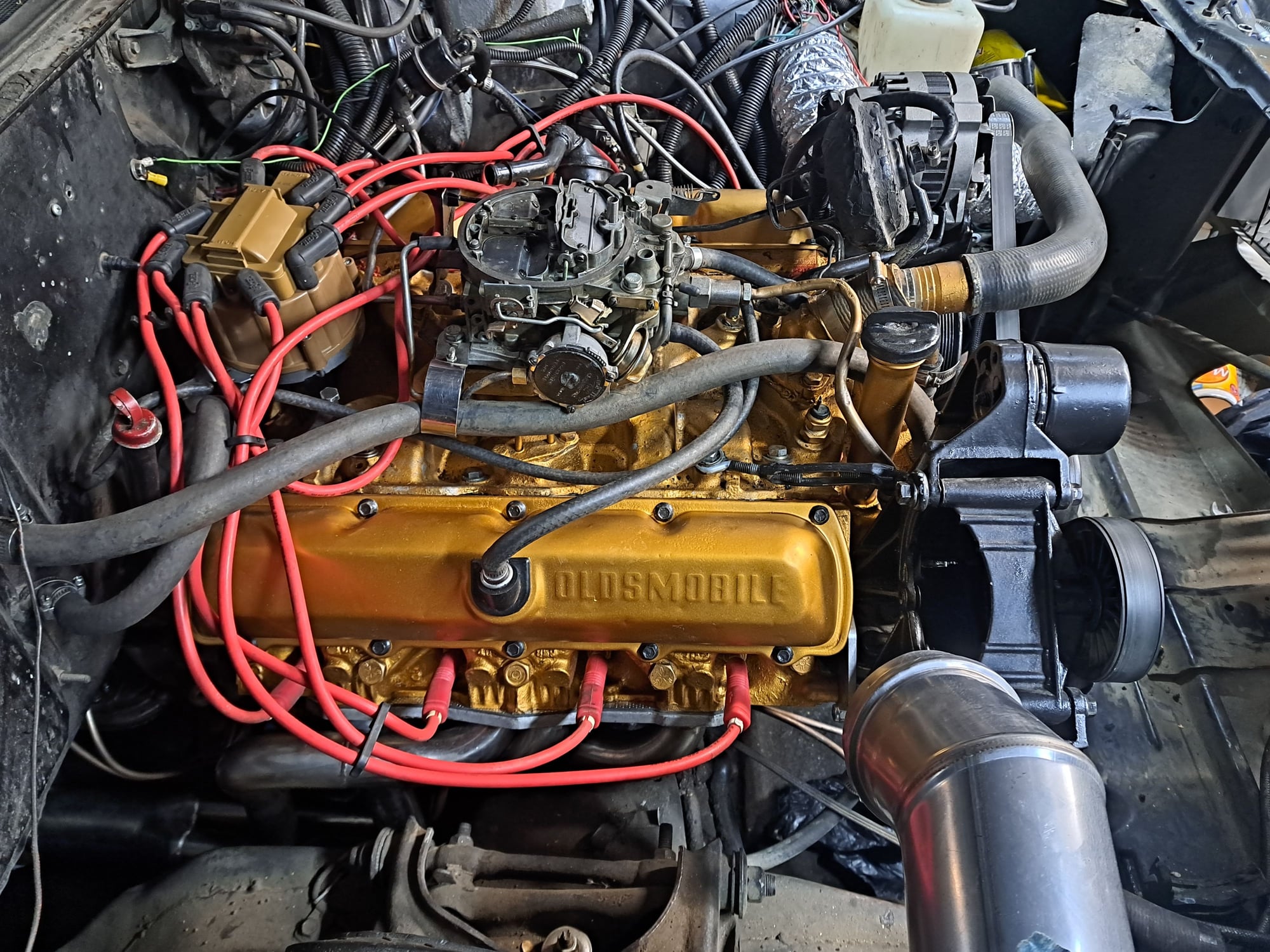

Oh yeah, after many hours, I remembered why full length headers suck! Good thing they are worth 30 HP/TQ over manifolds and dual exhaust. No way the taller Baldwin B9 would fit. Even the Napa 1258 just touched the pipe, the K+N was even worse. I used an exhaust clamp on the pipe, a tiny bit of space now. Now the starter, no way the Powermaster mini starter will fit, connections hit the pipe opposite is no good also. The no name fit but didn't have infinite adjustment, had multiple holes and needed to be half way in between. The solution was the infinite adjustment block off the Powermaster on the no name starter. I used double exhaust clamps to pull the two pipes together and moved the starter wire tube and attached to the back of the head. It is close on the main power connection, hopefully it will be fine.

Oh yeah, after many hours, I remembered why full length headers suck! Good thing they are worth 30 HP/TQ over manifolds and dual exhaust. No way the taller Baldwin B9 would fit. Even the Napa 1258 just touched the pipe, the K+N was even worse. I used an exhaust clamp on the pipe, a tiny bit of space now. Now the starter, no way the Powermaster mini starter will fit, connections hit the pipe opposite is no good also. The no name fit but didn't have infinite adjustment, had multiple holes and needed to be half way in between. The solution was the infinite adjustment block off the Powermaster on the no name starter. I used double exhaust clamps to pull the two pipes together and moved the starter wire tube and attached to the back of the head. It is close on the main power connection, hopefully it will be fine.