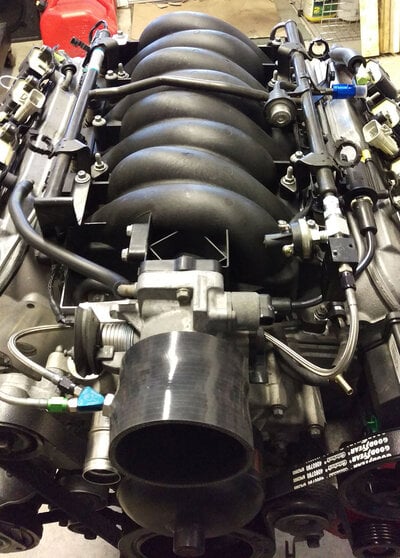

And that is pretty much it - the engine is built; except that I have to measure for and order some pushrods. The last thing I had to finish up was the nitrous kit. The goal here was to install all of the components on the intake itself (short of a few relays); just in case I need to remove it from the engine (to say install it into the car).

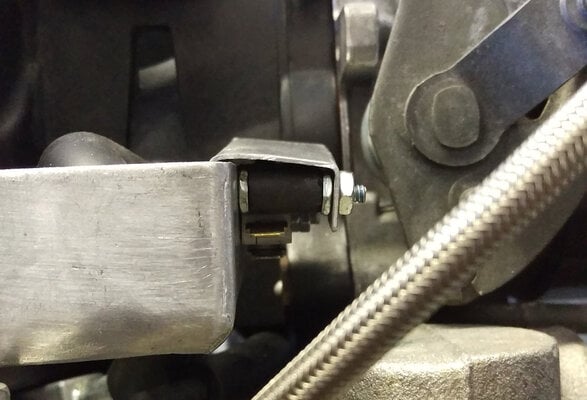

Unfortunately the old dishwasher I salvaged the micro-switch from didn't have a lever arm installed... so I made one and integrated it into the bracket. The WOT micro-switch is connected to a fuel pressure safety switch, which is connected to an RPM window switch - because safety first.

I would really like to set the purge up to bleed out of the unused antenna hole in the fender.

Unfortunately the old dishwasher I salvaged the micro-switch from didn't have a lever arm installed... so I made one and integrated it into the bracket. The WOT micro-switch is connected to a fuel pressure safety switch, which is connected to an RPM window switch - because safety first.

I would really like to set the purge up to bleed out of the unused antenna hole in the fender.