That double flare looks nice! The problem with stainless lines comes with working on lines that have already been flared. The line kit I got from inline tube had to be modified, and I ended up having to trash a couple lines! A buddy of mine has the eastwood tool, and we almost broke it trying to double flare.

I found out from inline tube that once they bend/flare the stainless becomes annealed and renders it almost impossible to work with unless a hydraulic flaring tool is used!

Sorry for being long winded, just glad to see you had success getting it done!

Not a problem at all. The back and forth discussions have been where I learn the most. I have yet to come away without picking up a tip, trick, or nugget of information that has served me well.

To you post: I always thought "annealing" metal made it easier to work with by rearranging the molecules to make it more malleable. I did read that using a pipe cutting tool can "work harden" stainless making it harder and more prone to cracking.

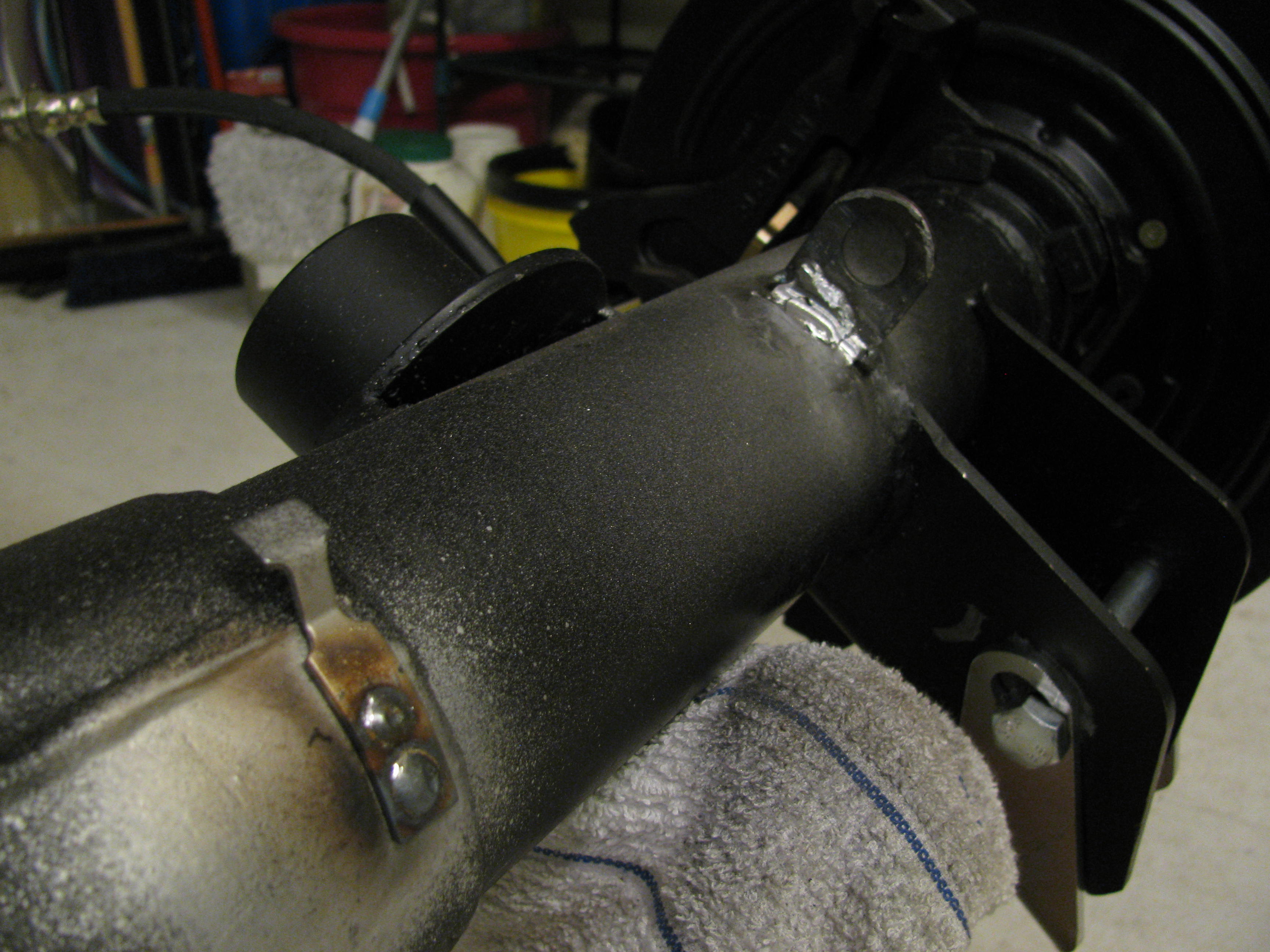

In either case, I used the excess SS line (and using a pipe cutter to cut it) to practice many times with. They all came out great, and so did the actual lines I needed double flaring.

I guess the real test will come when I bleed the brakes and really stand on them. They're either gonna leak or not. 😉

Hutch