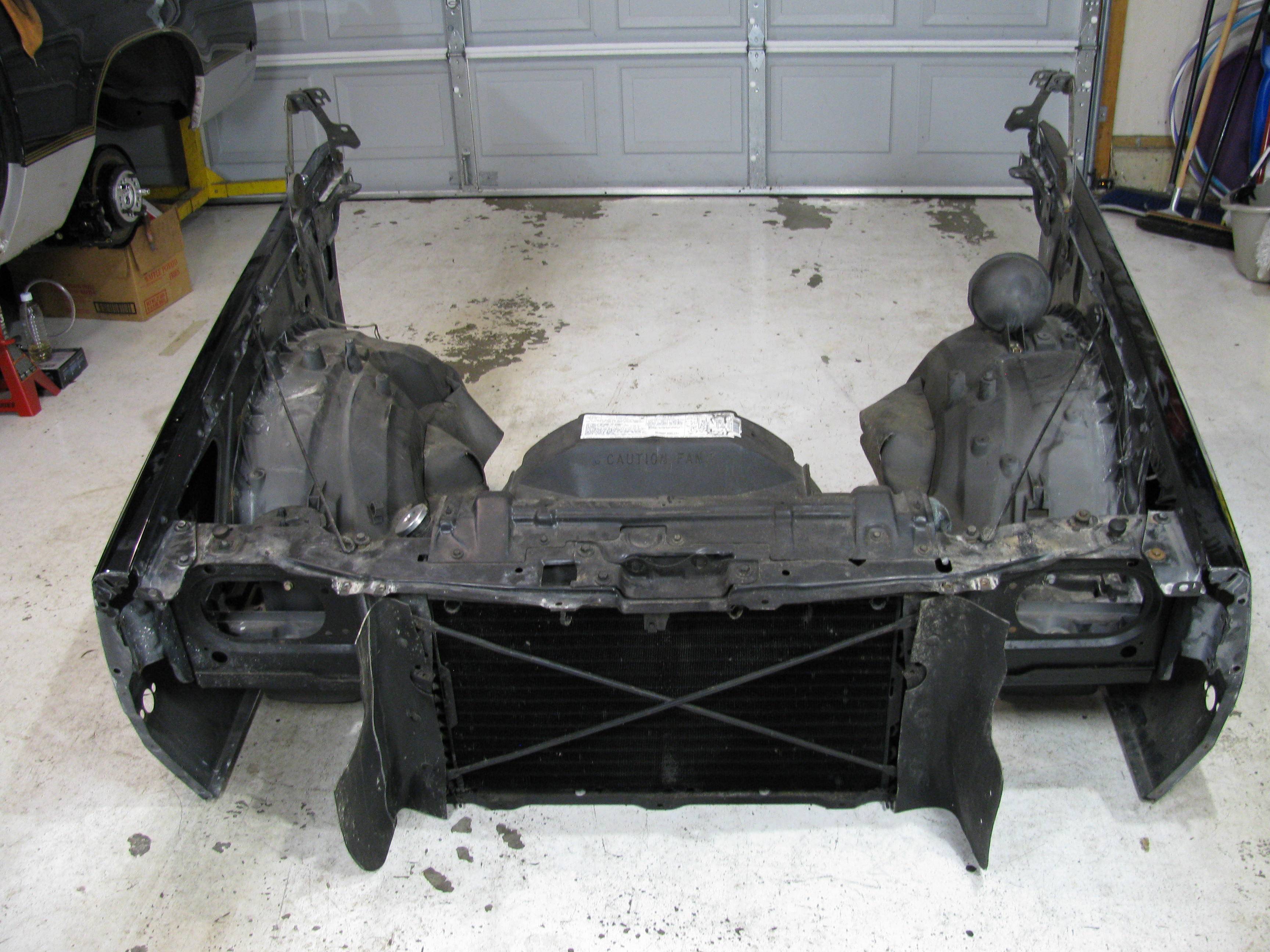

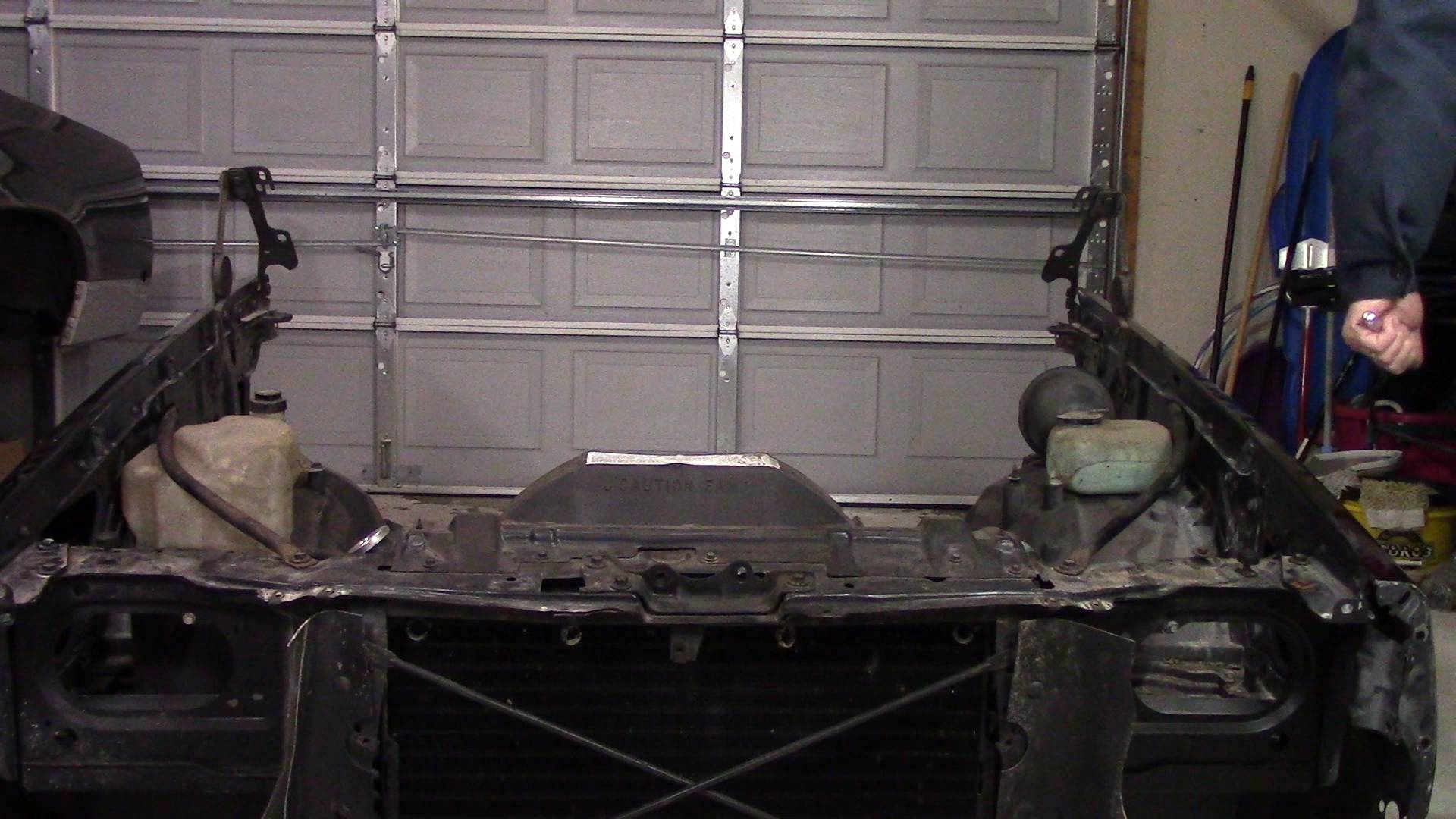

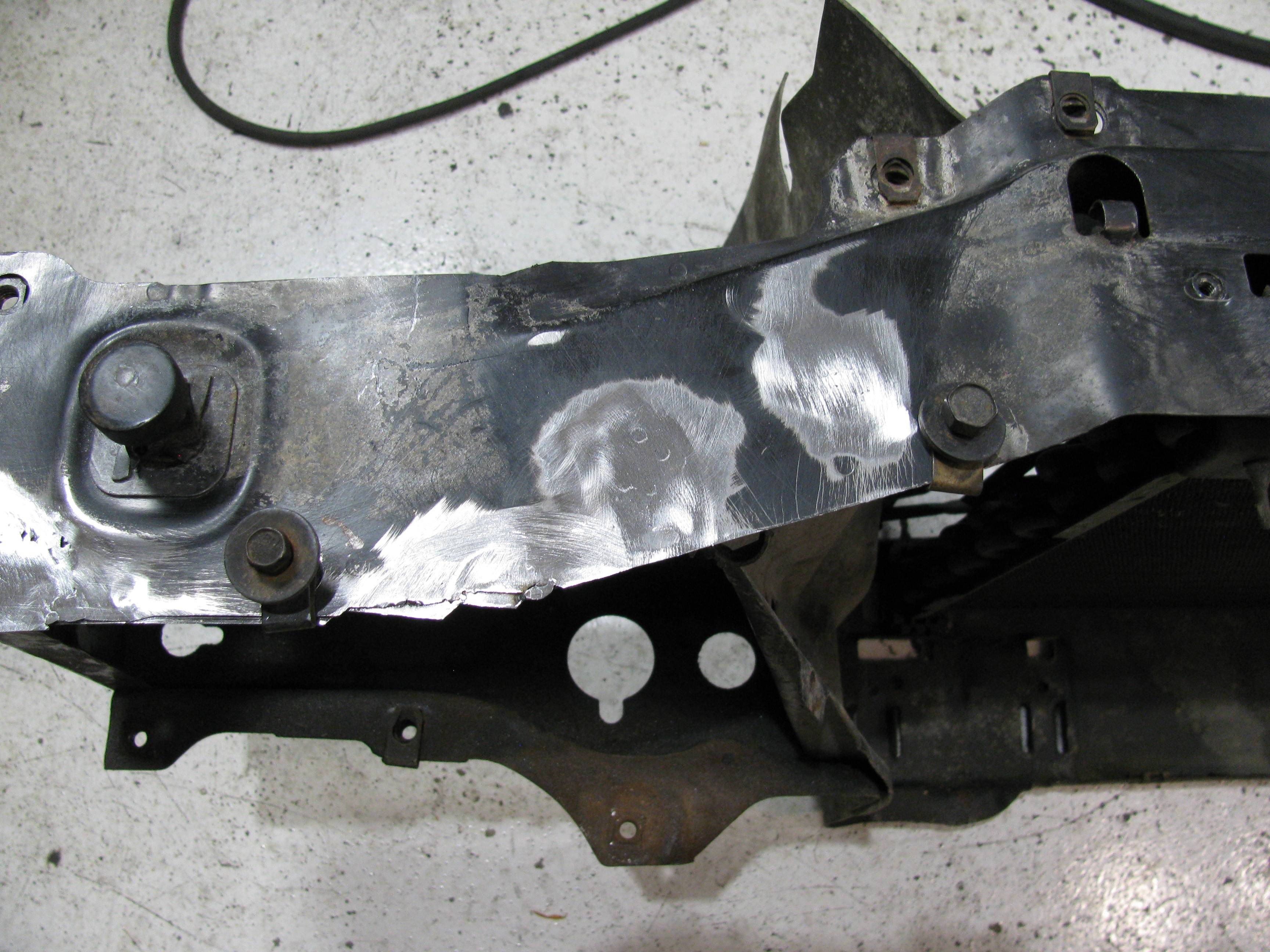

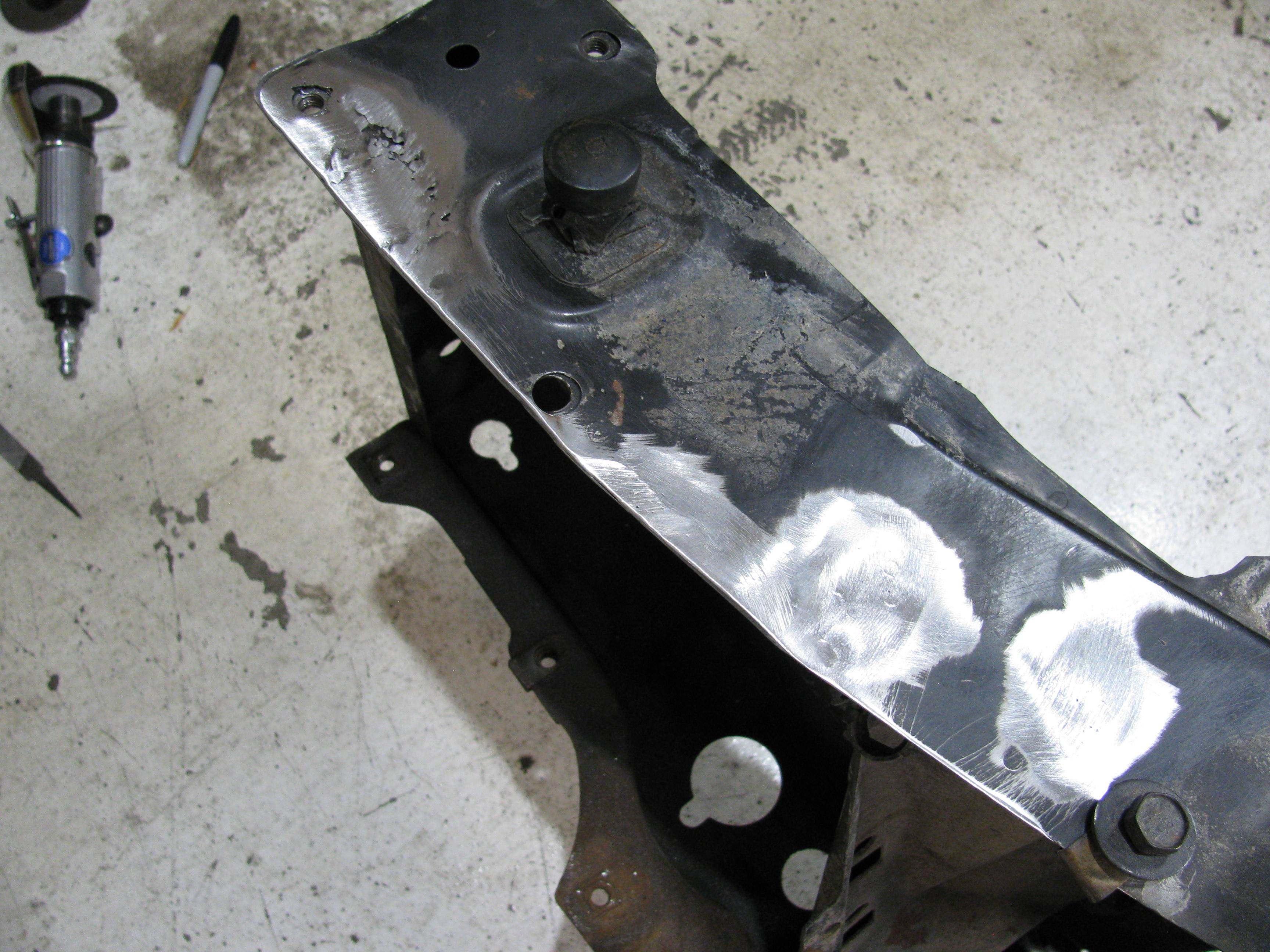

pshaw!!!!!Thank you! It's an odd mix seeing the sano frame and suspension in contrast to the desperate need for TLC on the body. I'm still on the fence about whether I'll do the body work and paint myself or send it to a shop. Finances may make that decision for me.

Hutch

I know you own a few of these cash cannons....