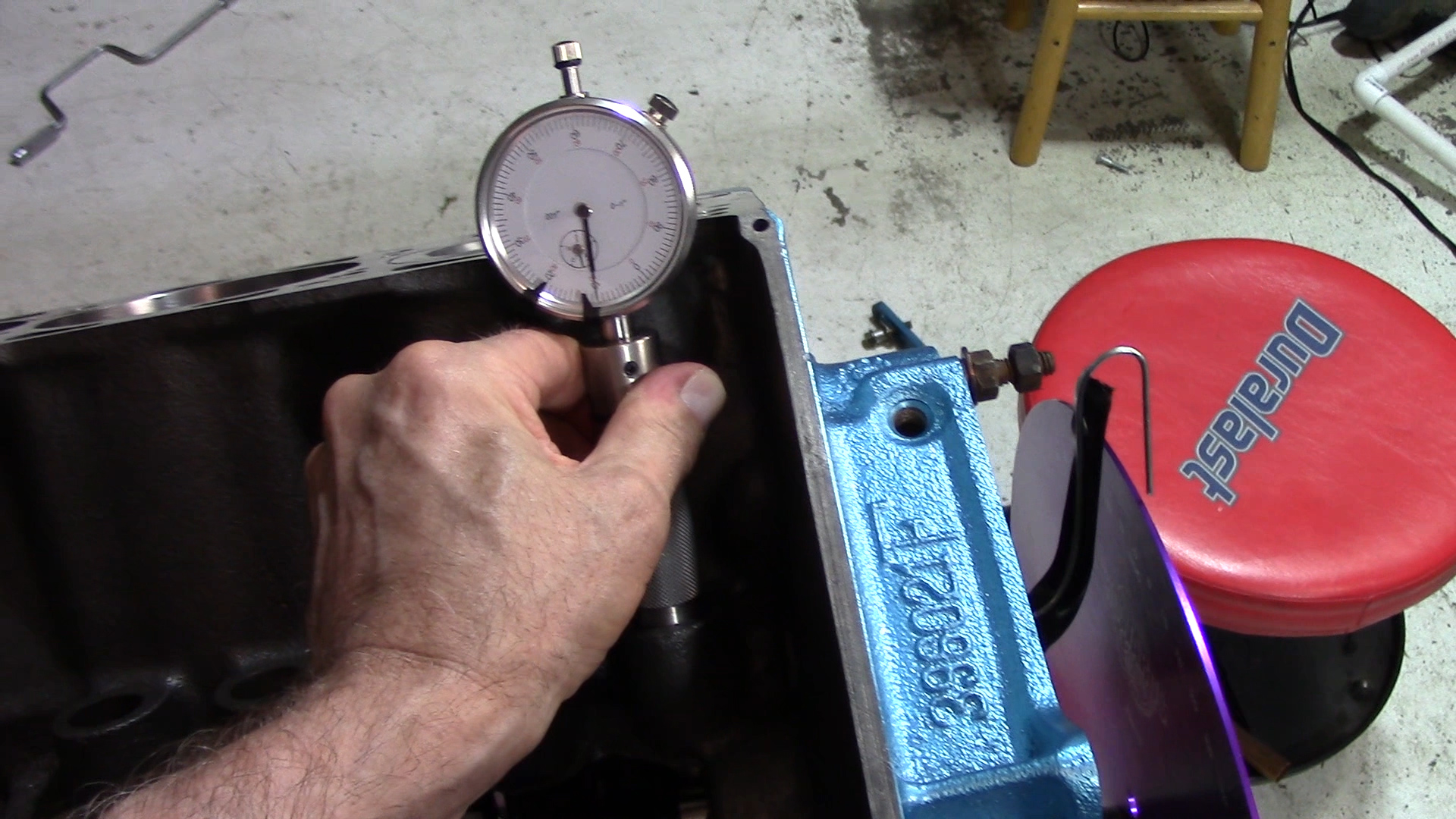

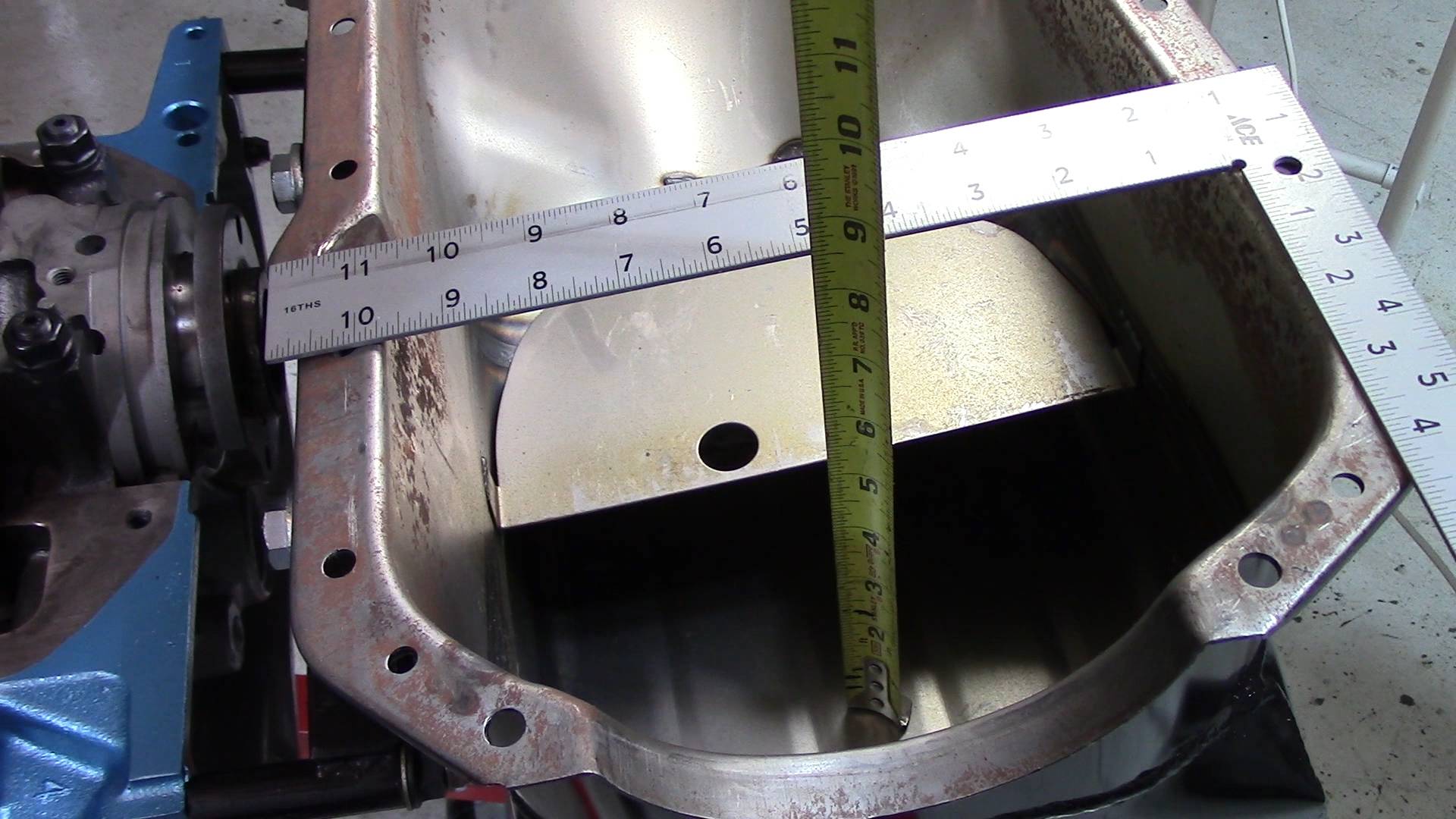

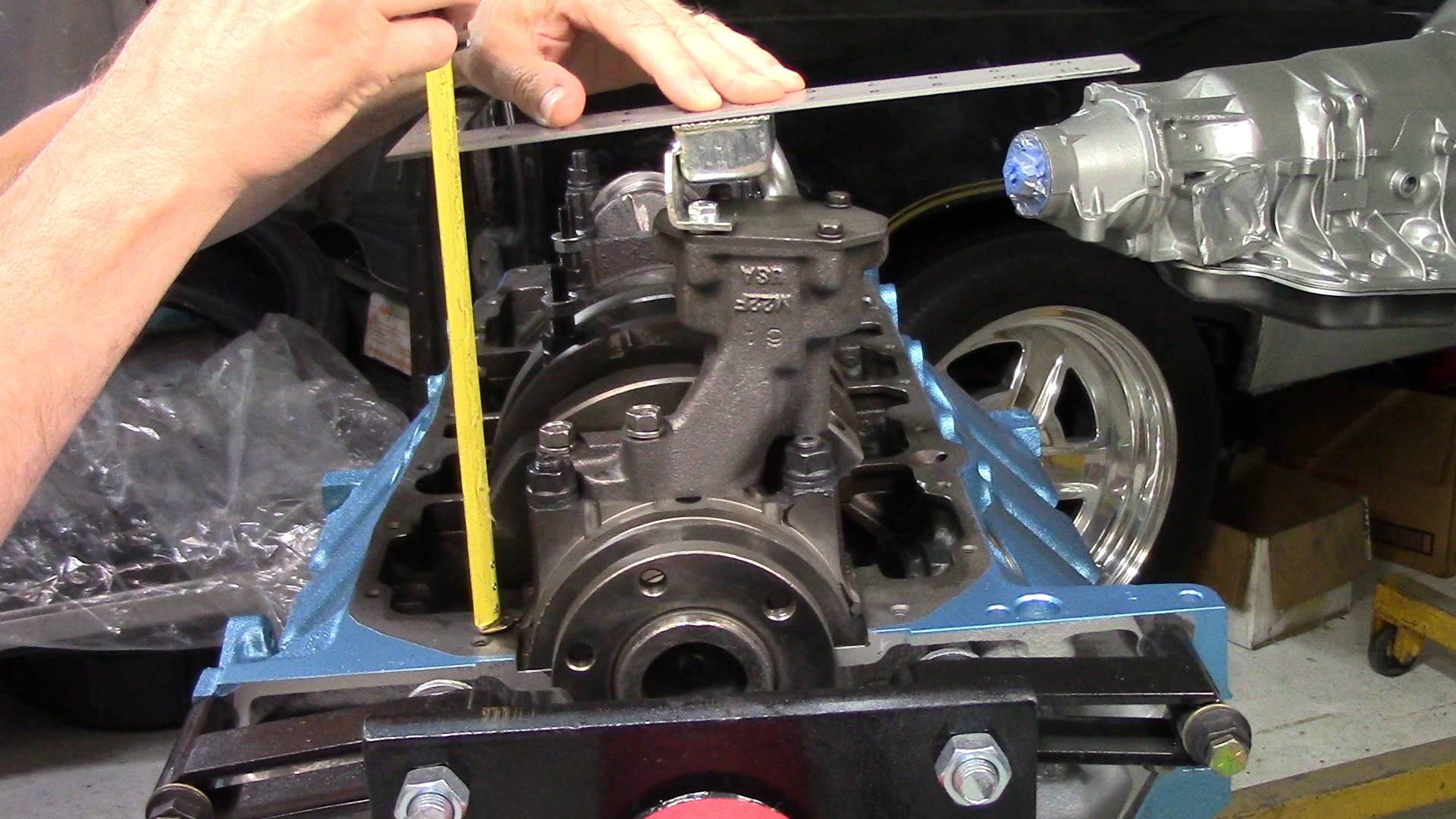

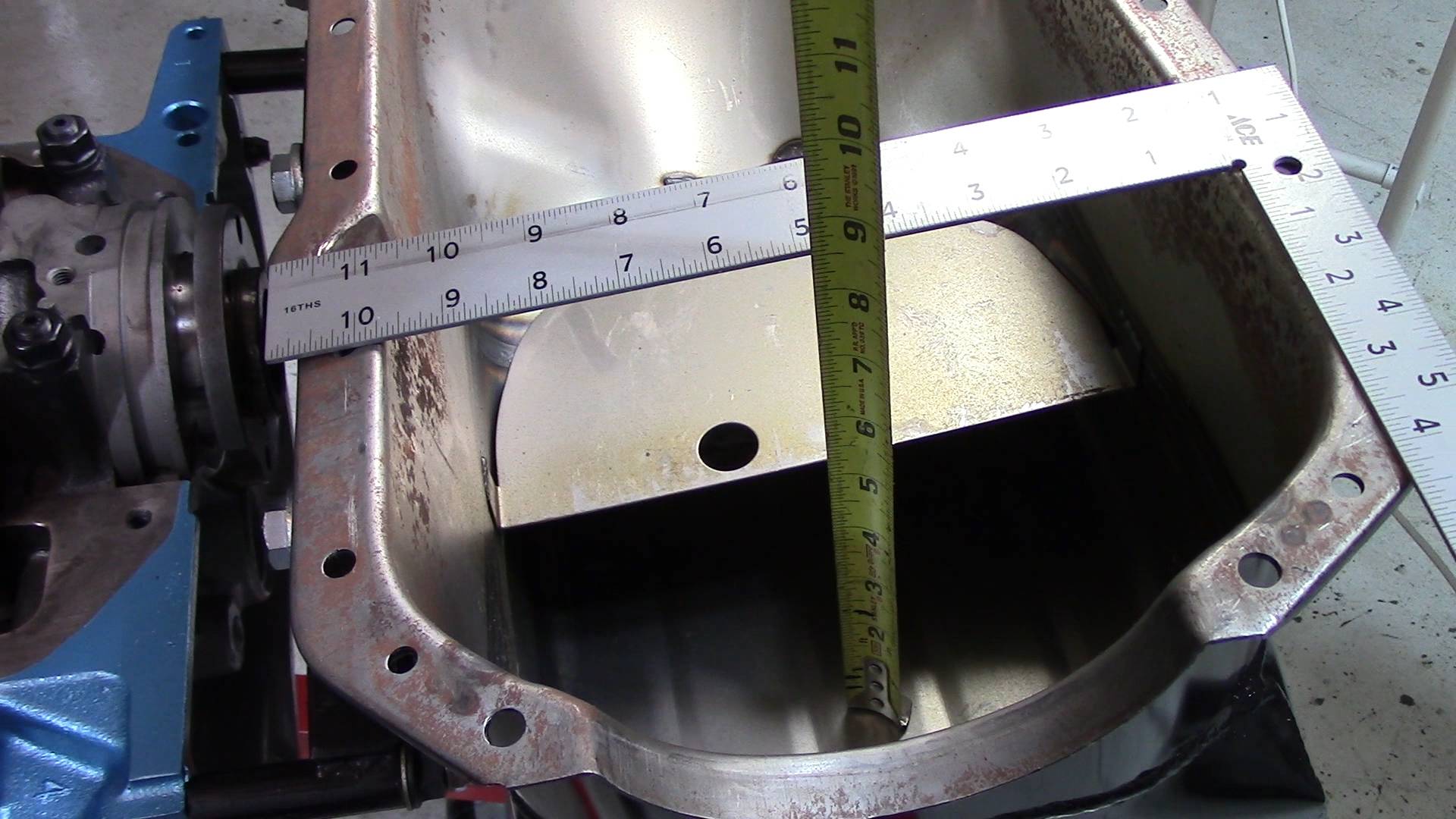

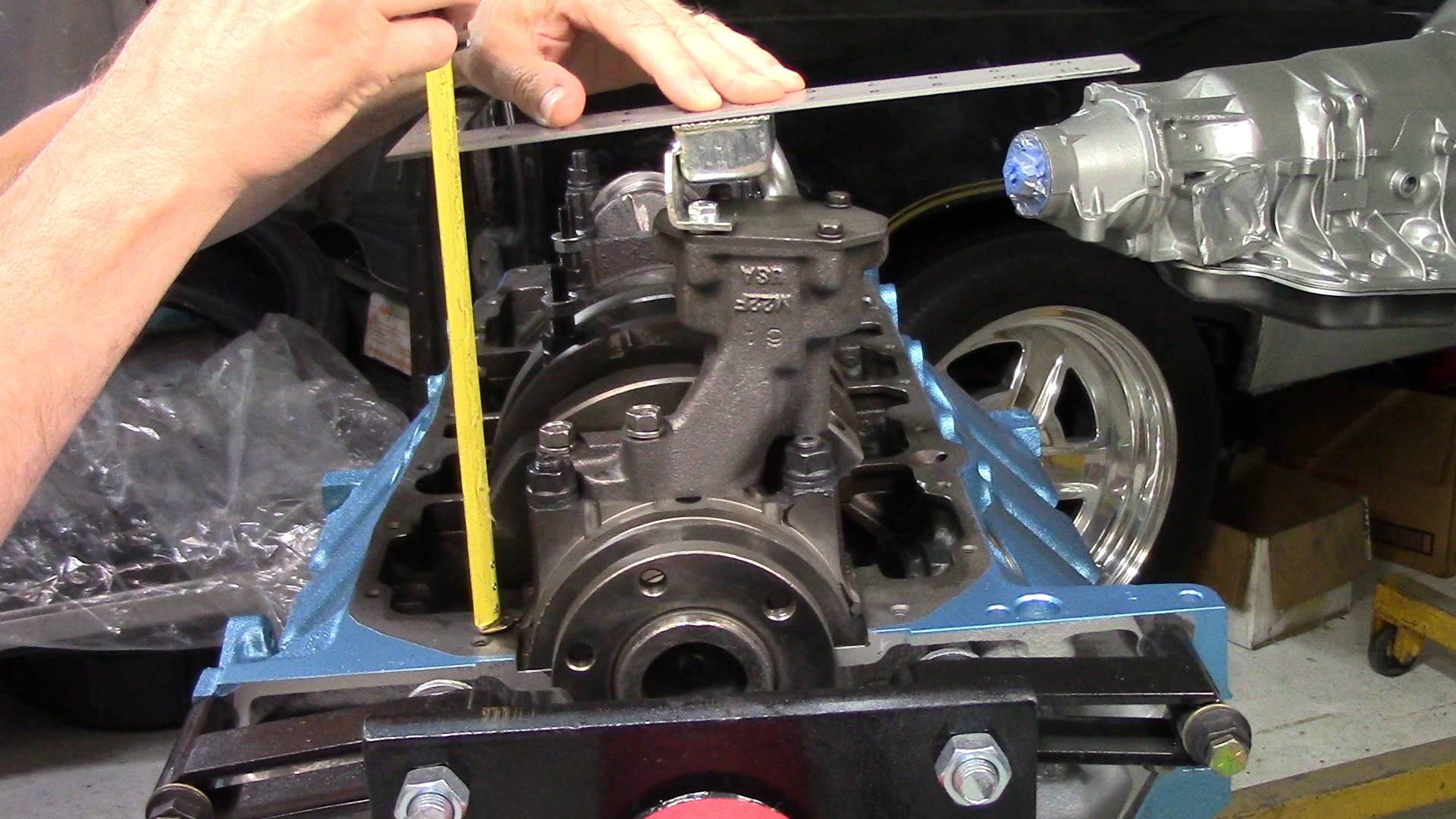

Got the Oil Pump mounted to check the screen height. All good by Moroso specs. Their tech line guy says it designed for 1/4 - 1/2 inch clearance. You also have to measure both sides and take an average because of the tilt of the screen. I got an average of 5/16.

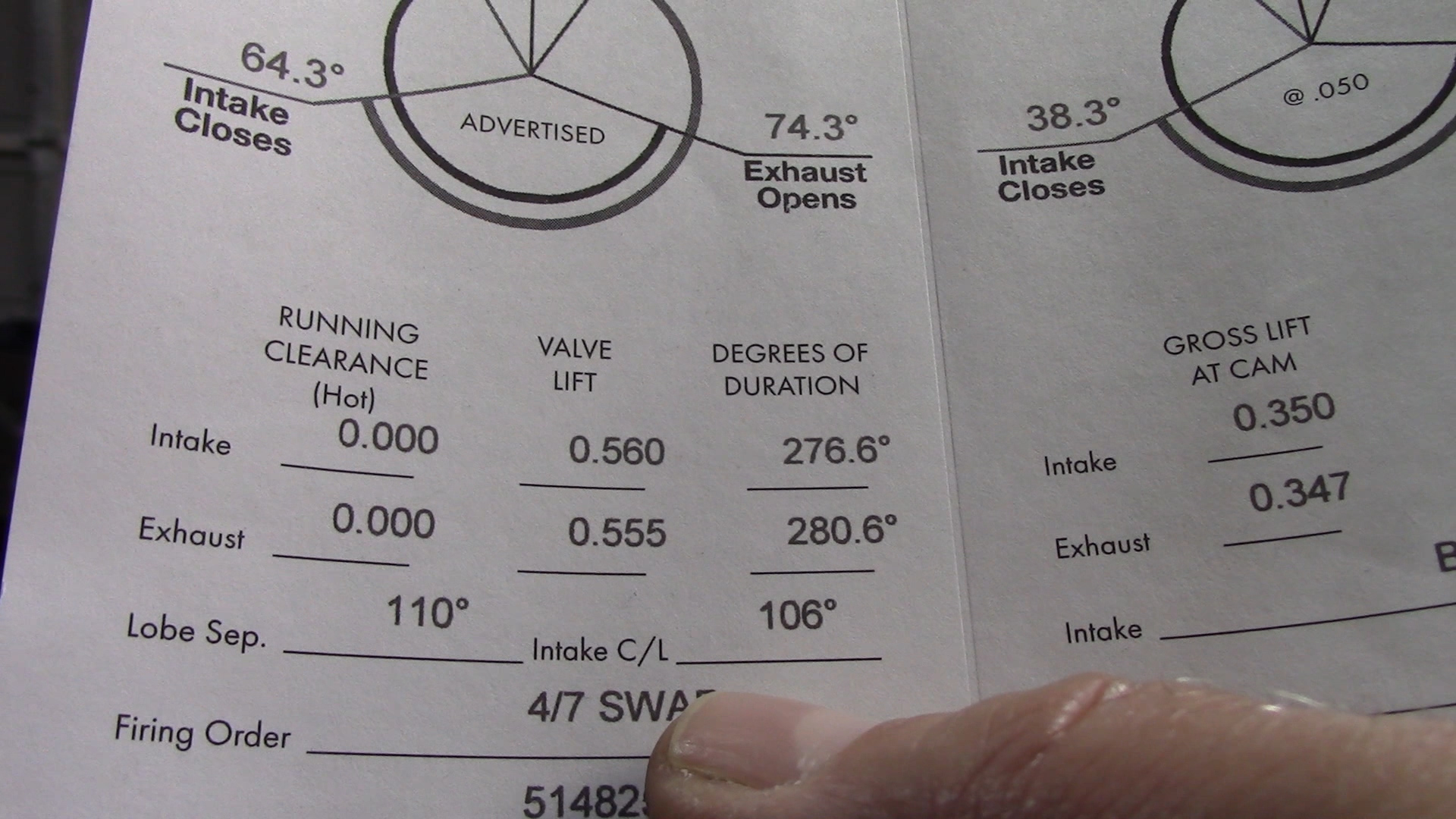

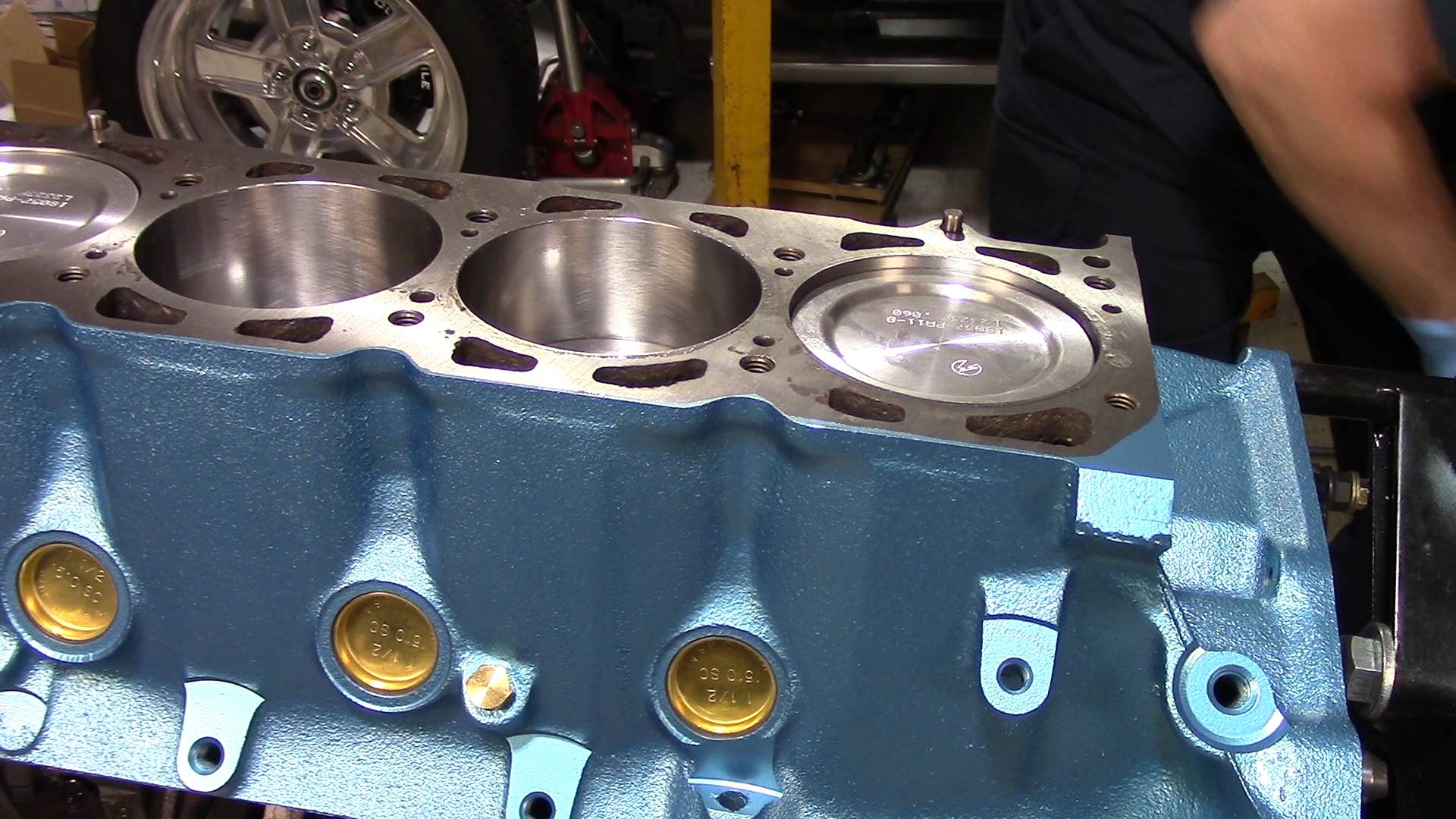

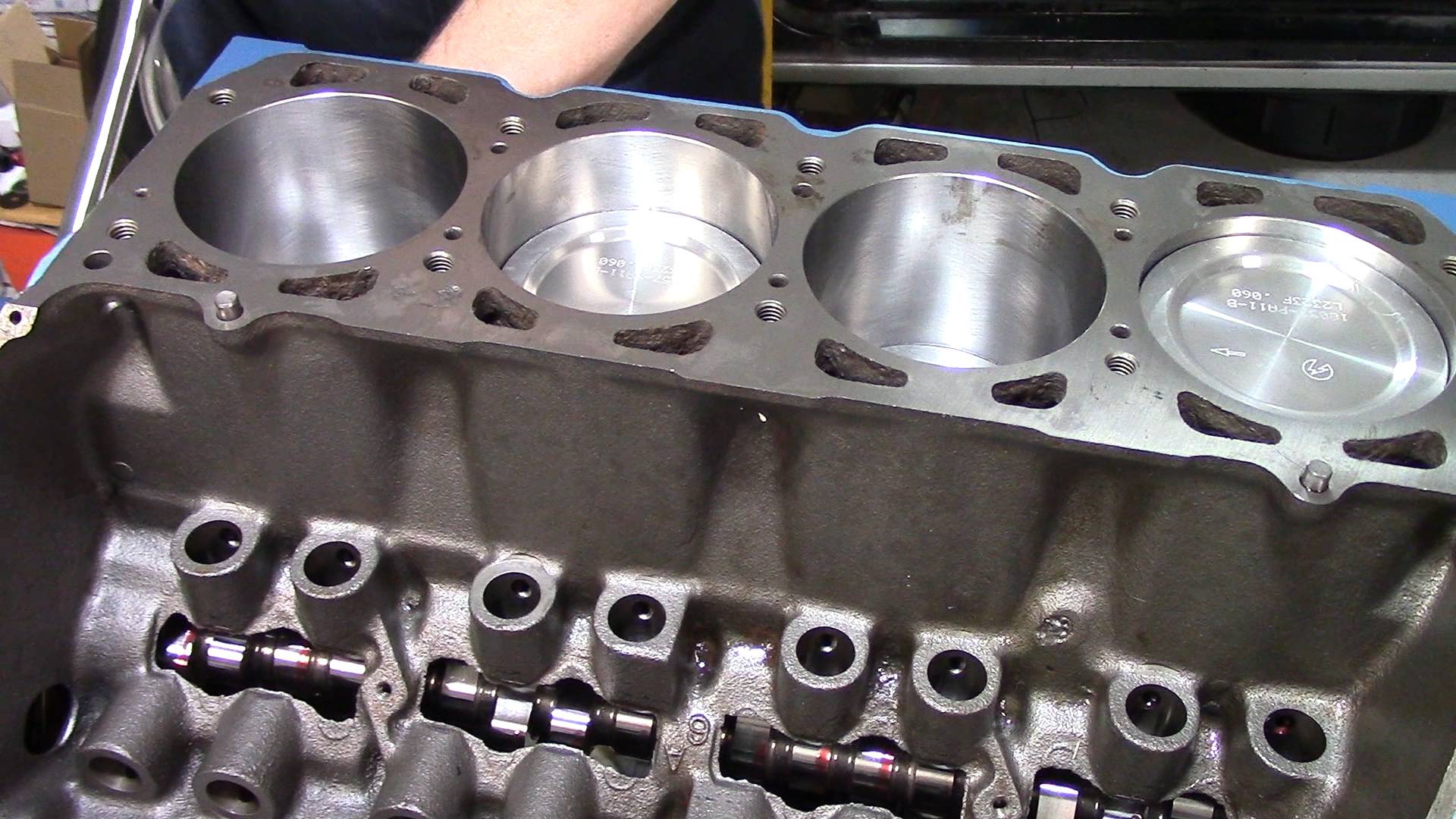

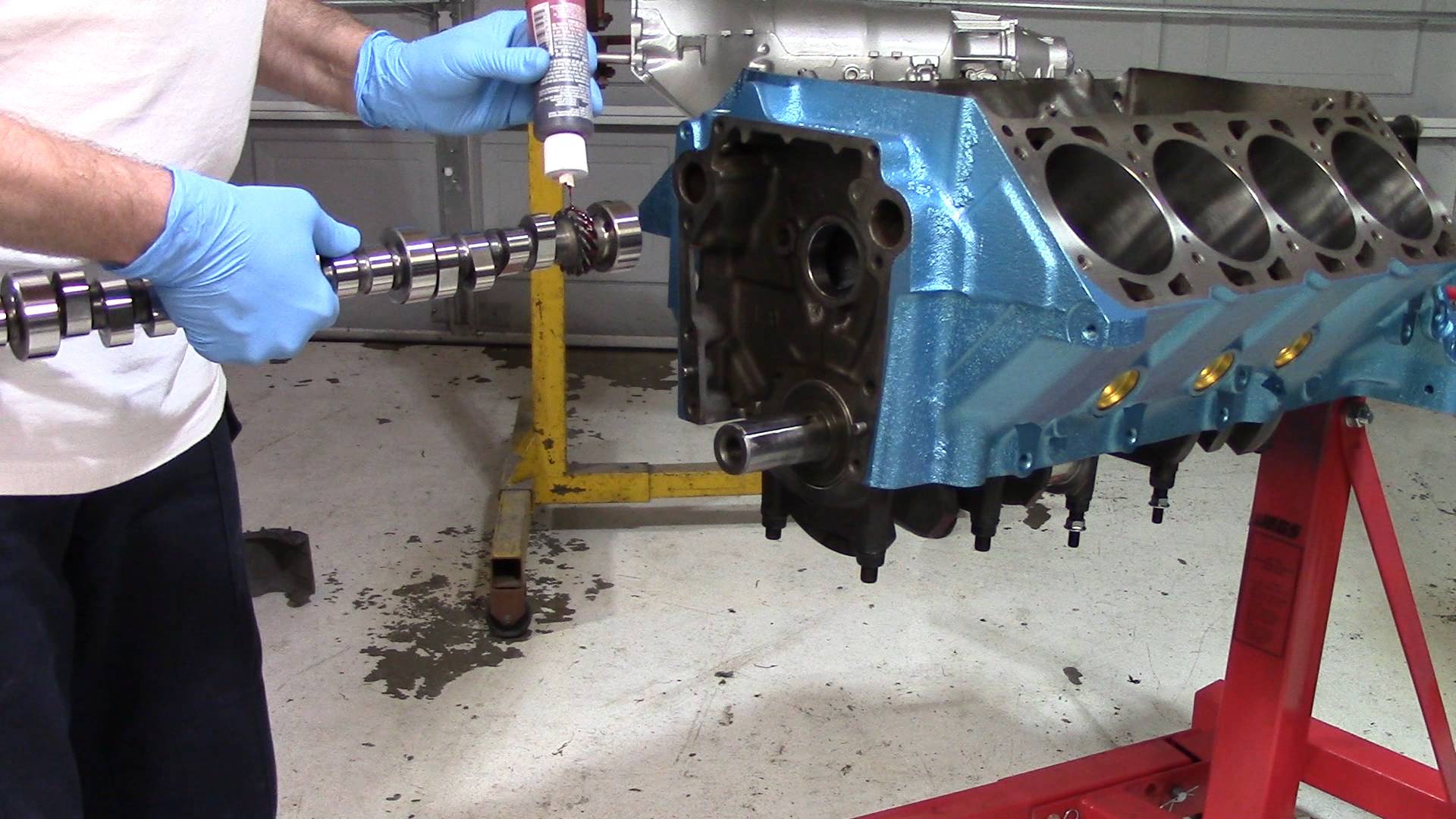

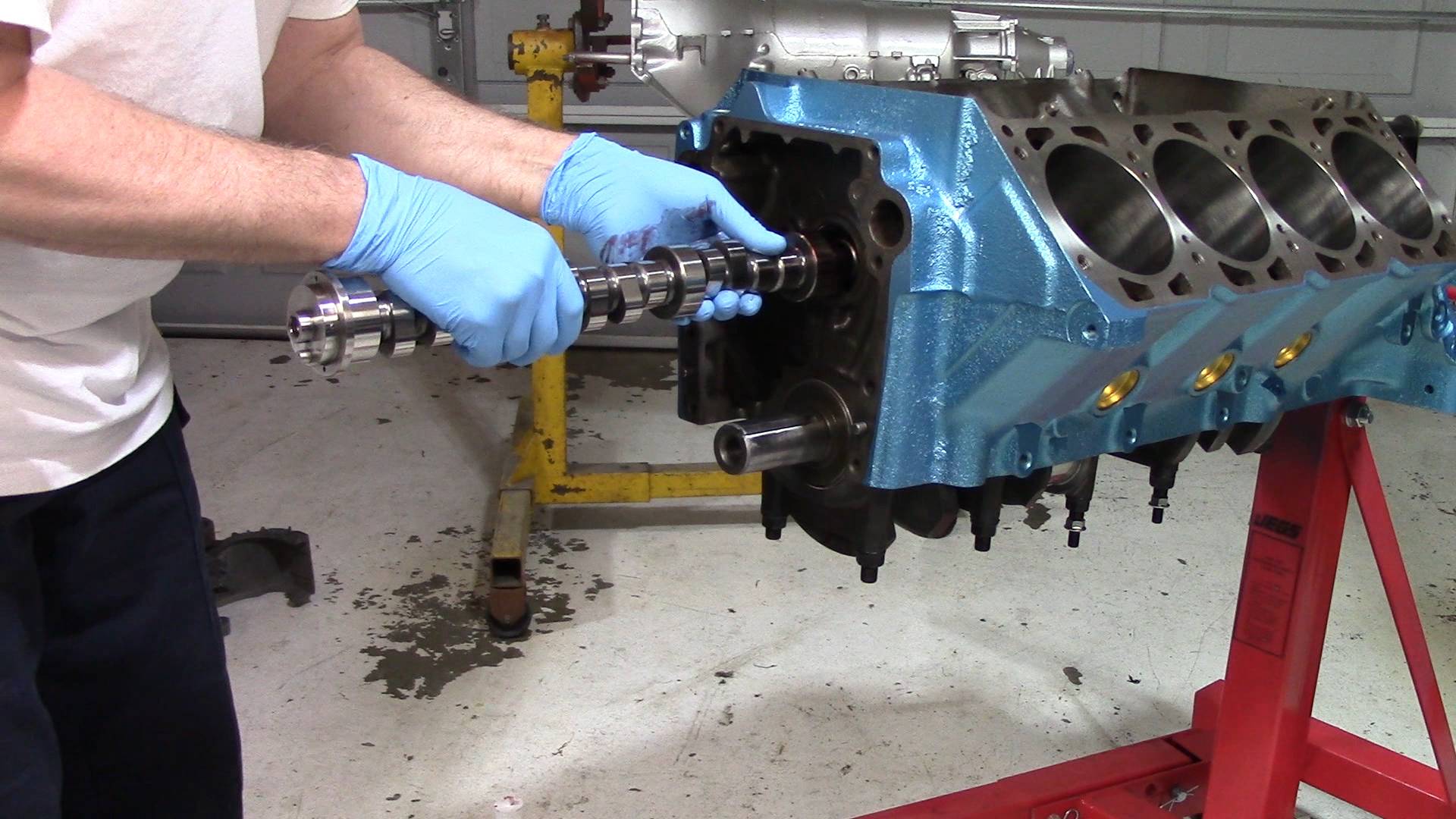

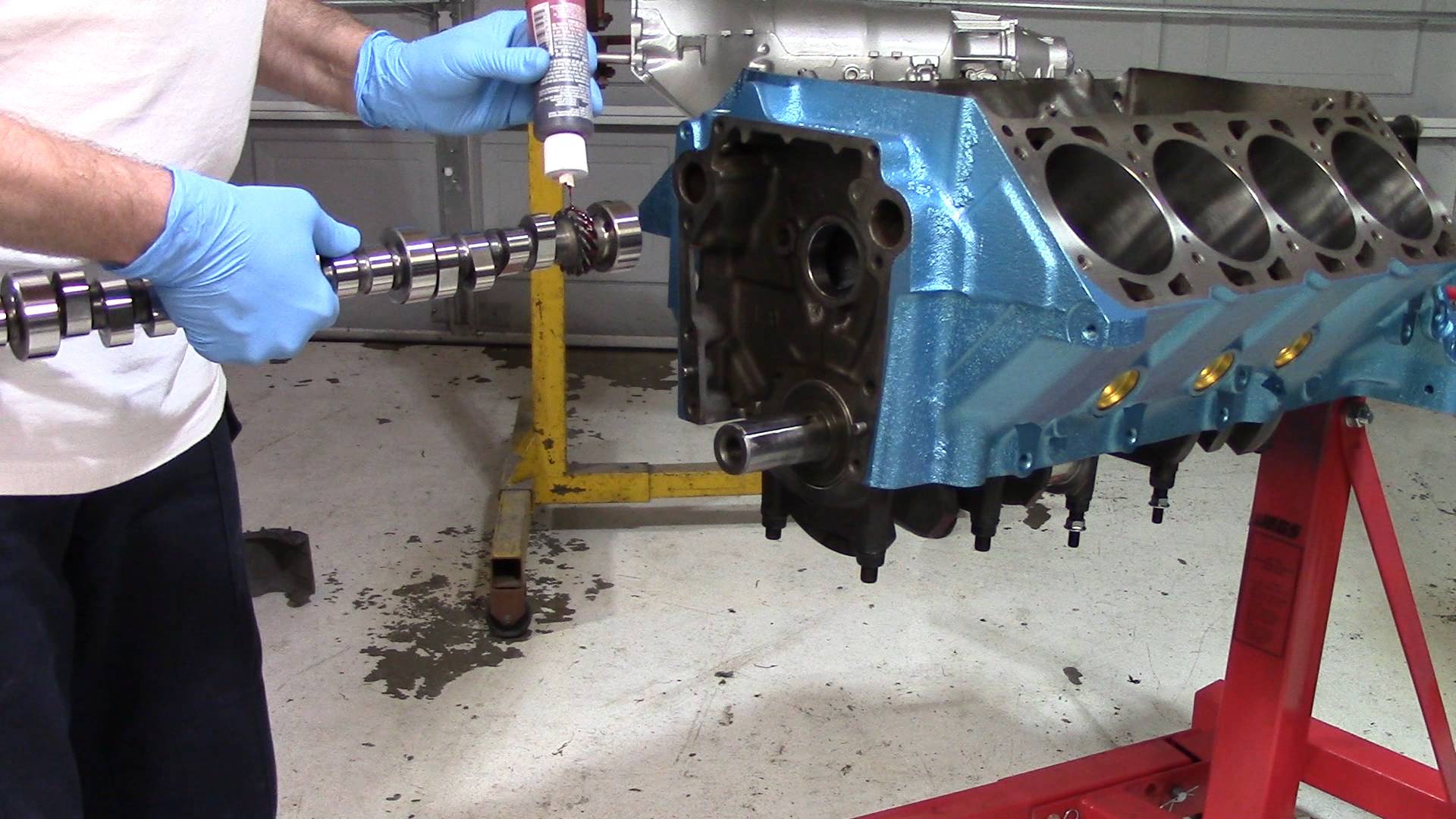

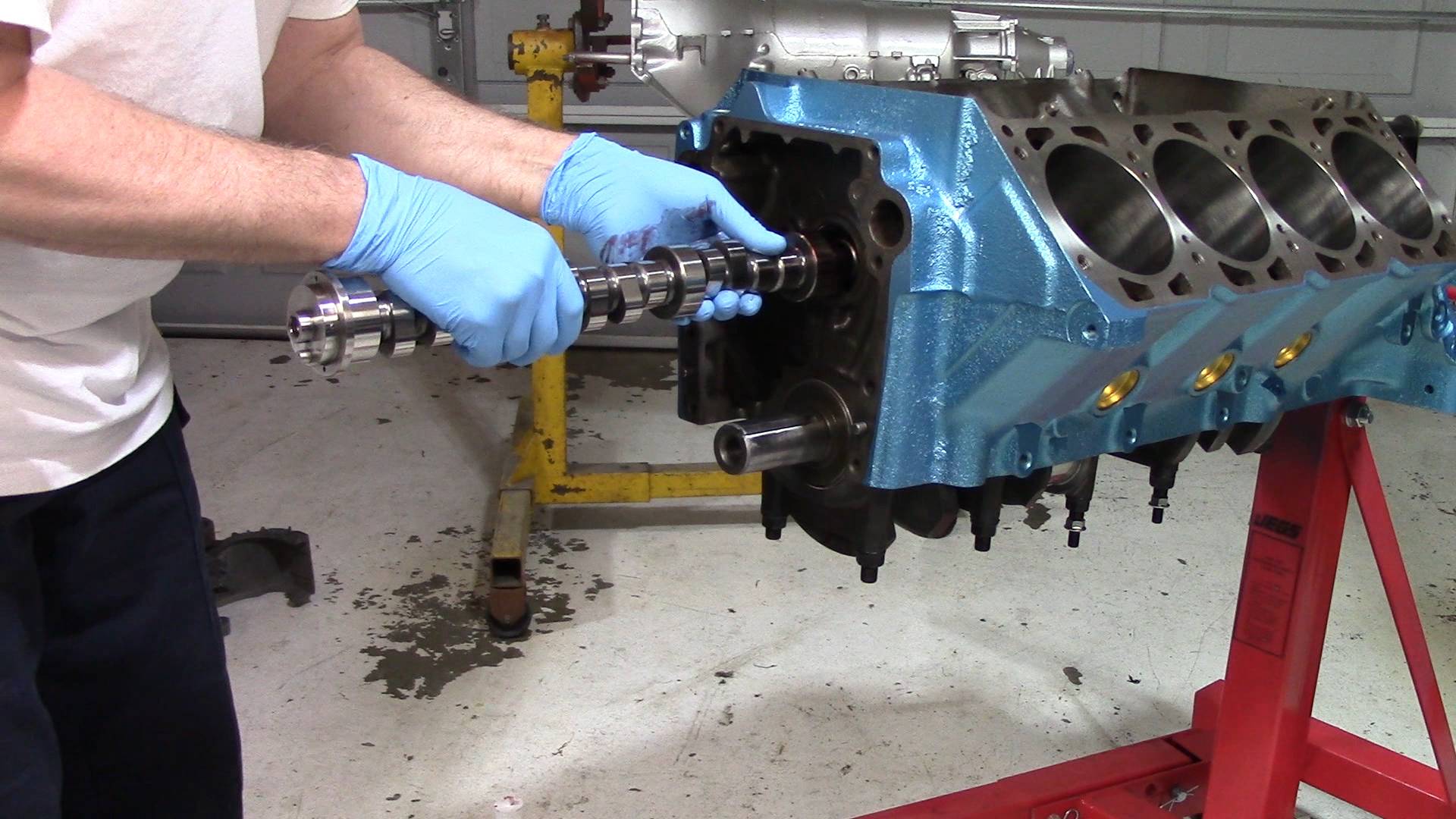

With that checked, I moved on to the Camshaft. It's a Howards Cams Hydraulic Roller 4/7 swap. 0.560/0.555 Lift 224/228 Duration @.050

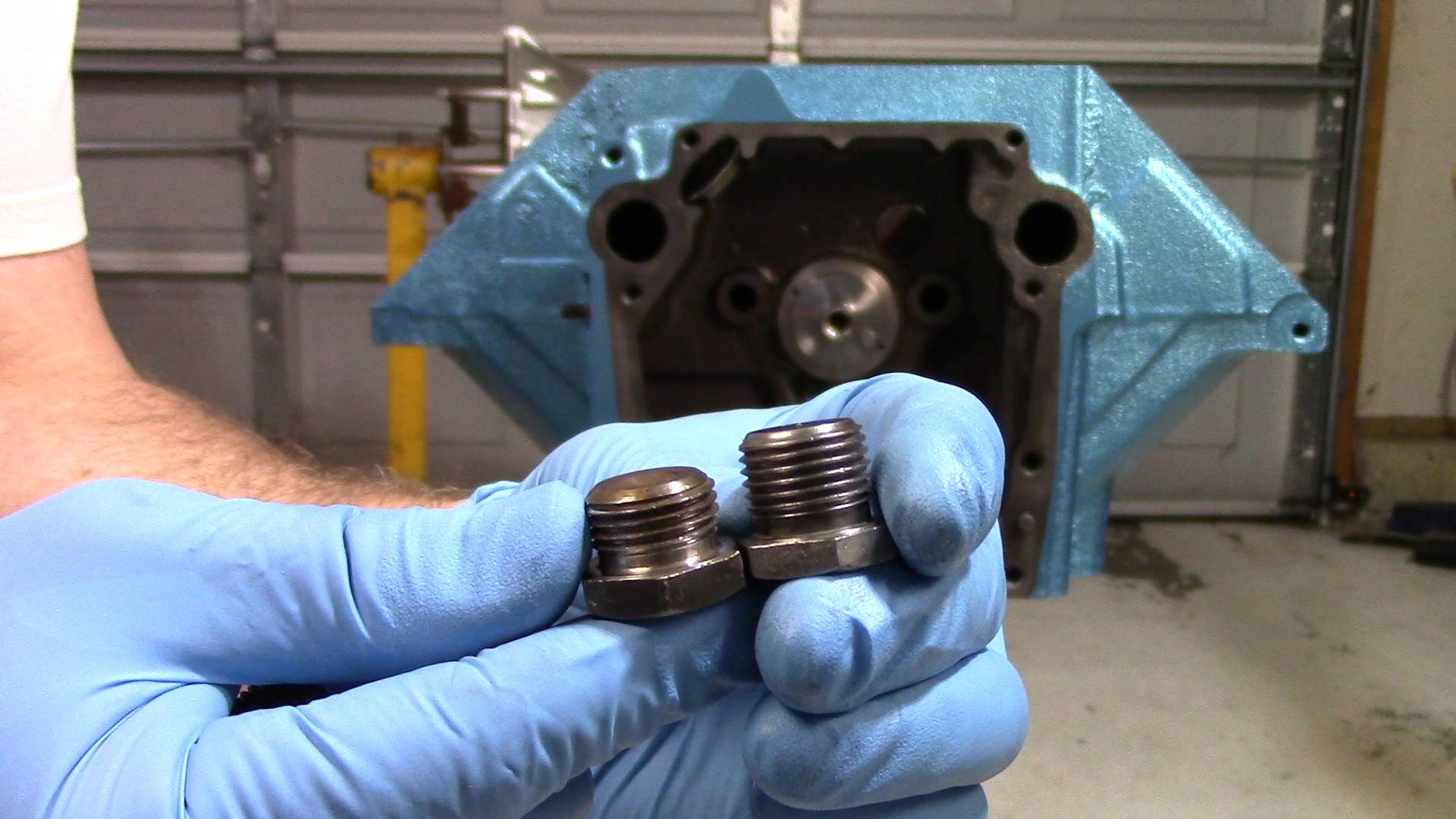

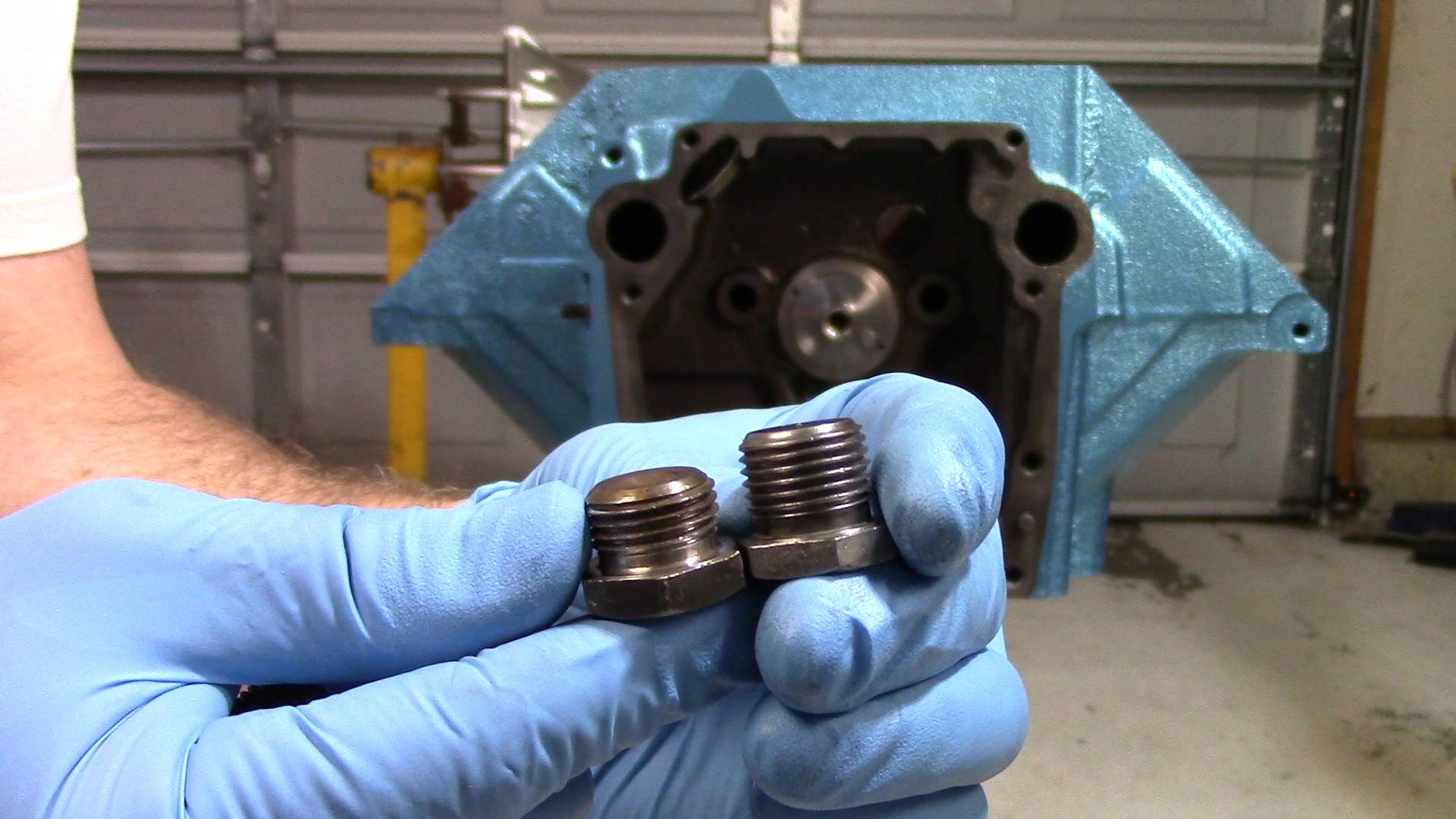

I use the front Oil Galley Plugs from the 307 (since they were longer to fit the Thrust Plate.

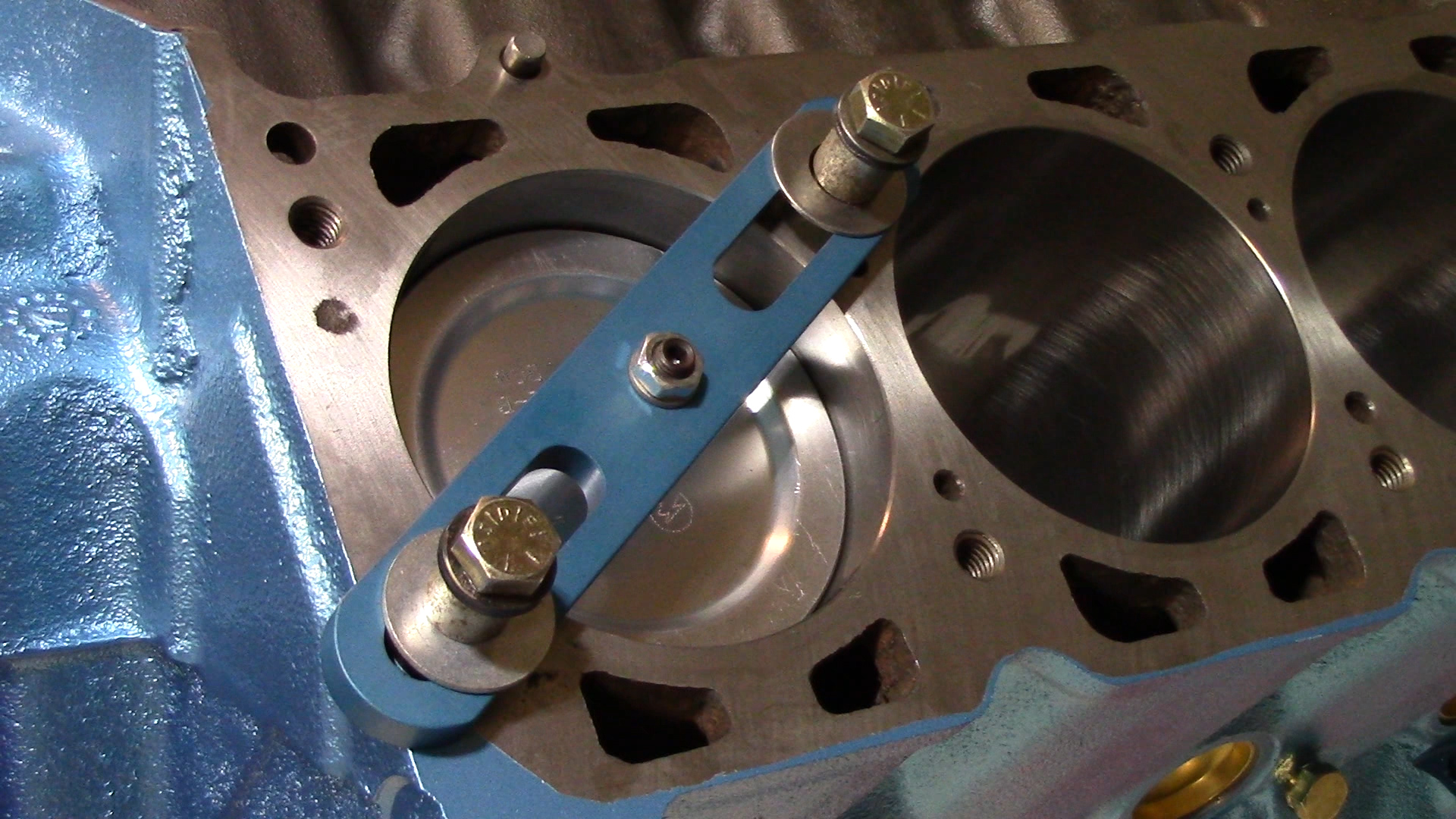

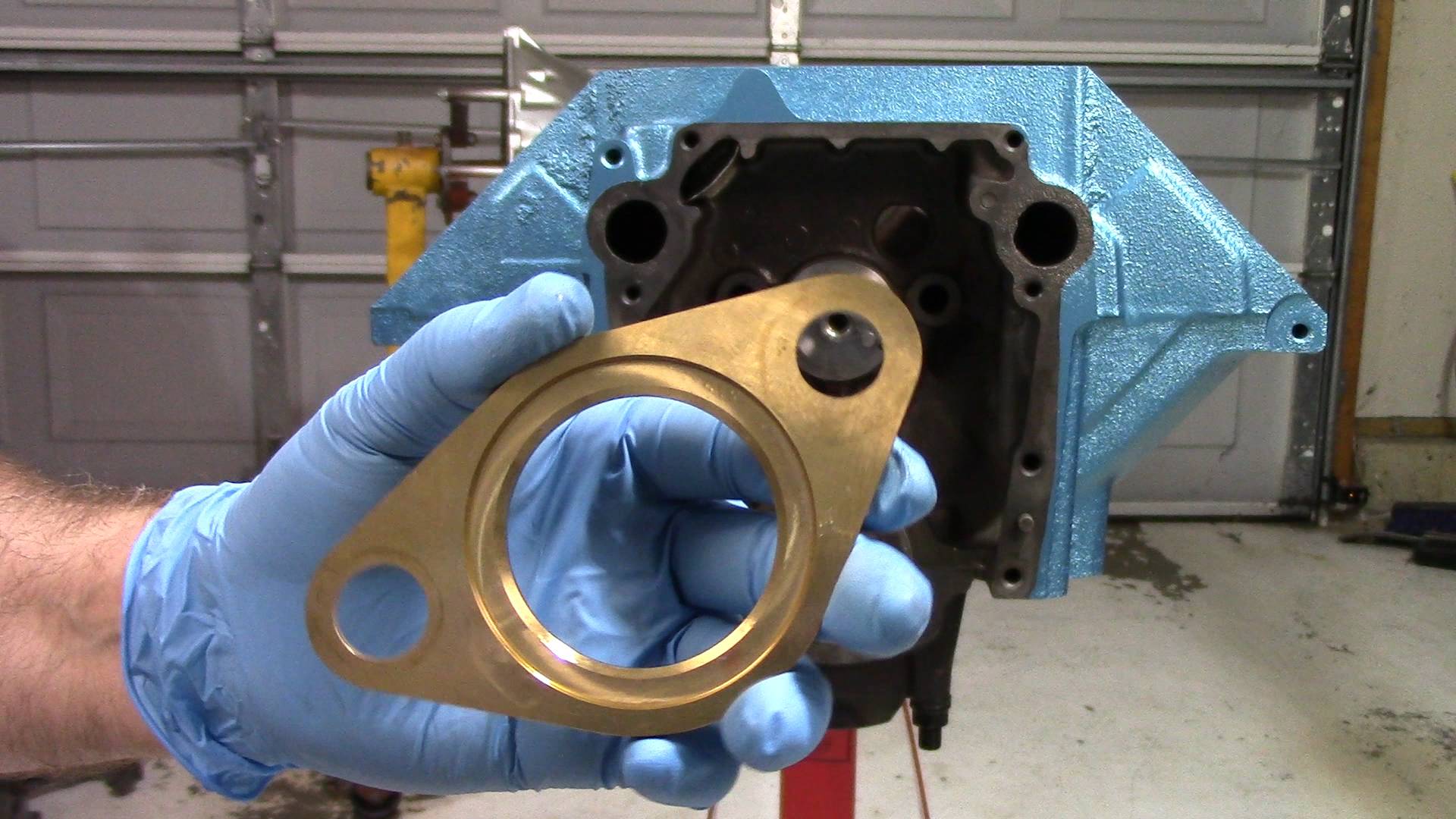

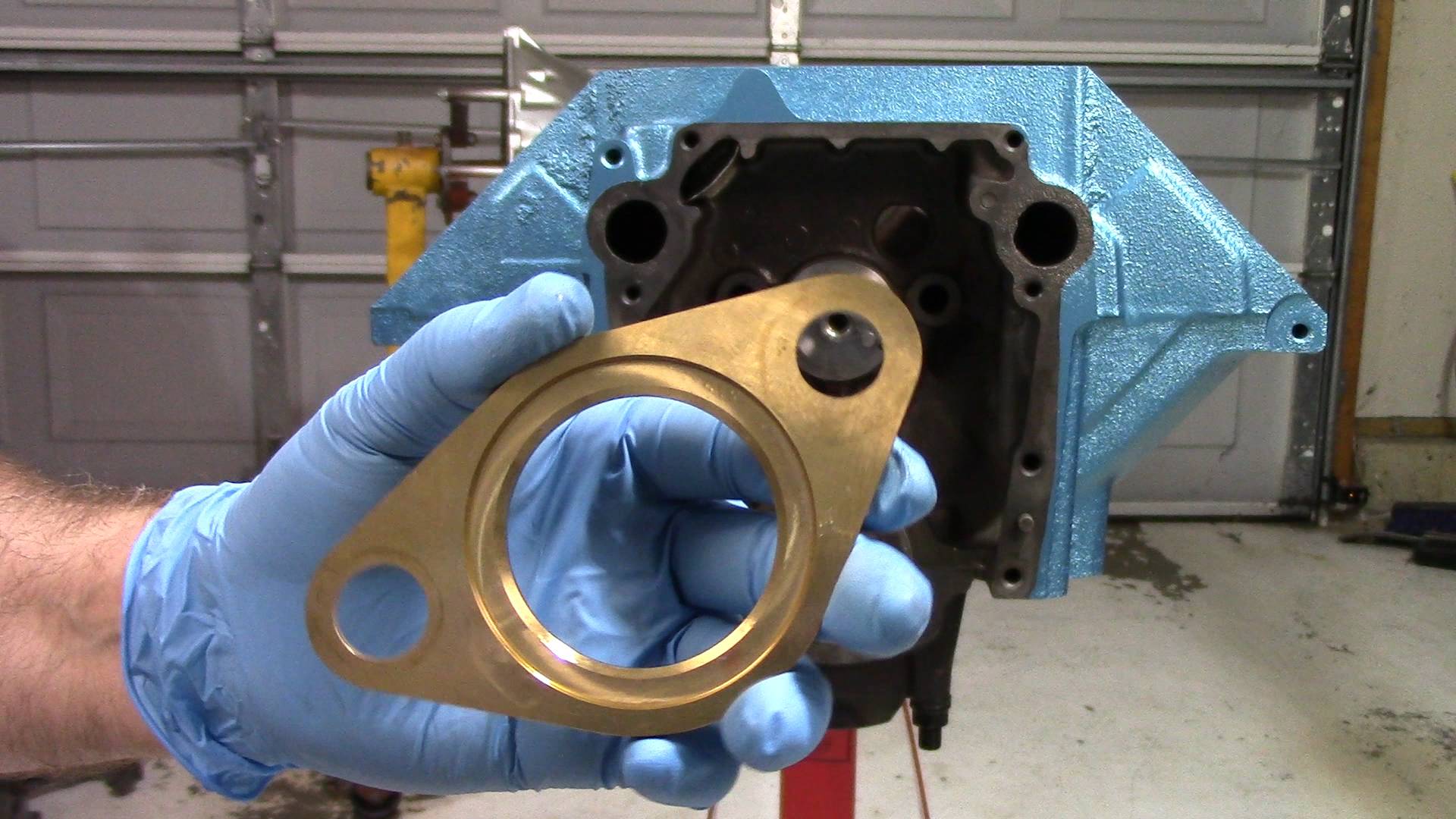

I used this custom Thrust Plate made by Clark455 over at ClassicOldsmobile.com. He used a bronze bearing material.

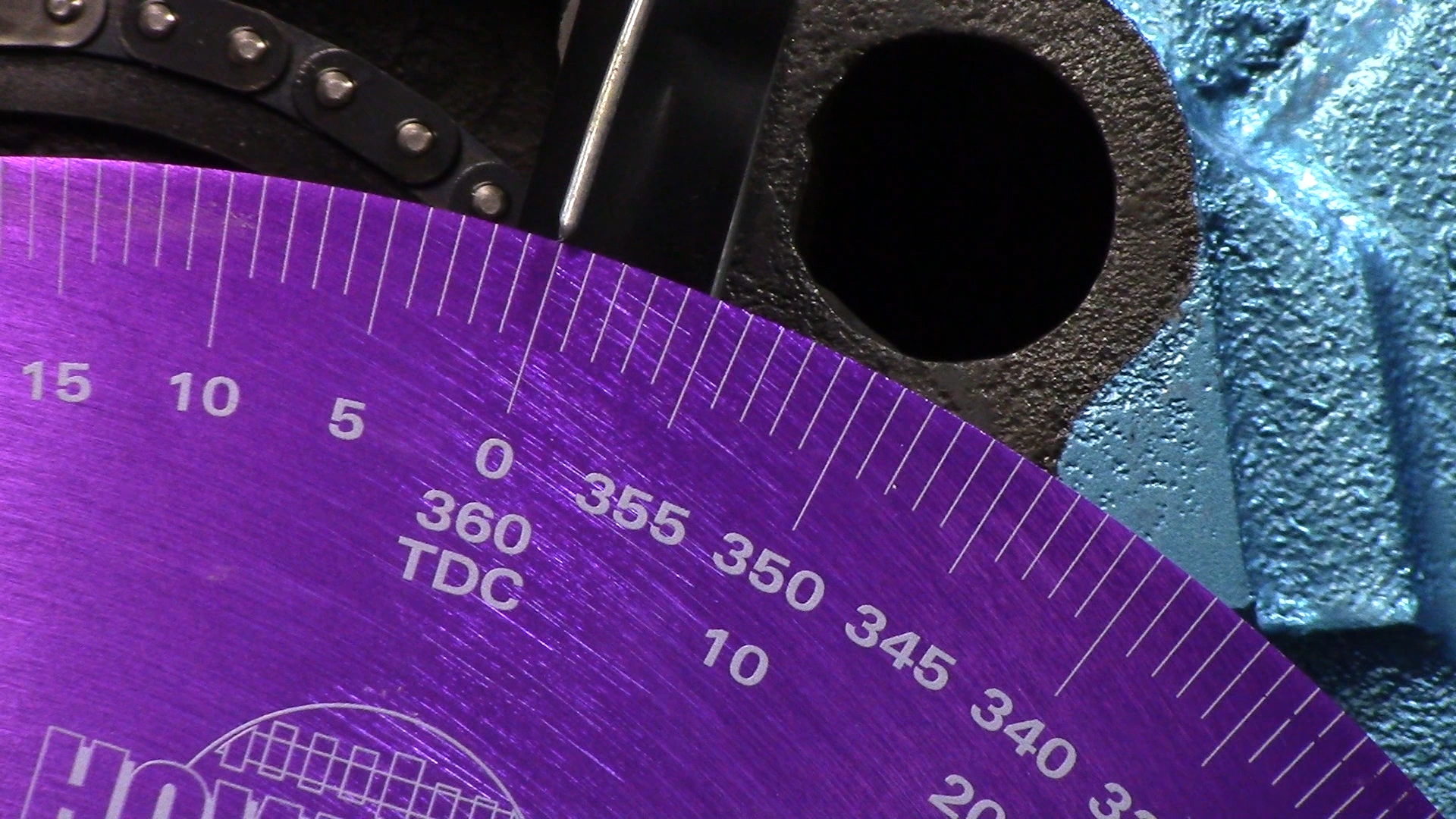

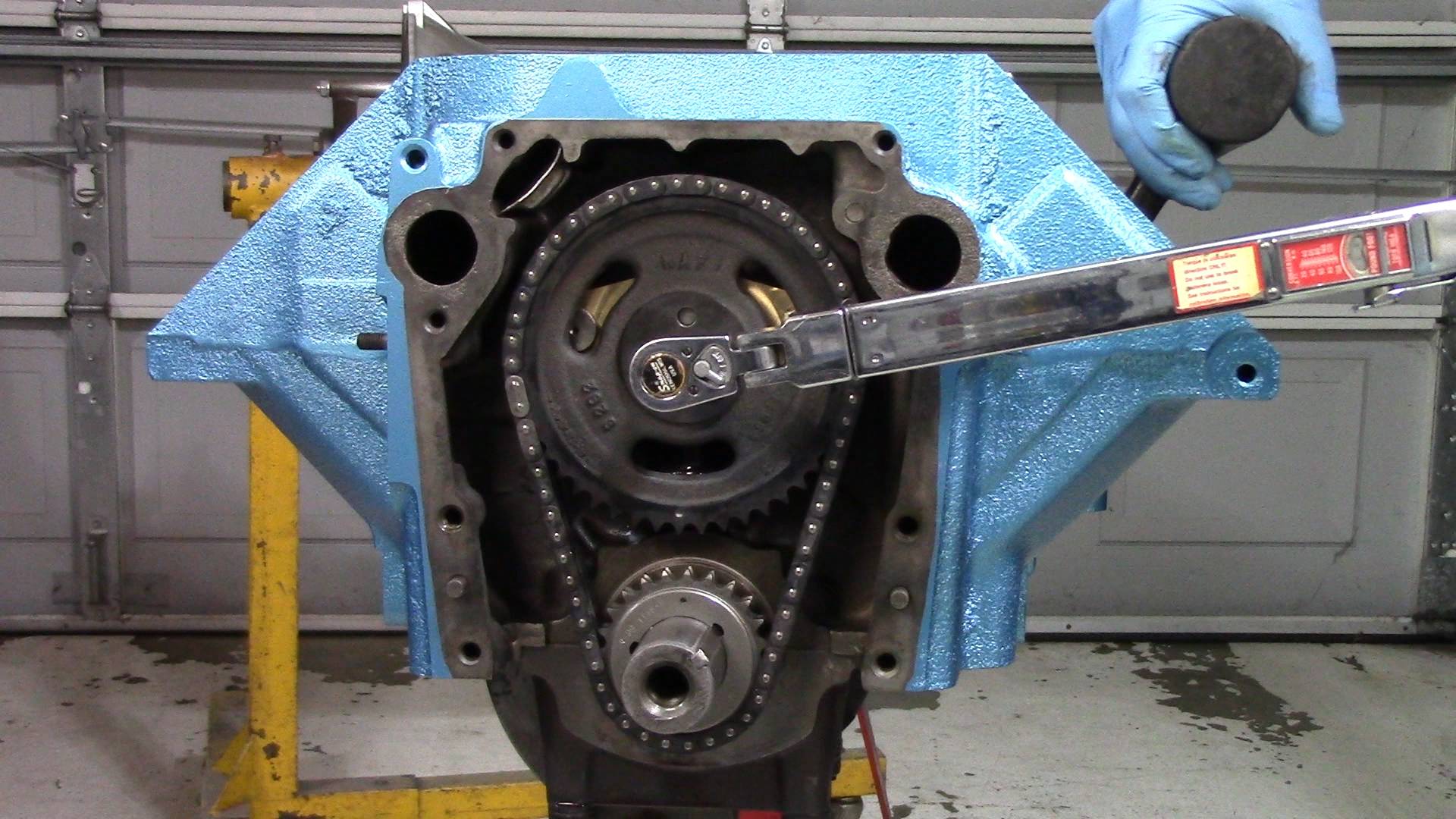

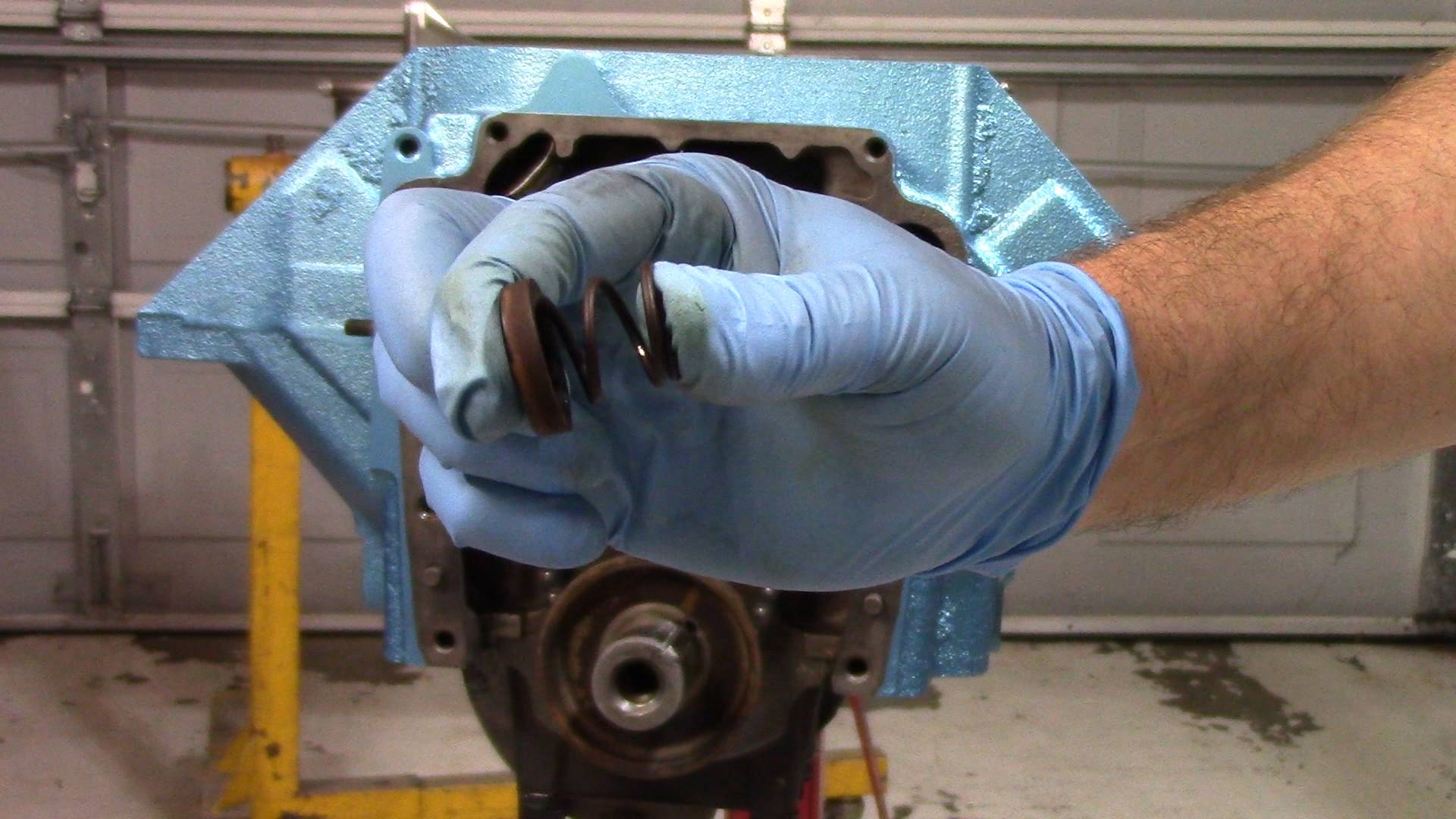

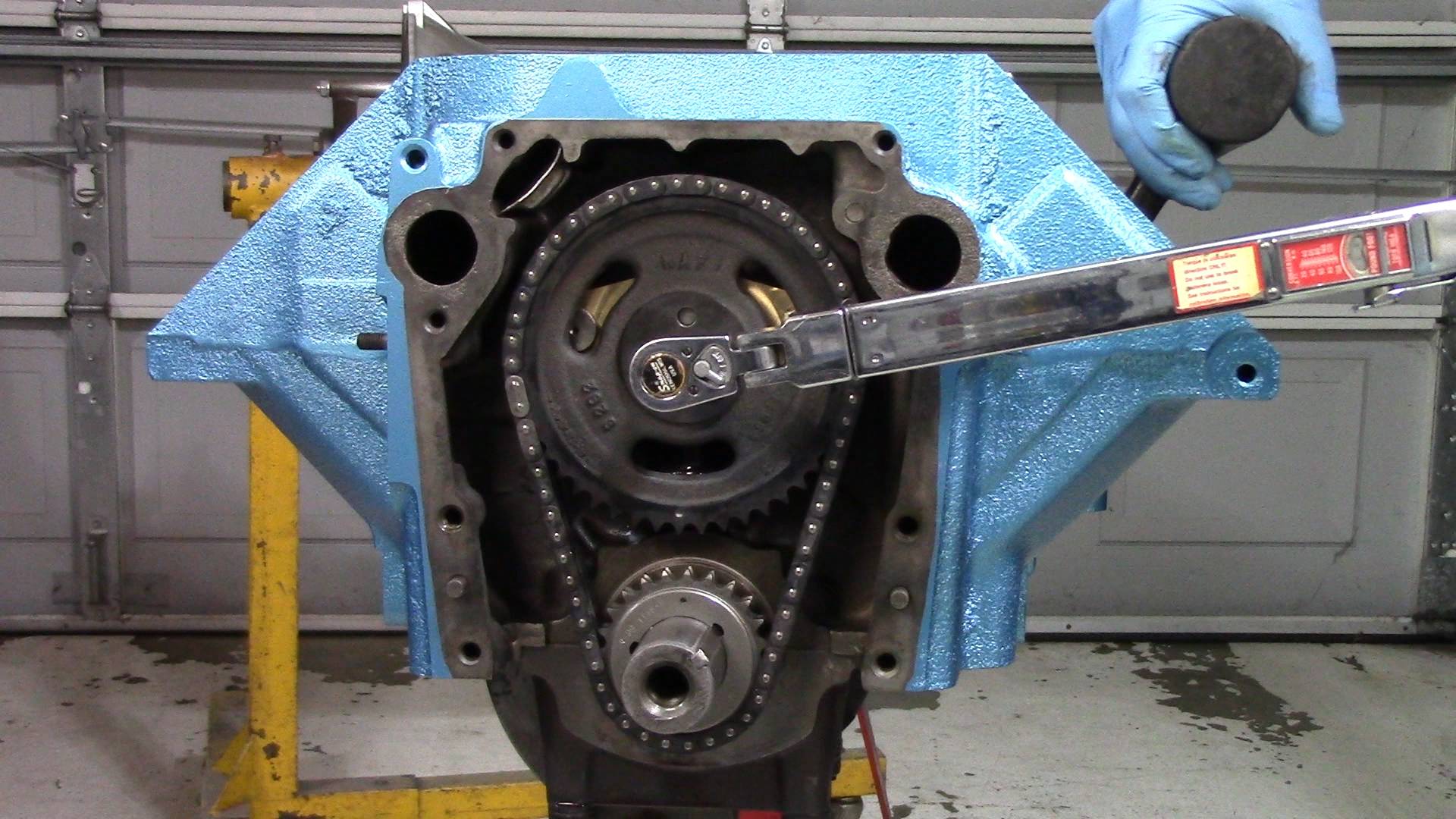

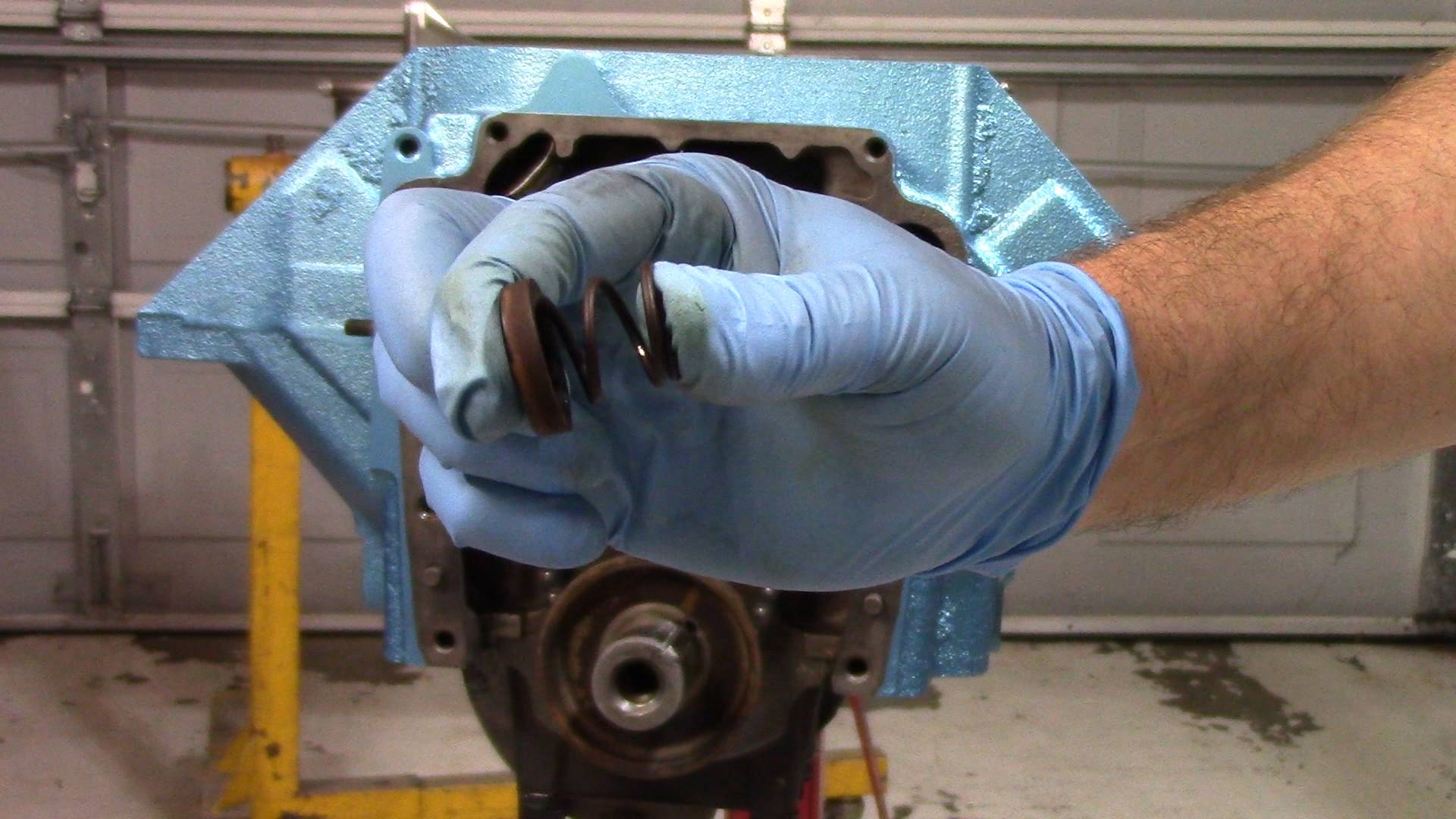

Install the Double Roller Timing Chain and put the spring and Cam Button on (also from the 307)

All for now. Happy Memorial Day!! Remember and Thank those who served!!

Hutch

With that checked, I moved on to the Camshaft. It's a Howards Cams Hydraulic Roller 4/7 swap. 0.560/0.555 Lift 224/228 Duration @.050

I use the front Oil Galley Plugs from the 307 (since they were longer to fit the Thrust Plate.

I used this custom Thrust Plate made by Clark455 over at ClassicOldsmobile.com. He used a bronze bearing material.

Install the Double Roller Timing Chain and put the spring and Cam Button on (also from the 307)

All for now. Happy Memorial Day!! Remember and Thank those who served!!

Hutch