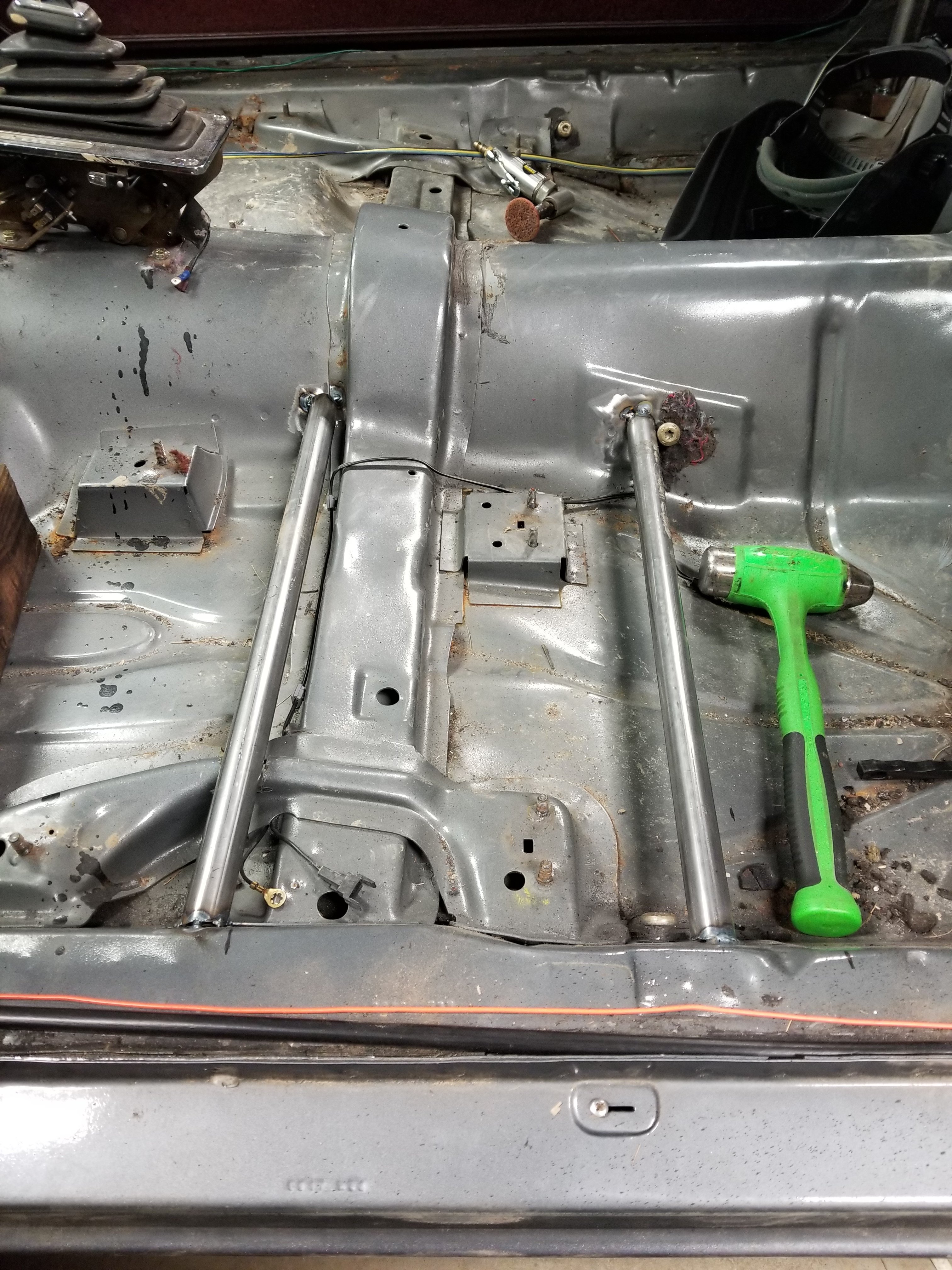

Looks like you have the rare solid floor option, don't see any rust holes.

And I'm chopping it up into a drag car...lol. Legit has VERY LITTLE rust overall. A bit of surface rust in floor pans about were seats were is the most i have seen in this car.