Somewhat productive weekend.

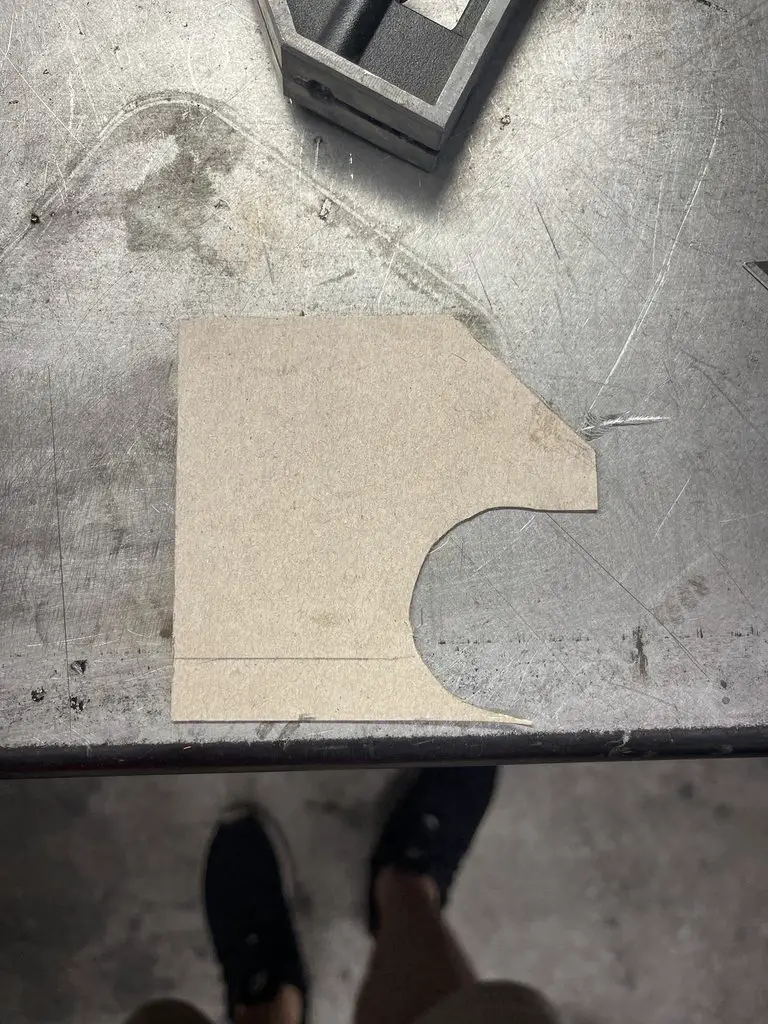

Longer fender tabs arrived on Thursday so Friday night i got them welded up and tacked in place. You can see the length difference from the original set.

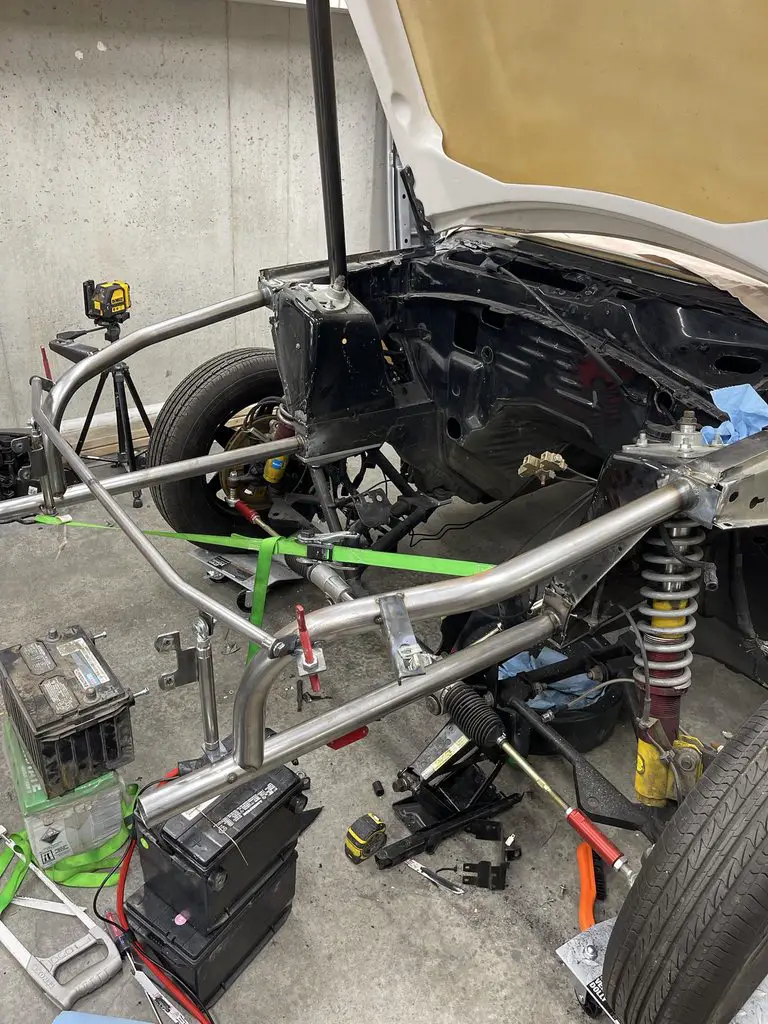

Tore everything off and burned in all of the bars! Even added back the quick latch posts so i can use them again.

Then i removed my K Member (UPR) to install my buddies K Member (AJE) which will be used to mock-up the motor front and mid plates. Set the engine in place and test fit the massive 2k Shearer A2W. I need about 1/4" of an inch lower to clear the 4" cowl.

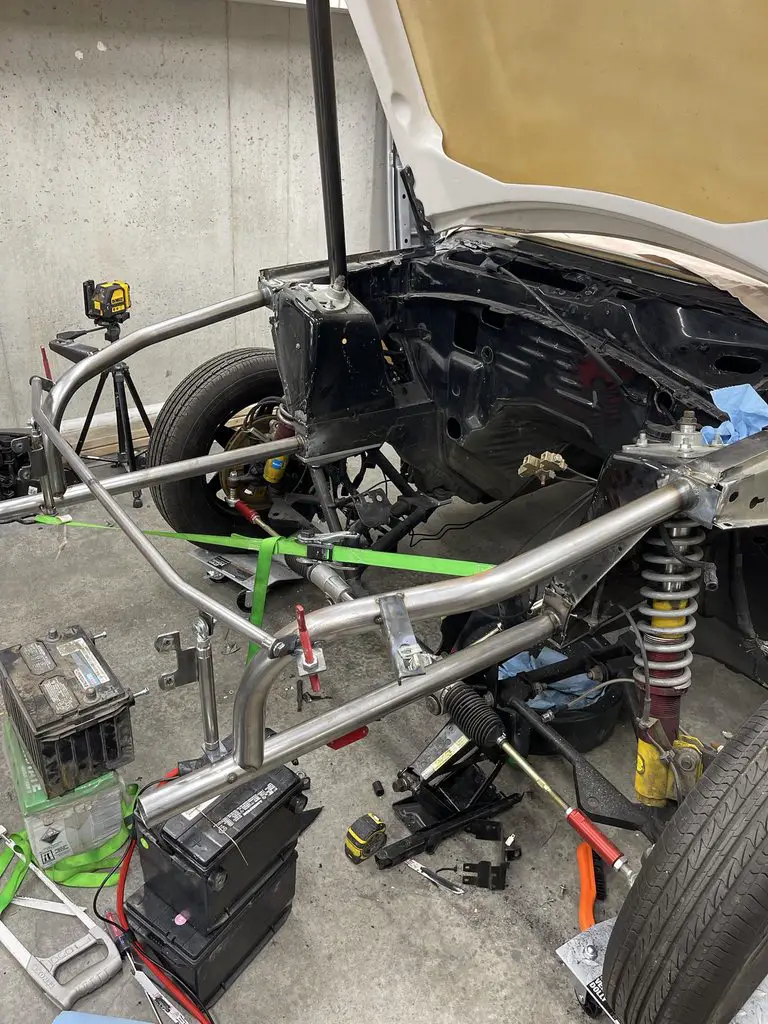

Went ahead and threw the suspension on to set ride height before establishing a drive-line angle for the motor. Fun fact UPR a-arms will fit AJE K members even though they both said it wont work lol.

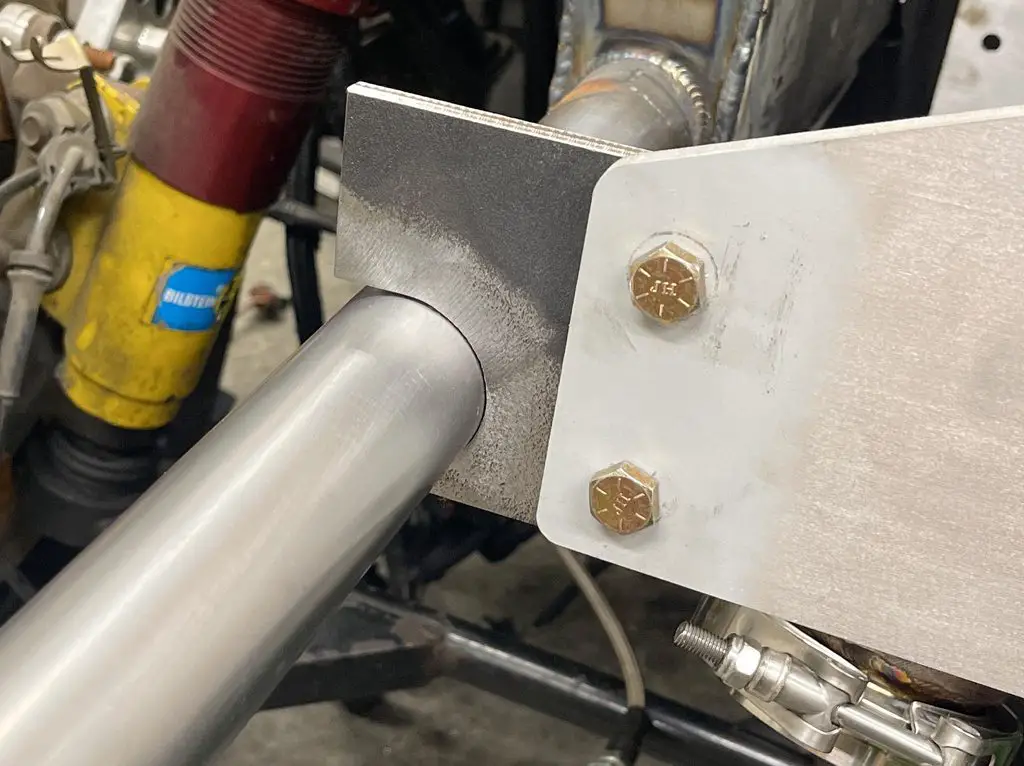

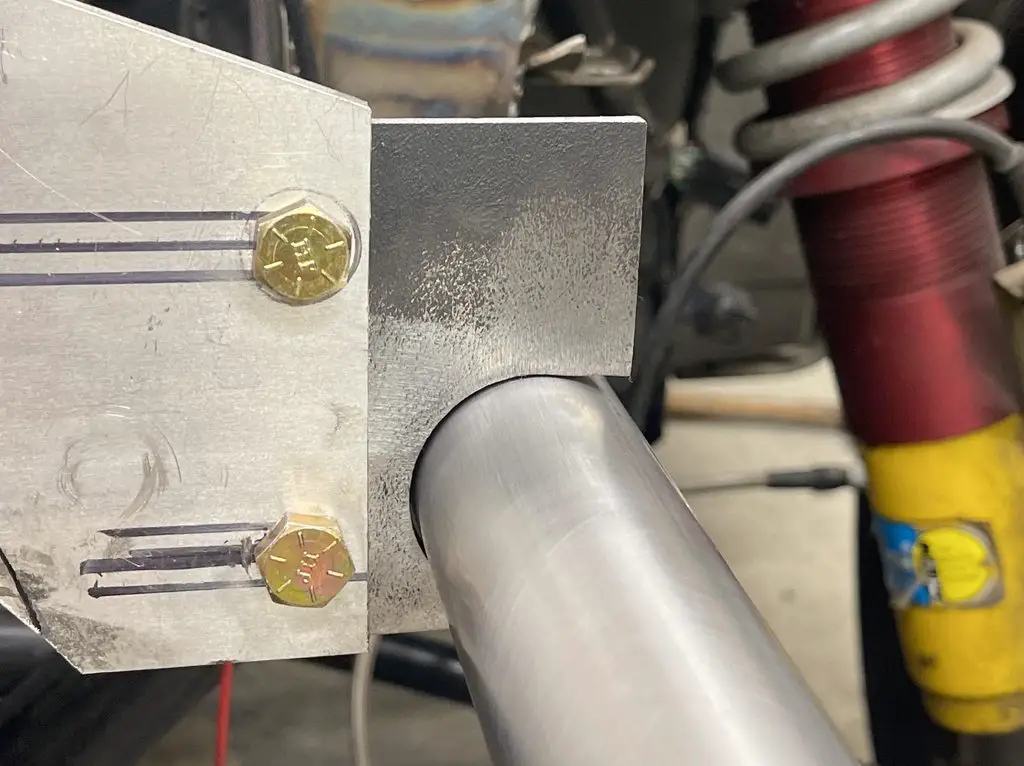

So i am running 3/8 aluminum spacer already to lower the k member but still need about 1/4" to clear my cowl (dont want to cut the hood and have this out if i cant help it). I am going to mock the motor plate up, and mark the tabs 1/2" lower to help adjust the motor down to clear the hood. Right now at the current ride height and with the 3/8" spacer and nothing under the transmission cross member i am at 2.8 degrees in relation to the concrete. Before i weld the mid plate in ill double check the degree again to see if i need to lower the tail-housing to get it back to 3 degrees +/- 0.5 degree. From my understanding 2-5 degrees is a good set point for drive-line angles. I do have adjustable rear upper control arms to adjust the pinion angle to match the engine as well.

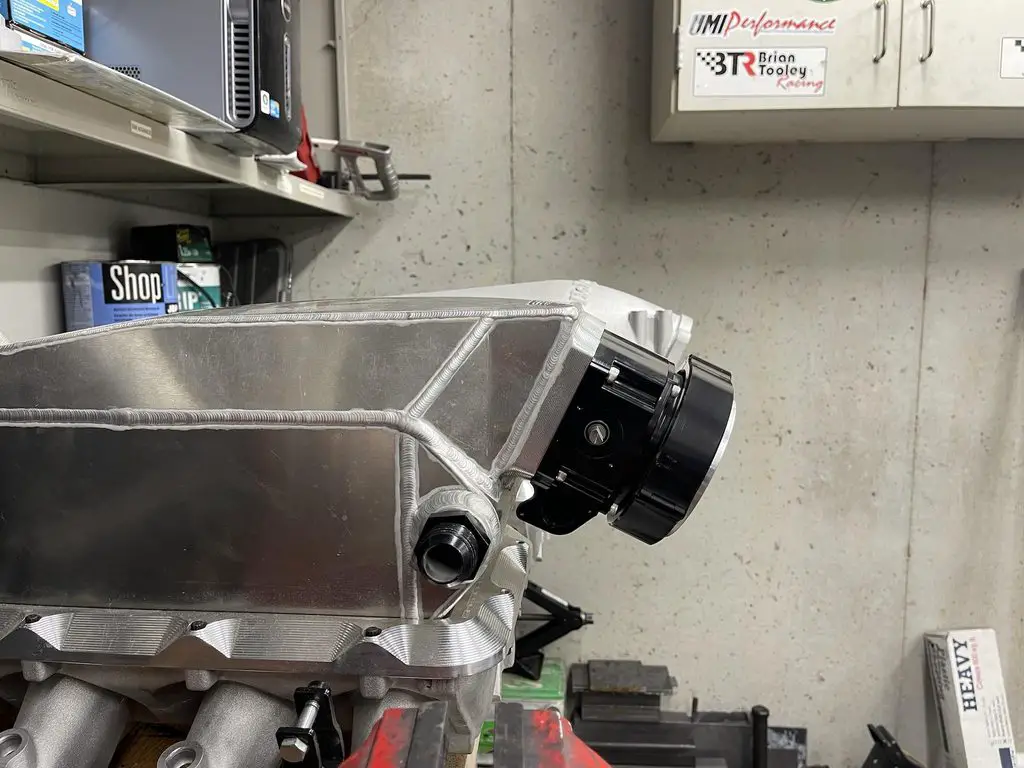

The Shearer fab t6 flange came in as well. Its a really nice piece well worth the wait and the cost.

Hopefully my GT55 from Forced Inductions ships any day now, Thats all for this week!

Longer fender tabs arrived on Thursday so Friday night i got them welded up and tacked in place. You can see the length difference from the original set.

Tore everything off and burned in all of the bars! Even added back the quick latch posts so i can use them again.

Then i removed my K Member (UPR) to install my buddies K Member (AJE) which will be used to mock-up the motor front and mid plates. Set the engine in place and test fit the massive 2k Shearer A2W. I need about 1/4" of an inch lower to clear the 4" cowl.

Went ahead and threw the suspension on to set ride height before establishing a drive-line angle for the motor. Fun fact UPR a-arms will fit AJE K members even though they both said it wont work lol.

So i am running 3/8 aluminum spacer already to lower the k member but still need about 1/4" to clear my cowl (dont want to cut the hood and have this out if i cant help it). I am going to mock the motor plate up, and mark the tabs 1/2" lower to help adjust the motor down to clear the hood. Right now at the current ride height and with the 3/8" spacer and nothing under the transmission cross member i am at 2.8 degrees in relation to the concrete. Before i weld the mid plate in ill double check the degree again to see if i need to lower the tail-housing to get it back to 3 degrees +/- 0.5 degree. From my understanding 2-5 degrees is a good set point for drive-line angles. I do have adjustable rear upper control arms to adjust the pinion angle to match the engine as well.

The Shearer fab t6 flange came in as well. Its a really nice piece well worth the wait and the cost.

Hopefully my GT55 from Forced Inductions ships any day now, Thats all for this week!