383 stroker rocker arms

- Thread starter Zzz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I'd confirm that the builder is going to be of no help prior top tearing in. And it is great advice to find a knowledgeable person to help him out if the builder is going to bone him.

My hip shot guess is that he has a header/exhaust manifold leak(s).

My hip shot guess is that he has a header/exhaust manifold leak(s).

If I could here it , I would most likely tell you what it is.

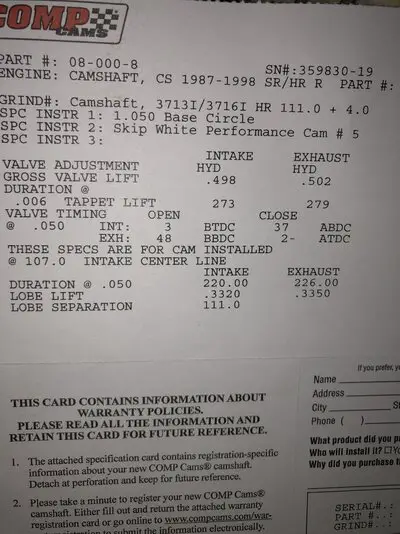

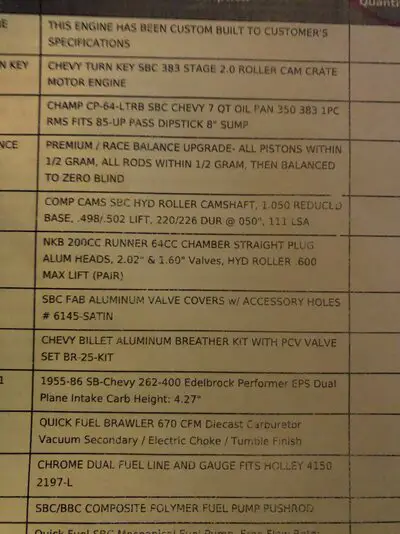

This is what’s in the engine which is a 383 stroker and I am not going to get a hold of the builder because once I lose my trust in somebody it’s a waste of time for anything especially when they don’t answer their phone. That’s just the way I am. I know they build good engines they have a ton of recommendations but the salesman was absolutely no help at all. They sent the wrong carburetor and no fuel pump and put the wrong water gaskets on. I’m done ranting and put a picture there anyone have an idea how to readjust the valves and yes it could be an exhaust leak but I’d still like to redo the valves they were make a noise at all times no matter what.

Attachments

This is what’s in the engine which is a 383 stroker and I am not going to get a hold of the builder because once I lose my trust in somebody it’s a waste of time for anything especially when they don’t answer their phone. That’s just the way I am. I know they build good engines they have a ton of recommendations but the salesman was absolutely no help at all. They sent the wrong carburetor and no fuel pump and put the wrong water gaskets on. I’m done ranting and put a picture there anyone have an idea how to readjust the valves and yes it could be an exhaust leak but I’d still like to redo the valves they were make a noise at all times no matter what.A

Attachments

EOIC - meaning as the Exhaust begins to Open adjust the intake valve on the same cylinder, then spin the engine over until Intake valve begins to Close and adjust the exhaust valve on the same cylinder. Following this ensures that you are adjusting the valve that is on the base circle of the cam.

EOIC implies a lot of spinning the engine over with a ratchet. You can’t turn the engine by the crank bolt - it will break or stretch. You need a tool to spin the engine.

When adjusting the valves you can use the twist method or jiggle method or both to determine zero lash. I use both. Do you know how to use either method of determining zero lash?

EOIC implies a lot of spinning the engine over with a ratchet. You can’t turn the engine by the crank bolt - it will break or stretch. You need a tool to spin the engine.

When adjusting the valves you can use the twist method or jiggle method or both to determine zero lash. I use both. Do you know how to use either method of determining zero lash?

Yeah, I didn't look at the cam card I noticed the heads in the build sheet were NKB which is what I bought from them for my 355 SBC which work great by the way.If it’s not skip white motor somebody’s using his grind numbers

- Status

- Not open for further replies.

Similar threads

BUILD THREAD

The never ending 383

- Replies

- 10

- Views

- 397

- Replies

- 18

- Views

- 921

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.