jrm81bu said:Hmm, I could have a real use for that black chrome coating!

I've thought about going nuts with it too. I wonder how bumpers, headlight bezels, rocker trim, etc would look if you did the entire car. I even thought about using it on the ZQ8's if I still get them. Too many random ideas I guess!

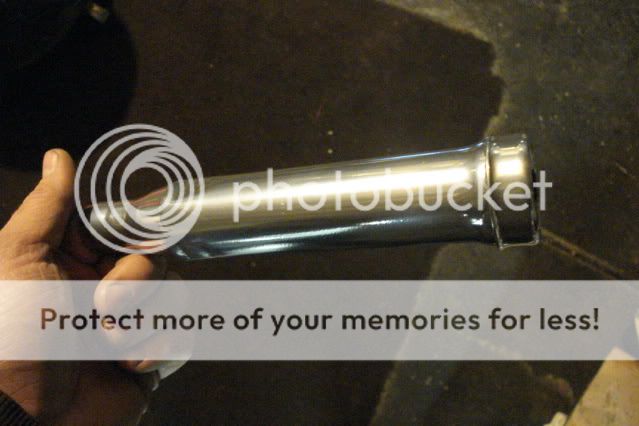

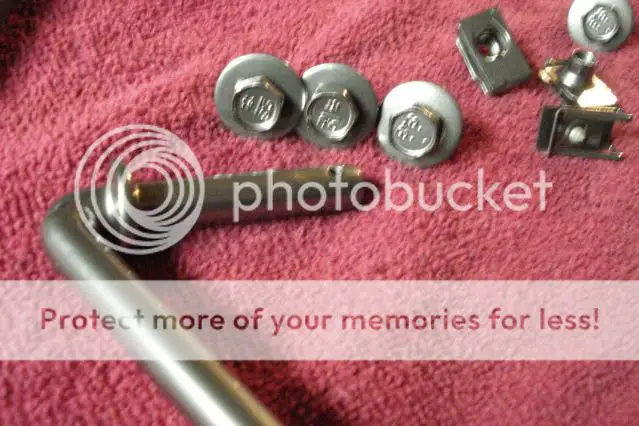

If it's any interest to you here's a link to the place I bought it from. http://www.powderbuythepound.com/Chromes-c-330/

I'm leaning towards using this color on engine bay components (valve covers, alt, master cyl, pulleys, power steering reservoir). If I do I'll most likely scrap the AMC blue for the engine color and go with a shade of gray or charcoal instead.