Yes, which is why you would want a torque to stall in the 2000 range, usually want a couple of hundred rpm higher. Of course you will probably be on the higher end of the rating. Also what size tires and what speeds do you want to drive on the highway?So, that is where my stall speed comes into play, correct?

GRAND PRIX 79 Grand Prix Resurrection

- Thread starter CDUNIGAN1981

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

26" tires

Crusing speed?

Honestly not sure bc I have never been able to really have any options.

After I put the 3.42 posi in with the TH350, I was virtually forced to putt putt around in order to keep my Poncho RPMs down.

Extreme Automatics told me I needed a 10" billet stall upgrade. On their website

they only have a 9.5" advertised and its lowest stall offering is 2100-2400 rpm which I assume is what I'll end up with.

Crusing speed?

Honestly not sure bc I have never been able to really have any options.

After I put the 3.42 posi in with the TH350, I was virtually forced to putt putt around in order to keep my Poncho RPMs down.

Extreme Automatics told me I needed a 10" billet stall upgrade. On their website

they only have a 9.5" advertised and its lowest stall offering is 2100-2400 rpm which I assume is what I'll end up with.

Yes, which is why you would want a torque to stall in the 2000 range, usually want a couple of hundred rpm higher. Of course you will probably be on the higher end of the rating. Also what size tires and what speeds do you want to drive on the highway?

I get 1800 rpm at 60 mph and 2100 at 70 mph. This calculator has been accurate, it seemed about 150 rpm high on my 70S but BFG Radial TA tires are known to be short on height.26" tires

Crusing speed?

Honestly not sure bc I have never been able to really have any options.

After I put the 3.42 posi in with the TH350, I was virtually forced to putt putt around in order to keep my Poncho RPMs down.

Extreme Automatics told me I needed a 10" billet stall upgrade. On their website

they only have a 9.5" advertised and its lowest stall offering is 2100-2400 rpm which I assume is what I'll end up with.

Last edited:

Whelp, I've started cutting out the floorboard cancer!

This is where my thread starts to get entertaining if nothing else.

😂👊👍🤔

This is where my thread starts to get entertaining if nothing else.

😂👊👍🤔

I bought this in April 1998 as a hs Jr. Immediately blew the 301 and was devastated. Luckily my Dad worked with a guy who was all about Pontiacs and didn't want to hear about putting a Chevy motor in a Grand Prix...he (Jamie) offered to build us a 455 at cost!

We supply the block and parts, bought the heads from him and he put it together.

I drove it for 3 yrs (not daily) until the rend end fell out of it in 2001.

This is where I screwed up. I moved away and she sat outside until 2014 when my now wife and I moved into apartment with a garage.

At this time, I began the search for a 8.5". First, I wasted a trip to Aurora, Il where some son of a Buick dealer in the 80's tried to sell me a non-posi for $1200. Right before we loaded it up my dad asked if we could spin dif cover off to be sure it wasn't toast. The guy was like "you cant tear these things up". We took the dif cover off and there was not clutch to be seen.

The rest of the story about this clown is for another day.

Found another 8.5" about a month later. We installed it along with new control arms and we once again on the road.

At this time I upgraded to MBI distributor.

3 years since I have started it. Not coincidentally, I have a 3 yr old.

Anyway, Im all in with it again.

Plans

OD transmission

New exhaust

Delete AC

Paint and Body has me nervous.

Entire floor pan

T top repair

T top header and inserts from gbody parts (bought)

GM A pillar with factory stickers! (bought)

My fear is that nobody will want to do the body work needed...more on this later.

Sent from my SM-G960U using Tapatalk

Nice build you have there! I’m one of your dad’s coworkers Chevy in a Pontiac guys.Luckily my Dad worked with a guy who was all about Pontiacs and didn't want to hear about putting a Chevy motor in a Grand Prix...

My 78 GP/SJ already had a 454 big block in it when I got it. It’s also rust free, so I’m lucky there. Maybe some day I’ll put a 400 Pontiac in it? Keep up the good work!

Nice build you have there! I’m one of your dad’s coworkers Chevy in a Pontiac guys.

My 78 GP/SJ already had a 454 big block in it when I got it. It’s also rust free, so I’m lucky there. Maybe some day I’ll put a 400 Pontiac in it? Keep up the good work!

Beautiful ride my friend

So, I bought a used Lincoln 140 and am preparing to weld floorboard in.

I believe I'm going to lap weld it as it's a floorboard and I've never welded.

My plan is...

1/2" overlap

Grind metal on backside of replacement piece and top side of car floorboard

Prep With SEM zince weld...both sides

Spot welds every 1"

Weld around entirety of top seam

Seam seal both sides

POR 15 entire top floorpan

Paint or POR15 replacement pan on bottom.

Any advice?

Please. Let me have it.

I'm borderline desperate

Attachments

Lap weld is fine. I wouldn't remove the primer in the lap joint. A couple pop rivets thru the lap splice to hold it in place. Remove them at the end and weld the hole shut. Skip the spots. Stitch weld everything even the bottom if you feel like you can run overhead. Knock them down with a grinder but leave most of the weld in place. POR15 top and bottom. Undercoat to hide the lap on the bottom.

Before you start get some scrap and practice on it. Get familiar with your welder. You don't want to burn holes cuz that just makes more work. Core shield is OK.

Good luck. If you practice it will go fine I'm sure.

Before you start get some scrap and practice on it. Get familiar with your welder. You don't want to burn holes cuz that just makes more work. Core shield is OK.

Good luck. If you practice it will go fine I'm sure.

Managed to remove front suspension.

Not something I had done without loads of adult supervision in the 90's.

I hesitated to do it. After all, you have to STOP somewhere. Right now, I'm stopping at firewall. If I had more space I would take body off the frame right now.

My thought is because engine is out and clip is off. I need to do as much as possible to the areas right in front of me. Easy access is hard to ignore.

In the end it's all 40 yr. old metal that needs attention....

Next up...wire wheel and paint.

I'm still on the fence about product.

Last edited:

While you're at this stage of your project, I would strongly recommend fixing the firewall. Ask me how I know... 😉 This is something that can be done with not much experience since most of the firewall won't be seen after you re-assemlbe your vehicle (unlike doing body work). However small your effort, it'll look much better than original. If down the road your project direction changes for the better, you won't regret having a nice firewall.

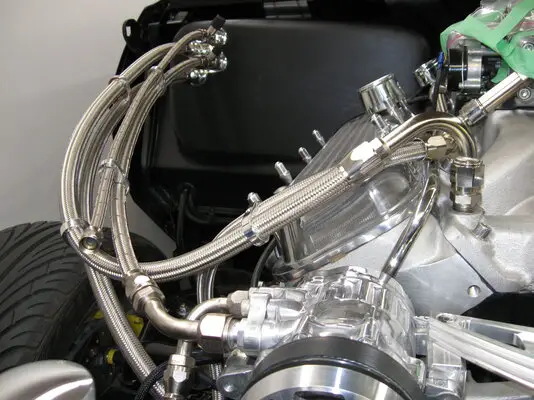

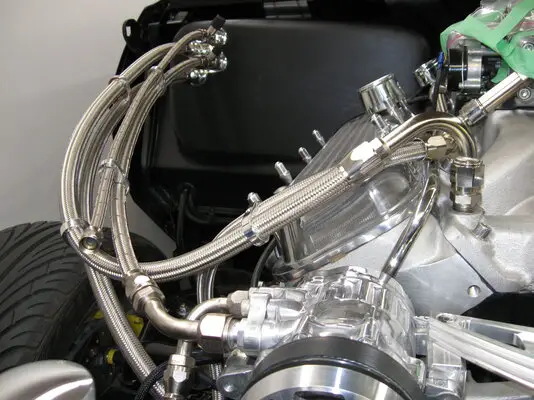

Here are some pics of mine -- nothing fancy, just wire wheel, sandpaper, some bondo, primer and paint. Good luck!

Here are some pics of mine -- nothing fancy, just wire wheel, sandpaper, some bondo, primer and paint. Good luck!

Similar threads

- Replies

- 5

- Views

- 120

- Replies

- 9

- Views

- 464

- Replies

- 2

- Views

- 123

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.