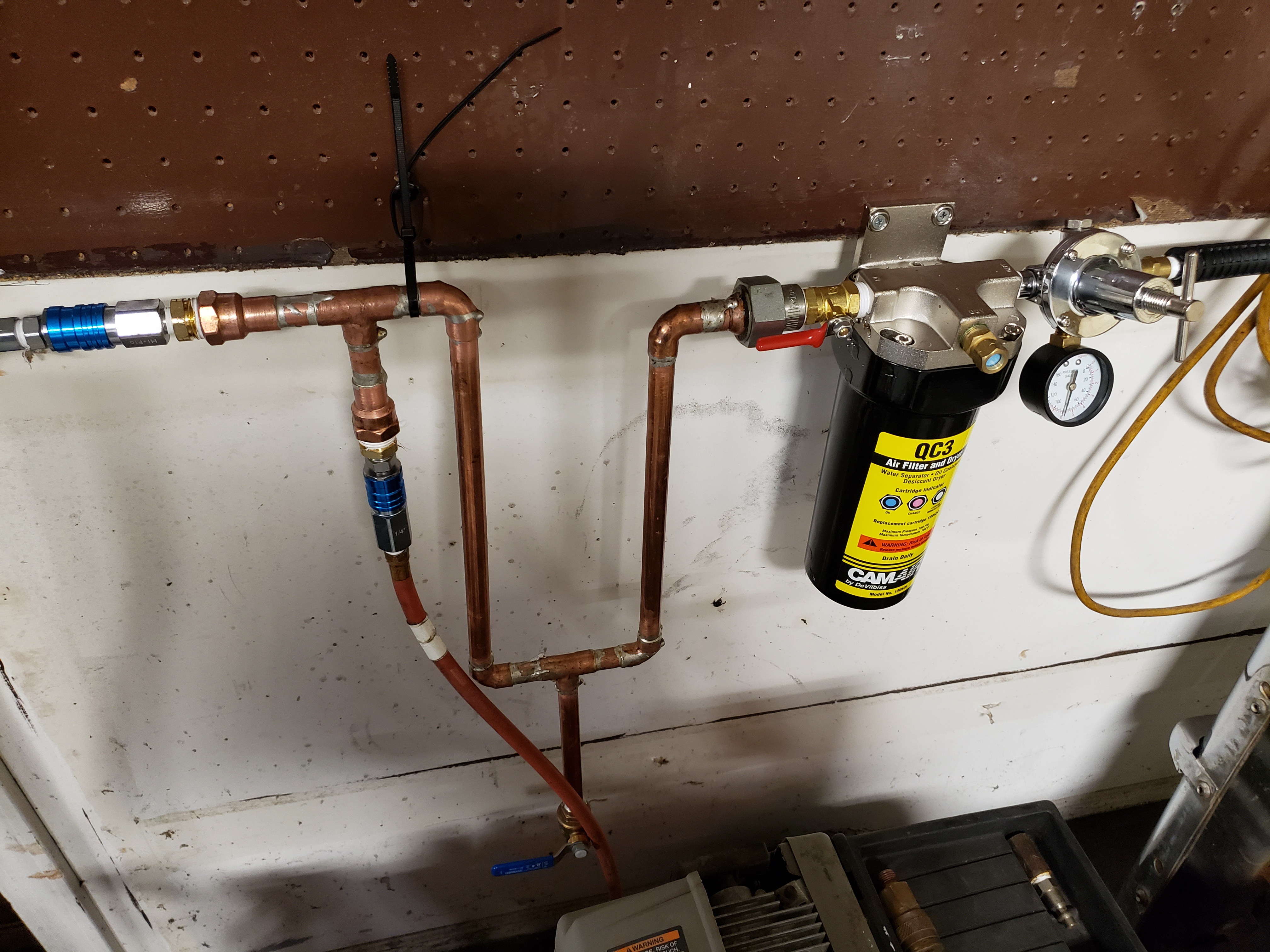

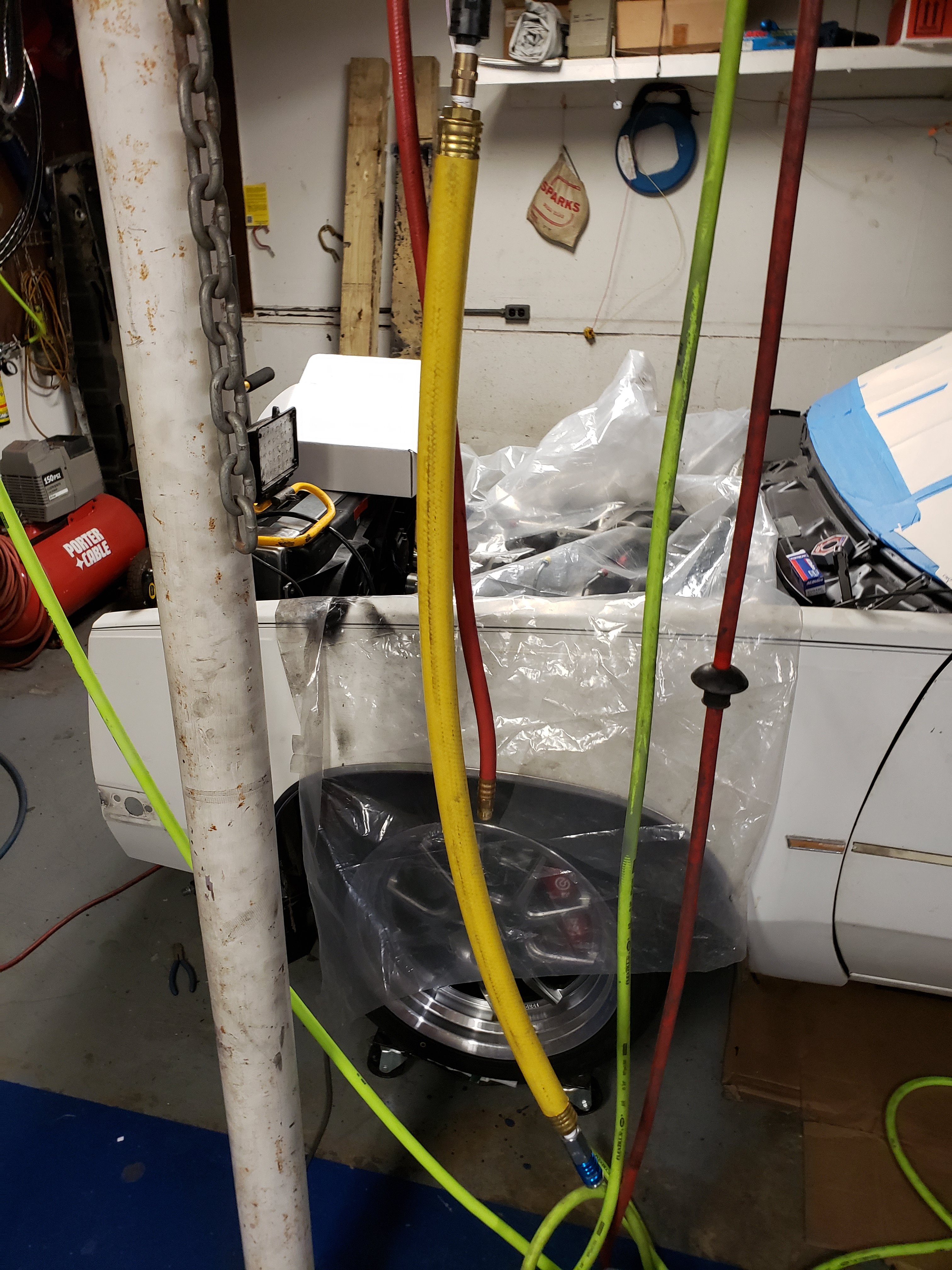

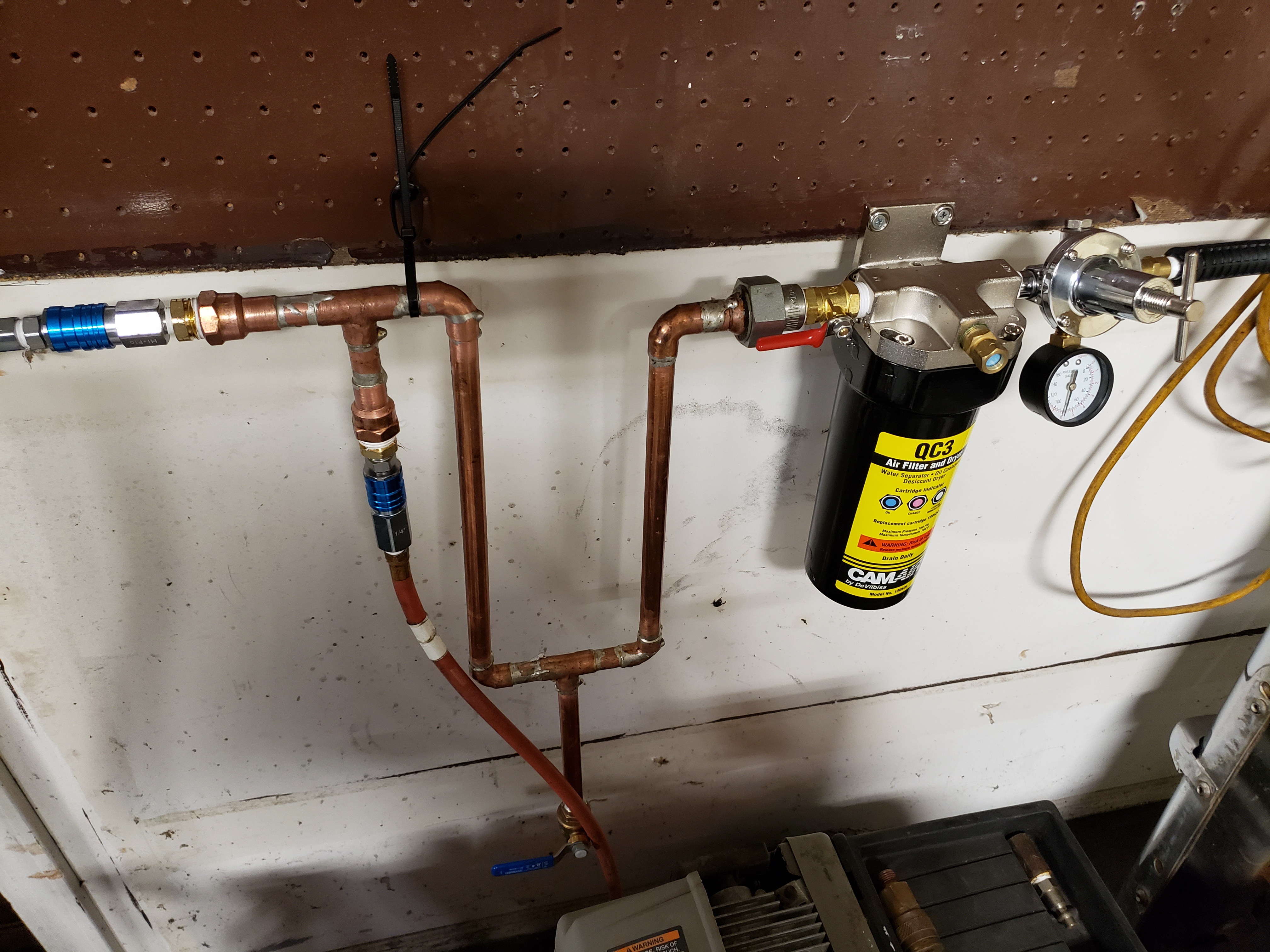

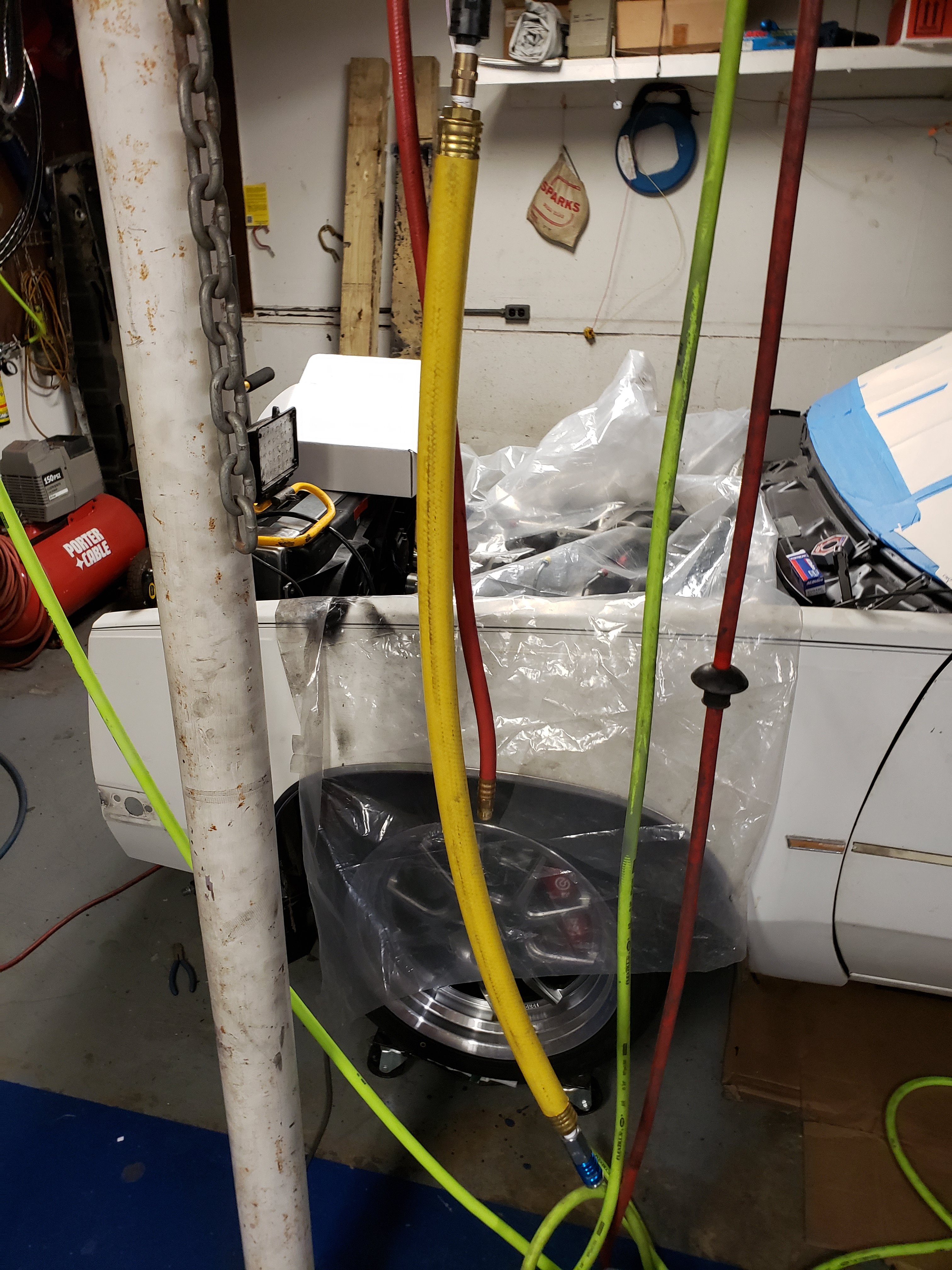

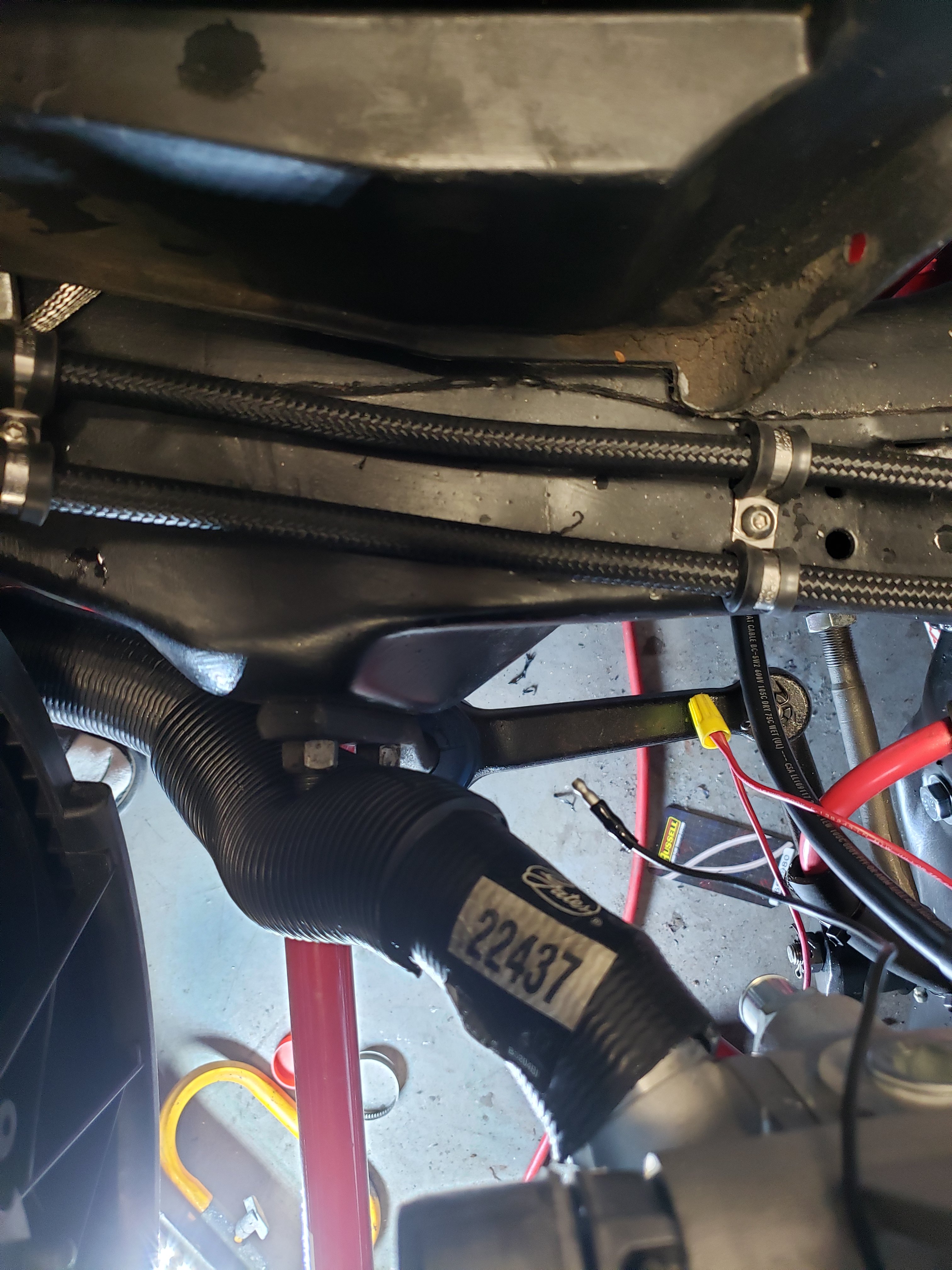

Well I got a little surface rust on the fender I stripped so I figured I better get a move on it. Knocked it out and hit it with 80 grit on the da sander. Set up my air filtration using 2 30 gallon air compressors tied together. Also using the large desiccant snake at the end connected to the spray gun. I think I need to change that because it's hard to maneuver with it. Any opinions? Did this outside with epoxy primer and only had a few little specs of debris from what I can tell