That's west up!!! Preaching the" good word" to these youngstas! WORK YOUR SUSPENSION AND GET IT RIGHT,before the :wink: m 22's yeah the hnr bushing tool is the bizness for this NESSASARY work..that girdle is gonna look tight with the bling sheen treatment.keep the movement going homie,and stock on some h8terade bcuz once this bct done they gonna be coming back for refills! :wink:

87 El Camino Daily Driver/Weekend Cruiser

- Thread starter Bumpin1ohmSS

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

L.A.X-RATED said:That's west up!!! Preaching the" good word" to these youngstas! WORK YOUR SUSPENSION AND GET IT RIGHT,before the :wink: m 22's yeah the hnr bushing tool is the bizness for this NESSASARY work..that girdle is gonna look tight with the bling sheen treatment.keep the movement going homie,and stock on some h8terade bcuz once this bct done they gonna be coming back for refills! :wink:

HAHAHA!! Preciate' that big dog! When I pull up at the shows, I may not have the baddest rims, or sweetest paint, but I fa damn sure will have some the hottest suspension, brakes and "home grown" cleaned up mods (sand blasted parts, ect) than those other candy drippin off the frame rides have. Im just tryin to get it into the youngins' heads that doin the basics first is where its at man...Clean it up and start with a good base. Man Chris got me wanting to pull her off the frame! HAAHAHA! Im not gonna do it tho. Imma save that for when I get my 68 Elco :wink: Skip and Dave both said do it on the SS. I'll see wassup 8) Thanks for checkin back and keeping me motivated on it bro...

Got a lil more done on plumbing the hoses for the oil coolers. Man Im trying to get these lines as clean and safe as possible. The trans lines are easy. The oil cooler lies are a lil tricky. Lines are running next to the header. Theres over a half inch of clearance but I just get nervous. LOL! Heat sould be ok cuz the headers are wrapped and I may run some heat shielding on the lines just for peace of mind. I also did a lil wiring: ran all the wires to the starter and alternator, and some of the wires for the gauges and sending units.. Pulled the axles (not hard as I thought it would be) and I sand blasted them up nice!!! I'll be taking them to get the studs pressed out and arp studs pressed in. Moving along now. Heres some pics..

Axels are out. I was gonna get some new Moeser 28 spline axles, but these were new when i got the rear so I'll keep em. I'll save the Moeser's for the rear I got from Skip...

Blasted em..

After removing the stock backing plate, I then used some aircraft stripper and cleaned the flange up so I could tape/mark it for cutting...

Wanted to de-rust this area so I stuffed a rag inside the tube and used a wire wheel drill end and cleaned it up..

Cleaned up ok..

Taped it off for the drilling out of the lower holes. I started small and work up. My cheap lil bits had a hard time with cutting thru. I'll get some better bits today...

I also used some cutting oil. But these cheapy lil bits went dull really quickly. Got it almost done tho...These holes are 5/16"

With that done, I started in on the axle tubes and cleaned up some of the lil rust spots...

Before using the wire wheel. This was just after stripping the por off and a wipe down with wax degreaser...You can see the rust line from where the brake lines were.

There was a deep rust line here where the brake lines ran. The previous owner just sprayed POR over everything instead of taking the lines off, cleaning the tubes and lines and then por treatment...But the POR did stop the rust in its tracks.. 😀

A lil bit more of the wire wheel...

Lil more to do and then I'll spray some wd40 on it until I can get the Eastwood Extreme chasis black in. Gotta go to AZ to get it. Cant get it here in Cali..

Gonna work on the Els wiring and hoses again for a couple hours today and then chill and relax. Thanks for checking back...

Elco Warren 8)

bonez305 said:What Stripper you use ? Rustoleum ? Brushed on ? That sh*t is serious.

Just some Rustolium brush on. The warmer it is the faster it reacts. I dabbed it on and came back 15 minutes later and it was a wrap for the por-15. Long sleeves (I have pretty thick long sleeved jump suits), gloves, eye protection and a mask are a must for me. That stuffs no joke!!

Bumpin1ohmSS said:Just some Rustolium brush on. The warmer it is the faster it reacts. I dabbed it on and came back 15 minutes later and it was a wrap for the por-15. Long sleeves (I have pretty thick long sleeved jump suits), gloves, eye protection and a mask are a must for me. That stuffs no joke!!

So the Por15 failed on the brake fluid ? you using Eastwood now ? I'll see how it goes and follow 😀

bonez305 said:So the Por15 failed on the brake fluid ? you using Eastwood now ? I'll see how it goes and follow 😀

It didn't hold up. When I installed the rear in the SS, I also replaced the rear wheel cylinders as well. I wasn't getting fluid to the back and unhooked the line going to each cylinder. Pump pump pump and finally got fluid. Some got on the axle tube and within 10 minutes it bubbled up. It would have been fine if I would have cleaned it up right away. Not sure how well the Eastwood stuff will hold up. But I'll give it a try and be more careful while bleeding the brakes....

Elco Warren 8)

L.A.X-RATED said:West up homies!!! Haven't been up in your threads for a min,but you already know im just trying to pLAy kectchup and following the leader! :wink: looking SStunning as usual.looks like ol lac got all us brake upgrading! **** yeah he's the man.i wanted to see if you needed. My bushing remover/puller from hnr parts and stuff,the tool makes this suspension work(removing,and installing) all the bushings(a-arms,trailing arms,etc) a breeze..i don't know if you're planning on replacing your dog ear bushings on your rear,but this tool also does this as well.nehoo,keep grinding homie,and pm me iwith a adress to shoot the tool to if interested.

Wassup fam... I couldn't find that bushing remover so I just drilled the rubber out, put a dent in the bushing case and smacked it out. Those bushings were good but I wanted the ones from my spohn kit in. Preciate that info!! Trying to get my tool game up so I'll be on the lookout for one. You mind posting a pic of what it looks like and a link where I can get one. Much love bruh.

Elco Warren 😀

Got the bottom holes drilled out on the Grand National flange. Man that flange is tough!! LOL! Went thru some drill bits quickly.. Glad I cleaned it up. Made things easier. I also stuffed a rag in the opening so no shavings or whatever could get in the tubes...I filed down the edges and smoothed the hole out.

Got the ear bushings out. No sweat. Drilled the rubber out and then used my orange mallet to tap out the case. Im running Edelbrock anti-hop bars so I just popped em out while I wait for the bars to come..

Hit the whole rear with a wire brush on my drill. Cleaned up nice!! Mel just ordered the Eastwood extreme chassis black and primer for me so I should be able to get started on the spray soon...

[youtube]vJLrrNLN9sY[/youtube]

Not sure if Im gonna get the ol girl into paint or not. I want to redo my suspension. Hotchkis extreme setup-lower trailing arms and adjustable uppers, Edelbrock anti hops, 1" drop springs,extreme front/rear sways, front SC&C jounce bar, edelbrock ias shocks all around and Spohn's front end rebuild kit. The works...I'll see how I feel the closer I get to the end of the month..

Thanks for checkin back..Should have the flanges cut and other holes drilled along with the backing plates mocked up this weekend...

Elco Warren 8)

80z UP!!!

Got the ear bushings out. No sweat. Drilled the rubber out and then used my orange mallet to tap out the case. Im running Edelbrock anti-hop bars so I just popped em out while I wait for the bars to come..

Hit the whole rear with a wire brush on my drill. Cleaned up nice!! Mel just ordered the Eastwood extreme chassis black and primer for me so I should be able to get started on the spray soon...

[youtube]vJLrrNLN9sY[/youtube]

Not sure if Im gonna get the ol girl into paint or not. I want to redo my suspension. Hotchkis extreme setup-lower trailing arms and adjustable uppers, Edelbrock anti hops, 1" drop springs,extreme front/rear sways, front SC&C jounce bar, edelbrock ias shocks all around and Spohn's front end rebuild kit. The works...I'll see how I feel the closer I get to the end of the month..

Thanks for checkin back..Should have the flanges cut and other holes drilled along with the backing plates mocked up this weekend...

Elco Warren 8)

80z UP!!!

Spohn, Speedway and Edelbrock goodies came in. (thanks for ordering em lil bro) Spohn Front steering rebuild kit, Spohn super travel upper ball joints, Speedway tubular upper control arms and Edelbrock front IAS shocks...I also got the correct ARP rear axle studs for my Grand National rear. Taking em into work and pressing em in...

The old Spohn setup used to be a nice silver. I may just spray em cuz I liked the look...

Adjusters look sweet!

Spohn Super Travel ball joints..

Speedway uca's Two right sides...

Screwed some 90 fittings in the arms and ball joins....

Edelbrock IAS shocks. Summit had em on the cheap so I just got a set. Having a hard time finding the rears tho. Looks like Edelbrock may have stopped making these(which is why Summit sells em for so cheap now) If I cant find a rear set, I'll just strap the new napa rear air shocks red and keep it moving...

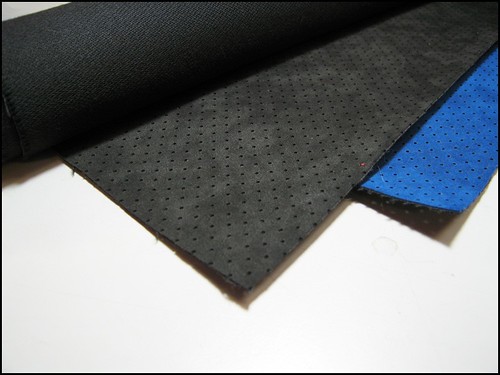

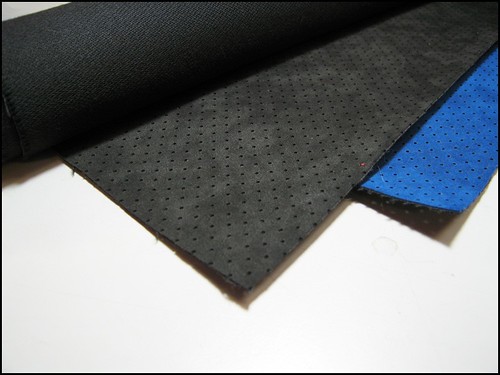

Dropping these 442 seats (I think or they are older Elco seats) off to Big Saints peeps on SAturday. Going with Alcantara perforated suede in blue down the center and grey suede (maybe or "pleather") on the sides. Drawing up how I want it done and will talk with the pro on Saturday. Bounce some ideas around and see wassup

I KNOW it will turn out clean after seeing Josh's seats and Big Saints seats! OMG CLEAN!!

Still waiting on the SC&C front brace and anti hop bars. Not gonna paint the El this month. I'll wait till it gets closer to summer. Instead Im getting the Hotchkis EXTREME TVS setup. Liked this kit alot so I should be ordering it this month after I take care of a few lil loose ends...

All thats left to do on the motor is finish plumbing the cooler hoses (trans and motor oil), hook up the power to the starter wires(I need some heat shielding wrap), hook the tach wire up, power for the dizzy, I did all the grounds already. May be over kill: 0 gauge from the block to the battery post, 4 gauge from the battery post to the frame, 4 gauge from the battery post to the fender wall, 4 gauge from the block to the firewall and the lil flat mesh ground strap from the block to the firewall. I got all the wires ran for the starter, braided hoses blumbed for the fuel, vac lines and the lower and upper coolant hoses. Nothing really left to do. Motor has been fired(when in the SS) so no need to break in and all that. Fluids, battery and crank it up and see what leaks. LOL! Looks like we may get rain this weekend so Im not sure if I'll be on the old girl. Other "garage" projects I can work on..

Thanks for looking..

Elco Warren 8)

80z up!!

The old Spohn setup used to be a nice silver. I may just spray em cuz I liked the look...

Adjusters look sweet!

Spohn Super Travel ball joints..

Speedway uca's Two right sides...

Screwed some 90 fittings in the arms and ball joins....

Edelbrock IAS shocks. Summit had em on the cheap so I just got a set. Having a hard time finding the rears tho. Looks like Edelbrock may have stopped making these(which is why Summit sells em for so cheap now) If I cant find a rear set, I'll just strap the new napa rear air shocks red and keep it moving...

Dropping these 442 seats (I think or they are older Elco seats) off to Big Saints peeps on SAturday. Going with Alcantara perforated suede in blue down the center and grey suede (maybe or "pleather") on the sides. Drawing up how I want it done and will talk with the pro on Saturday. Bounce some ideas around and see wassup

I KNOW it will turn out clean after seeing Josh's seats and Big Saints seats! OMG CLEAN!!

Still waiting on the SC&C front brace and anti hop bars. Not gonna paint the El this month. I'll wait till it gets closer to summer. Instead Im getting the Hotchkis EXTREME TVS setup. Liked this kit alot so I should be ordering it this month after I take care of a few lil loose ends...

All thats left to do on the motor is finish plumbing the cooler hoses (trans and motor oil), hook up the power to the starter wires(I need some heat shielding wrap), hook the tach wire up, power for the dizzy, I did all the grounds already. May be over kill: 0 gauge from the block to the battery post, 4 gauge from the battery post to the frame, 4 gauge from the battery post to the fender wall, 4 gauge from the block to the firewall and the lil flat mesh ground strap from the block to the firewall. I got all the wires ran for the starter, braided hoses blumbed for the fuel, vac lines and the lower and upper coolant hoses. Nothing really left to do. Motor has been fired(when in the SS) so no need to break in and all that. Fluids, battery and crank it up and see what leaks. LOL! Looks like we may get rain this weekend so Im not sure if I'll be on the old girl. Other "garage" projects I can work on..

Thanks for looking..

Elco Warren 8)

80z up!!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 120

BUILD THREAD

El Camino roll pan

- Replies

- 0

- Views

- 80

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.

I give up!!! Looking good bro!

I give up!!! Looking good bro!