Got sidetracked on house remodeling and model building the last month back to this one!

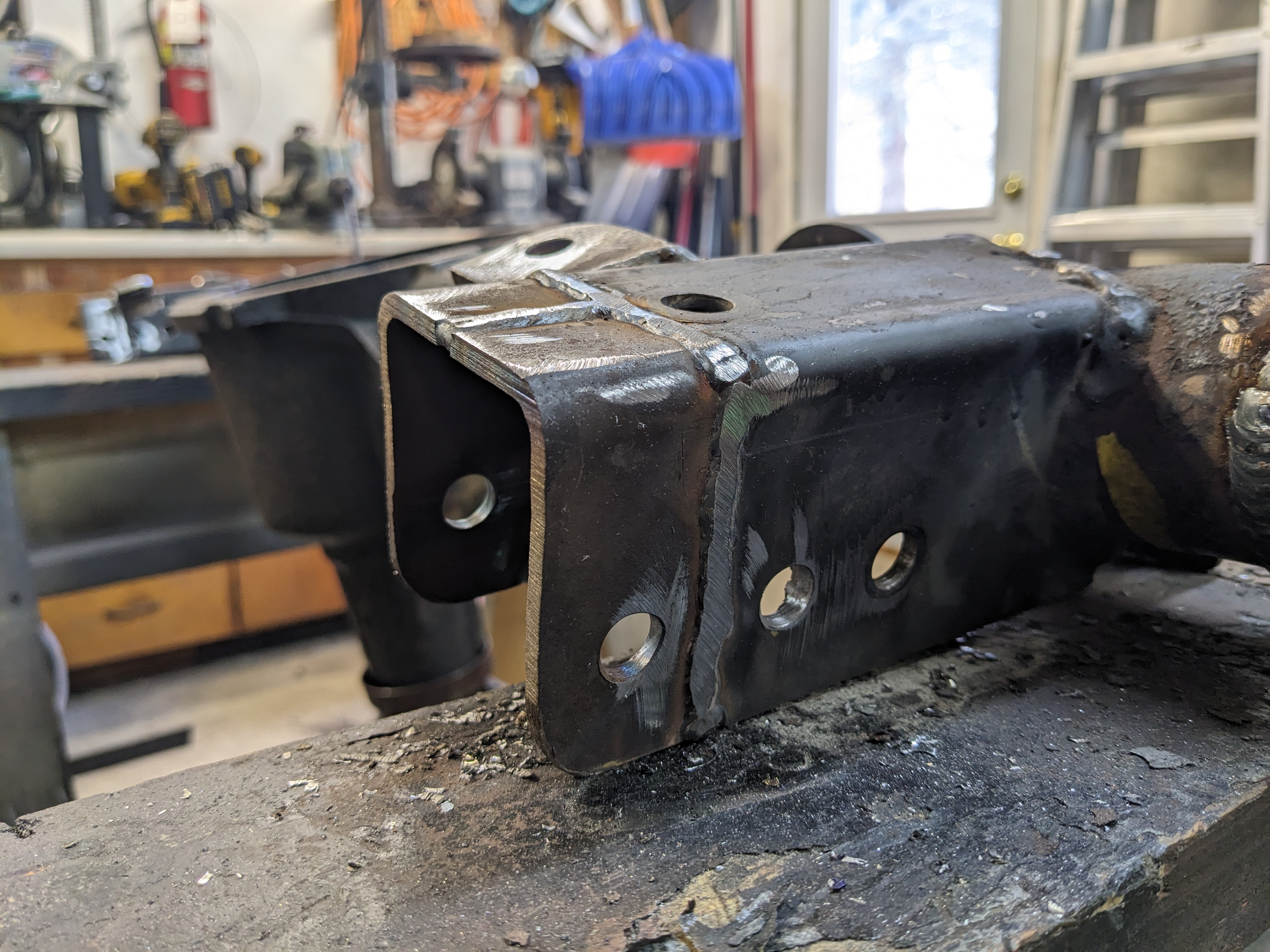

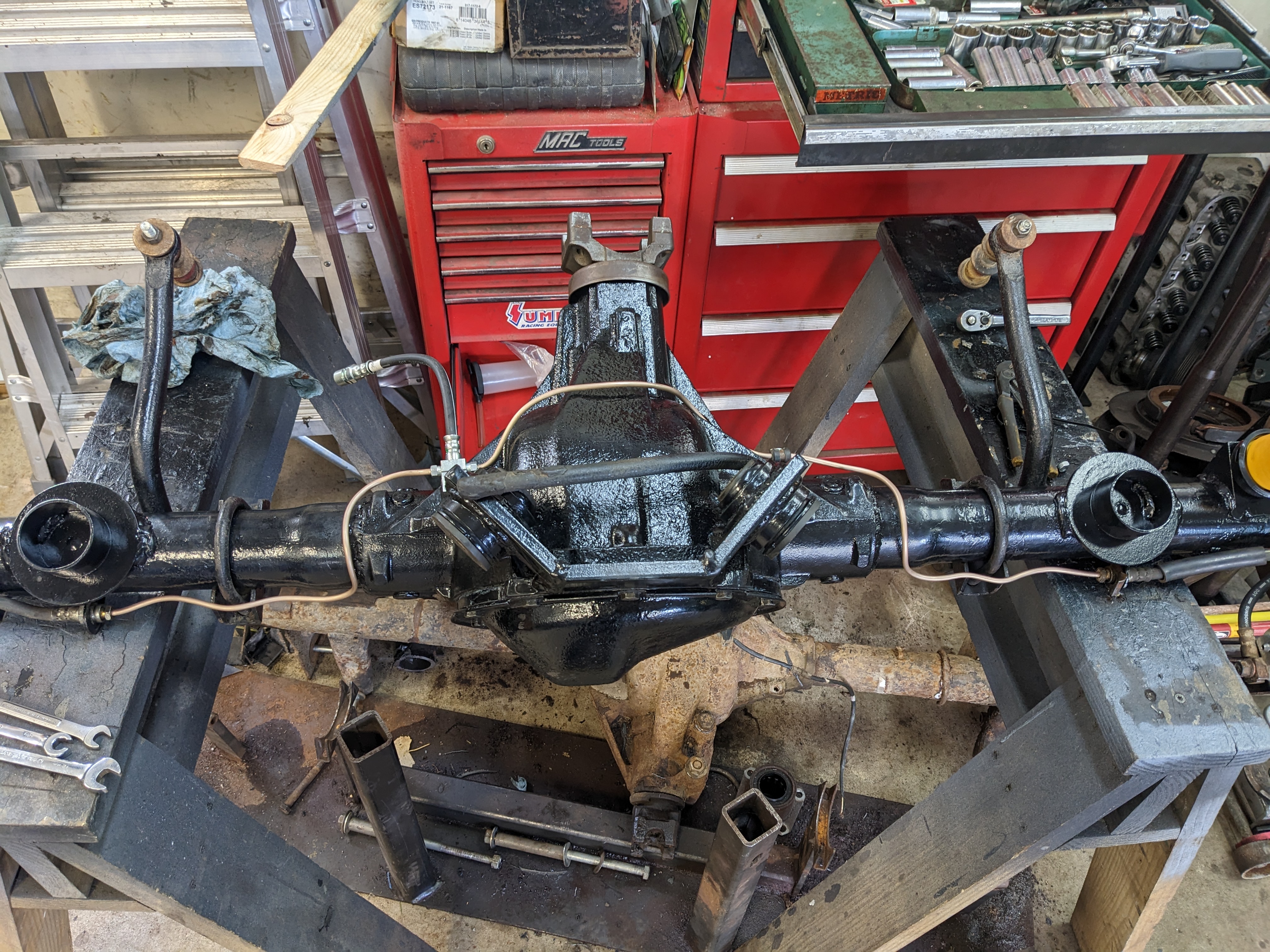

Fabricobbled some shock mount relocation brackets and bump stop mounts. Ordered and installed some wheel studs and finalized rotation of the f body rear disks.

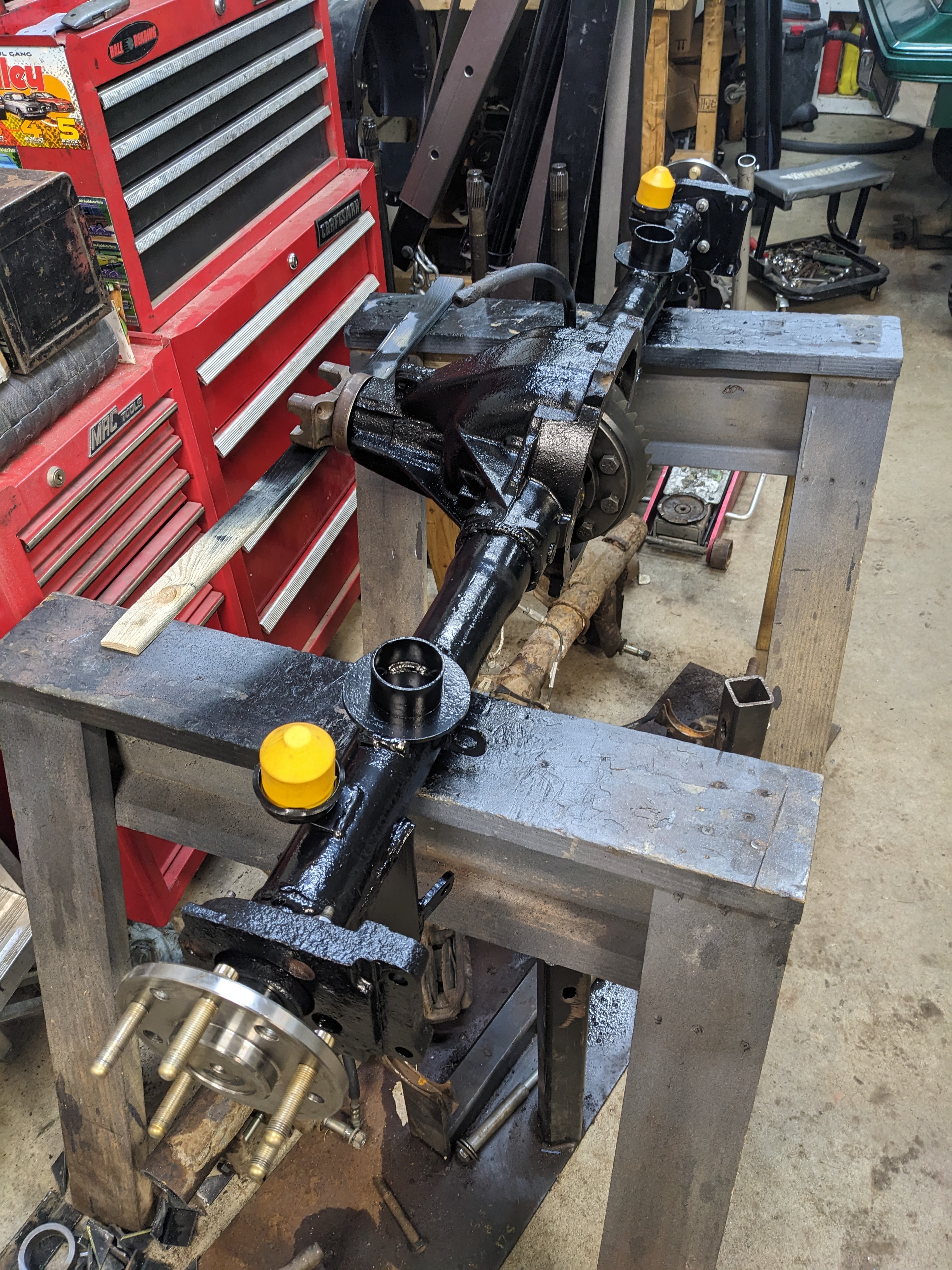

Welded half of the tube to ends on and ran out of argon. Glad they make grinder wheels because I need to gouge most of the crappy weld out.

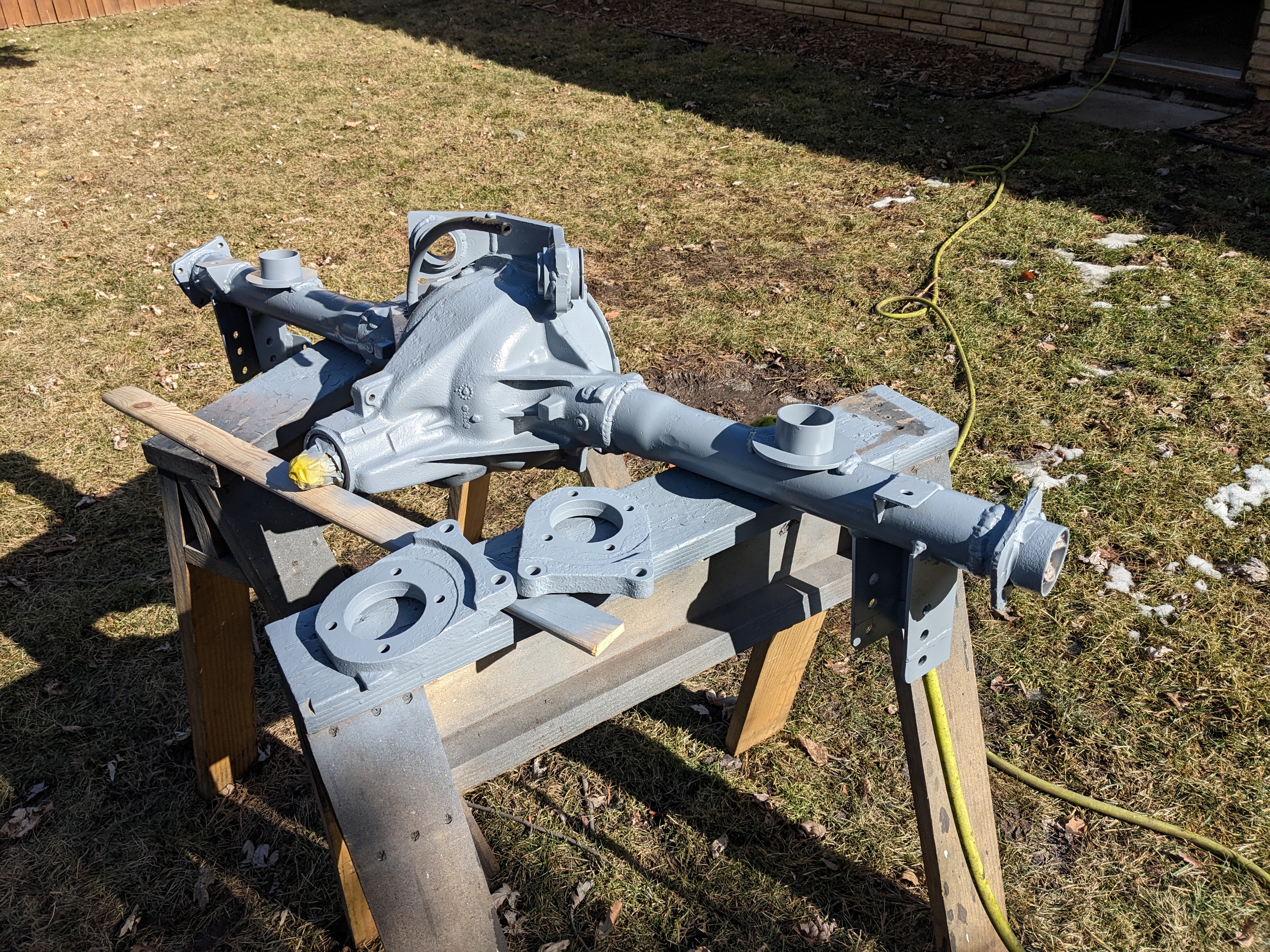

It's supposed to be mid 40's this weekend so I'm hoping to get this welded up so I can shoot a coat of paint on it outside

Fabricobbled some shock mount relocation brackets and bump stop mounts. Ordered and installed some wheel studs and finalized rotation of the f body rear disks.

Welded half of the tube to ends on and ran out of argon. Glad they make grinder wheels because I need to gouge most of the crappy weld out.

It's supposed to be mid 40's this weekend so I'm hoping to get this welded up so I can shoot a coat of paint on it outside