Doing the engine is a good next step along with detailing all the other ancillary parts (bolts/brackets etc.

Bernadine: 1978 Buick Regal Restoration/Build

- Thread starter 78Regal350

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Update, December 2, 2022: Things have been moving pretty slowly as of late. Both kids (ages 2 & 4) and I wound up getting RSV, which has lingered in all of us as colds, and then Thanksgiving came, followed by me needing to spend a fair amount of time putting up Christmas lights & decorations to appease my wife. Since getting the engine block ready for the machine shop I smoothed the casting seams on the rods so they were ready as well. Yesterday I was able to spend about an hour taking my first crack at the porting I’ll be doing on the heads. I spent my time finessing one of the intake bowls and shaping the guide boss.

But the best news, is that I got the block, pistons, & rods dropped off at the machine shop today! They’re doing the final cylinder hone & line hone check on the block, as well as resizing the rods.

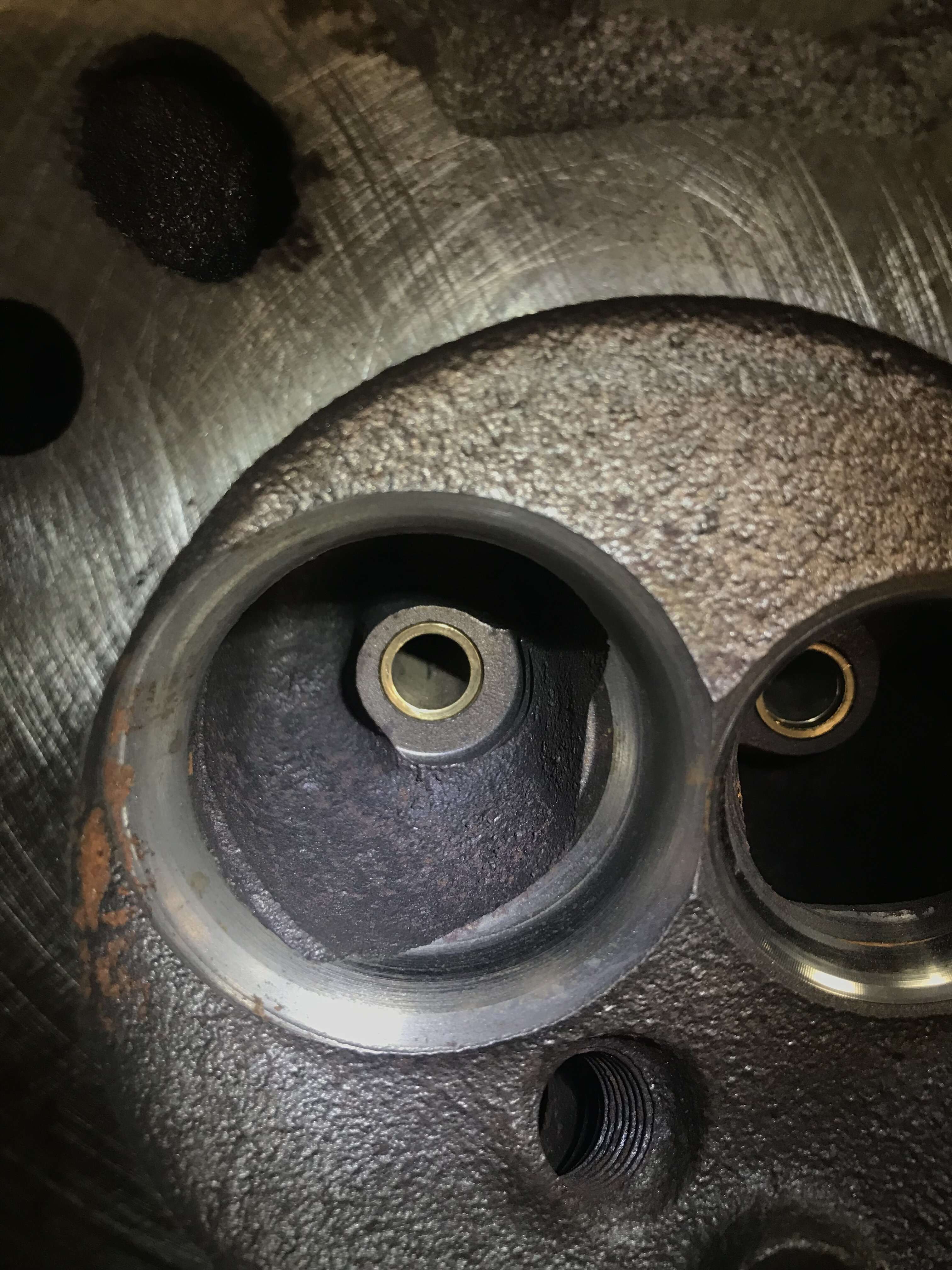

Intake bowl/valve guide boss before:

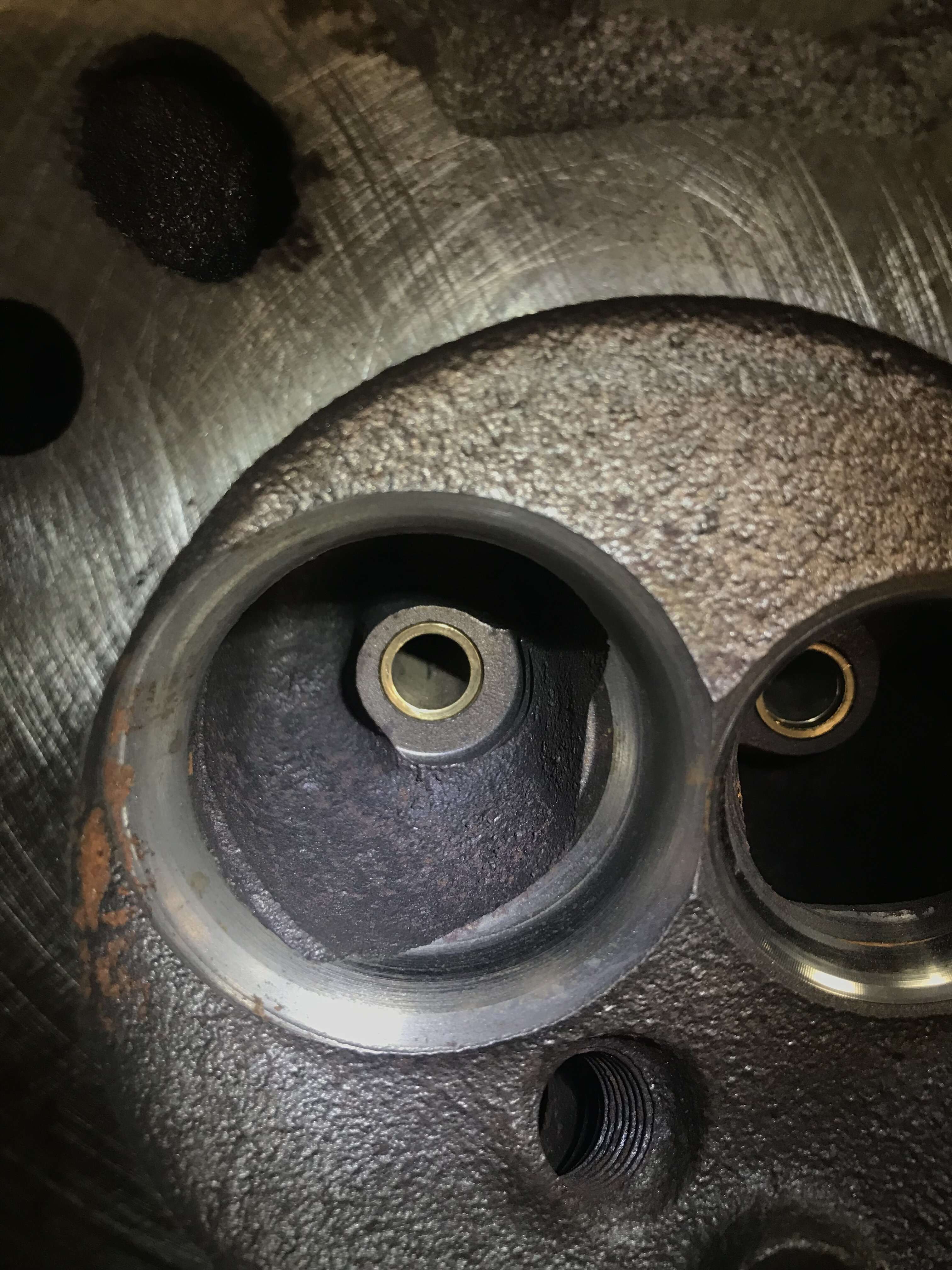

Intake bowl/valve guide boss after:

But the best news, is that I got the block, pistons, & rods dropped off at the machine shop today! They’re doing the final cylinder hone & line hone check on the block, as well as resizing the rods.

Intake bowl/valve guide boss before:

Intake bowl/valve guide boss after:

Update, January 11, 2023: Happy (belated) new year! Things have been moving fairly slowly the past several weeks. Between all the Christmas/holiday happenings and the several days of extreme, bitter cold we had a few weeks back I was able to “finish” porting one of the cylinder heads. I want to have this head flow tested before I do the other one, so my porting operations are currently on hold. I’ve also come to realize I can’t really lay out a game plan or timeline for rebuilding the engine until I have all the machine work complete. Before dropping off the block & rods on Dec 2nd I was told the lead time for the work I needed done (finish hone cylinders, align hone block, resize connecting rods) would be “about 2 weeks”, but after talking to them at the 4 week mark I was again told the work would be done in 2 weeks. Since I still have several machine shop-related tasks (flow test head(s), resurface flywheel, balance rotating assembly, finish machining the crank for pilot bushing) I’m guessing I’ll be well into the summer before I can actually expect to start getting the engine together.

Instead of letting my time get completely wasted, last week I decided to switch gears (pun only slightly intended) and get the transmission torn apart and cleaned up to start rebuilding it.

Saginaw 4 speed, 0 lines input/2.84 1st gear:

Instead of letting my time get completely wasted, last week I decided to switch gears (pun only slightly intended) and get the transmission torn apart and cleaned up to start rebuilding it.

Saginaw 4 speed, 0 lines input/2.84 1st gear:

I think the general consensus is that the Saginaw won’t hold up a lot of power/torque or a lot of abuse. My Buick 350 will be stout, but I won’t be beating this car up.I curious how much torque those Saginaw can take? Your 350 will twist really nicely. Machine shops are brutal up here for wait time. My experience, at least 3 times as much time as they are told.

As I’ve been tearing this trans apart I’ve been researching old GM part #s and discovered the Saginaws that came in V8 applications had different (stronger) input & output shaft bearings than the V6 versions. I was able to find NOS Delco/NDH “V8 version” bearings, so hopefully those do at least a little bit to help it hold up.

Update, January 14, 2023: I got the whole trans apart, and initially everything looked great. All the gears are in very nice shape with no chipped or broken gears. I did notice 2 of locks on the 1st/2nd gear synchro clutch hub had small pieces broken off of them, and when disassembling the main shaft/gears I found out at least one of the pieces ended up between the synchro clutch hub and 1st gear. Both were damaged, and the synchro hub so much so that I couldn’t even see the lock ring holding it & 2nd gear on the main shaft (much less remove it).

Since I had the trans case, counter gears/shaft, & reverse idler all ready for reassembly I decided to go ahead and throw them together yesterday. And last night I purchased a NOS 1st gear and good condition used synchro clutch hub on eBay.

I wasn’t sure how it would go, but with some creative & careful use of a 3” cut-off wheel, today I was able to hack up the synchro hub enough to get it (and 2nd gear) off the main shaft without damaging the main shaft!

Damage to 1st gear & 1st/2nd gear synchro clutch hub:

Synchro clutch hub after its meeting with the cut-off wheel:

Trans case, countershaft/gears, & reverse idler ready for reassembly with new washers & needle bearings:

Since I had the trans case, counter gears/shaft, & reverse idler all ready for reassembly I decided to go ahead and throw them together yesterday. And last night I purchased a NOS 1st gear and good condition used synchro clutch hub on eBay.

I wasn’t sure how it would go, but with some creative & careful use of a 3” cut-off wheel, today I was able to hack up the synchro hub enough to get it (and 2nd gear) off the main shaft without damaging the main shaft!

Damage to 1st gear & 1st/2nd gear synchro clutch hub:

Synchro clutch hub after its meeting with the cut-off wheel:

Trans case, countershaft/gears, & reverse idler ready for reassembly with new washers & needle bearings:

Update, January 18, 2023: I was able to pick up the engine block & rods from the machine shop yesterday, and all the work looks good.

I also got the replacement synchro locking hub for the trans yesterday, and the new 1st gear will deliver today, so I should be able to get the trans buttoned back up by the weekend.

Also sorry; no pictures. haha

I also got the replacement synchro locking hub for the trans yesterday, and the new 1st gear will deliver today, so I should be able to get the trans buttoned back up by the weekend.

Also sorry; no pictures. haha

Update, June 5, 2023: It’s obviously been quite some time since I posted any of my progress on the car. Truth is I’m just really bad at taking the time to stop and take pictures as I’m working. But since my last post I’ve accomplished the following:

- rebuilt the trans

- balanced the connecting rods

- hung the pistons on the rods

- removed the doors & trunk lid

- rebuilt the door hinges

- rebuilt the rear brakes

- installed the rear parking brake cables

- finished running new fuel & return lines

- disassembled & restored the non-A/C heater box (more on that later on in the build)

- replaced a rusted section of the driver side inner fender

- prepped (i.e. sanded) the entire body, doors, fenders, & trunk lid for epoxy primer

This past Saturday I was able to undercoat the body, and on Wednesday I’ll finally get the body mounted to the frame again.

I used Rusfre rubberized undercoating for the tub. (The pictures aren’t the greatest.)

- rebuilt the trans

- balanced the connecting rods

- hung the pistons on the rods

- removed the doors & trunk lid

- rebuilt the door hinges

- rebuilt the rear brakes

- installed the rear parking brake cables

- finished running new fuel & return lines

- disassembled & restored the non-A/C heater box (more on that later on in the build)

- replaced a rusted section of the driver side inner fender

- prepped (i.e. sanded) the entire body, doors, fenders, & trunk lid for epoxy primer

This past Saturday I was able to undercoat the body, and on Wednesday I’ll finally get the body mounted to the frame again.

I used Rusfre rubberized undercoating for the tub. (The pictures aren’t the greatest.)

Update, June 7, 2023: Today feels like a major accomplishment day, because the body & frame are once again a singular unit! The upper mounts are ones from Classic Industries that I painted to look like the GM mounts, the lowers are NOS “pink” mounts (p/n- 457915), and I used all new grade 10.9 bolts from Bel-Metric.

I also removed all the old seam sealer from the interior, as well as put down new Transtar seam sealer. There was a little surface scale/rust in places on the floorboards, so I cleaned that up & coated those areas too.

I also removed all the old seam sealer from the interior, as well as put down new Transtar seam sealer. There was a little surface scale/rust in places on the floorboards, so I cleaned that up & coated those areas too.

Update, June 15, 2023: I got the body & doors sprayed in epoxy primer yesterday. I had really hoped to be able to get high build primer on the body, doors & trunk lid as well, but I just didn’t have the time.

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 246

- Replies

- 0

- Views

- 320

- Replies

- 0

- Views

- 141

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.