Well, I took it back out at least temporarily. But, yeah, with the physically smaller but higher power amps I went with, I was able to cut the shelf from 12 down to 9.5 and then the cover with a 10" hole just for the sub speaker flipped up and fastened right to the subenclosure instead of to that extra bracket on the original design. It was not quite as bad as talking vs talking with your hand over your mouth but that was to a lesser extent the same effect the cover had on the sound in the car with the trunk lid and doors closed. I was frankly surprised 1/4" abs would muffle base frequencies that much? Or maybe the damn thing running top to bottom the length of that entire shelf space behind the rear seat has some resonant dampening effect when fastened directly to the "closed" sub enclosure? Just wondered if replacing 1/4" abs with 1/8th perf board might be a better idea?

Build Thread: '87 442 . . . Time to turn and stop

- Thread starter Canon_Mutant

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

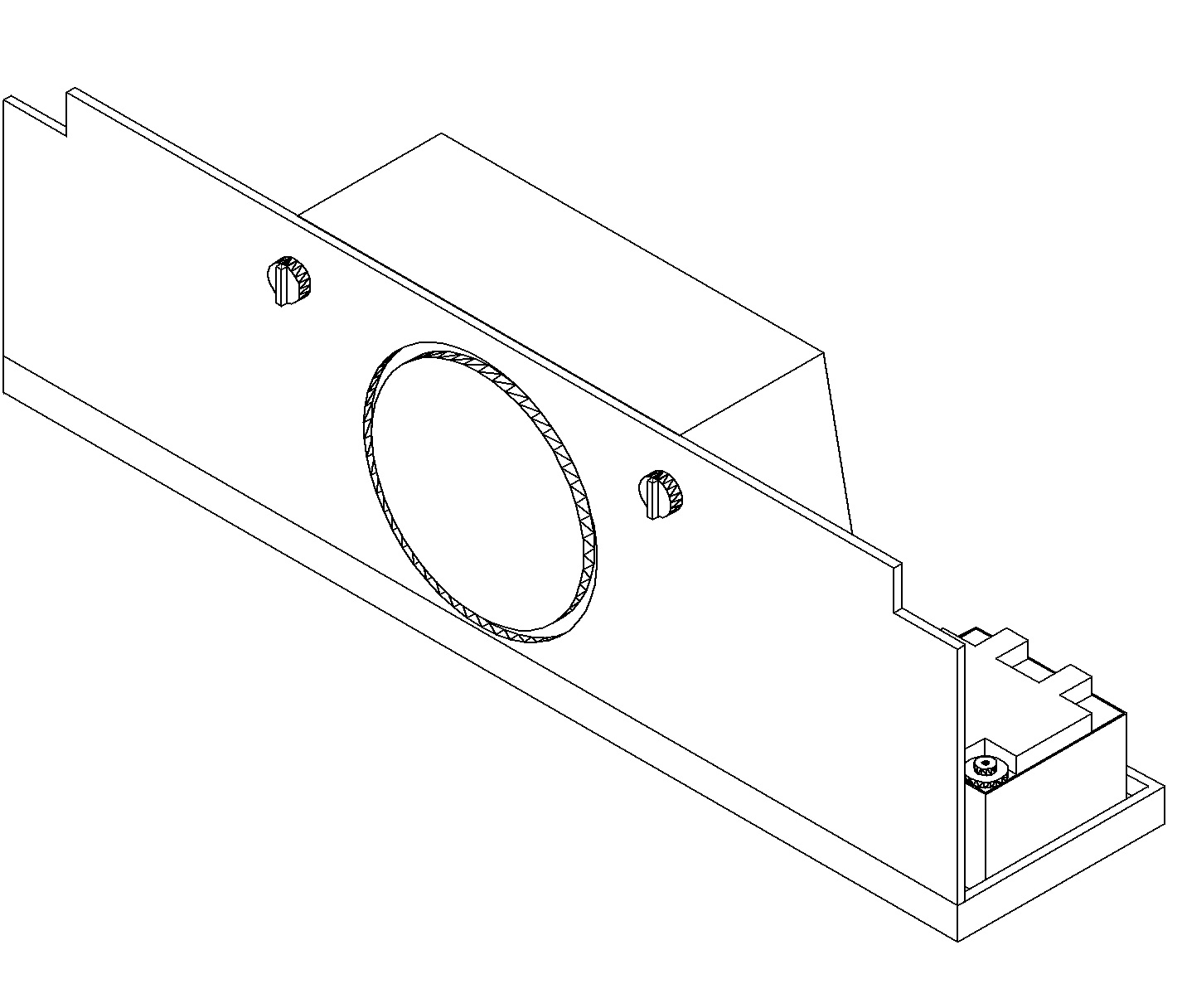

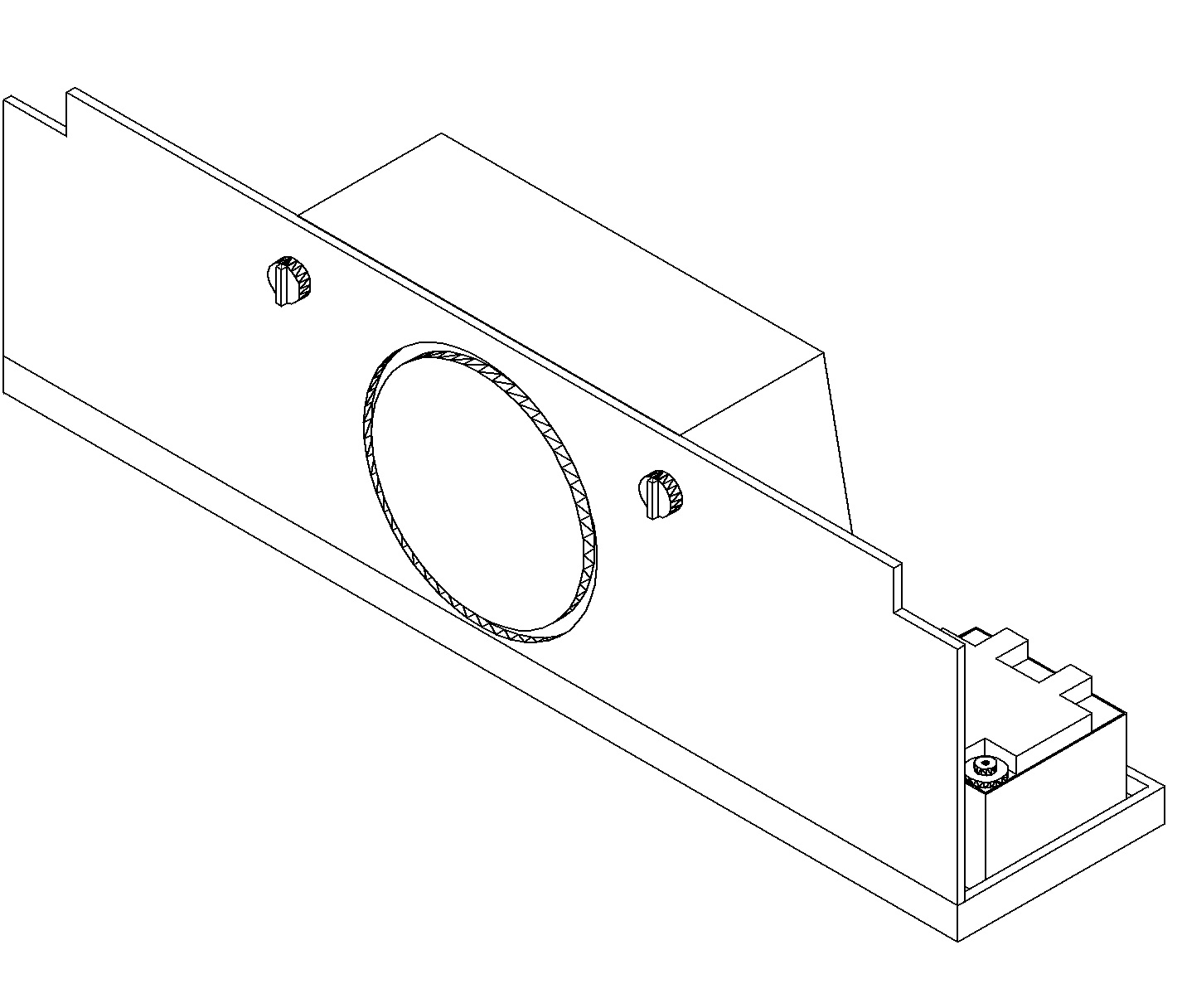

Until I get the power shelf back together and in the car . . . it looks just like this. Until I get this figured out, whether I use the "shelf" idea or just end up bolting everything to the car, I needed to get the wires ran, so I pulled it back out to do that. And, as you know, that heavy gauge stuff is a PITA . . . well if you have to turn corners anyway. There are plenty of turns getting up to the engine bay.

I think your best bet would be to cut out some windows on either side of the sub, maybe some square with nice routered edges, or circles with the same diameter as your sub, and put some mesh backing behind them, or some stretched grill cloth. You could even wrap the whole panel on the backside with the circular cutouts, and it would look like you had 3 subs flush mounted in there.

I think your best bet would be to cut out some windows on either side of the sub, maybe some square with nice routered edges, or circles with the same diameter as your sub, and put some mesh backing behind them, or some stretched grill cloth. You could even wrap the whole panel on the backside with the circular cutouts, and it would look like you had 3 subs flush mounted in there.

Well, since the solid cover ain't going to work, I think your idea is certainly worth a try. Easier to cut 2 more 11" holes in the cover I have than to make an entire new one out of perf board.

Buy 2 more of these , , ,

http://www.rockfordfosgate.com/products/details/t1sg-10

thanks

Buy 2 more of these , , ,

http://www.rockfordfosgate.com/products/details/t1sg-10

thanks

Last edited:

Why not cut slots across the face of the sub to act as a grille? 1/2" mdf with 1" slots might work.

The general rule of thumb is half the size of the cone to the nearest obstruction.

I've also fired the ports through the rear deck with decent results.

The general rule of thumb is half the size of the cone to the nearest obstruction.

I've also fired the ports through the rear deck with decent results.

Not sure I follow? 1" slots in the Sub or Cover?

Just thought a cover to neatly hide the batteries, amps, wiring, and sub might be good. So, per above, will have 3 10" holes across the cover instead of one to hopefully let more of that rear firing base back through the cover. If you are saying slots in the cover, you think a grid of 1" slots across the entire cover would work better than 2 more 10" holes?

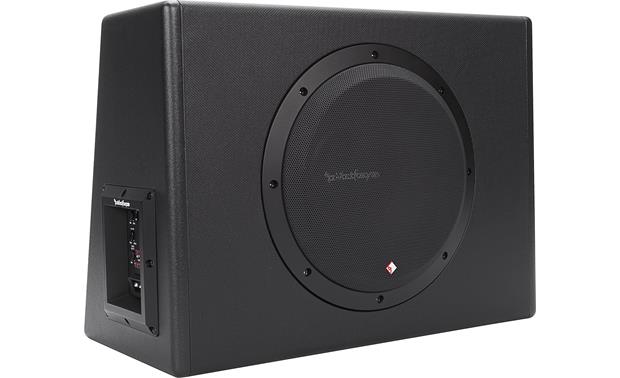

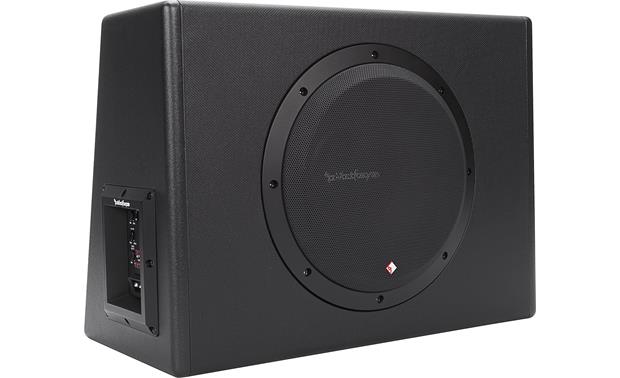

Here is the actual powered sub in behind the cover.

Just thought a cover to neatly hide the batteries, amps, wiring, and sub might be good. So, per above, will have 3 10" holes across the cover instead of one to hopefully let more of that rear firing base back through the cover. If you are saying slots in the cover, you think a grid of 1" slots across the entire cover would work better than 2 more 10" holes?

Here is the actual powered sub in behind the cover.

I'm glad you're picking up what I'm putting down... with your own twist. I think the grill idea is great. The problem with things like slots, or small peg board kind of perforations is that bass waves(20- 100hzish) have larger peak to peak waves and are way longer and less focused than something up let's say 10k to 20k hz. So even though they are invisible we still hear them. Imagine throwing a bucket of water at a perforated board, or something with small slits in it... not much is going to get through. Its going to hit the surface and reflect off. Do the same thing to mesh, or a speaker grill, and the resistance isn't nearly the same, and the sounwaves (water) can penetrate and end up on the other side.

I didn't say it was ideal. Personally, I would flush a steel waffle grill covered in matching acoustic cloth into the trim board. It's hard to tell someone's skill level from a screen......

Well, yeah, and with me, it is more about what my stupid health allows me to get done more than what I am capable of doing otherwise? Since I already have the ABS cover built, I will try the 2 more holes in it idea first. I even found [3] 10" speaker grills that are much cheaper and will all look the same that way plus, go figure, Rockford Fosgate does not sell "trim rings" just grills. And, if this works, I am toying with the idea of covering the flip cover with the same black carbon fiber sheet as I want to use on the CAI boxes up front. Should look good with the black carpeting below.

EDIT: A 24x48 sheet of .008 black matte or gloss would be enough to do the CAI boxes and this cover and would bend to wrap the corners on the CAIs. It's about $200 so it ain't cheap but nothing about this project is cheap . . . Just one supplier below, but there are probably cheaper ones out there.

https://www.rockwestcomposites.com/...n-fiber-plate/carbon-fiber-fabric-plate/49000

To do a cover with just a mesh center would certainly require something more substantial than 1/4" ABS anyway. At least 1/2, maybe 3/4 depending on the size of the mesh, and that wouldn't probably work quite as well as a flip cover, just a cover.

Anyway, thanks for the ideas.

EDIT: A 24x48 sheet of .008 black matte or gloss would be enough to do the CAI boxes and this cover and would bend to wrap the corners on the CAIs. It's about $200 so it ain't cheap but nothing about this project is cheap . . . Just one supplier below, but there are probably cheaper ones out there.

https://www.rockwestcomposites.com/...n-fiber-plate/carbon-fiber-fabric-plate/49000

To do a cover with just a mesh center would certainly require something more substantial than 1/4" ABS anyway. At least 1/2, maybe 3/4 depending on the size of the mesh, and that wouldn't probably work quite as well as a flip cover, just a cover.

Anyway, thanks for the ideas.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 115

- Replies

- 8

- Views

- 442

- Replies

- 60

- Views

- 2K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.