Carbon fiber is cool to work with. I used to use 3m contact adhesive and attach it to whatever flat panel I was using, with the holes already cut out and then use a high speed router with good bits or precision jigsaw with a quality fine tooth blade to cut out the CF after it is adhered to the trim panel. It reduces the chances of cracking the CF. Man cracking that sh*t sucks then you're recoating with resin, sanding, polishing.

Build Thread: '87 442 . . . Time to turn and stop

- Thread starter Canon_Mutant

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Carbon fiber is cool to work with. I used to use 3m contact adhesive and attach it to whatever flat panel I was using, with the holes already cut out and then use a high speed router with good bits or precision jigsaw with a quality fine tooth blade to cut out the CF after it is adhered to the trim panel. It reduces the chances of cracking the CF. Man cracking that sh*t sucks then you're recoating with resin, sanding, polishing.

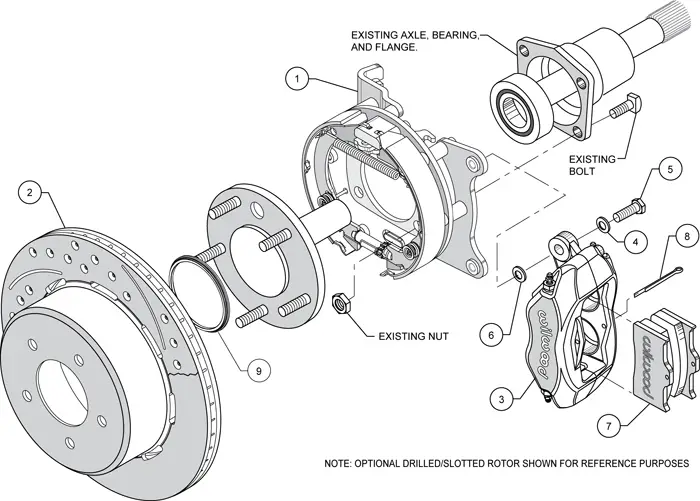

442 had a granted somewhat kludged but nonetheless 8.5 3.73 from the factory. Appears I have perhaps a S-10 SAE center with metric tubes and drums instead of all metric. Since I am converting everything else on the car to SAE as I go (almost everything under the hood already is) so having the SAE center is actually a good thing and the drum to disk out on the ends converts everything out on both ends plus going to 1/2-20 studs.

Per a couple pages back, I discovered the internals were junk just trying to put a decorative cover on the factory 3.73 (LOTS of metal came out with the fluid). So, Eaton Truetrac, Moser 30s, 1350 U-joint 30 spline yoke (I have been nervous about those tiny u-joints and yoke caps since I put the big block in it anyway), and moving to 3:42 gears while I am changing everything which should work better with the big block. Then the drum to disk conversion will all be easier while it's out on the bench too (or should).

Per a couple pages back, I discovered the internals were junk just trying to put a decorative cover on the factory 3.73 (LOTS of metal came out with the fluid). So, Eaton Truetrac, Moser 30s, 1350 U-joint 30 spline yoke (I have been nervous about those tiny u-joints and yoke caps since I put the big block in it anyway), and moving to 3:42 gears while I am changing everything which should work better with the big block. Then the drum to disk conversion will all be easier while it's out on the bench too (or should).

Nice bro. Don't know if you saw my recent rear end thread but I'm doing the same. Tru trac,moser 30 spline, but keepingthe original 3.73s (they look great). My 8.5 came out of an 85 442.

No I missed it but just gave your thread a peruse. I get around the c-clip problem with the drum to disk conversion. Rotors hold the axles in. Calipers hold the rotors on. Caliper mounts bolted solid to the updated axle flange geometries via the e-brake hub.

Last edited:

Thanks. I have an "unofficial" build thread also. Im sticking with the aluminum drums. I def need to do wheel cylinders/brakes when i have the rear doneNo I missed it but just gave your thread a peruse. I get around the c-clip problem with the drum to disk conversion. Rotors hold the axles in. Calipers hold the rotors on. Caliper mounts bolted solid to the updated axle flange geometries.

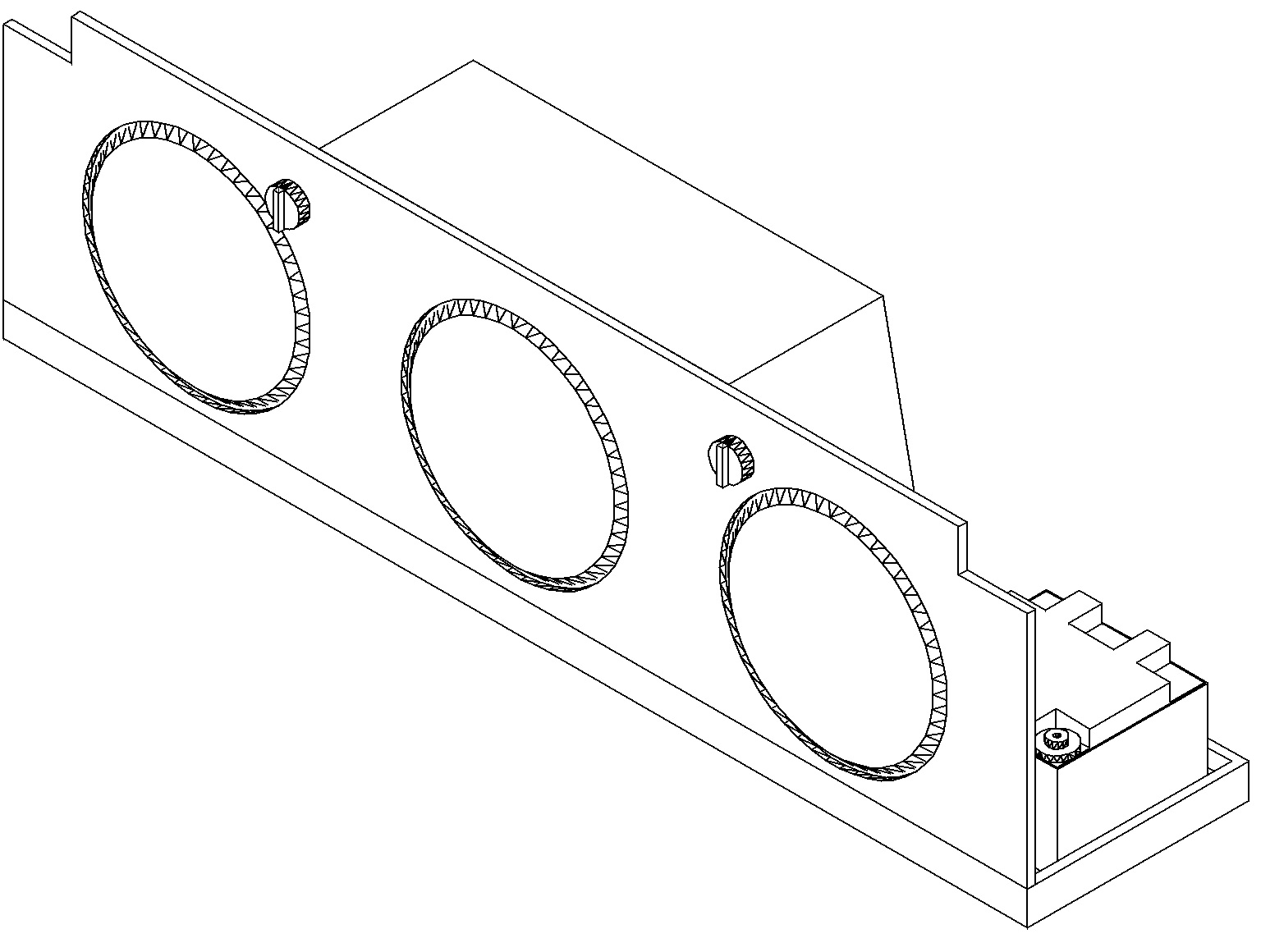

Basic idea?

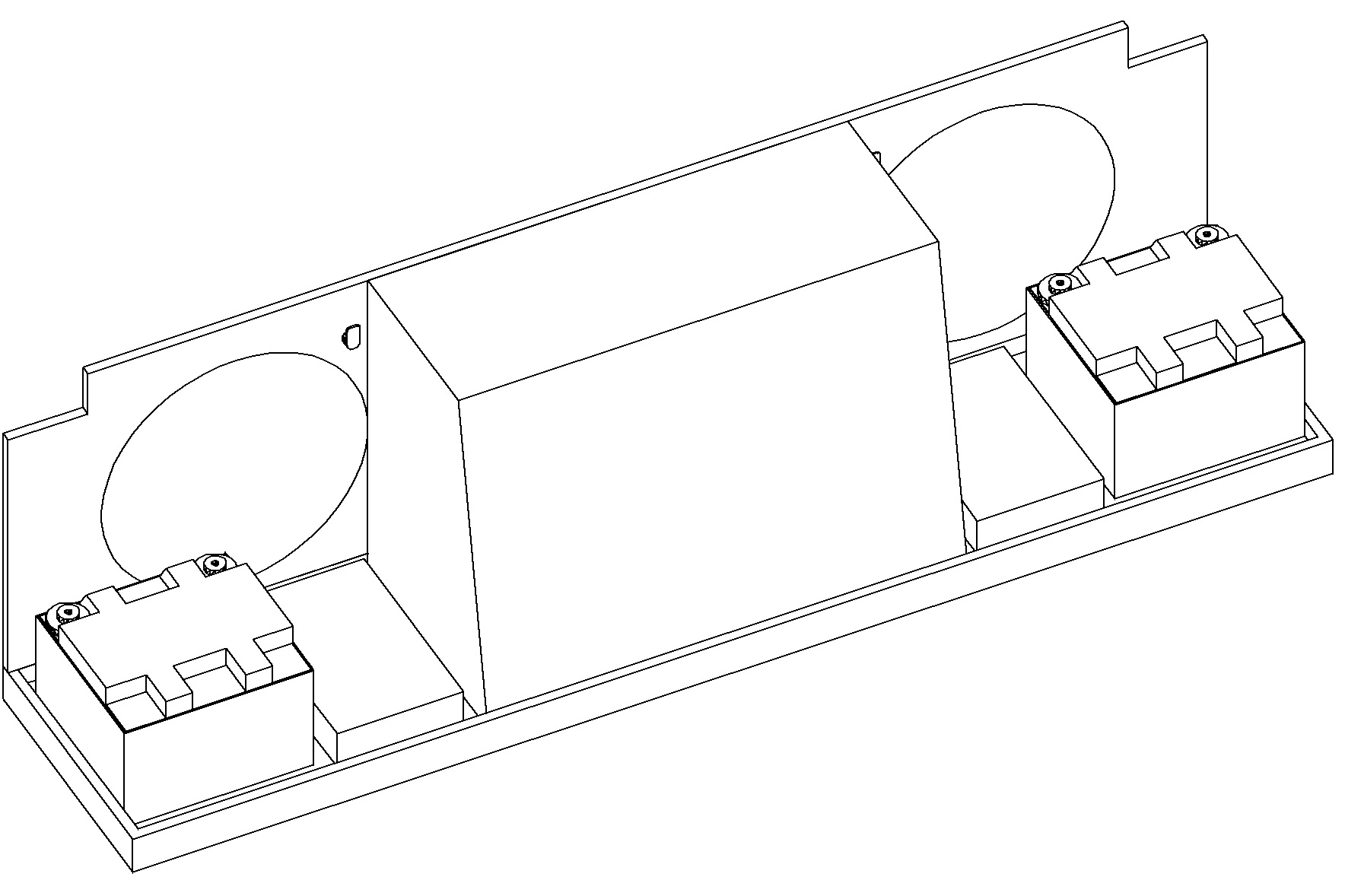

Reverse Angle . . .

Here we go . . . [I'm actually going with something, um, a little more subtle]

Last edited:

Interesting another bonus of converting to disk brakes. That is another thing I like about my 70S Type O rear, bolt in axles. And the C type used in 71-72 Cutlass still used them. The C clip eliminators supposedly, always leak. I plan on beating my 8.5" Type O with slicks, no worries of an axle exiting.No I missed it but just gave your thread a peruse. I get around the c-clip problem with the drum to disk conversion. Rotors hold the axles in. Calipers hold the rotors on. Caliper mounts bolted solid to the updated axle flange geometries via the e-brake hub.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 115

- Replies

- 8

- Views

- 442

- Replies

- 60

- Views

- 2K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.