It’s easy enough to try. A small nozzle pre- turbo works. I ran one part of last summer an it definitely drop the intake temps. But it can make a mess in an IC when pedaling. I believe your non-intercooled deal shouldn’t be messy at all.I'd be curious on the back to back. It clearly wasn't impeding peak power production.

MONTE CARLO "COPO" Monte Carlo SS - Turbosaurus Build (Swinging Dick Racing's c*ck got bent... she bounced a little too high & hard, & came down awkwardly)

- Thread starter motorheadmike

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

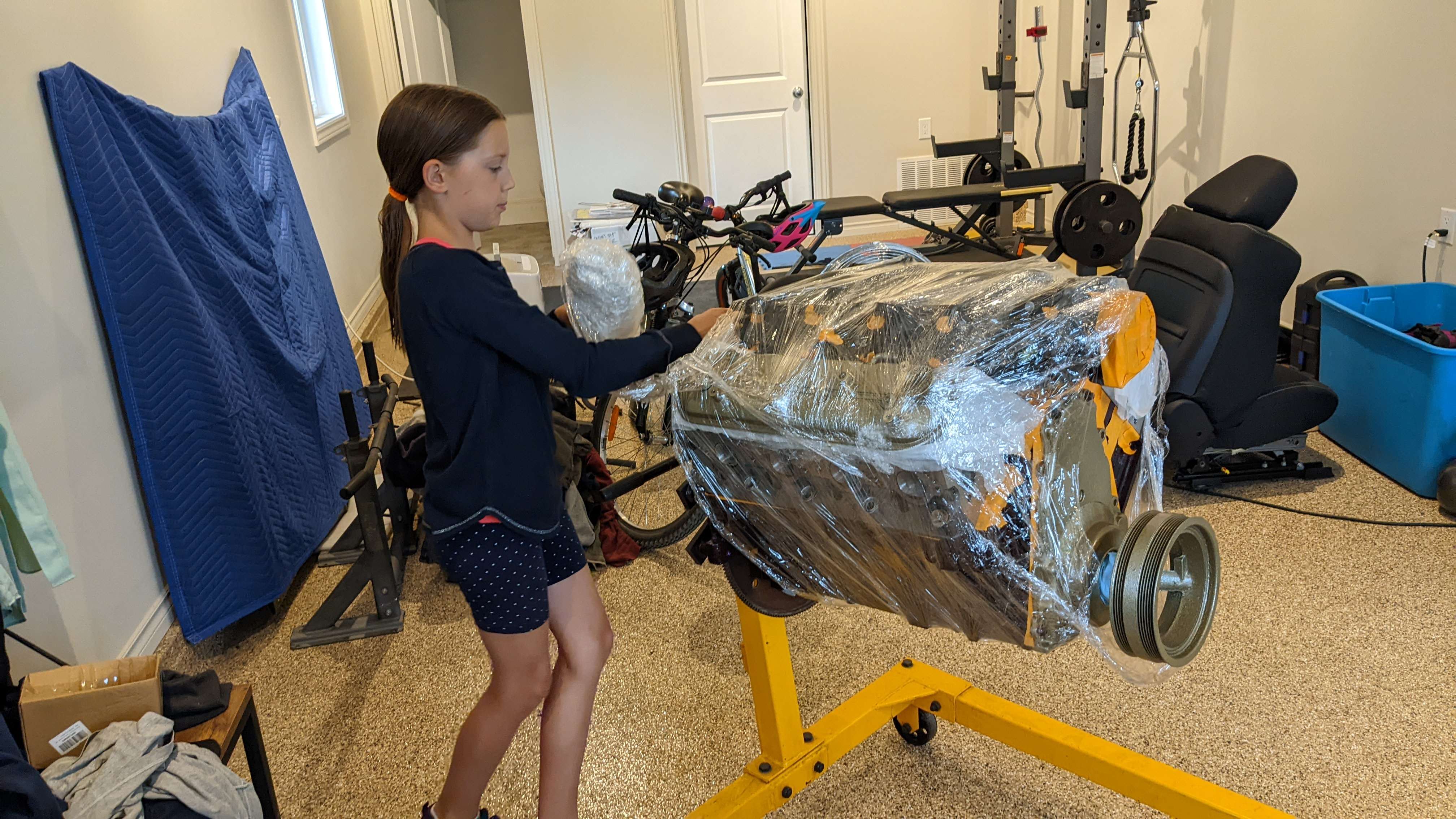

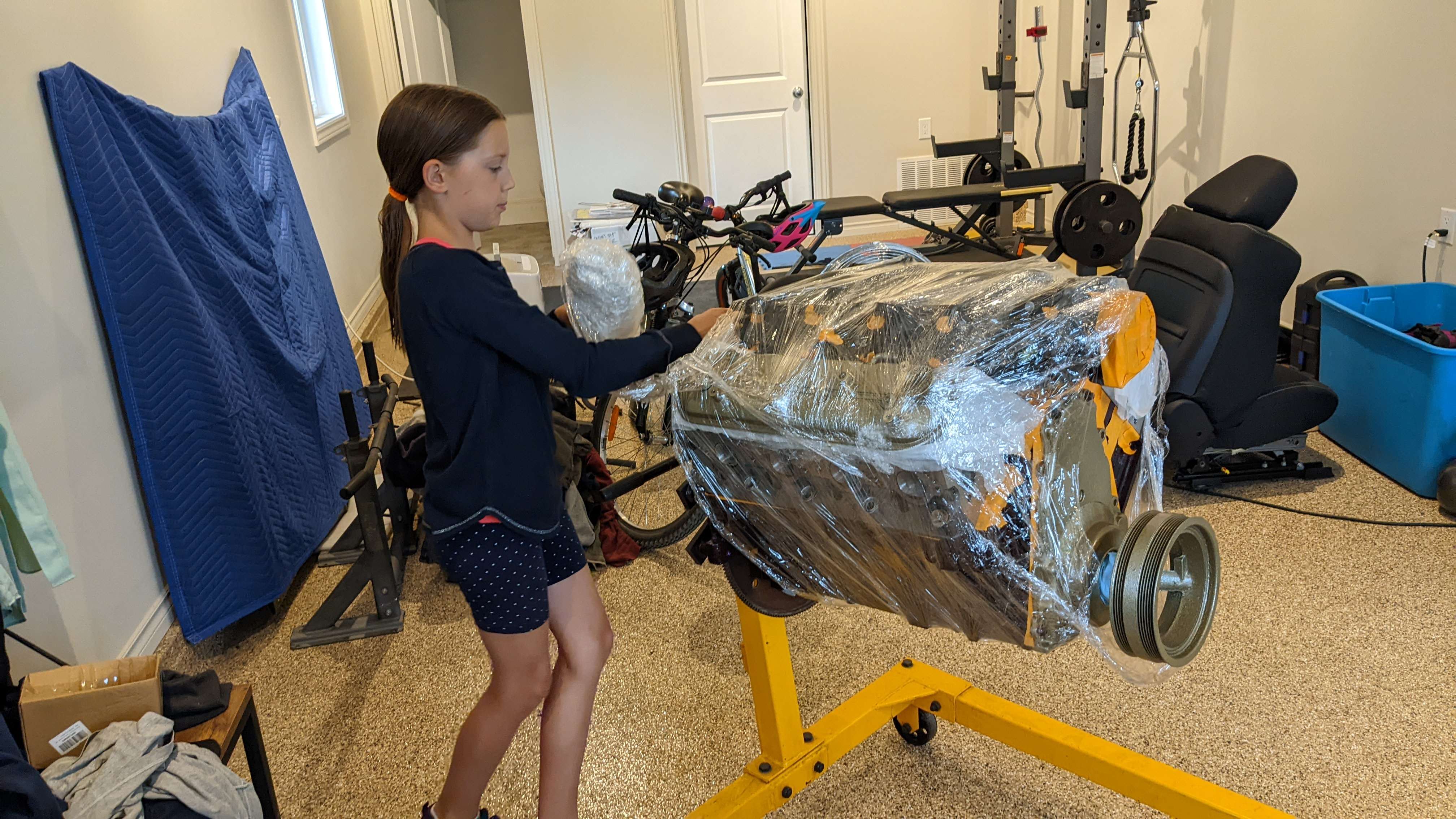

So we finally dipped into the 4.Grape. First step toward Full Send: Break Seal.

Next step, pull off the crap standing in the way of the cylinder heads... and then the heads themselves.

Fortunately when I last saw these heads, about 2.5 years ago, I was at the cartridge roll stage. So out came the 80 grits and I knocked out the last of the blending and carbon removal in the ports (much faster than using solvents). For a quick refresher here are the figures for the bowl work. The main focus on the intake side was all in the bowls and blending them (biggest, quickest return), the exhaust got a full port job because that is where this engine needs it most. Also, they are 241s. Not the best, not the worst for a boosted engine.

You can see how crusty the exhaust valves were, look pretty decent after a few moments of wiring wheeling.

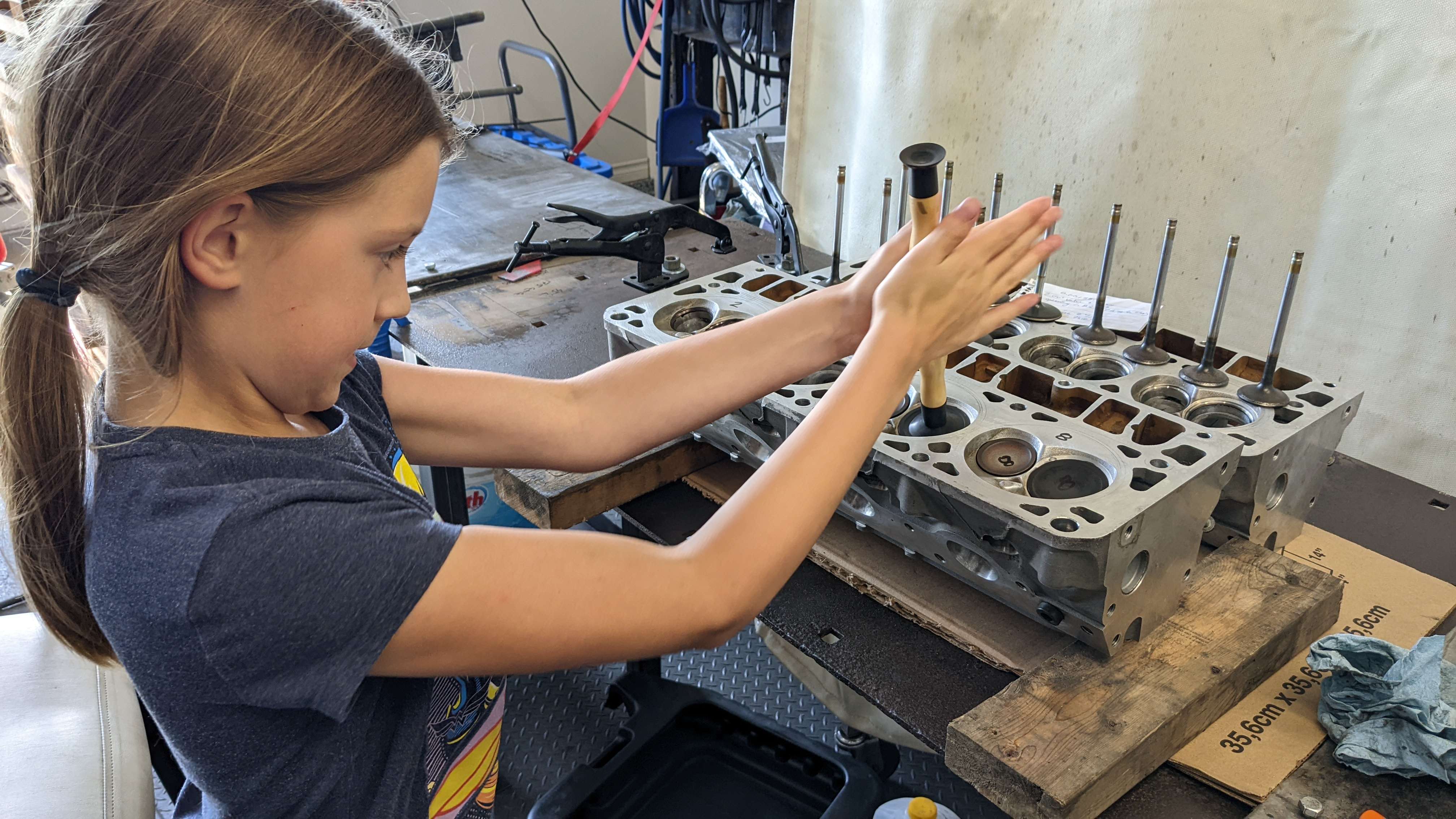

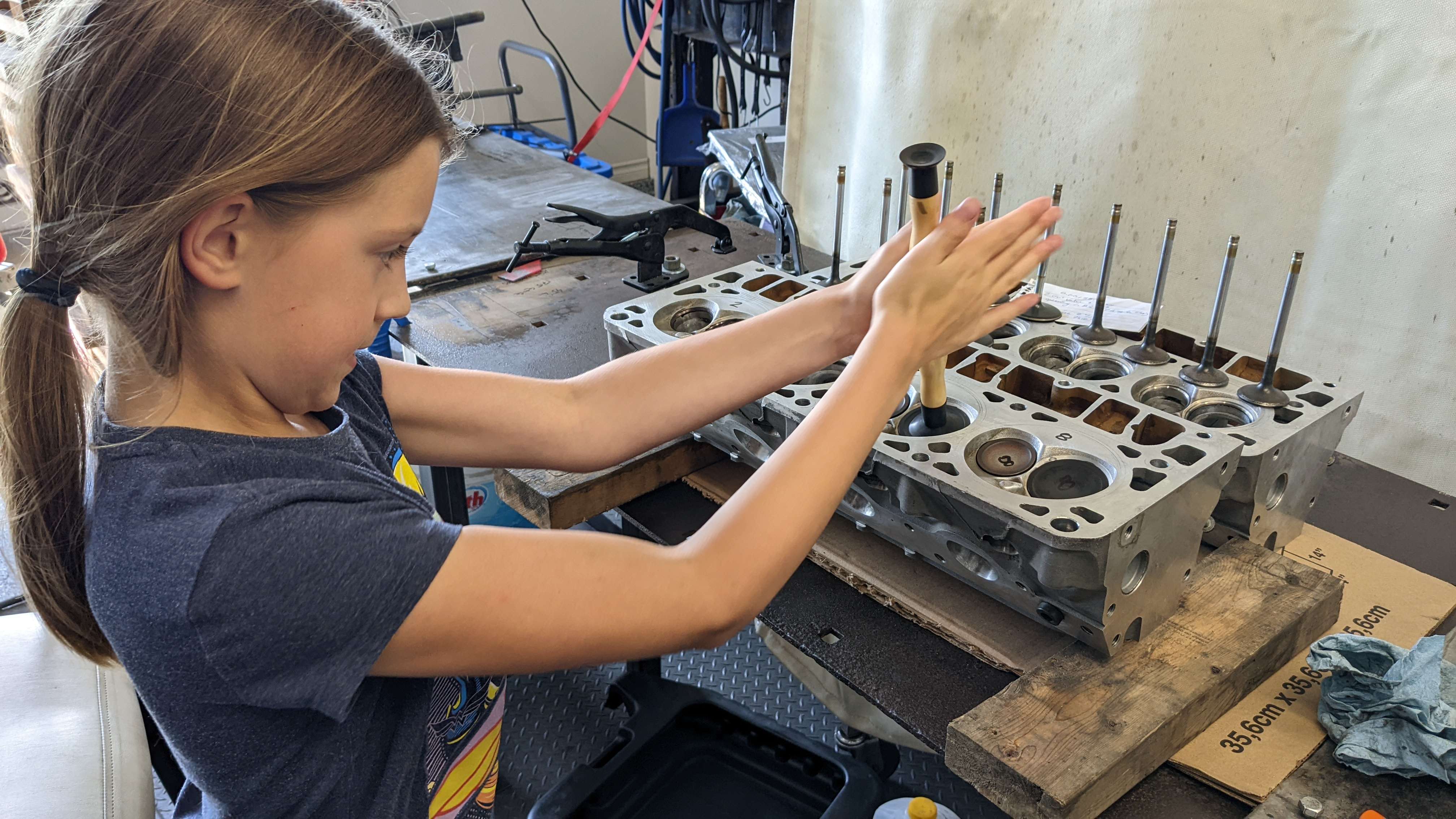

Then we lapped the valves.

In my experience this is as good as it gets with lapping compound on high-mile exhaust valves, Both the seats and the valves are pitted upon disassembly, after lapping the valves they usually have some residual minor pitting. This is how they looked in my LS2, and the 706s on the now defunct 5.3. The intake valves clean up very well... and honestly the quality of the factory valves is impressive. These heads have 200K+ kilometers on them.

Then we popped in the valves and Summit Racing dual springs, Nice kit, just pay attention to any manufacturing grime during assembly.

A few ugha dughas...

And in with keepers. A little petroleum jelly to get them to cooperate.

And... tada... a bunch of really expensive parts stuffed into really cheap parts to make some functional parts.

I hit a bit of a wall when digging through my parts stash... I am short a pair of head gaskets. FML. Now I need to source a pair... of head gaskets before we can bolt these on.

Next step, pull off the crap standing in the way of the cylinder heads... and then the heads themselves.

Fortunately when I last saw these heads, about 2.5 years ago, I was at the cartridge roll stage. So out came the 80 grits and I knocked out the last of the blending and carbon removal in the ports (much faster than using solvents). For a quick refresher here are the figures for the bowl work. The main focus on the intake side was all in the bowls and blending them (biggest, quickest return), the exhaust got a full port job because that is where this engine needs it most. Also, they are 241s. Not the best, not the worst for a boosted engine.

You can see how crusty the exhaust valves were, look pretty decent after a few moments of wiring wheeling.

Then we lapped the valves.

In my experience this is as good as it gets with lapping compound on high-mile exhaust valves, Both the seats and the valves are pitted upon disassembly, after lapping the valves they usually have some residual minor pitting. This is how they looked in my LS2, and the 706s on the now defunct 5.3. The intake valves clean up very well... and honestly the quality of the factory valves is impressive. These heads have 200K+ kilometers on them.

Then we popped in the valves and Summit Racing dual springs, Nice kit, just pay attention to any manufacturing grime during assembly.

A few ugha dughas...

And in with keepers. A little petroleum jelly to get them to cooperate.

And... tada... a bunch of really expensive parts stuffed into really cheap parts to make some functional parts.

I hit a bit of a wall when digging through my parts stash... I am short a pair of head gaskets. FML. Now I need to source a pair... of head gaskets before we can bolt these on.

Last edited:

Shoulda got her to unshroud the cylinder wall side of the intake valve while she was in there. Otherwise it looks like she did good work.

Guess there's not child labour laws up north. Making that poor girl work during her summer break. Bet you didn't even offer half of shop rate to her.

Shoulda got her to unshroud the cylinder wall side of the intake valve while she was in there. Otherwise it looks like she did good work.

It was on the table... but, it was a trade off of flow vs. compression. I'd rather have the compression. For reference, the stock 706 heads have 61cc chambers and the 241s have 66cc chambers. This drops the static compression ratio from ~9.5:1 to ~9.0:1 - and I don't want an off-boost dog.

I thought about decking the heads and doing other tricks, even going balls out with a maximum effort port job. But, there are other things I need to do with my life and resources. These should be plenty as-is.

You are using 241 heads? Interesting move, especially on a 4.8.It was on the table... but, it was a trade off of flow vs. compression. I'd rather have the compression. For reference, the stock 706 heads have 61cc chambers and the 241s have 66cc chambers. This drops the static compression ratio from ~9.5:1 to ~9.0:1 - and I don't want an off-boost dog.

I thought about decking the heads and doing other tricks, even going balls out with a maximum effort port job. But, there are other things I need to do with my life and resources. These should be plenty as-is.

We're the 706 heads the Castec heads or do you have some sort of magic Mike thing up your sleeve?

I don't think investing money in stock heads is really worth it, marginal gains for the $$$ spent compared to aftermarket castings. I think you made the right decision there.

A balls-out port job on 241s can net 300+cfm. I am just hoping for something in the 260+ range.You are using 241 heads? Interesting move, especially on a 4.8.

We're the 706 heads the Castec heads or do you have some sort of magic Mike thing up your sleeve?

I don't think investing money in stock heads is really worth it, marginal gains for the $$$ spent compared to aftermarket castings. I think you made the right decision there.

The 706s are Castech. They weren't cracked before installation... and I am hoping they will be salvageable once I get into the 5.3. I'd like to keep them on hand. A little bit of my time, mostly to see what I can do, makes farting around with stock castings viable. But, the cost of any machine work is a non-starter.

Especially considering that you can get a whole running engine with accessories and ECM for $500-700, and I just dropped $100 on a pair of head gaskets. FML.

I made sure to get the tight bore "thin" .048" 4.8L gaskets and not the big bore or thicker .056" LS1 or LS9-type units.

This video really hits too close to home.

I need to find a lathe.

I need to find a lathe.

My god, the pics of your daughter helping out are priceless. You should be proud of her (I'm sure you are.)

Regarding your headgasket, you'd be better of with the additional layers of the LS9 gasket and not worry about the increased bore of it. The little bit of compression lost is miniscule and not note worthy. And the concern of too large of a bore is an NA issue, not boosted.

Regarding the port job, your setup needs the most possible even flow too all cylinders because of the meth and what you need it to do. You need every cylinder to receive an equal amount of your Mike's Boost Juice, otherwise you're running a cylinder lean and hot. I'd strongly urge you to leave the General's work alone only for distribution purposes only.

My two cents. Take them for what they're worth.

p.s put a 125-150ml meth nozzle pre-turbo to help.

Regarding your headgasket, you'd be better of with the additional layers of the LS9 gasket and not worry about the increased bore of it. The little bit of compression lost is miniscule and not note worthy. And the concern of too large of a bore is an NA issue, not boosted.

Regarding the port job, your setup needs the most possible even flow too all cylinders because of the meth and what you need it to do. You need every cylinder to receive an equal amount of your Mike's Boost Juice, otherwise you're running a cylinder lean and hot. I'd strongly urge you to leave the General's work alone only for distribution purposes only.

My two cents. Take them for what they're worth.

p.s put a 125-150ml meth nozzle pre-turbo to help.

Last edited:

I used to have a lathe. Pre WW2 and a really nice piece. Makes me sad that it's long gone. Speaking of inflation, I bought my rims not to long ago for 425 each. Now I see they are a tic under 600 now. Jeez

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 96

- Replies

- 0

- Views

- 213

- Replies

- 16

- Views

- 421

- Replies

- 0

- Views

- 110

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.