Damn! Summit got this here fast through FedEx.

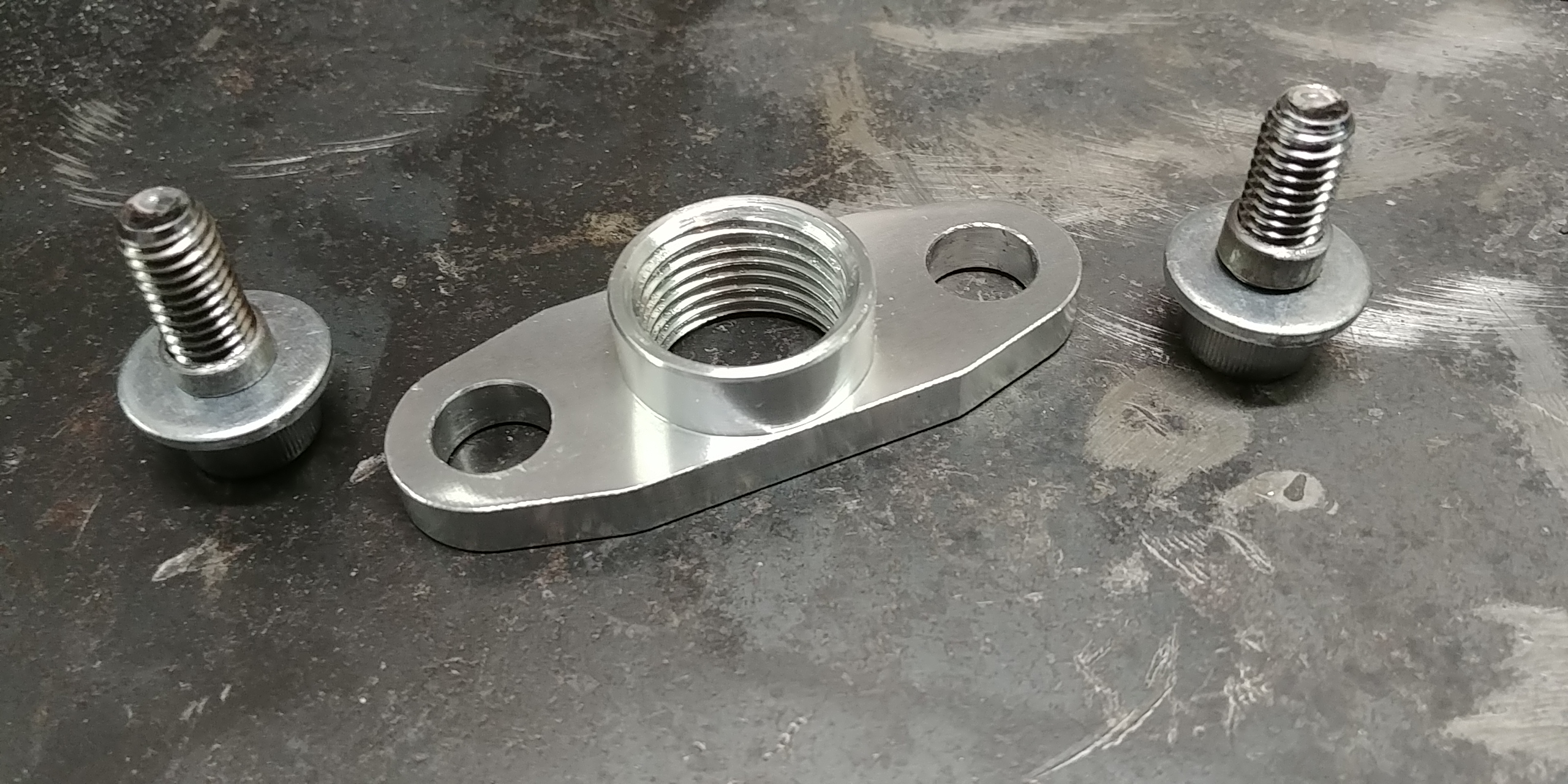

Everything is great except the rad cap... which seems unusually small. Quarter added for scale.

What is this? A radiator cap for ants?!

Everything is great except the rad cap... which seems unusually small. Quarter added for scale.

What is this? A radiator cap for ants?!