One of the side bar projects I have toying with is a low-buck methanol injection system. The $500+ systema are nice - but they are engineered to make somebody else money... and that goes against the general nature of this build.

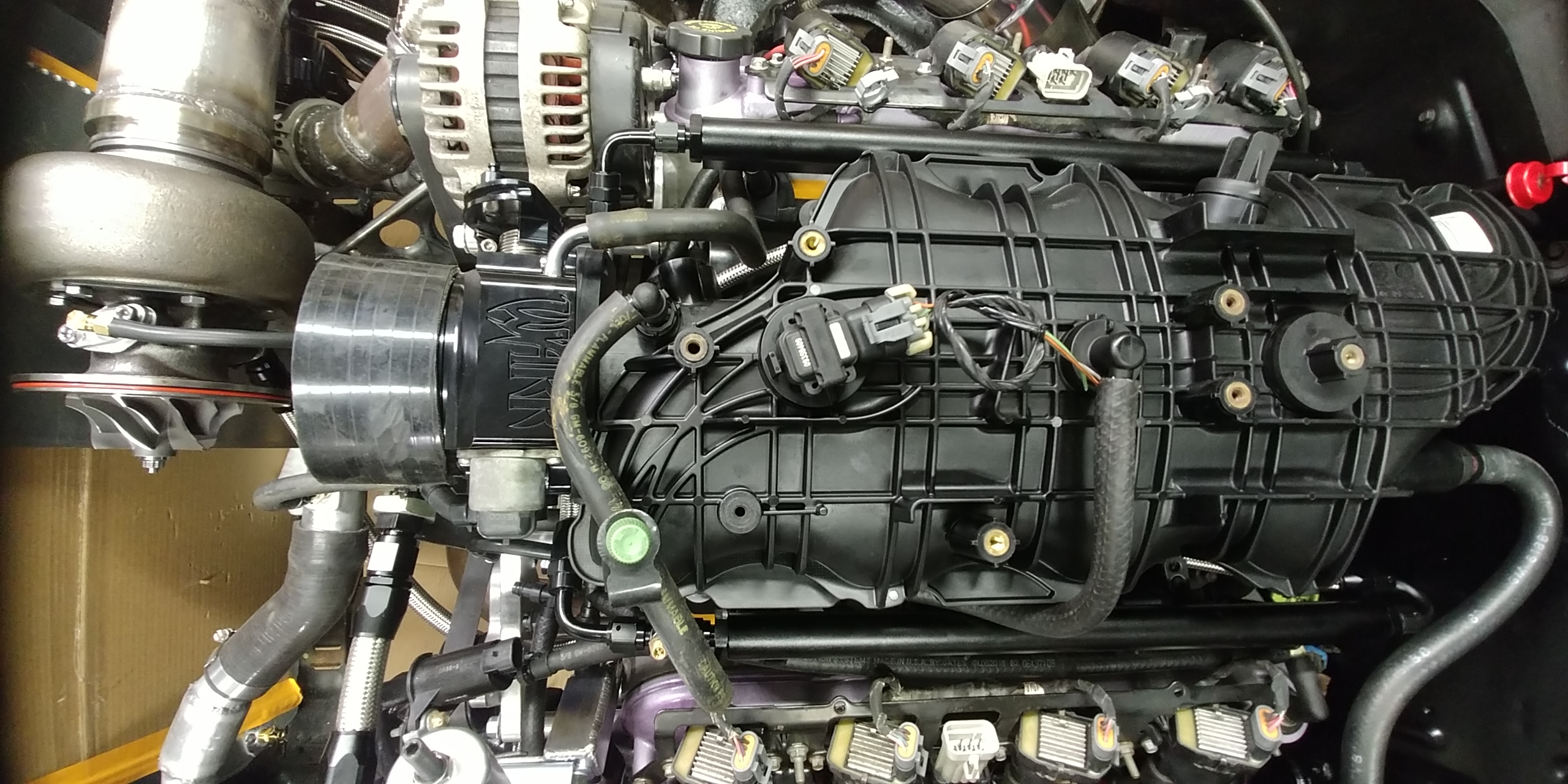

So I've tossed around a few known options: pre-turbo with a washer pump(s), or a supplemental fuel system using a dedicated alcohol-safe pump that injects post-turbo. I have both of these on hand.

In my intrawebz travels today I learned about waste oil nozzles (which are about $20 on Amazon or ebay) - the problem is they are not tunable. Then I found this video:

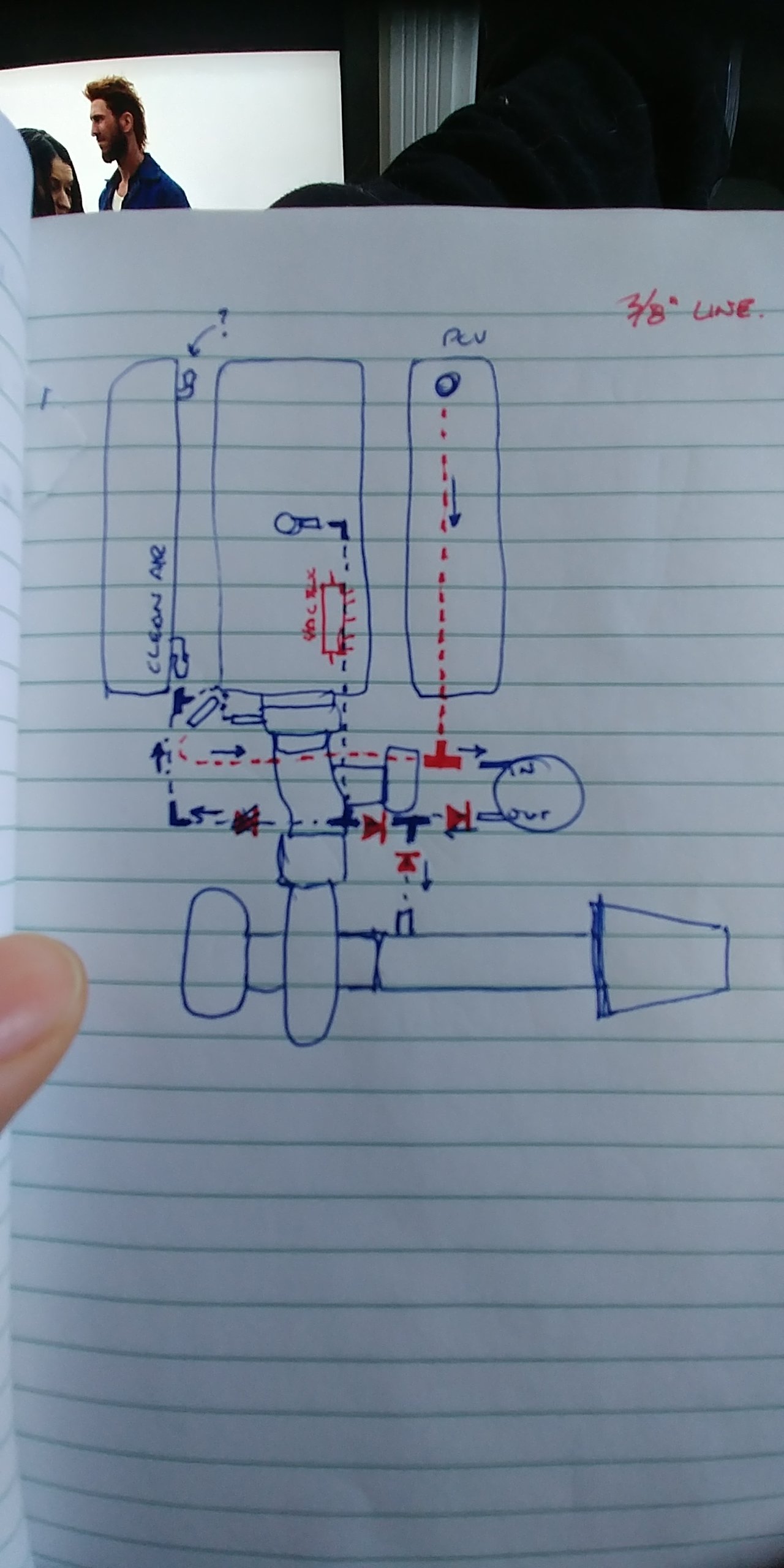

Seems easy enough, right? However, it would be a self-tuning system that would adjust its flow rate as the pressure rises. Except one problem - she ain't no diesel running 100psi of boost - and therefore the atomization would suffer at 14.7psi/2 bar. So how could I compensate? Pressurize the fuel source (fuel pump on a Hobbs switch) and apply boost pressure to the air side to compensate for pressure at the nozzle tip (same as a rising rate fuel pressure regulator)?

Not sure yet - it just seems like a fun concept to fart around with.

So I've tossed around a few known options: pre-turbo with a washer pump(s), or a supplemental fuel system using a dedicated alcohol-safe pump that injects post-turbo. I have both of these on hand.

In my intrawebz travels today I learned about waste oil nozzles (which are about $20 on Amazon or ebay) - the problem is they are not tunable. Then I found this video:

Seems easy enough, right? However, it would be a self-tuning system that would adjust its flow rate as the pressure rises. Except one problem - she ain't no diesel running 100psi of boost - and therefore the atomization would suffer at 14.7psi/2 bar. So how could I compensate? Pressurize the fuel source (fuel pump on a Hobbs switch) and apply boost pressure to the air side to compensate for pressure at the nozzle tip (same as a rising rate fuel pressure regulator)?

Not sure yet - it just seems like a fun concept to fart around with.