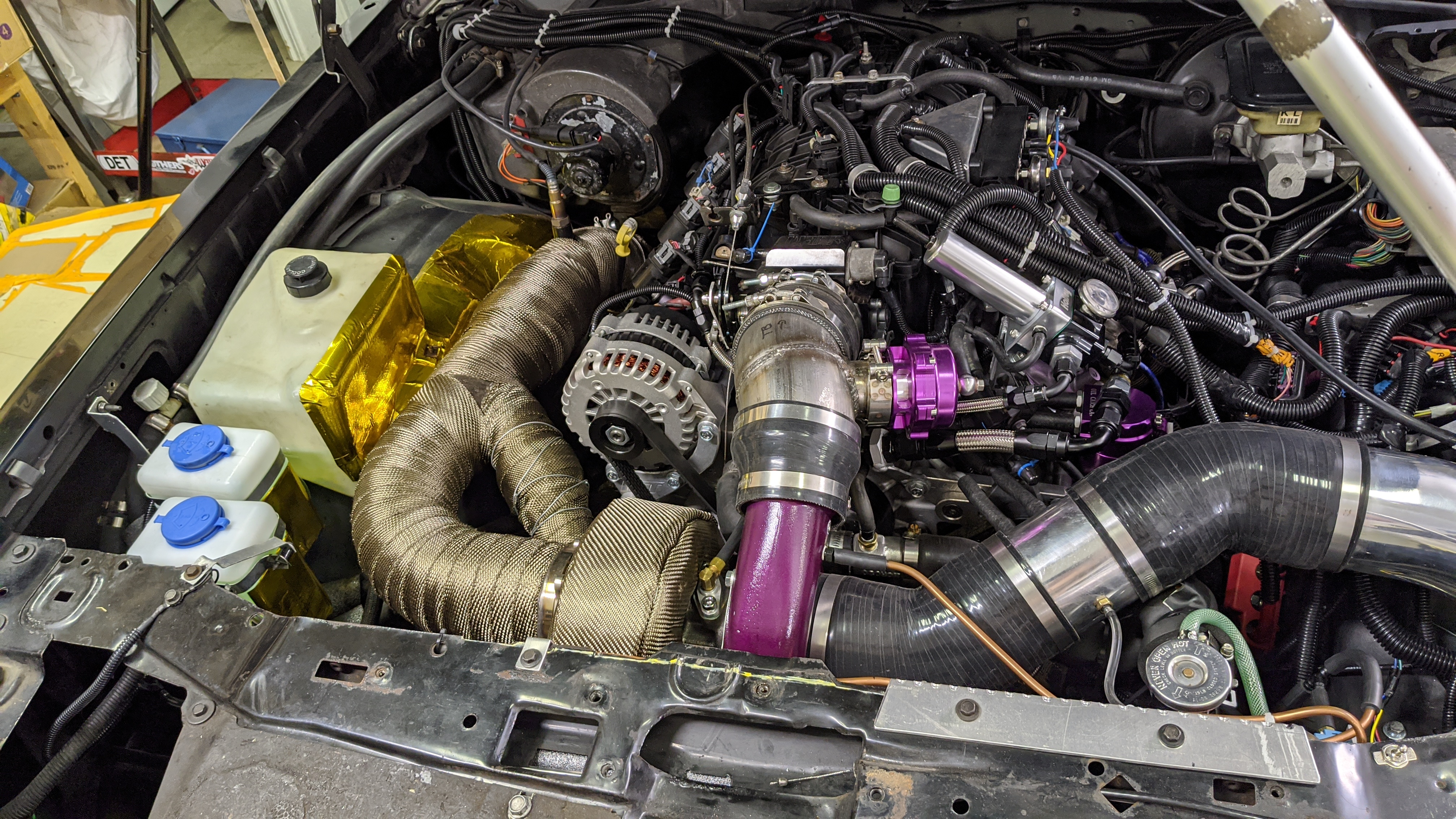

Finished up the primary wiring for the meth injection. Test switch and LEDs pending. Foil wrapped the reservoirs for sex appeal.

And then decided I am going to make more changes. Needs more nozzles.

With the heat/humidity wave we are in the middle of I might be able to see how effective it is. Because chemical intercooling.

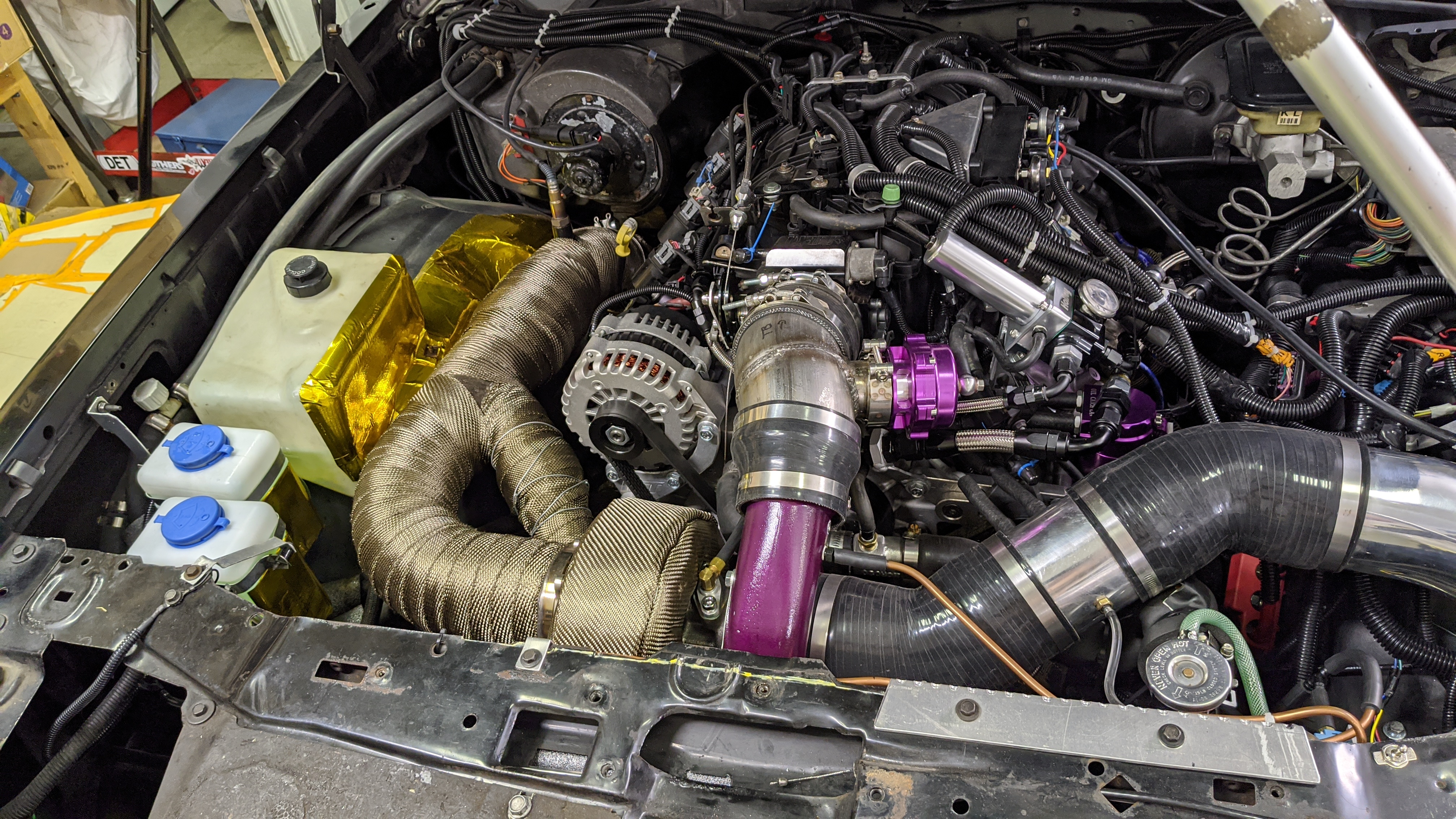

And then decided I am going to make more changes. Needs more nozzles.

With the heat/humidity wave we are in the middle of I might be able to see how effective it is. Because chemical intercooling.