Nice car. Reminds me of my dads 62. Patience is the biggest asset when doing a resto. Wait till I post some of the pictures of my 70 Plymouth resto if you want to see some insane body work. BTW, I worked for a Ford dealer in the parts dept for 10 years. I have the 1960 - 1964 and 1965 - 1972 Parts and Illustrations books....genuine Ford issue. If you ever need to know the Ford part number for something you're looking for just ask. I'd be happy to look it up for you.

Dad's 62 Ford Galaxie

- Thread starter Texas82GP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think it's awesome that you got another part into production for an old car like the Galaxie. Quality reproduction parts can be hard or impossible to find sometimes. Does the approach you used work with other manufacturers? Maybe if some of us G body guys started talking to some of these parts manufacturers we could get some more parts reproduced.

Every time I see that Galaxie it looks better than the last. You guys are doing great work.

Thanks Opie. I've encouraged some on here to pursue getting parts they need reproduced by contacting some of the manufacturers but to a mixed reception. Part of the hard part is you have to have something decent to send in for the prototyping to be done. Thanks for the kind words on the project. Sean and I are excited for Dad.

Nice car. Reminds me of my dads 62. Patience is the biggest asset when doing a resto. Wait till I post some of the pictures of my 70 Plymouth resto if you want to see some insane body work. BTW, I worked for a Ford dealer in the parts dept for 10 years. I have the 1960 - 1964 and 1965 - 1972 Parts and Illustrations books....genuine Ford issue. If you ever need to know the Ford part number for something you're looking for just ask. I'd be happy to look it up for you.

Thanks for the offer for help. I will keep it in mind. Dad definitely has a parts manual that covers 62 but I'm not sure what else. I doubt it covers 60-64 so I'll keep in mind that you have the information. I've been enjoying your thread on the Plymouth. Wow, that's a lot of work. Thanks for saving that car. I agree, patience is key and is the hard part on building these cars.

Progress on the Galaxie has been ongoing. Since the last update, Dad did a lot of work fitting the headlight buckets, which he restored while they were off the car. He also fit the grill and the headlight doors. He repainted the splash pan as well. Most or all of this will come off the car when it gets painted but all of this needed fitting. Dad did a lot of work massaging the grill to a much straighter and better fitting condition. Here is a pic my brother snapped Saturday morning...

We are loving the fact that the entire car is in black epoxy primer and that all of the major eye-sores on the body are gone. Here is a neat pic. This is from under the front wheel well on the passenger side, looking forward. This is a splash shield that fits behind the headlight bucket. Dad found a pair of these NOS. He never had them before. Just another nice rare part on the car....

When Sean went over to Dad's Saturday, Dad had got the car off the stands as pictured above. He decided he didn't like how the passenger door was fitting. He felt it was a little low with respect to the top of the fender and the top of the quarter panel. This door is not off of this car. The door off of this car had a crease all the way down it so it was replaced with this door many years ago. Unfortunately, the door was all the way up on the hinges and wouldn't go higher. Dad and Sean pulled the door off the car, elongated the holes to get a little more adjustment, re-hung it on the car, and then touched up the paint on the bolts. It went very well. Here are some pics of the process....

Here's the door coming off the car on the 'dolly'. This is an attachment you can add to just about any floor jack. It is made by Steck and we really like it. It is very affordable. Is it as good as a dedicated door jack? Probably not but for half the price and taking up half the space, it's pretty good....

I believe this pic shows the holes after being opened up some to provide more adjustment....

Here it is back on the car and they are touching up the paint on the bolts....

Next, they moved on to installing new felts or 'dew sweeps' on the outside side of the window opening. Dad had replaced them previously (years ago) but wasn't happy with how the first shot at it turned out. With Sean's help, they got new sweeps on both the passenger door and quarter panel installed. It went well for them...

The sweeps are held on with clips and screws. The hard part is drilling the new sweep for the screws as they don't come drilled. It's nice that it turned out well for them. The new weatherstrip now needs to go on the passenger door but the wing window needs to go in first. We're waiting on a special tool for the rivets that hold the wing window together and hold the seals in it. We got the special rivets last week but it's unclear whether they are correct or not. Hopefully we'll have everything we need to restore the passenger wing window by the weekend.

Meanwhile, I've been working on the second Toploader transmission. Sean and I got the main case cleaned up last week. It was a bit of a project with the wire wheel, thread chasers, a razor scraper, wire brushes, mineral spirits, a few cans of carb spray and lots of compressed air but it came out pretty clean....

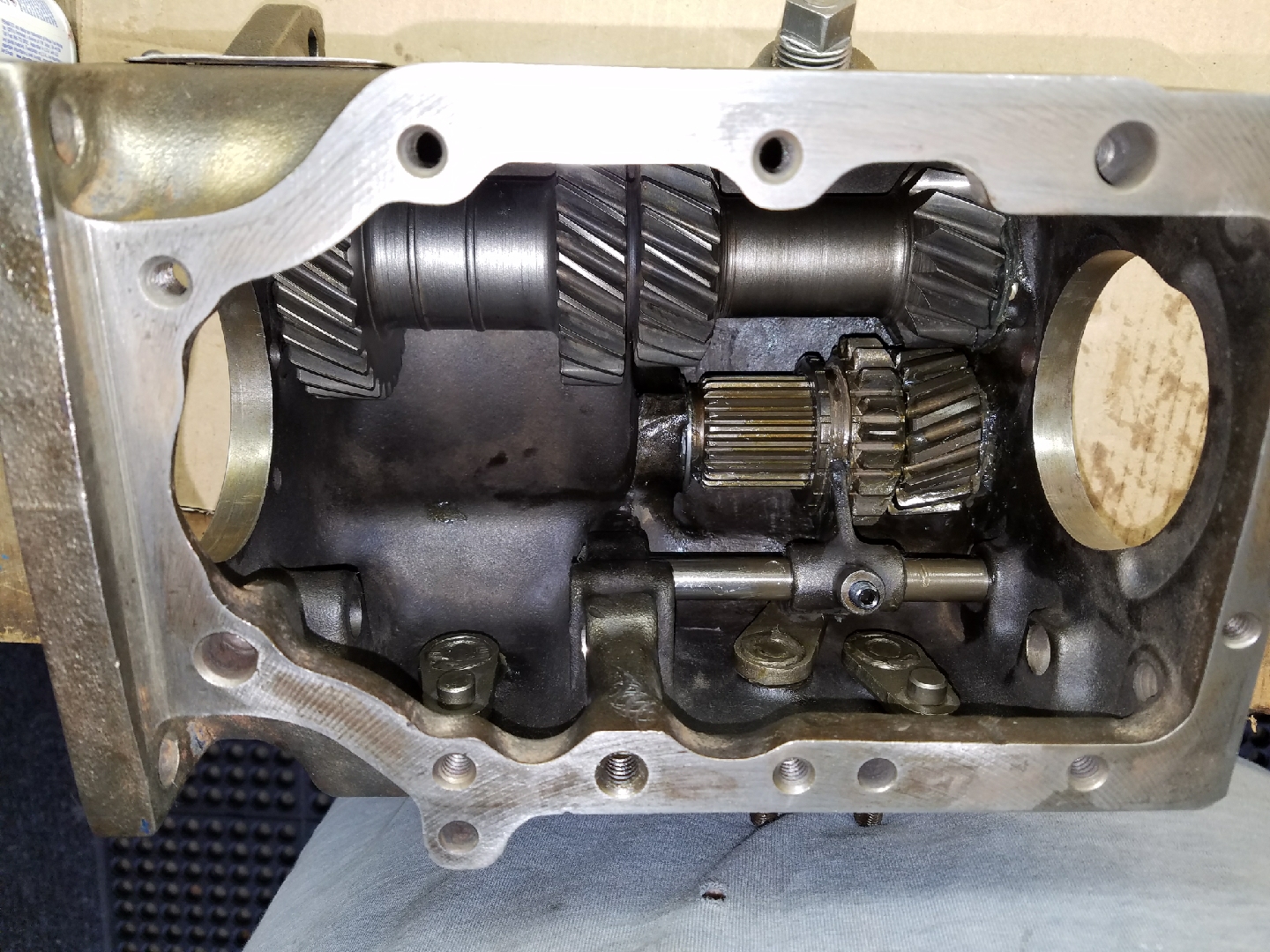

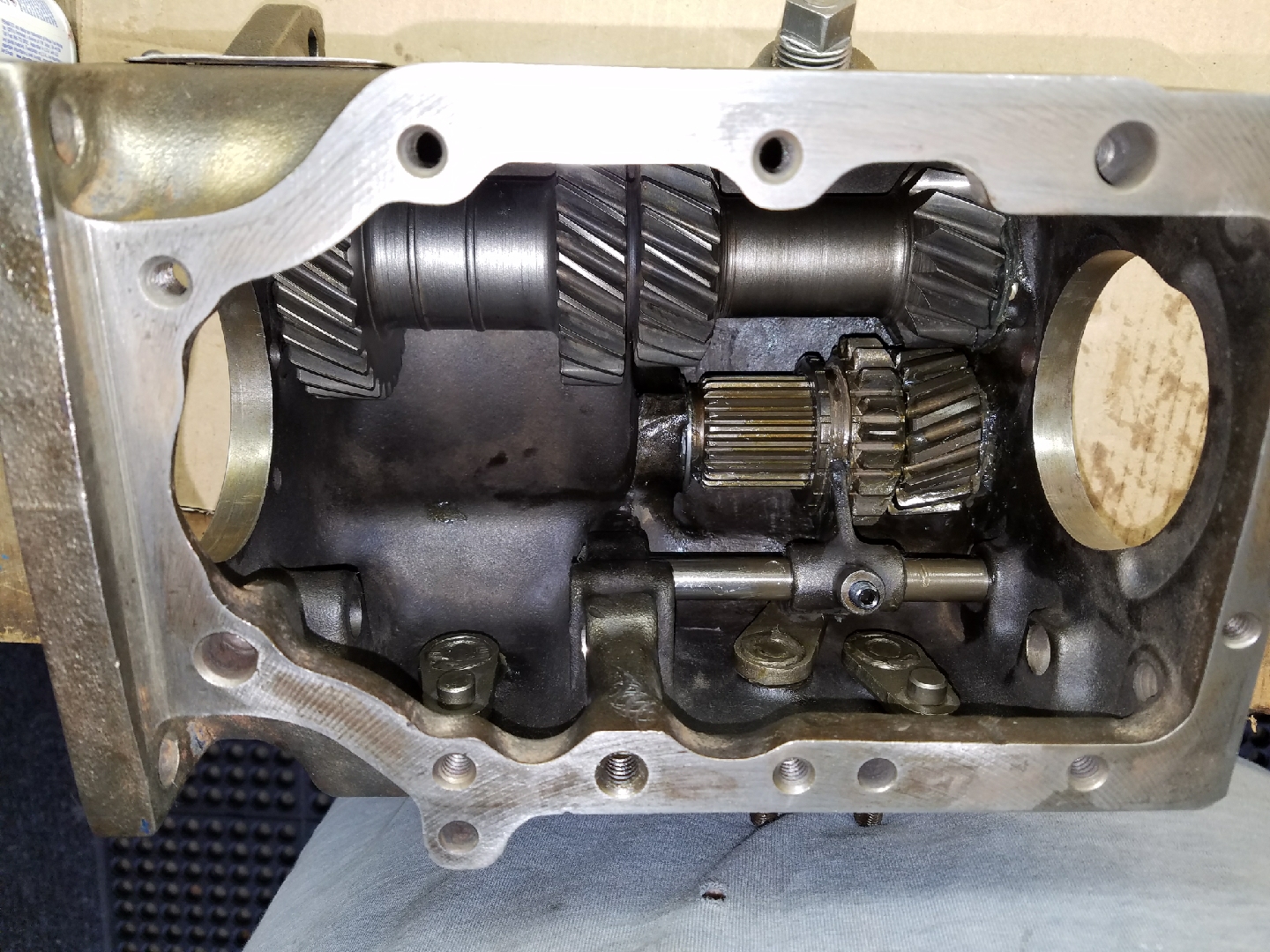

While Dad and Sean were working on the passenger door and the dew sweeps on the Galaxie I stayed home Saturday morning and worked on putting the transmission back together. It went pretty well considering I had to clean each and every part as I went. With the previous transmission, everything was already clean and overhauled from a previous teardown when I swapped the long mainshaft for the short one. By lunchtime I had the reverse idler back in it along with the shift levers. I also had all the needle bearings in the cluster gear with the dummy shaft and had it laying in the case. I was ready to start cleaning the main gear train, rebuilding the synchronizers and swapping everything to the short shaft...

Around 3:00 PM Sean and Dad came over to see if they could lend a hand. With their help I got the rest of the gear train on the short shaft, got the shaft and the gear train placed in the case, got the 1-2 and 3-4 shift rails and forks installed and got the rear main bearing pressed on. By then I was tired and it was 5:00 PM. I decided to pick up the tools and felt confident I could finish it up on Sunday. Unfortunately things didn't go our way Sunday. It was one of those days where everything was a fight. Sean and I got it all buttoned up by around 2:00 PM but something is wrong. If the tailhousing bolts and the front bearing retainer bolts are all tight, the gear train is in a bind and the transmission won't turn. I think I know what is wrong. At the back of the main case, there is a big thrust washer that goes between first gear and the rear main bearing. There was a new washer in the kit and it looked like an improved design so I used it. I'm guessing it is thicker than the O.E. washer and is the cause of the difficulty. Unfortunately we are going to have to tear the trans most of the way down to find out. Sean and I are planning to do that tonight. I'm guessing we might be able to button it up tomorrow night. I hope for the next update I can tell you we have the transmission buttoned up and have a wing window done or we've started on putting the transmission and the Gear Vendor's overdrive in the car. Stay tuned. More to come. Thanks for following along.

We are loving the fact that the entire car is in black epoxy primer and that all of the major eye-sores on the body are gone. Here is a neat pic. This is from under the front wheel well on the passenger side, looking forward. This is a splash shield that fits behind the headlight bucket. Dad found a pair of these NOS. He never had them before. Just another nice rare part on the car....

When Sean went over to Dad's Saturday, Dad had got the car off the stands as pictured above. He decided he didn't like how the passenger door was fitting. He felt it was a little low with respect to the top of the fender and the top of the quarter panel. This door is not off of this car. The door off of this car had a crease all the way down it so it was replaced with this door many years ago. Unfortunately, the door was all the way up on the hinges and wouldn't go higher. Dad and Sean pulled the door off the car, elongated the holes to get a little more adjustment, re-hung it on the car, and then touched up the paint on the bolts. It went very well. Here are some pics of the process....

Here's the door coming off the car on the 'dolly'. This is an attachment you can add to just about any floor jack. It is made by Steck and we really like it. It is very affordable. Is it as good as a dedicated door jack? Probably not but for half the price and taking up half the space, it's pretty good....

I believe this pic shows the holes after being opened up some to provide more adjustment....

Here it is back on the car and they are touching up the paint on the bolts....

Next, they moved on to installing new felts or 'dew sweeps' on the outside side of the window opening. Dad had replaced them previously (years ago) but wasn't happy with how the first shot at it turned out. With Sean's help, they got new sweeps on both the passenger door and quarter panel installed. It went well for them...

The sweeps are held on with clips and screws. The hard part is drilling the new sweep for the screws as they don't come drilled. It's nice that it turned out well for them. The new weatherstrip now needs to go on the passenger door but the wing window needs to go in first. We're waiting on a special tool for the rivets that hold the wing window together and hold the seals in it. We got the special rivets last week but it's unclear whether they are correct or not. Hopefully we'll have everything we need to restore the passenger wing window by the weekend.

Meanwhile, I've been working on the second Toploader transmission. Sean and I got the main case cleaned up last week. It was a bit of a project with the wire wheel, thread chasers, a razor scraper, wire brushes, mineral spirits, a few cans of carb spray and lots of compressed air but it came out pretty clean....

While Dad and Sean were working on the passenger door and the dew sweeps on the Galaxie I stayed home Saturday morning and worked on putting the transmission back together. It went pretty well considering I had to clean each and every part as I went. With the previous transmission, everything was already clean and overhauled from a previous teardown when I swapped the long mainshaft for the short one. By lunchtime I had the reverse idler back in it along with the shift levers. I also had all the needle bearings in the cluster gear with the dummy shaft and had it laying in the case. I was ready to start cleaning the main gear train, rebuilding the synchronizers and swapping everything to the short shaft...

Around 3:00 PM Sean and Dad came over to see if they could lend a hand. With their help I got the rest of the gear train on the short shaft, got the shaft and the gear train placed in the case, got the 1-2 and 3-4 shift rails and forks installed and got the rear main bearing pressed on. By then I was tired and it was 5:00 PM. I decided to pick up the tools and felt confident I could finish it up on Sunday. Unfortunately things didn't go our way Sunday. It was one of those days where everything was a fight. Sean and I got it all buttoned up by around 2:00 PM but something is wrong. If the tailhousing bolts and the front bearing retainer bolts are all tight, the gear train is in a bind and the transmission won't turn. I think I know what is wrong. At the back of the main case, there is a big thrust washer that goes between first gear and the rear main bearing. There was a new washer in the kit and it looked like an improved design so I used it. I'm guessing it is thicker than the O.E. washer and is the cause of the difficulty. Unfortunately we are going to have to tear the trans most of the way down to find out. Sean and I are planning to do that tonight. I'm guessing we might be able to button it up tomorrow night. I hope for the next update I can tell you we have the transmission buttoned up and have a wing window done or we've started on putting the transmission and the Gear Vendor's overdrive in the car. Stay tuned. More to come. Thanks for following along.

Wow when you guys are on it your really on it the car looks greatProgress on the Galaxie has been ongoing. Since the last update, Dad did a lot of work fitting the headlight buckets, which he restored while they were off the car. He also fit the grill and the headlight doors. He repainted the splash pan as well. Most or all of this will come off the car when it gets painted but all of this needed fitting. Dad did a lot of work massaging the grill to a much straighter and better fitting condition. Here is a pic my brother snapped Saturday morning...

View attachment 69281

We are loving the fact that the entire car is in black epoxy primer and that all of the major eye-sores on the body are gone. Here is a neat pic. This is from under the front wheel well on the passenger side, looking forward. This is a splash shield that fits behind the headlight bucket. Dad found a pair of these NOS. He never had them before. Just another nice rare part on the car....

View attachment 69282

When Sean went over to Dad's Saturday, Dad had got the car off the stands as pictured above. He decided he didn't like how the passenger door was fitting. He felt it was a little low with respect to the top of the fender and the top of the quarter panel. This door is not off of this car. The door off of this car had a crease all the way down it so it was replaced with this door many years ago. Unfortunately, the door was all the way up on the hinges and wouldn't go higher. Dad and Sean pulled the door off the car, elongated the holes to get a little more adjustment, re-hung it on the car, and then touched up the paint on the bolts. It went very well. Here are some pics of the process....

Here's the door coming off the car on the 'dolly'. This is an attachment you can add to just about any floor jack. It is made by Steck and we really like it. It is very affordable. Is it as good as a dedicated door jack? Probably not but for half the price and taking up half the space, it's pretty good....

View attachment 69283

I believe this pic shows the holes after being opened up some to provide more adjustment....

View attachment 69284

Here it is back on the car and they are touching up the paint on the bolts....

View attachment 69285

Next, they moved on to installing new felts or 'dew sweeps' on the outside side of the window opening. Dad had replaced them previously (years ago) but wasn't happy with how the first shot at it turned out. With Sean's help, they got new sweeps on both the passenger door and quarter panel installed. It went well for them...

View attachment 69286 View attachment 69287

The sweeps are held on with clips and screws. The hard part is drilling the new sweep for the screws as they don't come drilled. It's nice that it turned out well for them. The new weatherstrip now needs to go on the passenger door but the wing window needs to go in first. We're waiting on a special tool for the rivets that hold the wing window together and hold the seals in it. We got the special rivets last week but it's unclear whether they are correct or not. Hopefully we'll have everything we need to restore the passenger wing window by the weekend.

Meanwhile, I've been working on the second Toploader transmission. Sean and I got the main case cleaned up last week. It was a bit of a project with the wire wheel, thread chasers, a razor scraper, wire brushes, mineral spirits, a few cans of carb spray and lots of compressed air but it came out pretty clean....

View attachment 69288

While Dad and Sean were working on the passenger door and the dew sweeps on the Galaxie I stayed home Saturday morning and worked on putting the transmission back together. It went pretty well considering I had to clean each and every part as I went. With the previous transmission, everything was already clean and overhauled from a previous teardown when I swapped the long mainshaft for the short one. By lunchtime I had the reverse idler back in it along with the shift levers. I also had all the needle bearings in the cluster gear with the dummy shaft and had it laying in the case. I was ready to start cleaning the main gear train, rebuilding the synchronizers and swapping everything to the short shaft...

View attachment 69289

Around 3:00 PM Sean and Dad came over to see if they could lend a hand. With their help I got the rest of the gear train on the short shaft, got the shaft and the gear train placed in the case, got the 1-2 and 3-4 shift rails and forks installed and got the rear main bearing pressed on. By then I was tired and it was 5:00 PM. I decided to pick up the tools and felt confident I could finish it up on Sunday. Unfortunately things didn't go our way Sunday. It was one of those days where everything was a fight. Sean and I got it all buttoned up by around 2:00 PM but something is wrong. If the tailhousing bolts and the front bearing retainer bolts are all tight, the gear train is in a bind and the transmission won't turn. I think I know what is wrong. At the back of the main case, there is a big thrust washer that goes between first gear and the rear main bearing. There was a new washer in the kit and it looked like an improved design so I used it. I'm guessing it is thicker than the O.E. washer and is the cause of the difficulty. Unfortunately we are going to have to tear the trans most of the way down to find out. Sean and I are planning to do that tonight. I'm guessing we might be able to button it up tomorrow night. I hope for the next update I can tell you we have the transmission buttoned up and have a wing window done or we've started on putting the transmission and the Gear Vendor's overdrive in the car. Stay tuned. More to come. Thanks for following along.

Nice work again. To bad about the trans. I'm sure that Sean and you will get it straight. Keep the updates coming

The car is shaping up nicely, Jared.

It's too bad you have to tear into the trans again, but at least you know it will be right after you've gone thru it again.

It's too bad you have to tear into the trans again, but at least you know it will be right after you've gone thru it again.

Thanks Opie. I've encouraged some on here to pursue getting parts they need reproduced by contacting some of the manufacturers but to a mixed reception. Part of the hard part is you have to have something decent to send in for the prototyping to be done. Thanks for the kind words on the project. Sean and I are excited for Dad.

Thanks for the offer for help. I will keep it in mind. Dad definitely has a parts manual that covers 62 but I'm not sure what else. I doubt it covers 60-64 so I'll keep in mind that you have the information. I've been enjoying your thread on the Plymouth. Wow, that's a lot of work. Thanks for saving that car. I agree, patience is key and is the hard part on building these cars.

Anytime. The illustration section also has blow-up views of the different sections of the car. A great way to see how things go back together in case you're unsure. Just ask and I can scan it in to my computer and post it to you. And thanks for watching the thread. I wasn't kidding when I said "insane body work". I've probably done as much work on it as the original guys who put it together on the assembly line. I've been watching yours too. You guys are doing a great job too. I think I have a pic of myself as a wee lad standing next to my dads 62 when it was new. If I can find it I will post it to your thread

I have quite a few NOS panels for my 63 & 69 restos including a NOS 63 convertible quarterpanel. I have thought about that for years as a way of getting some panels I don't have. With computer imaging technology as advanced as it is today, a manufacturer should be able to take the dimensions of something such as a right side quarterpanel and then invert it to make a left side quarterpanel since they are identical....just reversed. Like turning something inside out. My only problem is trust. If I send them a rare irreplaceable quarterpanel or wheelhouse will I ever see it again...and in the same condition as it was sent? Here are a few pics to show you some of what I have. I call this the sheetmetal room.

Just to the right of the fenders and in front of that trunk lid is the 63's left hand quarter.

Last edited:

Nice work again. To bad about the trans. I'm sure that Sean and you will get it straight. Keep the updates coming

Thanks David. It's funny how some days everything seems to go your way and some days everything is a fight. Sunday was one of those days where everything was a fight. Sometimes you just have to get away from it and come back at it with a fresh set of eyes.

The car is shaping up nicely, Jared.

It's too bad you have to tear into the trans again, but at least you know it will be right after you've gone thru it again.

Thanks Jack. It was just one of those deals where something wasn't quite right.

Anytime. The illustration section also has blow-up views of the different sections of the car. A great way to see how things go back together in case you're unsure. Just ask and I can scan it in to my computer and post it to you. And thanks for watching the thread. I wasn't kidding when I said "insane body work". I've probably done as much work on it as the original guys who put it together on the assembly line. I've been watching yours too. You guys are doing a great job too. I think I have a pic of myself as a wee lad standing next to my dads 62 when it was new. If I can find it I will post it to your thread

I have quite a few NOS panels for my 63 & 69 restos including a NOS 63 convertible quarterpanel. I have thought about that for years as a way of getting some panels I don't have. With computer imaging technology as advanced as it is today, a manufacturer should be able to take the dimensions of something such as a right side quarterpanel and then invert it to make a left side quarterpanel since they are identical....just reversed. Like turning something inside out. My only problem is trust. If I send them a rare irreplaceable quarterpanel or wheelhouse will I ever see it again...and in the same condition as it was sent? Here are a few pics to show you some of what I have. I call this the sheetmetal room.

View attachment 69337

View attachment 69338

Just to the right of the fenders and in front of that trunk lid is the 63's left hand quarter.

View attachment 69339

View attachment 69340

Wow! That's quite a horde or NOS stuff! I love NOS parts. Nothing fits better than the real deal. I can understand your reluctance to send off a NOS part and risk not getting it back. Please do post that pic of you and your Dad's 62 if you find it. There are a lot of us that would enjoy that. Thanks for the kind words about our build. We are proud of it and the time with Dad is the most important part. In the crunch to move the project along even I lose sight of that sometimes.

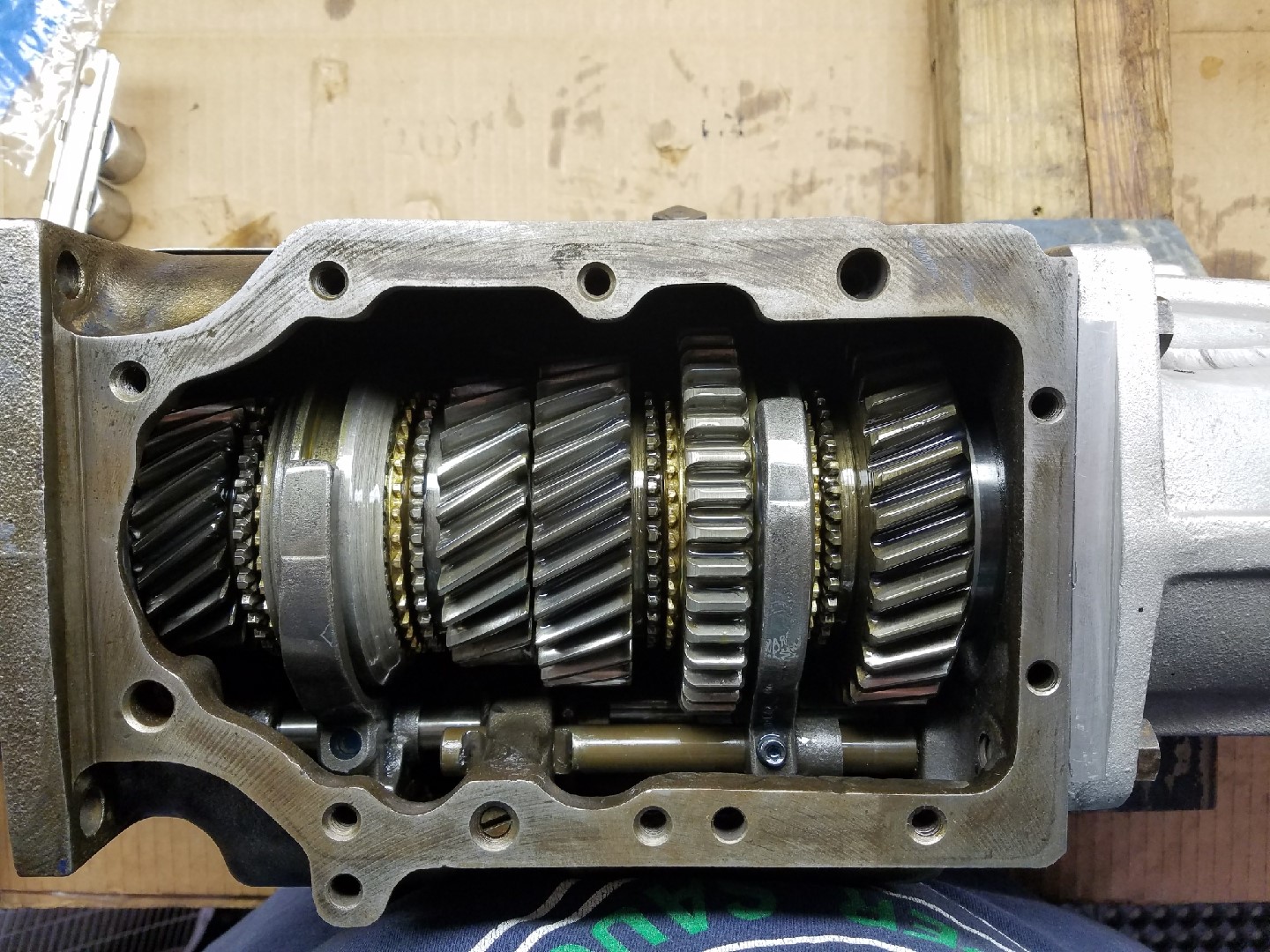

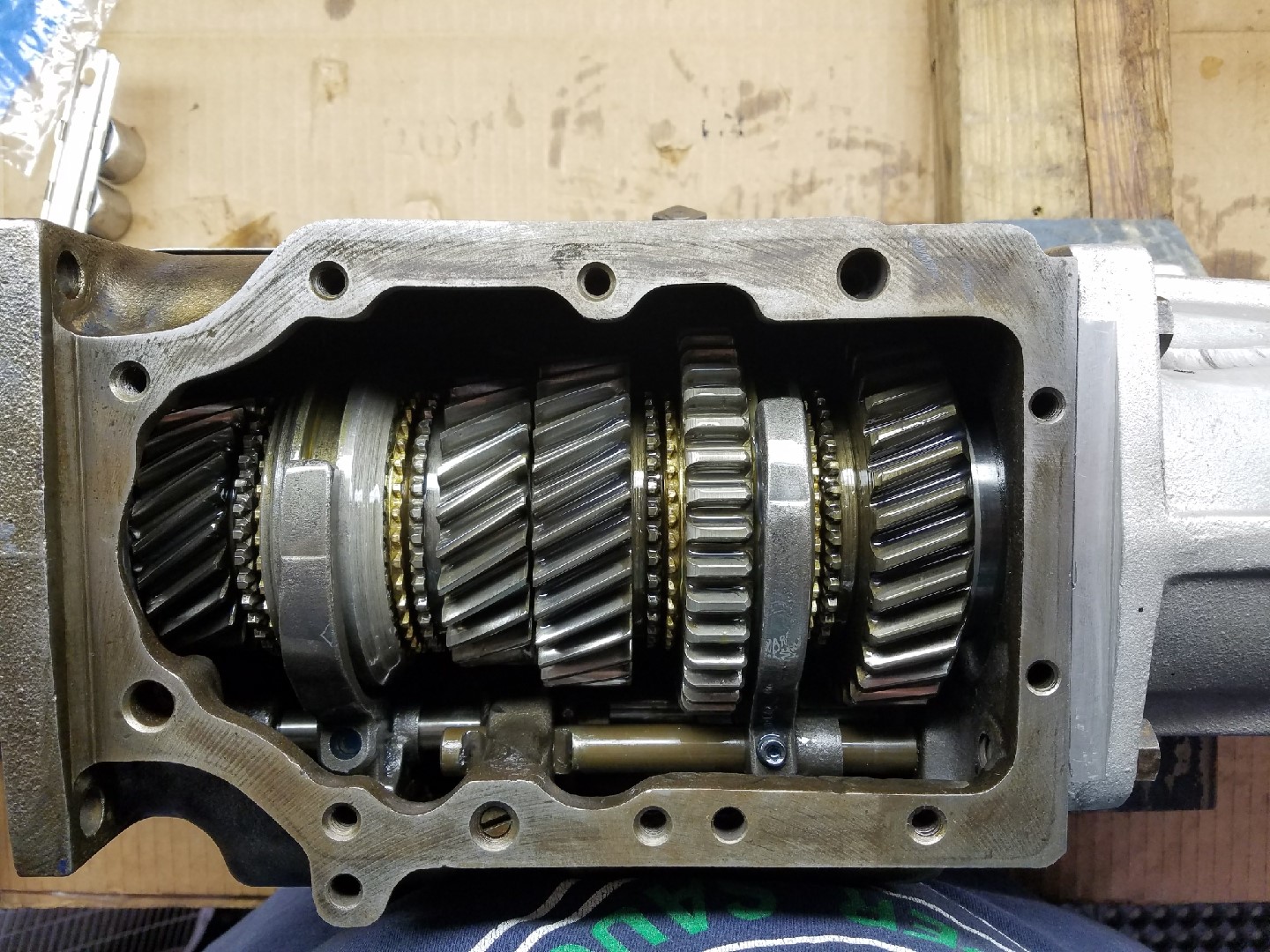

Sean and I got the Toploader buttoned up last night. We had to tear it pretty far down to get the main shaft and gear train out of it. My theory on the thrust washer behind first gear was wrong. The aftermarket replacement was actually 0.010" thinner. I replaced it with the original washer anyway. It turned out I made a mistake when I reassembled the 3-4 synchronizer. It turns out there are two different sized detents for the synchronizers and I forgot it. The long detents go in the 1-2 synchronizer, and I had that right, but the 3-4 synchronizer takes short detents and I had the long ones in it. This only happened because I have some extra parts from buying a small parts kit for extra lock rings. Consequently, when the tailhousing and front bearing support were bolted on, it was jamming the 4th gear blocker ring up against the 3-4 synchronizer and jamming the entire gear train against the rear bearing, putting pre-load on the whole assembly. Fortunately nothing was damaged since I had enough sense to not bear down or force anything. We corrected the assembly mistake and put it all back together. It turned out really well. Everything moves freely and it shifts like a dream. I think it might be the nicest trans I've built so far. I'm looking forward to getting it in the car and getting the Gear Vendors unit bolted on. Here are a few pics of the finished product...

I received the rivet tool we need for the wing window earlier this week. We should have the rivets and the tool we need to replace the rubber in the passenger wing window so I think that will be the focus of this Saturday/Sunday. If we can get the rubber in the vent window replaced then we can get it in the door, get the passenger roll up window back in the door and get the new door seal on the passenger door. If we decide we don't have what we need for the wing window project, we may start pulling the T-10 out to replace it with this Toploader and work to finally install the Gear Vendors. It's been about three years since I bought it for Dad. I'm looking forward to going down the road and feeling that thing go into overdrive. I'm also looking forward to getting out on the open road and getting it wound up to 80 or 85 in overdrive and see the car be able to do it relatively effortlessly. That will likely take a little more work to accomplish. We will likely tweak the combination with a taller rear tire. Right now the car has 235/60/15's on it all the way around. Previously it had 255/60/15's on it all the way around. The 255's really were too big for the front of the car, though we loved the look. I think we will likely go back to 255/60/15's on the back or possibly even taller to reduce the cruise RPM. We might even look at changing the rear gear from the current 3:56 down to like a 3:23. Now that we have a wide ratio transmission for the car the steeper first gear gives us a lot of flexibility to perfect the combination.

My brother and I recently made a quick weekend trip to Dallas to see a show up there and see some good friends of ours. We took Sean's truck (02 Sierra). He had the cruise set on 80 (75 mph speed limit) and there were plenty of cars passing us. I wouldn't say we were in the way of anyone but here in Texas you need to be able to do 80-85 out on the open road or you are in the way. It's going to be great to have the Galaxie where it can comfortably do that. That's it for now. Thanks as always for following along. I should have another update Saturday or Sunday. Hopefully I'll have some good progress to report.

I received the rivet tool we need for the wing window earlier this week. We should have the rivets and the tool we need to replace the rubber in the passenger wing window so I think that will be the focus of this Saturday/Sunday. If we can get the rubber in the vent window replaced then we can get it in the door, get the passenger roll up window back in the door and get the new door seal on the passenger door. If we decide we don't have what we need for the wing window project, we may start pulling the T-10 out to replace it with this Toploader and work to finally install the Gear Vendors. It's been about three years since I bought it for Dad. I'm looking forward to going down the road and feeling that thing go into overdrive. I'm also looking forward to getting out on the open road and getting it wound up to 80 or 85 in overdrive and see the car be able to do it relatively effortlessly. That will likely take a little more work to accomplish. We will likely tweak the combination with a taller rear tire. Right now the car has 235/60/15's on it all the way around. Previously it had 255/60/15's on it all the way around. The 255's really were too big for the front of the car, though we loved the look. I think we will likely go back to 255/60/15's on the back or possibly even taller to reduce the cruise RPM. We might even look at changing the rear gear from the current 3:56 down to like a 3:23. Now that we have a wide ratio transmission for the car the steeper first gear gives us a lot of flexibility to perfect the combination.

My brother and I recently made a quick weekend trip to Dallas to see a show up there and see some good friends of ours. We took Sean's truck (02 Sierra). He had the cruise set on 80 (75 mph speed limit) and there were plenty of cars passing us. I wouldn't say we were in the way of anyone but here in Texas you need to be able to do 80-85 out on the open road or you are in the way. It's going to be great to have the Galaxie where it can comfortably do that. That's it for now. Thanks as always for following along. I should have another update Saturday or Sunday. Hopefully I'll have some good progress to report.

Not sure what small parts you are looking for but when I did my 57 Ford and My 64 xl 500 I used a guy named Dennis Carpenter in Concord North Carolina he was great and had all the small chrome pieces I needed hope this helps Jeff from WinnipegSean and I got the Toploader buttoned up last night. We had to tear it pretty far down to get the main shaft and gear train out of it. My theory on the thrust washer behind first gear was wrong. The aftermarket replacement was actually 0.010" thinner. I replaced it with the original washer anyway. It turned out I made a mistake when I reassembled the 3-4 synchronizer. It turns out there are two different sized detents for the synchronizers and I forgot it. The long detents go in the 1-2 synchronizer, and I had that right, but the 3-4 synchronizer takes short detents and I had the long ones in it. This only happened because I have some extra parts from buying a small parts kit for extra lock rings. Consequently, when the tailhousing and front bearing support were bolted on, it was jamming the 4th gear blocker ring up against the 3-4 synchronizer and jamming the entire gear train against the rear bearing, putting pre-load on the whole assembly. Fortunately nothing was damaged since I had enough sense to not bear down or force anything. We corrected the assembly mistake and put it all back together. It turned out really well. Everything moves freely and it shifts like a dream. I think it might be the nicest trans I've built so far. I'm looking forward to getting it in the car and getting the Gear Vendors unit bolted on. Here are a few pics of the finished product...

View attachment 69426

View attachment 69425

I received the rivet tool we need for the wing window earlier this week. We should have the rivets and the tool we need to replace the rubber in the passenger wing window so I think that will be the focus of this Saturday/Sunday. If we can get the rubber in the vent window replaced then we can get it in the door, get the passenger roll up window back in the door and get the new door seal on the passenger door. If we decide we don't have what we need for the wing window project, we may start pulling the T-10 out to replace it with this Toploader and work to finally install the Gear Vendors. It's been about three years since I bought it for Dad. I'm looking forward to going down the road and feeling that thing go into overdrive. I'm also looking forward to getting out on the open road and getting it wound up to 80 or 85 in overdrive and see the car be able to do it relatively effortlessly. That will likely take a little more work to accomplish. We will likely tweak the combination with a taller rear tire. Right now the car has 235/60/15's on it all the way around. Previously it had 255/60/15's on it all the way around. The 255's really were too big for the front of the car, though we loved the look. I think we will likely go back to 255/60/15's on the back or possibly even taller to reduce the cruise RPM. We might even look at changing the rear gear from the current 3:56 down to like a 3:23. Now that we have a wide ratio transmission for the car the steeper first gear gives us a lot of flexibility to perfect the combination.

My brother and I recently made a quick weekend trip to Dallas to see a show up there and see some good friends of ours. We took Sean's truck (02 Sierra). He had the cruise set on 80 (75 mph speed limit) and there were plenty of cars passing us. I wouldn't say we were in the way of anyone but here in Texas you need to be able to do 80-85 out on the open road or you are in the way. It's going to be great to have the Galaxie where it can comfortably do that. That's it for now. Thanks as always for following along. I should have another update Saturday or Sunday. Hopefully I'll have some good progress to report.

Similar threads

- Replies

- 4

- Views

- 323

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.