Thanks for the detailed explanations.81cutlass explained the idea of the returnless setup better than I can.

Regarding boost, and why the need for a boost referenced FPR, when boost pressure is present in the manifold it is also applying pressure to the injector tip. And that pressure has to be overcome - basically,

there is a pressure differential between the manifold and fuel system. The fuel supply end of the injector has fuel pressure on it and the other end has manifold pressure on it. The difference between the two is referred to as ‘pressure differential’ in this discussion.

The goal of the referenced FPR regulator is to keep the pressure differential between manifold and fuel system the same for all boost levels. For example , you have a system that runs at 43psi base fuel pressure (set at atmospheric pressure with the engine off.) 43 is now the value to be set as the pressure differential number. At 10 psi of boost the FPR adds that same 10psi to the fuel system to generate 53psi of fuel pressure. At 20 psi of boost the fuel pressure becomes 63psi. I’m sure you get it, but the important piece of puzzle is that the injector is now in a constant pressure differential of 43 psi all the time. And this occurs in vacuum as well, hence the reason why the fuel pressure drops in vacuum to a negative psi.

The negative psi number starts becoming confusing because rarely does anyone reference pressure in negative psi. The most common unit of measure that is simplest is kpa due to the scaling of it. And kpa infers ‘absolute’ pressure rather relative pressure. But that’s another discussion if needed.

Onto injector data consideration and how fuel pressure affects injector flow. All injectors’ flow characteristics are not the same as fuel pressure varies. A Siemens Deka flow rate flow rate change due to fuel pressure variance might be 5-10% more than a Bosch, Multec, Delphi, etc. This makes tuning an injector swap even more demanding at a varying fuel pressure differential. So again, a constant fuel pressure differential across the injector makes for very linear, predictable and most importantly - consistent - tuning.

One variable that is tuned by most every ECU is flow rate changes due to voltage changes. The varying flow rates due to voltage changes are what is entered into most every ECU as ‘injector data’. With this in mind, consider running with a consistent fuel pressure that doesn’t take fuel injector pressure differential into account. Now you are having to adjust for both voltage change and pressure differential change. This situation turns into a 3 dimensional aspect of the tune rather than a 2 dimensional aspect (aspect implies a table). Perhaps the newer factory ECM’s can handle this, and I’ll guess they can, but that is because they have at least one of two things going on or both - they have very specific injector data for all 3 dimensions and/or they have the O2 sensor commanding wild injector duty cycle changes. The factory ECM is probably doing more than what I just referenced

This leads to a simple question. Why not put in a 1 to 1 vacuum/boost referenced FPR and make this very easy - so easy in fact that all of the big name aftermarket ECM manufacturers can handle - I.e Holley, Haltech, Big Stuff, Fuel Tech, Megasquirt, etc.?

I referenced absolute pressure via relative pressure a couple of paragraphs back. Having a full understanding of the difference between the two is extremely important when trying to understand what is happening in your fuel system and inside your intake. I only mention this, because I either didn’t understand or overlooked this when I first started messing with tuning cars. It was something taught in most every chemistry and physics class through my high school and college classes, but dang, that was 25 years before I needed to know how it applies to tuning a motor on earth lol.

p.s. I typed this post on my IPhone - I’m trying to force myself to be better at using this damn dinky key pad 😉

I do not fully understand the the absolute vs relative pressure. My head went to the concept of dew point vs RH% measurements. Or like the way a weatherman measures fronts, but how it coincides with tuning, or how it effects fueling, idk.

I have a question about your fuel pump wiring video. I have a 10ga wire from my relay, so do I just split that into 2 14ga wires a little before the pigtail?Yeah basically returnless that's not vacuum referenced has in effect non continuous flow rates. The injectors get 'bigger' as the manifold vacuum increases as you gain relative fuel pressure.

In a manifold pressure reference set-up NA you have 42.5 psi of fuel pressure at wide open throttle, no vacuum or with the engine off. At idle with 28" of vacuum you have about 30 psi of fuel pressure relative to the air you breath but it's actually 42psi relative to the air in the manifold because it's at a vacuum.

Returnless setups can be harder to tune because if it's not manifold pressure reference the effective fuel pressure at idle is say 56psi which makes the injectors roughly 10% larger. You have to ramp the injectors size as the air pressure in the manifold changes.

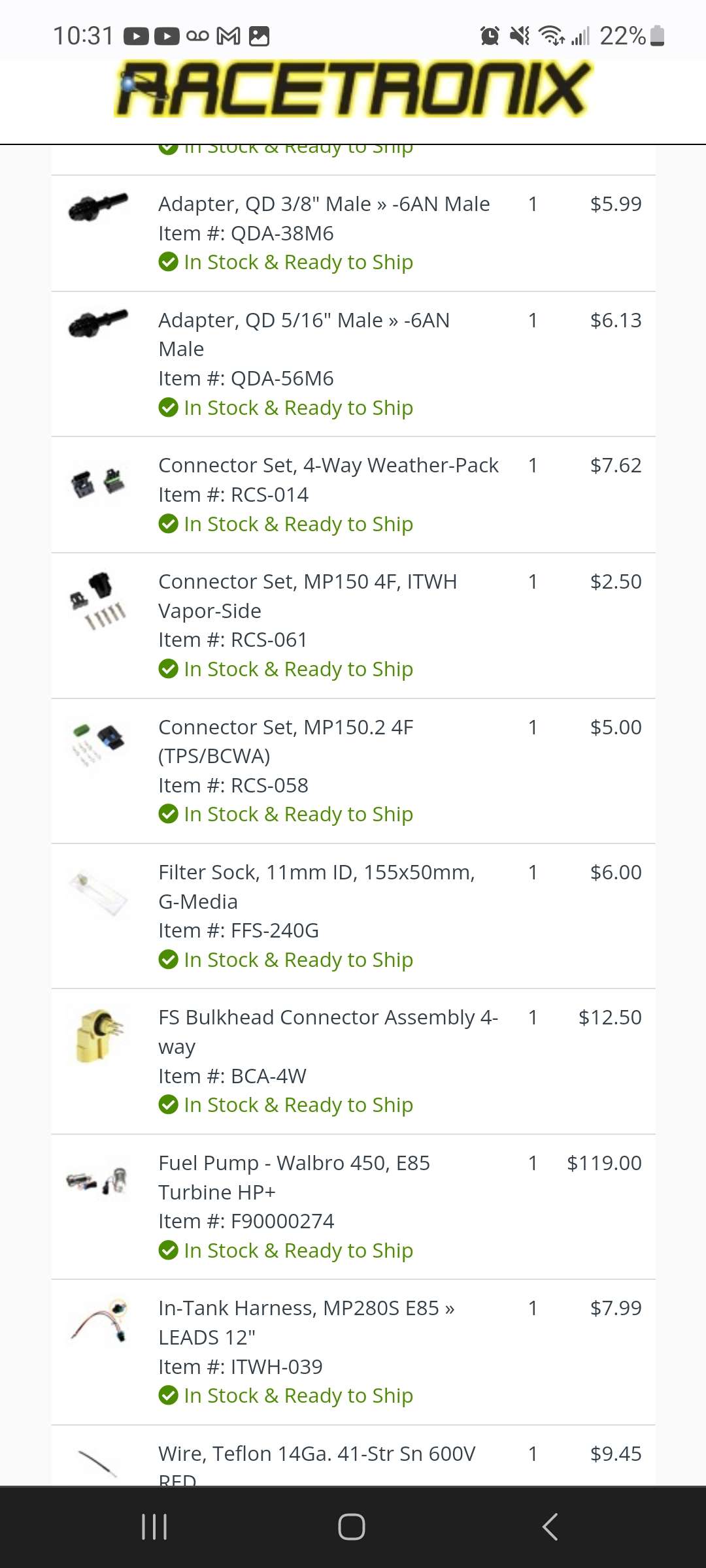

And yeah, walbro or TTI pumps are great but there are a lot of fakes. If you go with one from a reliable seller, I got mine from highflowfuel or from racetronix, where I get my bigger wiring bulkhead parts from, you should be fine. But Amazon and eBay are yikes.

Then put both 14ga wires off the 4pin bulkhead into the pin for the fuel pump pigtail?

Thanks for the returnless setup breakdown.I understand what your saying. All this makes me wonder how much I would've struggled trying to tune the returnless setup N/A.

Doesn't really matter now. I ordered the tank and sender from rockauto, that fpr from Amazon, plus the pump and everything needed to install it from racetronix(no sales tax). It was around $600, includes tax and s/h. The fuel system will be completely new now. I think I have about 750 in the whole fuel system.