Everyone that has had a G-body power antenna from the factory has found this out the hard way. Or will find out if not already. At one point of the original antenna's life, it will just stop moving (usually won't go down or all the way down) and the motor continues to run until you pull the motor plug from under the hood.

I have some new and unused antenna pieces whether complete or just the masts. They all come with nylon cables. And 95% of them are more than 20 years old at the newest. It's worse for the complete masts.

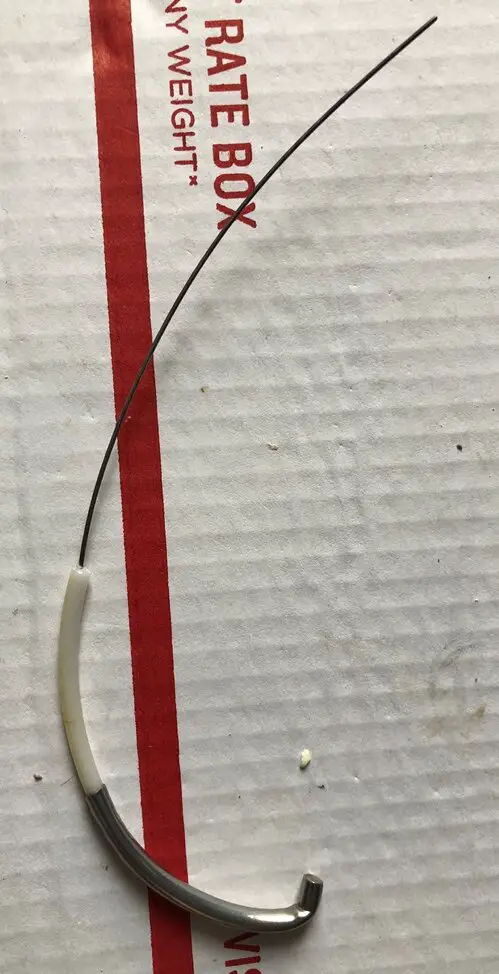

I yanked one out of my stash to change the nylon cable to a metal one as a pre-emptive strike. I got the metal one from Mike M. aka 88hurstolds here. If you don't have a metal one, get it. It's worth every penny. I figured I'd do a mini picture book and discuss how to do one. It's NOT hard. Tedious in a couple of places, but not tough. If you have patience and half-way decent mechanical skills, you can do this. If you're Wreck-It-Ralph, you may want to get someone else to do it for you.

So here we go.

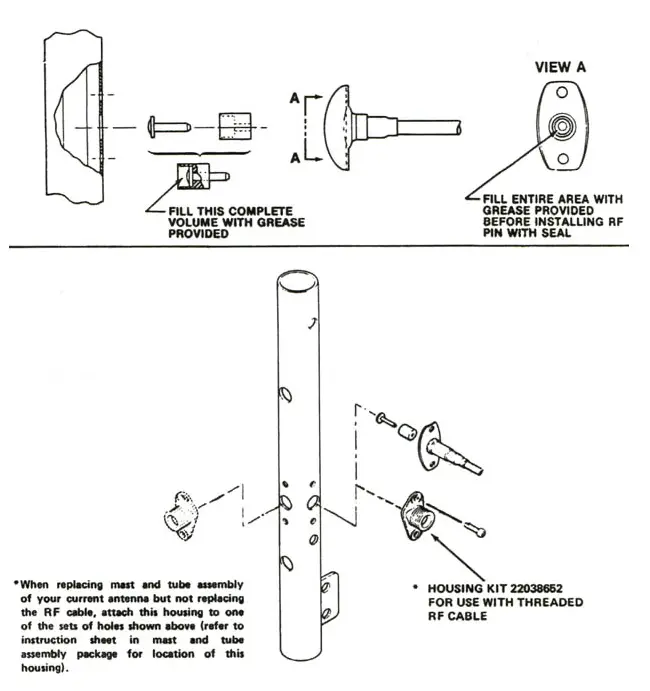

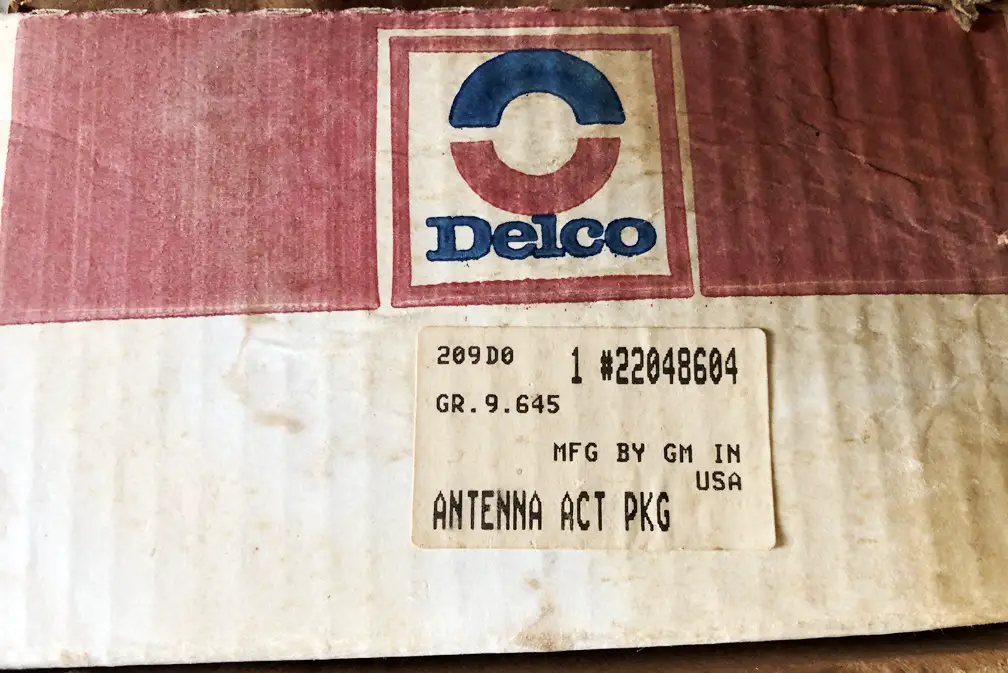

First up, here's the antenna part number we're working with today. Inside the box was several thingies. Obviously, the antenna, but also came with a Cutlass Supreme, Riviera, and several other cars style of lower bracket. This bracket is tack welded on the factory jobs, but there's a couple of screws that comes with the bracket to be able to attach it. This is because the brackets attach differently if you have a different car. More about that later. Or you may need to get a new bracket if it wasn't included in the box. The box also includes a little packet of di-electric grease for the antenna cable connection (for the radio).

You will need some tools and supporting stuff. Here's a list of tools I used, and not all inclusive, but you can do whatever you like.

1. A 7mm scocket for removing the finial from the end of the mast.

2. A pair of needle nose vise grips (with some cushioning available for the antenna mast). Gotta hold the end of the mast when removing/installing the finial.

3. Smallish flat blade screwdriver. Helps to get the case clips off the casing.

4. Paper/clean shop towels. You'll do a lot of wiping and cleaning, especially if you're working on used stuff.

5. Drill and 1/4" drill bit. You need to drill the OEM rivet end off so you can push the rivets through to the other side to get the case apart.

6. Phillips head screwdriver, #2. You'll need this for the bracket, if used.

7. Spanner wrench or equivalent to remove the antenna nut from the fender if fixing your existing antenna.

8. 10 mm wrench, socket, and various other tools to get the fender loose to get the dang thing out of the fender.

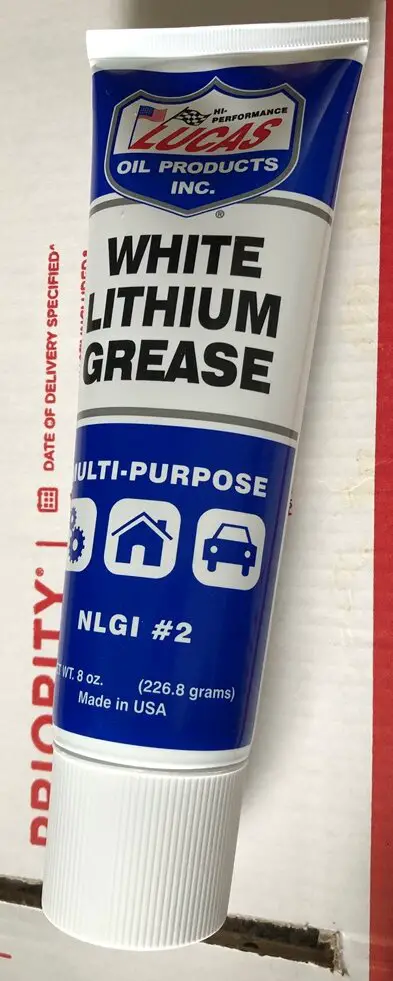

9. Lithium grease. For lubing the rotating cable wheel axis, cable "guide" and motor scroll. Don't need much. The older CSM's say to use Sunoco Prestige #2 or equivalent grease (lithium soap-based grease). I'm using Lucas brand white lithium. Works fine.

10. Silicone or RTV sealer. You need it for sealing the top half of the casing split to keep moisture out of the motor.

11. CSM if you happen to have one. It's in the "accessories" portion on how to disassemble/reassemble the antenna.

The antenna box:

A look inside:

Mast says 093 090, which correlates to April 3, 1990. I thought it was March 31, but no, it's April 3.

The motor was built on day 102 of 1990, which is April 12, 1990.

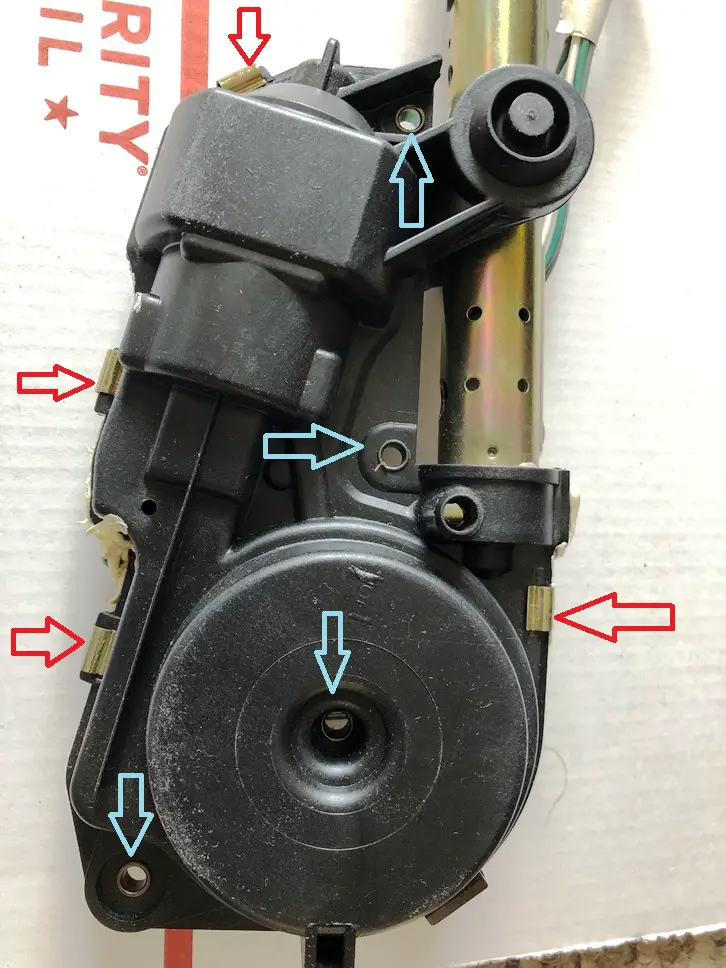

Now, we got to figure out how to get that casing apart. The CSM shows 5 clips, but I've only got 4 (red arrows). Also, there are 4 rivets (blue arrows) that need to be removed.

Drill baby drill. Just drill enough to cut off the flange of the hollow rivets. They're brass and can easily be knocked through the hole with a small screwdriver or similar.

The dead rivet

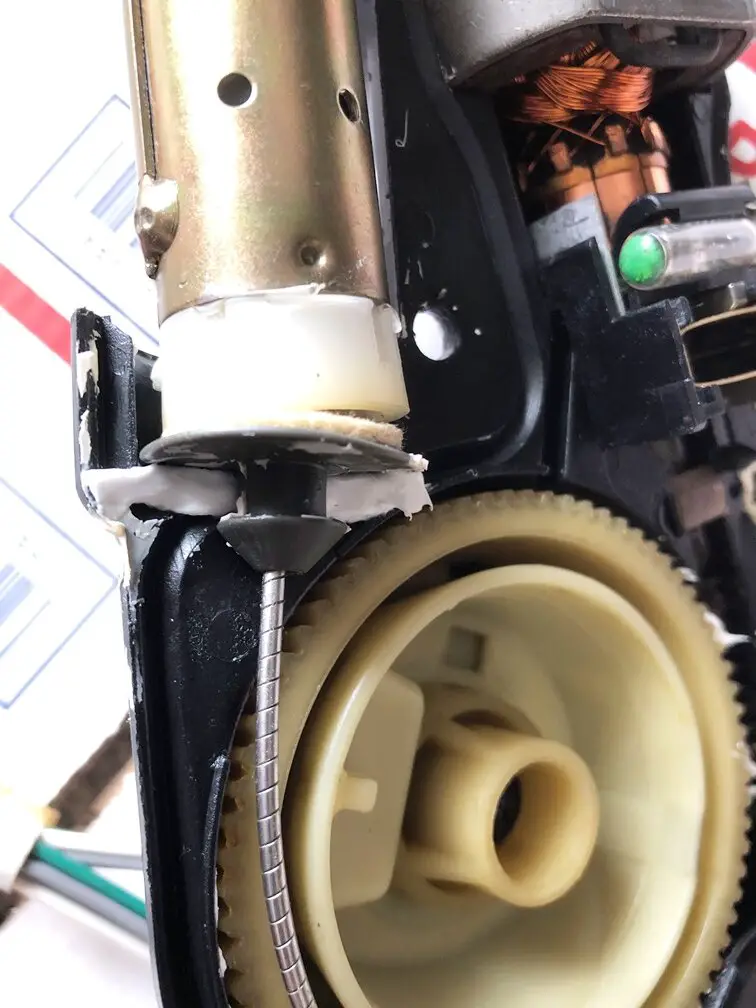

And now we can pry that case open. There's RTV sealer on the top half of the casing so it'll take a bit of prying, but be gentle. It will come. So lets dig into this bad boy and get all up in them guts.

I have some new and unused antenna pieces whether complete or just the masts. They all come with nylon cables. And 95% of them are more than 20 years old at the newest. It's worse for the complete masts.

I yanked one out of my stash to change the nylon cable to a metal one as a pre-emptive strike. I got the metal one from Mike M. aka 88hurstolds here. If you don't have a metal one, get it. It's worth every penny. I figured I'd do a mini picture book and discuss how to do one. It's NOT hard. Tedious in a couple of places, but not tough. If you have patience and half-way decent mechanical skills, you can do this. If you're Wreck-It-Ralph, you may want to get someone else to do it for you.

So here we go.

First up, here's the antenna part number we're working with today. Inside the box was several thingies. Obviously, the antenna, but also came with a Cutlass Supreme, Riviera, and several other cars style of lower bracket. This bracket is tack welded on the factory jobs, but there's a couple of screws that comes with the bracket to be able to attach it. This is because the brackets attach differently if you have a different car. More about that later. Or you may need to get a new bracket if it wasn't included in the box. The box also includes a little packet of di-electric grease for the antenna cable connection (for the radio).

You will need some tools and supporting stuff. Here's a list of tools I used, and not all inclusive, but you can do whatever you like.

1. A 7mm scocket for removing the finial from the end of the mast.

2. A pair of needle nose vise grips (with some cushioning available for the antenna mast). Gotta hold the end of the mast when removing/installing the finial.

3. Smallish flat blade screwdriver. Helps to get the case clips off the casing.

4. Paper/clean shop towels. You'll do a lot of wiping and cleaning, especially if you're working on used stuff.

5. Drill and 1/4" drill bit. You need to drill the OEM rivet end off so you can push the rivets through to the other side to get the case apart.

6. Phillips head screwdriver, #2. You'll need this for the bracket, if used.

7. Spanner wrench or equivalent to remove the antenna nut from the fender if fixing your existing antenna.

8. 10 mm wrench, socket, and various other tools to get the fender loose to get the dang thing out of the fender.

9. Lithium grease. For lubing the rotating cable wheel axis, cable "guide" and motor scroll. Don't need much. The older CSM's say to use Sunoco Prestige #2 or equivalent grease (lithium soap-based grease). I'm using Lucas brand white lithium. Works fine.

10. Silicone or RTV sealer. You need it for sealing the top half of the casing split to keep moisture out of the motor.

11. CSM if you happen to have one. It's in the "accessories" portion on how to disassemble/reassemble the antenna.

The antenna box:

A look inside:

Mast says 093 090, which correlates to April 3, 1990. I thought it was March 31, but no, it's April 3.

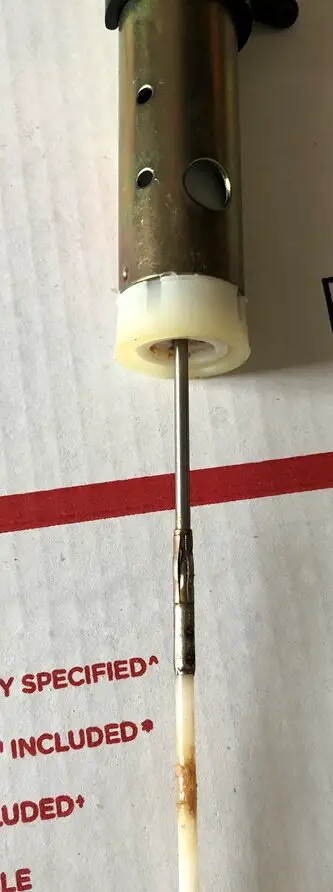

The motor was built on day 102 of 1990, which is April 12, 1990.

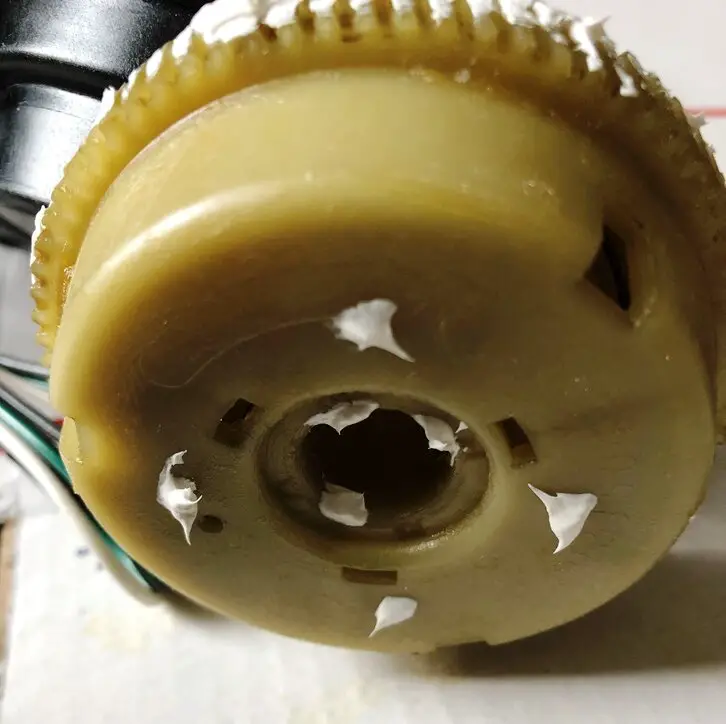

Now, we got to figure out how to get that casing apart. The CSM shows 5 clips, but I've only got 4 (red arrows). Also, there are 4 rivets (blue arrows) that need to be removed.

Drill baby drill. Just drill enough to cut off the flange of the hollow rivets. They're brass and can easily be knocked through the hole with a small screwdriver or similar.

The dead rivet

And now we can pry that case open. There's RTV sealer on the top half of the casing so it'll take a bit of prying, but be gentle. It will come. So lets dig into this bad boy and get all up in them guts.