I pounded my face against a wall this spring trying to find why my single 450 was not keeping up. The short version of what I found

-The single 450 was flowing 17% under the published amount (experimentally validated)

-Best case scenario (the pump flowed the published rate and zero voltage drop) a single 450 was only able to fuel 92lb injectors to (80's at 4 bar base) 80% duty cycle

I overcomplicate things with math and HATE overkill so I use my math to 'skimp' as much as I can while maintaining function. No matter how I crunched it and validated with tests, I couldn't get one pump to pencil out. I saw consistent voltage drop and underflowing pumps. 2 pumps was the best solution (plus if one pump dies on the street I can just flip the second race pump on with a toggle switch). Already saved me once.

Probably should clarify a tad-

(WARNING POORLY PRESENTED DATA OVERLOAD)

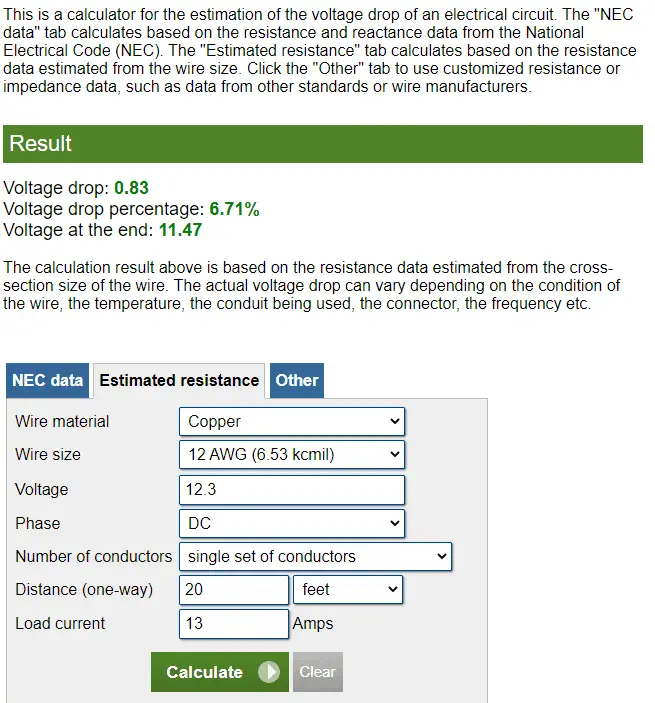

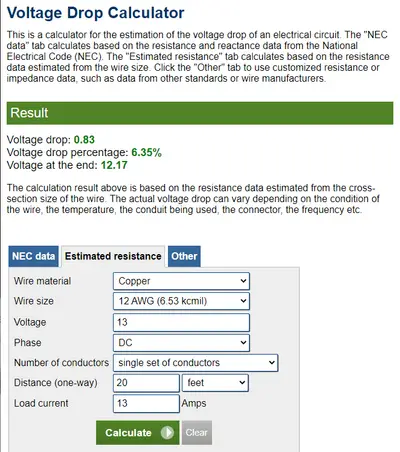

I used to have 12 gauge from the alternator to the single 450, with 12.3V at the battery (engine off wall charger on) I had 11.5V at the plug where the harness goes into the tank. I didn't like that and put 8 gauge in and it reduced the voltage loss to 0.3V instead of the 0.8V with 12 gauge, but not enough to get me the flow I needed.

I plugged my info into a voltage loss calculator and it predicted exactly what I observed.

I now have 8 gauge from the alternator to the battery and a junction block about 2 ft off the alternator where my injectors and fuel pumps pull power off (it helped). The voltage coming off the alternator gets the 'choice' of sending voltage to the fuel pumps OR battery at that junction block. I pull the fan power off the battery so they don't pull the system down as bad when they turn on.

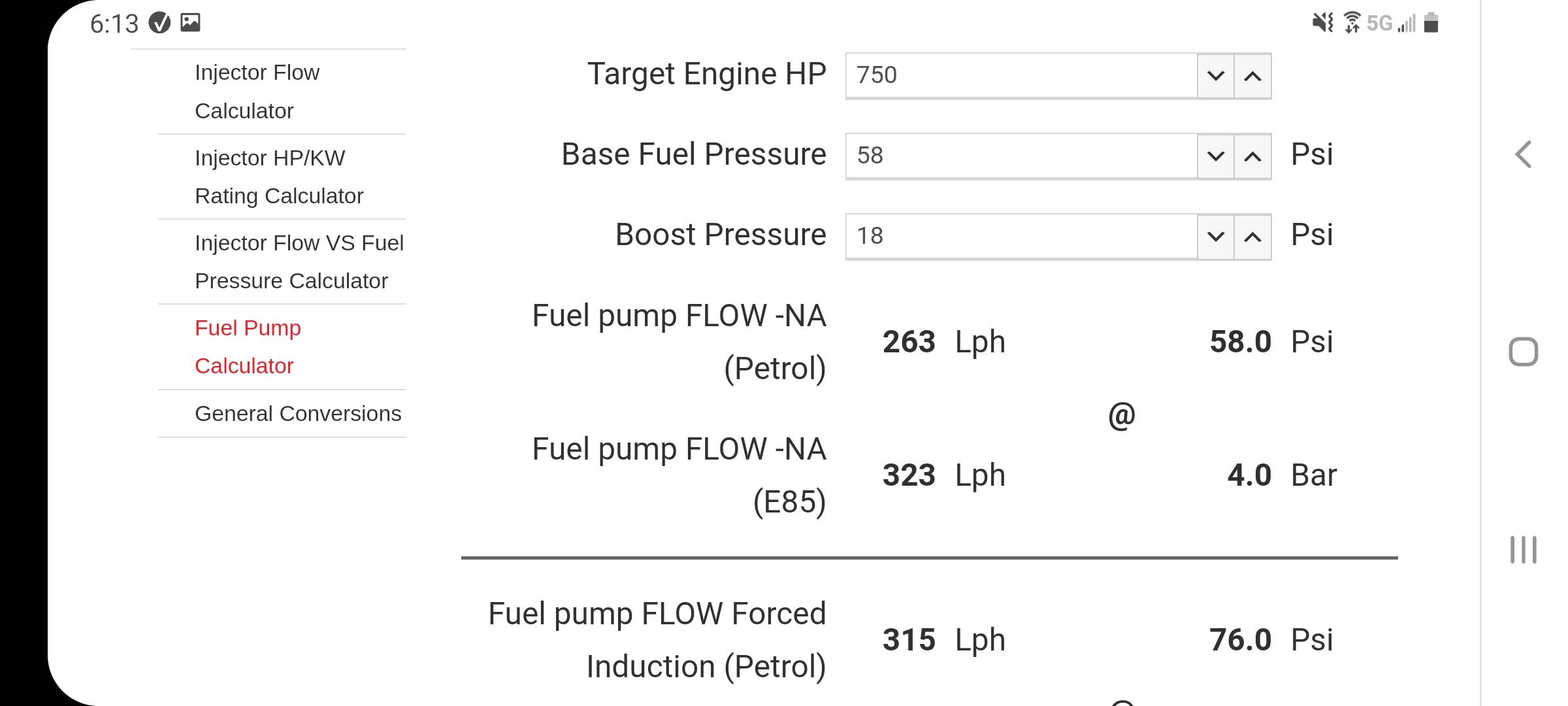

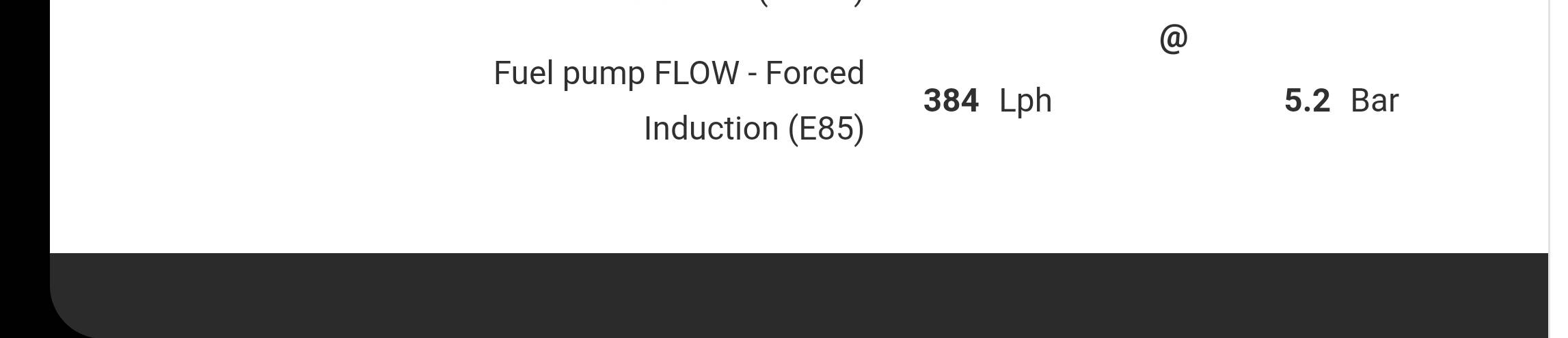

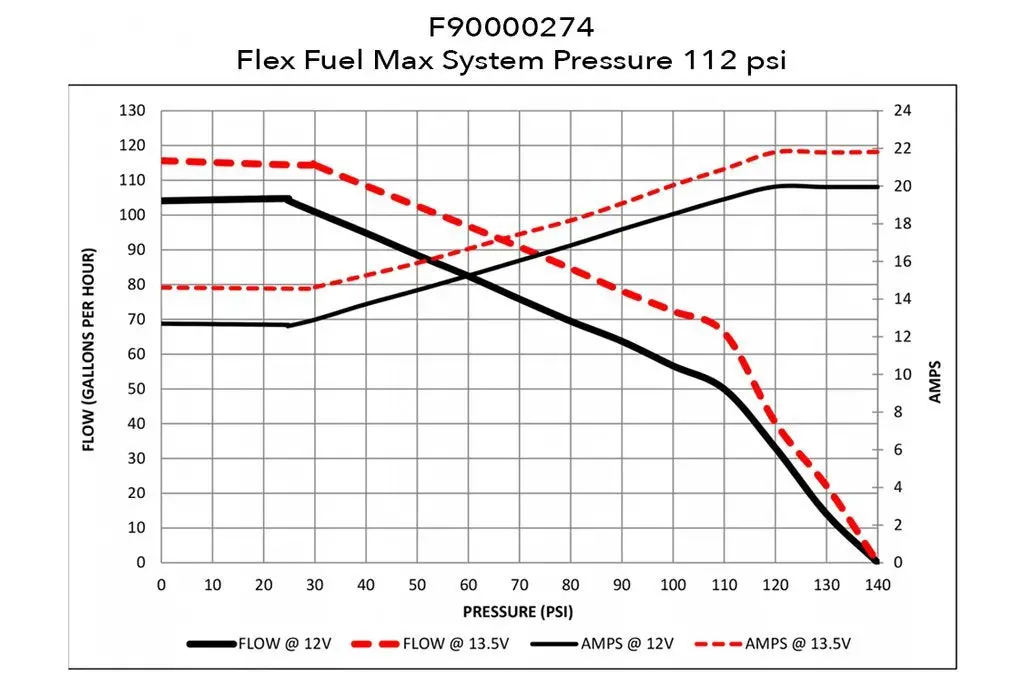

In order to max 80lb injectors out on E85 you need ~110 GPH (418 lph)

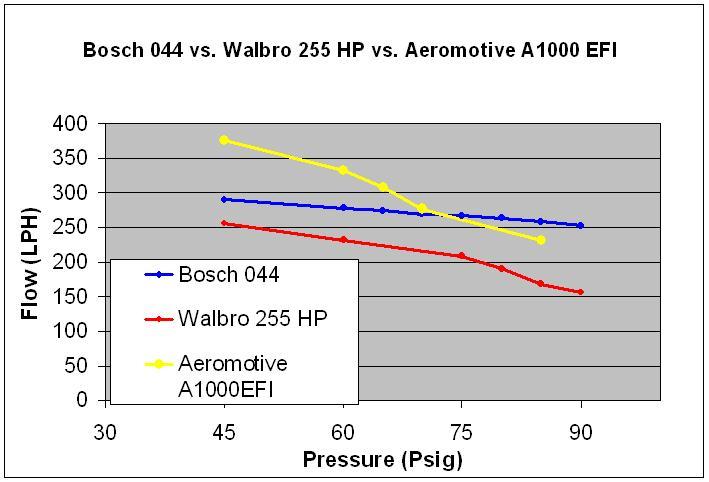

At 70 psi and 12V (worst case) the pump flows 75GPH (285lph) and draws 18 amps.

I physically measured the flow of a single pump and observed 66.5GPH of flow at 64 PSI at 12V which is 17% under the catalog flow.

And since I am cheap (and had 8 gauge on hand so I used it) if I have 13.5 at the alt and am drawing 32 amps at top pressure I am only going to see ~13V at the pump figuring in my poor pump efficiency, I am probably only seeing 140GPH with twin 450's, which is like 128% injector duty cycle. Twin 340's didn't get me there either.

2 450's draw 25 amps (12.5A each) at 56 psi. The chart claims 15 each.

Did i confuse you, the reader? I know I confuse myself most of the time too.