Looks to be the short flange like all the normal stuff now. Reason I ask is to see what the Flexplate looks like. Factory congifuration they are flat and no spacer is needed, then again that depends on what Convertor you have also. If yours was built for a 4L80E in an LS Engine application it will need the flat Flexplate, and fully seated Convertor will be about 3/16" from the Flexplate when installed and spin freely.

LS to 4l80e flexplate and TC installation help

- Thread starter johnnunez29

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Was able to snap this pic at the engine builders shop.Looks to be the short flange like all the normal stuff now. Reason I ask is to see what the Flexplate looks like. Factory congifuration they are flat and no spacer is needed, then again that depends on what Convertor you have also. If yours was built for a 4L80E in an LS Engine application it will need the flat Flexplate, and fully seated Convertor will be about 3/16" from the Flexplate when installed and spin freely.

Attachments

Yup short flange.

My previous post was incorrect, I was thinking of the pilot spacer.

That short flange crank with a flat flexplate you WILL need a spacer between it and the crank, with the longer bolts.

Then again that is factory configuration, have to see what flexplate you get.

My previous post was incorrect, I was thinking of the pilot spacer.

That short flange crank with a flat flexplate you WILL need a spacer between it and the crank, with the longer bolts.

Then again that is factory configuration, have to see what flexplate you get.

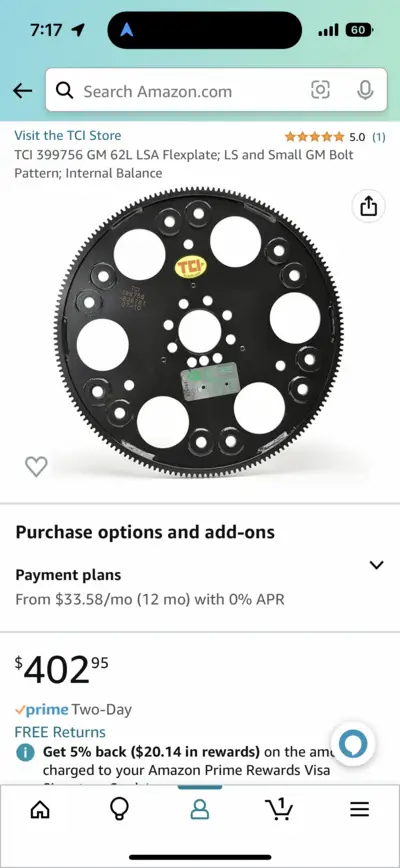

This is the flexplateYup short flange.

My previous post was incorrect, I was thinking of the pilot spacer.

That short flange crank with a flat flexplate you WILL need a spacer between it and the crank, with the longer bolts.

Then again that is factory configuration, have to see what flexplate you get.

I got I don’t recall if it came with a spacer.

Attachments

Yup looks flat, see if there's an 8 bolt Crank Spacer, they are .400" thick if I remember right.

You just need to measure to insure you have an 1/8-3/16 of clearance between the converter and flexplate.

I went through this and Built6spdMCSS helped me with it. I made much more of it than was needed. You might have to space the flexplate away from the crank or put a spacer between the engine and trans. Once I discovered the engine to trans spacer, all was resolved in my scenario.

I’d strongly recommend measuring before the engine is in the car.

Edit - forgot to ask - what converter are you using (who did you get it from)?

I went through this and Built6spdMCSS helped me with it. I made much more of it than was needed. You might have to space the flexplate away from the crank or put a spacer between the engine and trans. Once I discovered the engine to trans spacer, all was resolved in my scenario.

I’d strongly recommend measuring before the engine is in the car.

Edit - forgot to ask - what converter are you using (who did you get it from)?

Last edited:

Yup looks flat, see if there's an 8 bolt Crank Spacer, they are .400" thick if I remember right.

This is what came with the flexplate.Yup looks flat, see if there's an 8 bolt Crank Spacer, they are .400" thick if I remember right.

Attachments

That’s the measurement I was worried about. I’m going to be running a circle d TCYou just need to measure to insure you have an 1/8-3/16 of clearance between the converter and flexplate.

I went through this and Built6spdMCSS helped me with it. I made much more of it than was needed. You might have to space the flexplate away from the crank or put a spacer between the engine and trans. Once I discovered the engine to trans spacer, all was resolved in my scenario.

I’d strongly recommend measuring before the engine is in the car.

Edit - forgot to ask - what converter are you using (who did you get it from)?

OK, seeing how that flexplate is made with some really thick bosses around the holes, that is the pilot spacer.This is what came with the flexplate.

Basically you bolt the flexplate on the back of the crank and put that spacer in the middle and the converter pilot sits in that.

First time I'm seeing that new crank in a build. Very cool 😎

- Status

- Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 376

- Replies

- 5

- Views

- 206

- Replies

- 1

- Views

- 255

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.