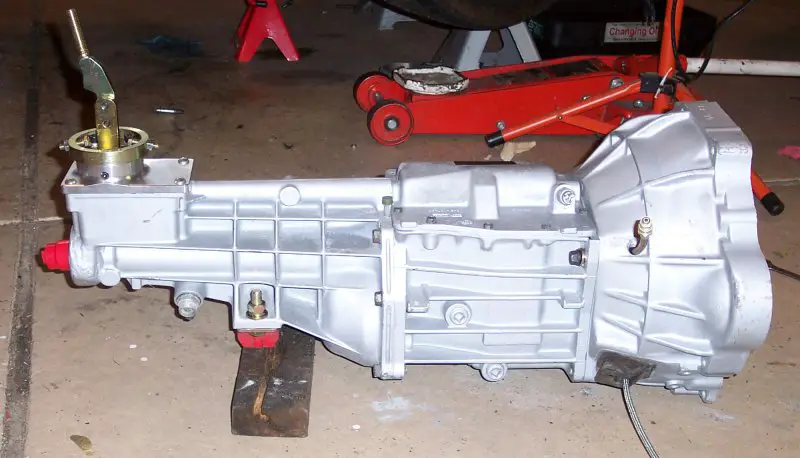

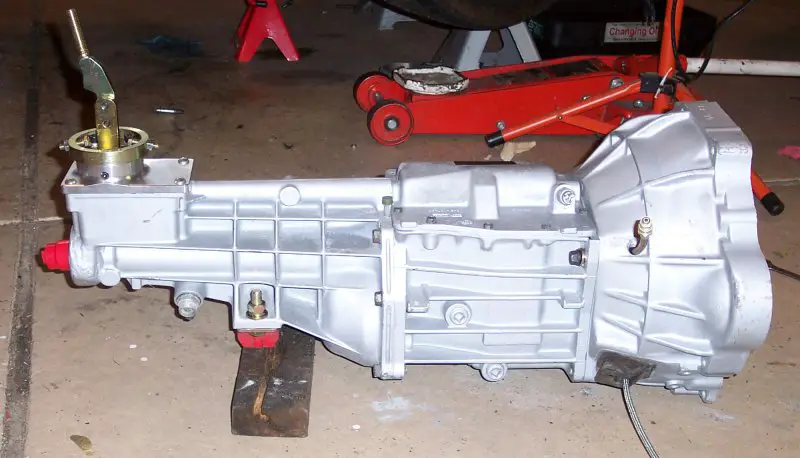

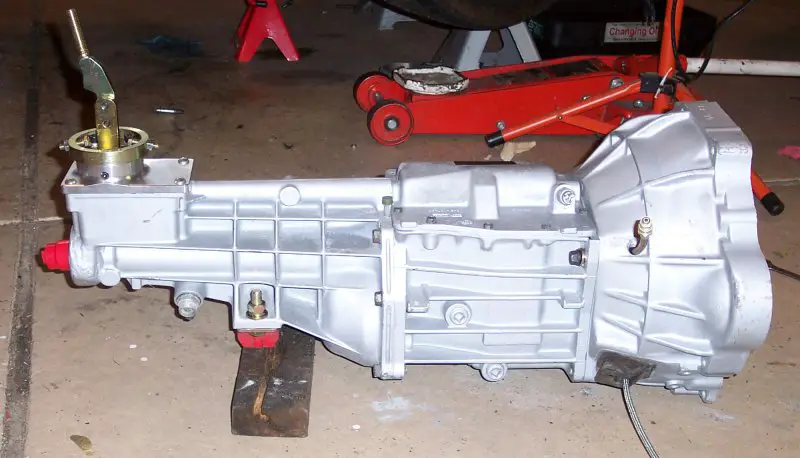

What did you do for the 18 degree transmission mount?I have an older bellhousing so my T5 sits straight. I removed the fulcrum from the hurst shifter, heated it up and removed the 17° angle. I like the McLeod TOB better then the Howe cause the Howe has a limit of maximum 3/4" pedal travel with a 3/4" master. more that the limit over extends the piston on the Howe and the piston can pop out. The McLeod on the other hand has a minimum limit of 1" pedal travel and mentions no maximum travel so it is easier to set the stop for the clutch pedal.

Mechanical or Hydraulic? (vote)

- Thread starter 307 Regal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

What did you do for the 18 degree transmission mount?

I moved the pad over on the iceman support and made an angled shim out of aluminum. I'm trying to find a Nissan T5 tailhouse since that transmission sits straight and the tailhouse looks like it may work

Last edited:

Is that out of a 300ZX?I moved the pad over on the iceman support and made an angled shim out of aluminum. I'm trying to find a Nissan T5 tailhouse since that transmission sits straight and the tailshaft looks like it may work

Also, so you put the 18 degree wedge on the tail and your rubber mount sits straight up? How’s your ground clearance?

Is that out of a 300ZX?

Also, so you put the 18 degree wedge on the tail and your rubber mount sits straight up? How’s your ground clearance?

I am not sure what Nissan that transmission is out of, I came across it when searching for a tailstock. The poly mount sits on the crossmember and the shim is between the mount and transmission. Ground clearance is fine as the transmission sits above the crossmember and the engine is sitting at a good angle

Just came across this....Borg-Warner T-5 in 1982-1983 280ZX Turbo

Last edited:

What is that weird bellhousing?I moved the pad over on the iceman support and made an angled shim out of aluminum. I'm trying to find a Nissan T5 tailhouse since that transmission sits straight and the tailhouse looks like it may work

You are really far back with the tail housing and shifter. Where will it come up?

What is that weird bellhousing?

You are really far back with the tail housing and shifter. Where will it come up?

it's very close to where my shifter is....

Nissan T5. I read that some of the Z cars used them.What is that weird bellhousing?

You are really far back with the tail housing and shifter. Where will it come up?

I ran 84-92 Camaro V8 T5, master / slave and bell. The shifter position is really good for a G-body console. The 200-4R speedo cable worked with it. The hydraulics worked like in a Camaro. It required crossmember mods, a hole in the floor, and pedals welded to work. Everything else was "buy replacement parts for a Camaro." This was a nice setup because I had a stock style clutch, the V8 ratio T5 which matched the 305 / 3.73 rear very well (your V6 setup is one I've passed by many times on purpose.) For used parts, I was very happy with this setup and I drove it over 1000 miles one way shortly after the swap.I can’t decide! I’m doing a manual transmission swap and I can’t decide between a hydraulic throw out or a factory type mechanical setup. I would prefer to do an external slave cylinder style but that seems like it will take some skilled fabrication out of good metal. This is a Buick V8, a Firebird bellhousing, and a Camaro V6 T5. Is a mechanical setup really that hard on your leg? Are internal hydraulics really that prone to failure? What’s your experience?

My next setup was mechanical speed direct rod-end linkage, the 83 camaro bellhousing, and another V8 Camaro T5. Basically nothing was "better" except the trans. was WC and I had rebuilt it but it all worked correctly. The 83 camaro has no benefit over the 84 Camaro. Would I rather unbolt and replace hydraulics, or get the z-bar and linkage re-welded? I'd go hydro.

I later modded a 94-97 T56 to take a T56 throwout bearing and clutch in the 93-97 bellhousing. Worked fine. But no real benefit over the hydraulic. In retrospect, the 94 Camaro ratios weren't a good match like the V8 T5 ratios.

Any time a pair of gears are farther apart in size, they are weaker in design. A small pinion in a 4.56 gearset is automatically weaker than a larger pinion in a 2.73 gearset. This same concept applies to the V6 ratios vs. the V8 ratios. The main issue though, is the gear ratios putting the engine in a happy power range, and percentage of rpm drop off with shifts.I think that sounds right. TKO 500 and 600 only differ in their gear ratios. Less multiplication of torque means more capacity they say.

I'll leave the V6 ratios deadhorse alone now. 🙂

IDK if it corrulates, but I put an SBC/ T5 compo into a 3rd gen Supra using the factory slave/master from the car. They use an external slave that was fairly easy to fabricate a bracket to attach to tha bellhousing. I cut a factory 2nd gen F body fork down to clear the tunnel. Pedal was light and worked like a champ. IDK what it would take to mate with a GM master, or get the Nippon master correctly into the G body chassis, but it was a functional compact hybrid that worked for me. Seems to me that if you can make what you have work, you got a winner.Guys have used the 84-88 Corvette bell housing which seems to be easier to find. I can't answer whether you need the 78-81 A body specific fork as I have never used anything but the 78-81 stuff.

The problem with using a standard bell housing and fork is the end of the fork makes contact with the floor pan in the corner under the gas pedal.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 98

- Replies

- 6

- Views

- 331

- Replies

- 0

- Views

- 362

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.