So which cover should go to vacuum?Don’t be, exactly the same plumbing setup as was used in the 60’s. Two lines, one for when cruising with vacuum that’s hooked to pcv and behind the throttle plate. And a second line for WOT or low vacuum from a valve cover to in front of the throttle plate.

Forget how the parts look and see where they go.

BUILD THREAD Project long time coming

- Thread starter Streetbu

- Start date

New to posting on forums?Is there anyone selling 6.0 motor?

There's a classified section but your best bet is your local junk yardIs there anyone selling 6.0 motor?

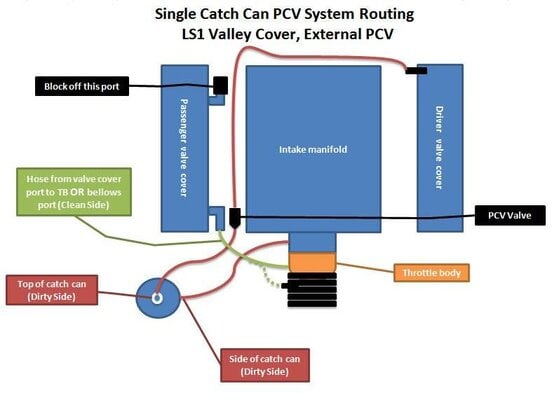

Driver's side valve cover i have pcv installed so pressure is relieved thru that to catch can. Then clean air (hopefully) sent back into manifold.

Passenger side front get fresh filtered air from throttle body

I don't have a fitting at rear pass side.

Passenger side front get fresh filtered air from throttle body

I don't have a fitting at rear pass side.

Tony's picture is a very good setup and it will definitely work. Something to keep in the mind - there is always crankcase pressure. Compression is always escaping past the rings causing the crankcase to be pressurized - all of the time. That pressure is the issue and is the reason the crankcase has to be ventilated. Something to remember though, you need a PCV only because of emissions and odor. The vacuum created behind the throttle plate at cruising conditions help ventilate the 'suck' the vapor out - the dilemma comes in the oil mist that is contained in the vapors and ends up getting in the cylinder.

At WOT the crankcase pressure is at it's greatest and even though a normal vacuum reading will show little to no vacuum, the engine is still producing vacuum at a greater amount as the rpm's increase and this is why you hook the valve cover IN FRONT of the throttle plates. In the old days (non LS) this was a standard setup. Now most all of the oem's have come up with gaskets that are rubber embossed with steel and are much more forgiving to leaking due to crankcase pressure. Hence my point several posts back, you cold just hook both the PCV outlet (without a PCV in stalled) and the other valve cover to a catch can and frget about. You could even ditch the catch can of you want, but the fumes will be worse than what you expect and you'll probably find an oily residue coming out of the hose. Iran all 3 setups, and a PCV is for a street driven car, catch cans are needed to keep the oil out of the intake.

You choose how you want to go - Tony's diagram is a great setup for a street driven vehicle. T each hos own, and as always, there is more than one way to skin a cat. But you still need to unhook the hose from the valve cover to the throttle body port - for initial startup you can leave the valve cover open and plug the port on the TB

At WOT the crankcase pressure is at it's greatest and even though a normal vacuum reading will show little to no vacuum, the engine is still producing vacuum at a greater amount as the rpm's increase and this is why you hook the valve cover IN FRONT of the throttle plates. In the old days (non LS) this was a standard setup. Now most all of the oem's have come up with gaskets that are rubber embossed with steel and are much more forgiving to leaking due to crankcase pressure. Hence my point several posts back, you cold just hook both the PCV outlet (without a PCV in stalled) and the other valve cover to a catch can and frget about. You could even ditch the catch can of you want, but the fumes will be worse than what you expect and you'll probably find an oily residue coming out of the hose. Iran all 3 setups, and a PCV is for a street driven car, catch cans are needed to keep the oil out of the intake.

You choose how you want to go - Tony's diagram is a great setup for a street driven vehicle. T each hos own, and as always, there is more than one way to skin a cat. But you still need to unhook the hose from the valve cover to the throttle body port - for initial startup you can leave the valve cover open and plug the port on the TB

Filing to fit was necessary on mine too. Remember, LS swaps are easy. I had already modified my firewall for a lokar style cable with my old setup, so the pass thru was the same for me. I did put some rtv on it though as a preventative measure to keep moisture out.Yes, had to use a small fender washer on each side of the firewall, and enlarge the hole for the cable to fit thru. Could've just used a larger fender washer but didn't like the look of it. Cut my original throttle cable and pulled the little plastic retainer off that keeps the cable in the gas pedal. Also had to ever so slightly file the barrel down to fit into the cam arm on the throttle body. Might have just been a burr on it.

View attachment 177079

Scott correct me if I'm wrong but didn't you have that darned whistle?Filing to fit was necessary on mine too. Remember, LS swaps are easy. I had already modified my firewall for a lokar style cable with my old setup, so the pass thru was the same for me. I did put some rtv on it though as a preventative measure to keep moisture out.

I can't remember but did you correct it somehow?

Thanks

He did, and I think he put a factory t-body back on.

Similar threads

- Replies

- 10

- Views

- 369

- Replies

- 216

- Views

- 13K

- Replies

- 13

- Views

- 560

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.